DIY options for bending wire materials

For bending, sometimes it is enough to use the tools at hand. Much depends on the thickness of the material used.

For bending products with your own hands with a diameter of up to 3 mm, suitable:

- locksmith vice;

- pliers;

- round nose pliers.

The material is cut with side cutters or ordinary nippers.

Products with a large diameter will require the use of a hand-made device. The assembly of the machine is carried out in stages:

- a 19 cm long steel corner is screwed to the table with bolts;

- a frame is made of a metal plate, holes are drilled in it;

- a frame with guide rollers and handles is screwed to the corner;

- a metal bar is selected to the bed groove;

- several through and blind holes are made in the bar;

- a handle and a grooved roller are bolted to the bar;

- plates are welded at the bottom of the bed;

- the bar is inserted into the bed groove so that it slides in it and does not fall out;

- guide rollers are screwed in;

- bar construction is screwed to the corner.

A hand-made mechanism will make it possible to make products of a more complex configuration.

UME-65. Wire bending machine with a diameter of 2 - 6.5mm

Automatic machine for wire bending, model UME-65, is intended for unwinding, straightening and bending of wire products, in accordance with the CNC program, in any quantity (piece, small-scale and serial production).

The UME-65 wire bending machine consists of an unwinder, a straightening unit, a wire feed unit and a bending-cutting unit. All nodes are interconnected and work in automatic mode. The machine can produce various flat products, for example: frames, rings, ovals, products with variable and constant radii, closed contours of simple and complex shapes.

The angle of rotation of the inclined table in the UME-65 bending machine is manually adjusted by the operator. The tilting table can be either in a horizontal position or practically in a vertical position.

The UME-65 wire bending machine has no hydraulic assemblies or components. All movements of the machine are carried out using servo motors or pneumatics. Servomotors are used for basic movements: wire feeding and bending operation. Wire cutting is done pneumatically.

Simple tooling allows you to bend products both with a small (fixed) radius and pushing (large arcs, variable radii).

COMPLETE SET OF WIRE BENDING MACHINE UME-65:

- Automatic CNC machine for flat wire bending.

- Wire bending is performed using a servo drive.

- Wire feed is servo-driven

- Wire cutting is done pneumatically. The machine has no hydraulic units or components.

- A unique flatness correction system that allows you to get absolutely flat products even on domestic wire, which is distinguished by internal torsion stresses.

- The working table of the machine has several positions, so the operator can adjust a convenient angle of inclination, in accordance with the geometry of the product.

- Easy and intuitive CNC programming interface for machine control. Saving programs to the internal memory of the machine, or to a USB drive.

- Hand tool kit.

- Operating instructions in Russian.

DESCRIPTION OF THE POSSIBILITIES OF THE CNC PROGRAM:

- The CNC program has a simple and user-friendly interface, displayed on a 15-inch color touch screen. Operating system - Windows XP. There is a USB port for connecting flash drives. The internal memory of the machine can contain more than 10,000 programs.

- The NC program allows both roll bending (small radius) and push (large, variable radius) bending.

- The product program allows you to cyclically produce several types of parts, which in some cases is convenient when assembling a finished product.

- The CNC program allows you to work in several modes: Manual (each drive works separately by pressing a button); Semi-automatic (operations are performed step by step, according to the CNC program); Automatic (operations are performed non-stop, according to the CNC program).

- Setting in the CNC program the speeds of the drives (feed and bending rates) for each bending operation.

- Electronic self-diagnostics with error display on the screen.

- Possibility of connecting automation devices.

Machine for 2D wire bending. Automatic wire bending according to the CNC program. Bending hooks, etc.

Machine for 2D wire bending. Manufacturing of special springs for mattresses.

Automatic CNC machine for 2D bending of wire products. Bending of wire products.

UME-65T. Bending machine with 2 heads.

play

2D wire bending + welding machines.

play

Bending of flat wire hooks.

play

2D bending of wire products.

play

Specifications

| The lineup |

UME-65 |

|---|---|

| Blank | |

| Wire diameter (mm) steel | 2 — 6.5 |

| Max. square frame size (mm) | 600 x 600 |

| Functional characteristics | |

| Number of bending heads | 1 |

| The number of different radii on the rig | 1 + push |

| Bending speed, deg / s | 1500 |

| Feed rate, mm / s | 1800 |

| Push (large radii) | Yes |

| Number of servo-driven axes | 2 |

| Availability of hydraulics | No |

| Accuracy characteristics | |

| Bending accuracy, degrees | +/- 0.1 |

| Feed accuracy, mm | +/- 0.1 |

| Performance characteristics | |

| Consumed (peak) power of the machine, kW | 6.5 |

| Required area of the machine with unwinder (L x W), mm | 5000 x 1800 |

| Weight (with unwinder), kg | 1700 |

Samples made on CNC wire bending machines.

Thank you for checking out the SAMPLES section. The range of wire bending machines from two world manufacturers (Nicemach and Ultimation) is quite large, it includes single-arm and double-arm machines, and with automatic welding, and modules for welding transverse bars, etc. We bring to your attention a selection of photos of samples of products made on wire bending machines with CNC. Do not forget that if you have any questions or wishes, you can call us, and we will be happy to answer and help you ... How to contact us - you can find in the Contacts section. Good luck!

Types of professional equipment

The simplest type of professional equipment on which wire bending is performed is single-arm machines. Meanwhile, such devices can only produce products of simple geometrical shape, the sweep length of which does not exceed 1000 mm.

More complex products with a sweep length of more than 1000 mm makes it possible to create double-cantilever equipment, on which the workpiece is deformed simultaneously from both ends. This machine can produce products with many complex bends.

The most sophisticated wire products allow you to create 3D machines on which bending can be performed simultaneously in three dimensions. Such unique functions of the machines of this category are endowed with a rotary bending arm, all movements of which are controlled by an electronic automated system. Despite all the advantages of processing on such equipment, it is quite expensive, so these machines are used in exceptional cases.

Equipment overview

For large volumes of work, various automatic metal bending machines are used. It is not necessary to apply only the manual method of reshaping the material. You can use machines or other machines that can increase productivity indicators. It is worth taking a closer look at the range of tools and techniques for bending wire.

For manual bending

Metal wire is in demand in everyday life. Mostly hand-held locksmith equipment is used to change the configuration. This allows you to achieve the following elements:

- clamps;

- brackets;

- hangers.

To achieve the desired result, you should use soft and flexible types of wire.

It is customary to use houses to change the shape of metal elements:

- round nose pliers;

- pliers;

- locksmith vice.

If the wire needs to be cut, you can use wire cutters or purchase special side cutters. Such a tool is sufficient to provide the required result for shaping the wire into the required shape. Difficulties arise when it becomes necessary to fold products of large diameters. To do this, you will need to purchase special devices. You can also make them yourself.

Machine tools

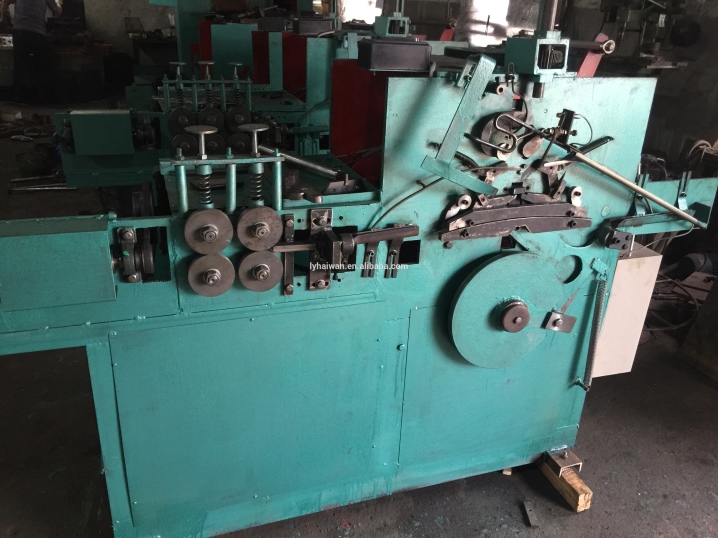

When it becomes necessary to make a large number of metal products from wire of different diameters, manual bending is out of the question. For the implementation of the operation, special equipment and special techniques are used. The bay method of changing the configuration of the metal is considered in demand. When using this technology, the following steps are performed.

- The wire is wound on special coils and fed to a machine with rollers, in which two planes are additionally provided. They will ensure the alignment of the product.

- After that, the material is fed to the machine, which will form the required configuration of the product.

- The formed wire is cut off to begin the first step again.

This process automates the bending procedure, which increases productivity. The wire bending machine is a static template. The design of the machine is provided with pressure rollers, which ensure the winding of the wire around the template. With the help of such devices, it is possible to achieve any configuration, as well as to ensure a bend of even the smallest radius. The latter cannot be provided by manual bending.

This equipment uses the principle of pushing the processed material to further reshape... The end of the wire is connected to the wire before the operation. He pulls it through the rollers, which give the material the desired shape, set by the program. A separate machine is also used for wire alignment. The role of working bodies ensuring the achievement of the desired result can be:

- frames of the correct form;

- blocks with two planes.

The first ones are highly effective, therefore they are in demand in production, where a smooth and high-quality procedure is required. Modern technologies in the field of machine tool construction have made it possible to start the production of machines equipped with several bending consoles. This type of equipment is called CNC machine tools. They are designed for the production of flat and 3D products.

Wire bending with the use of such a figured technique allows increasing the productivity of factory facilities, as well as organizing the production of products of various shapes. To carry out the procedure, it is enough to set the necessary parameters in the program, the machine will independently cope with the task.

Samples of bending of spatial (3D) wire products.

| Bending a small pocket for leaflets. () | Suspension element for greenhouses. () | Wire antenna element for TV. () | Wire coasters for hats () |

| Bending of a wire suspension for a cable. () | Bending brackets for the brake system of cars. () | Bending wire anchor for modular block. () | Wire insert bending () |

| Bending of a spring wire element. () | Bending frames with bent ends. (Wire bender R70 / OR70) | Making a part for a wire trap. () | Bending of a suspension element for greenhouses. () |

| Car muffler bracket. () | Bending of heating elements elements. (Special wire bender) | Bending the frame of the street lamp. () | Bending of various wire products. () |

| Suspension element made of 8mm wire. () | Trap spring, spring wire. () | Special hooks for suspensions. () | Element of the stand for commercial equipment. () |

| Hydraulic tube with nuts at the ends. (Special wire bender.) | Wire frame for built-in household appliances. () | Car seat wire element. () | Samples of products bending on two-console machines. () |

| Drawer handles made of 6 and 8mm wire. (Wire bender OR-100) | Car headrest made of tube or wire. (Special wire bender) | Shop equipment hooks and pockets. () | Extension springs and other springs. (Machine - multiformer) |

Wire bending machines

- A wire bending machine that makes parts directly from the coil. It is the most productive and economical option for mass production of wire products. This happens due to the fact that the coil with the wire is installed in a special device - the unwinder, from which the metal thread enters the correct block. There it is exposed to the action of a roller or flat mechanism, as a result of which it takes the form of a flat and straight rod at the exit. After that, the wire enters the bending block of the machine, where, with the help of mechanical devices, it is given the required shape of the finished product. At the end of the process, the finished part is cut with mechanical shears. Typically, such a wire bending machine can produce one kind of finished product, which is determined by pre-installed mechanical devices and is limited by the manipulation of the feeder. Therefore, the shapes of products produced on such machines are not very complex in configuration, since the number of bending operations is limited to five.

- A wire bending machine for bending wire from a metal bar is a more technologically advanced method, which has a number of advantages compared to working from a coil. This is especially necessary when the finished product needs additional processing. This can be tapping or stamping, which can only be done before the product is finished. The disadvantages of such a machine are its need for an additional complex feed mechanism for workpieces and a relatively low overall productivity.

- The wire bending machine is mainly used to make various round shaped parts and various kinds of round springs. For example, such a wire bending machine by rolling works due to the fact that the wire is fed through the guide rollers to a shaft of a given radius, where, due to its rotational movement, it bends around the finger a predetermined number of times. In this case, the wire is twisted along a predetermined radius, which has a bending pin and rolling rollers. Due to the position of the rolling rollers in relation to the central shaft, it is possible to set and regulate the bending angle or spring pitch. A wire bending machine by rolling, like other similar mechanical devices, is capable of producing only one type of product per operation. To change the range of products, both the replacement of bending devices and commissioning are required.

- Wire bending machine for bending metal wire by pushing method.For certain wire parts, during their manufacture, it is required to give them complex shapes of certain geometric shapes, such as variable radii, irregular arcs, a spiral appearance, and the like. It is not very efficient to do it by running it in, and sometimes it is simply impossible even technologically. Hence, the only possible way is to use the wire pushing method. The principle of operation consists in the translational movement of the metal wire through a three-roll roll forming block or a special spring-coiling device, in which, due to the position of the rolling rolls, the finished product is shaped. As a result, you can get any given curvature or a smooth change in the size of the radius. The main difference between running-in and other bending methods is a more complex equipment arrangement that requires special knowledge during adjustment and maintenance.

- Straightening machines are used as an additional device in technological lines for the production of various metal wire meshes for straightening and shaping the wire. Two technologies are used here: the revolving straightening with a frame and straightening with a two-plane straightening block. The two-plane block does not guide perfectly, but does not twist the wire. But the rotating regular frame has a more complex design, but many machine tool manufacturers still prefer it to the classic regular block design.

How to align the wire with your own hands

If the wire rolled into bays can be considered conditionally flat, then in order for it to become straight, we just need to get rid of the curvature of a large radius. But how to straighten the wire in the form of crumpled residues and poorly stored waste? They represent not only turns, but various zigzags located in different directions from the axis. In this case, straightening the wire with the right approach to the state of an ideal straight bar is quite achievable. There are some of the most effective ways to align the wire. Depending on the choice, they will have slightly different results in terms of quality.

So, from simple to complex:

- You can remove the kinks on the wire by securing both ends in your hands and start rolling with effort through a pipe or doorknob.

-

Straightening of the wire turns out well if its straightened sections are placed on a flat surface of the workbench. Covering it with a wooden block, start rolling it on it so that it can move freely while doing this. Just a few of these rolls give quite good results.

- To straighten soft copper wire, you need to fix it with one end at a height. Hang a not very heavy load on the other, such that it could not tear it. By rotating the weight clockwise and back a few revolutions around its axis, the ideal result can be achieved.

- The wire will be straightened in a similar manner. If one end of it is fixed in a vice, and the other is clamped in the chuck of a screwdriver or electric drill. The straightening process will take place by rotating slowly while holding the wire under strong tension. Just a few turns will be enough for full straightening.

- Also, a screwdriver or electric drill will be needed to straighten small pieces of wire up to 30 centimeters. To do this, in a wooden block we make a die hole with a diameter slightly larger than a wire hole and pass one end of the bar through it. We fix this end in the chuck and begin to rotate slowly, pulling the wire through the hole.

- To align a wire of not very large diameter, you can make a fairly simple and cheap device with your own hands.

To do this, we need a massive wooden board with dimensions of 500 x 120 x 50 mm. We drive 5-7 nails with a diameter of 3-5 mm into it in a straight line with an indent by the diameter of the wire.The distance between the nails directly depends on the diameter of the wire and its elasticity. The higher these indicators, the larger the gaps between the metal rods. The process of straightening the wire will consist in simply pulling it between the nails along the marking line. For clarity, a schematic photo will help you.

If you know your original way of how to align the wire with your own hands, then please share it with us in the comment block.

Useful video

Watch a video where a person shows how to assemble a simple reinforcing bender structure for bending bars and a square:

In the second video, an overview of the mechanism for bending wire and curling hooks:

Conclusion

What is used for bending wire is described in detail in the article. To work with this material, you can use both simple tools and complex installations that allow you to perform a large number of operations per minute.

With a limited budget, you can make your own mechanical device that will not be inferior in quality to factory products.

Bending machines for rebar, wire, sheet metal and pipes offers. On our site, not only technical specifications are presented, but also videos of bending machines and photos of finished products, which will allow you to better understand the production process. If you have not found the equipment you need on the site, send the technical specification to the mail, we will select the machine for your tasks.

Basic bending rules

Wire bending is easy

However, in order to achieve the best result, several rules should be taken into account.

- Gloves made of thick fabric should be worn when performing the task and working with the tool to prevent injury.

- Only serviceable tools or automatic machines are suitable for work. Before you start bending metal, you should check the technique for damage or deformation.

- If a vise is required for the operation, you should first make sure that the workpiece is securely fixed.

- Before starting work, it is necessary to align the position of the workpiece.

- If the actions with the tool are carried out with one hand, the other should be kept away from the place where you plan to make the fold. This is explained by the fact that pliers or other tool can break loose and injure the hand.

- It is not recommended to place heavy instruments on the edge of the working table during the procedure. Otherwise, when performing bending, they can be touched and dropped on their feet, which will result in injury.

In addition, during the bending process, it is recommended to pay attention to the integrity of the wiring and the organization of grounding when it comes to the use of electric machines. It is worth noting that manual bending allows you to work with small amounts of materials.

This is explained by the fact that the procedure has a high labor intensity, which adversely affects the state of the human body.