Types of sealants for plastic windows

According to the method of application, sealants are vulcanizing, drying and non-drying. By composition: one-component and multicomponent. By chemical composition, sealants are:

- acrylic;

- silicone;

- thiokol;

- polyurethane;

- bituminous;

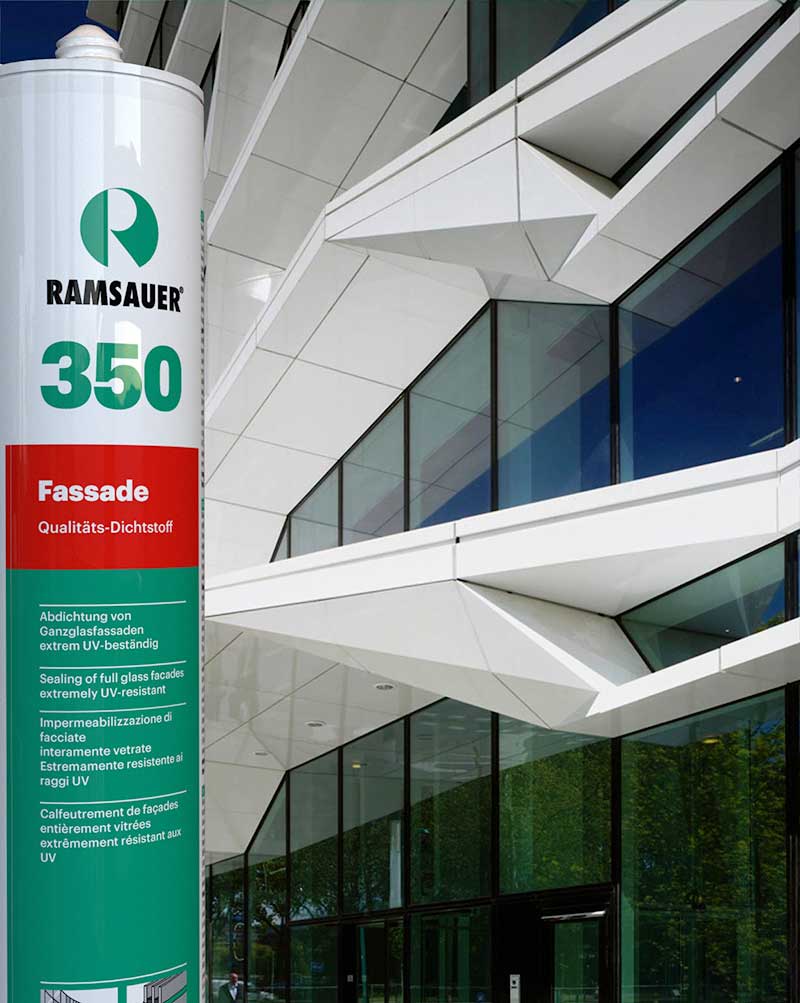

- front.

Silicone sealants are most commonly used to seal PVC. Bituminous sealants are rarely used due to their black color, but they are used to treat external seams as a primer. Facade mastics are also rarely used for sealing plastic windows, but it is advisable to use them for sealing work.

Rice. 3. Varieties of PVC sealants

Acrylic window sealants

Acrylic sealants are viscous acrylic-based compounds used for sealing window openings, sealing small cracks and seams, and sealing gaps between the opening and the frame. They differ in moisture resistance. No primer required. Usually white. Fading slopes. They are applied using a special pistol. They harden within 24 hours. Not suitable for surfaces constantly exposed to moisture, as they can shrink. Not used for sealing. They have excellent adhesion. Can be applied to a wooden opening.

Rice. 4. Acrylic sealant

Thiokolic window sealants

Thiokol or polysulfide sealants are a flowable mass based on thiokol with high density and viscosity, very elastic and retains their properties for a long time. The sealant is temperature-resistant, frost-resistant and weather-resistant. It is used as a sealant for application on a slope. Depending on the additional components in the composition, it can dry from several hours to several days. Must be used with primers (undercoats). Thiokol sealants are superior in strength and durability to similar materials of other compositions.

Rice. 5. Thiokolic sealant

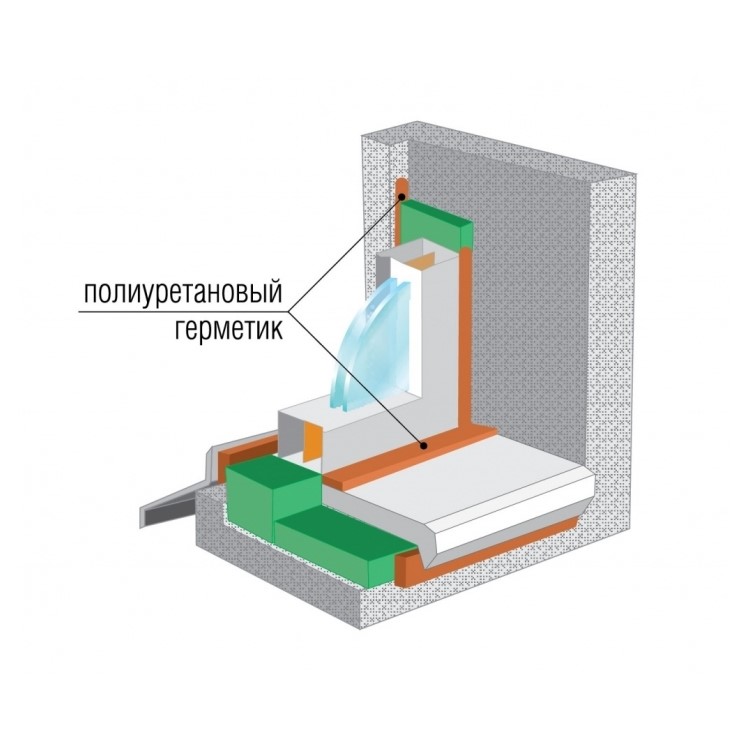

Polyurethane Window Sealants

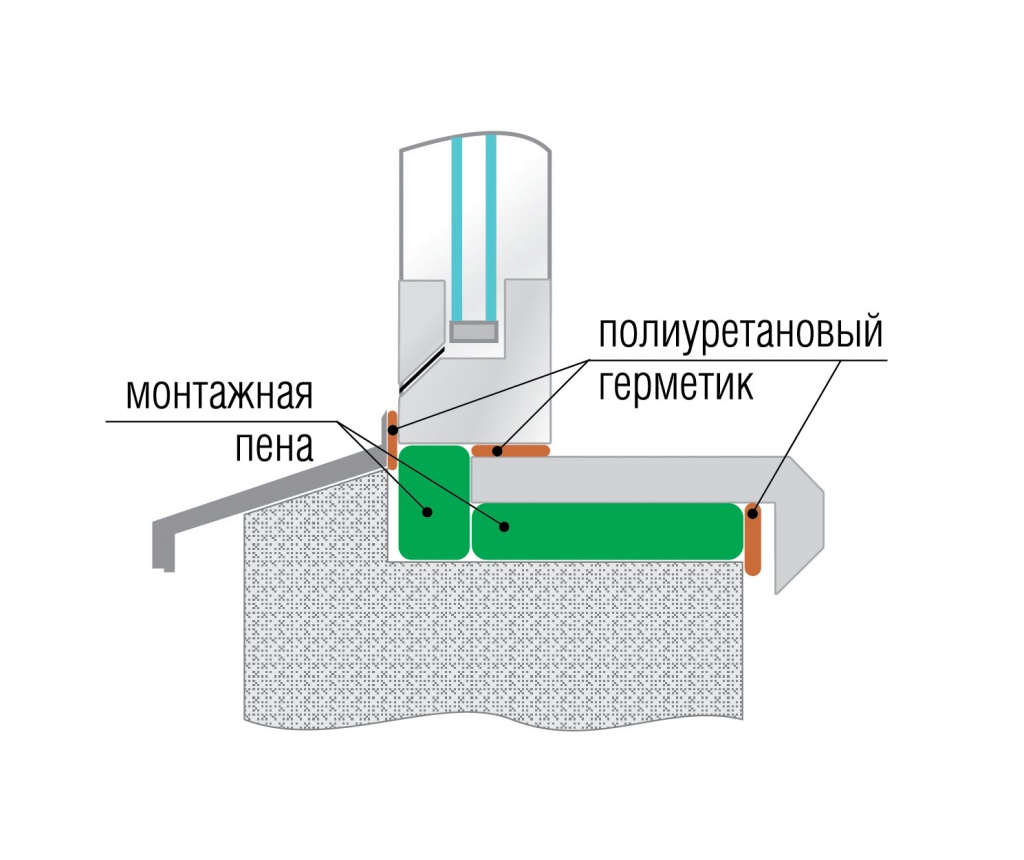

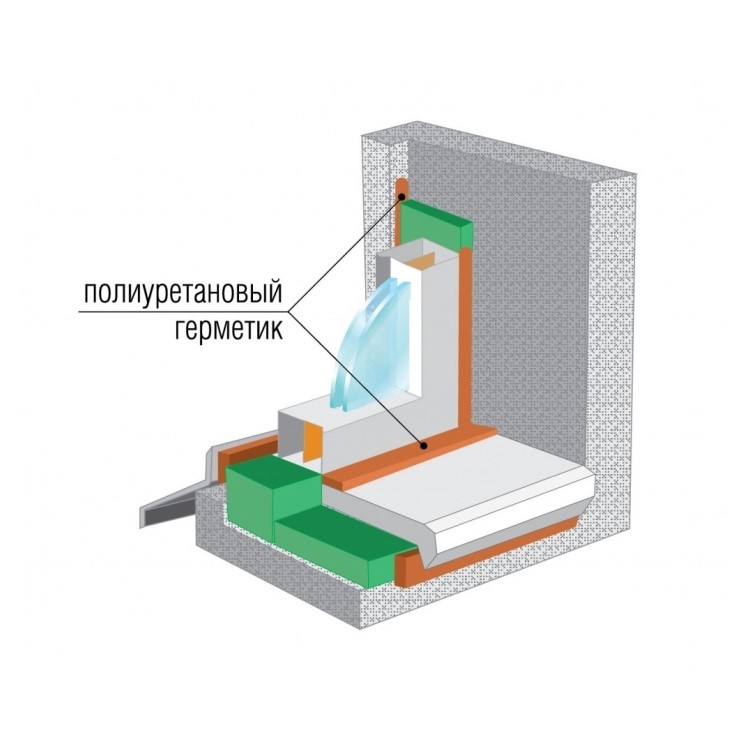

Polyurethane sealants for windows and joints are used to treat window joints with cold materials (concrete and brick) and are considered one of the most budgetary proposals among sealants. They are resistant to atmospheric precipitation, impervious to moisture, durable and able to withstand heavy loads. Retain their appearance for up to 20 years. Cracks can be bridged with polyurethane sealant. The material provides heat and sound insulation, and also retains its sealing properties even at -50 and +80 degrees.

Rice. 6. Polyurethane sealant

Varieties of automotive adhesives

Many car owners mistakenly think that it is enough to buy the first contact superglue that comes across, stick a windshield on it or mask the damage. In fact, this is a huge misconception. This glass adhesive can have the following side effects:

- Reduced transparency of glasses.

- The appearance of noticeable unsightly stains.

- An increase in the size of the crack during the further operation of the car, that is, the ineffectiveness of the glue.

In fact, this substance is intended to combine fixed objects. In the case of a windshield, when driving a car, there will be constant vibration and external factors such as moisture, wind, temperature changes.

Therefore, for gluing auto glass and filling microcracks, a special substance is needed, intended for operation under conditions of heavy loads and vibration.It is necessary to choose an adhesive sealant for gluing glasses depending on the type of glass and the size of the damage.

To seal the windshield of a car and carry out repairs, you can use one of the proposed types of glue:

- Assembly composition for pasting. Experienced motorists know that rubber gaskets have long since moved aside, they were replaced by polyurethane glue. It allows you to reliably process all joints, ensuring the structure is tight. At the same time, the safety for passengers is also increased, since in the event of a collision or accident, the glass will not fly out.

- Optical or repair sealant for bonding glass. It exactly repeats the properties of the material to be repaired or glued.

Among the popular manufacturers of polyurethane adhesives were DOW Automotive, 3M, Sikaа, as well as European manufacturers Wurth, Teroson, Eftec AG.

Which composition should you choose?

As a rule, for external and internal work, different types of sealants are selected. A simple algorithm will help you not to make a mistake in your choice.

Sealant selection algorithm

- Decide on the location of the seam (indoors or outdoors). On the street, it is better to use silicone or acrylic (but at the same time, it will have to be covered with an antifungal compound) sealant. An acrylic sealant is ideal for sealing joints indoors.

- The choice of the color of the sealant or paint for it.

- Selection of weather conditions corresponding to the weather conditions specified by the manufacturer.

Also, useful tips on choosing a sealant for internal joint sealing - see below:

Usage Tips

When working with sealants, the contact surfaces should always be thoroughly cleaned and degreased. In the case of repairing individual glass parts, it is easiest to use cyanoacrylate preparations. Algorithm of work:

- apply the composition with a thin layer on the crack, if possible, on both sides;

- in case of repair of parts, apply the substance to all contacting surfaces;

- compress the parts with force for a few seconds;

- remove the film remaining on the joint after final hardening (about half a day).

Before using the sealant for construction installation, the frame windows and openings must be thoroughly cleaned of dust and dirt. Despite the fact that moisture in itself promotes the polymerization of the sealant, it also greatly interferes with the adhesion of materials, so the surfaces must be allowed to dry well. Installation is best done in the weather no colder than +5, and it is highly undesirable to perform them in the heat above +40 degrees.

First, the material is applied in a thin even layer along the abutting surfaces and leveled along their entire length. The detected gaps are neatly filled with a thin layer of material. Drops of uncured composition can be carefully and quickly removed with a damp cloth. Any irregularities that may form after the repair compound has dried can be cut off with a sharp knife.

After the window frames are mounted, you can start filling up possible gaps. This will also require:

- water in a basin;

- masking tape.

We glue the tape along the gap, which will protect against contamination of the glass surface and slopes. We thoroughly clean the gaps to be closed from dirt and dust.

Finally, you can proceed with the final cleaning of the surface. A soft sponge well moistened with water is just right for this. Since the sealant has not yet completely hardened, this work should be done quickly, but very carefully.

Such work is best done in stages:

- we apply the material to a not too large section of a seam or crack;

- level the sealant;

- quickly remove the resulting surplus;

- We clean the working field with a sponge and only then proceed to the next section.

In the next video, you will find the installation of glass on a sealant.

Sealant rejection time

- The curing time of the sealant depends on the temperature and humidity of the environment.

- It is not recommended to use sealant at ambient temperature less than 15 ºС

- Loss of pot life of the sealant (loss of workability during application) occurs 40 - 60 minutes (at 20 ºС) after mixing component A and hardener B

- The curing time of the sealant (reaching a hardness of 30 conventional units of Shore A) is 100 - 120 min (at 20 ºС). When the sealant reaches a hardness of 30 conv. units On Shore A, in-plant transportation of the finished insulating glass unit is possible

- Final cure of the sealant (to ensure the required performance) is after 24 hours.

Views

Today the construction market is represented by a huge selection of glass sealants. Each of them is characterized by individual characteristics and scope.

Depending on the basis on which the material is made, two product groups are distinguished:

- Acetate.

- Neutral.

Sealants belonging to the first group are most often used for structural sealing of insulating glass units or for glazing windows. As for the second type, it has high adhesion, so it can be used not only for sealing glass, but also for sealing the external seams of facades, supporting structures made of metal.

The sealant can differ in the components that make up its composition and can be varied.

- Acrylic. This material is considered ideal for sealing windows. It can be used to cover both new glass units and to use it to seal old ones. The sealant creates a strong layer between the glass and the frame and prevents air from entering. The result is a tight connection that is resistant to moisture and low temperatures. Most builders consider this sealant to be a versatile glass sealant.

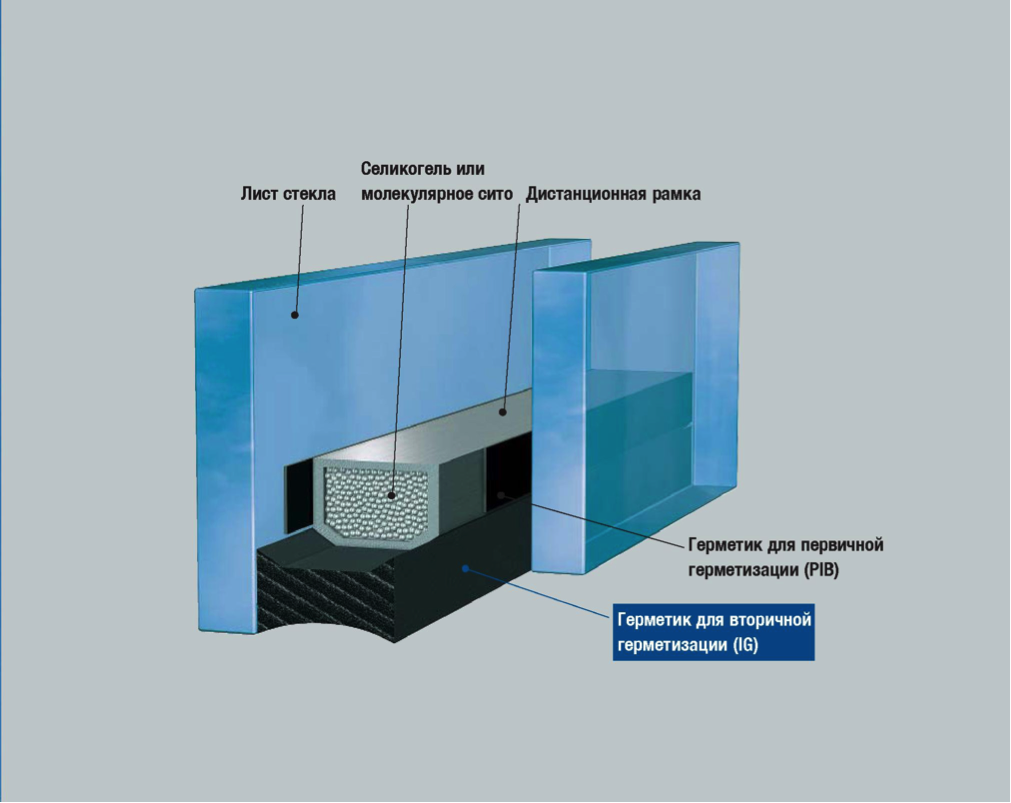

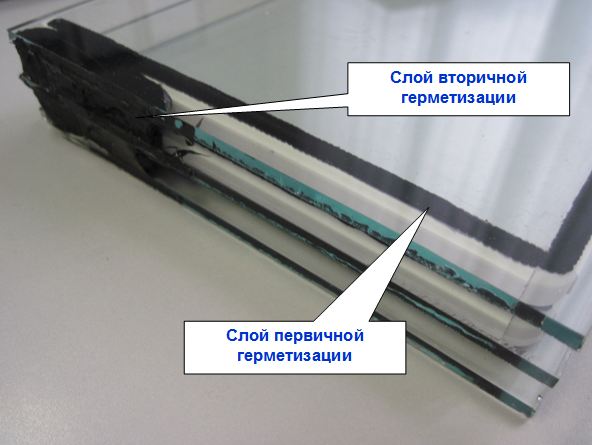

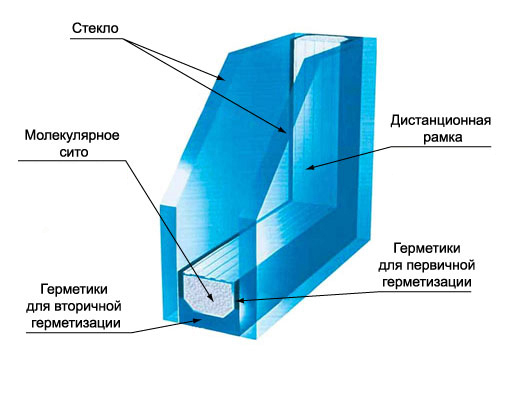

- Butyl. It is a construction product that is intended for finishing double-glazed windows. It is mainly used when several glasses need to be joined together. Such a sealant is characterized by excellent protection and well resists the penetration of wet steam and air into the space between the panes. It should be applied to the work surface at temperatures above 100C.

- Polyurethane. The material has an excellent seal structure and is therefore often chosen for sealing plastic and glass. In addition, it can additionally play the role of thermal insulation. The surface after sealing with such a sealant acquires strength, and its service life increases. Craftsmen most often use this material for edge joining. Glass reinforced with sealant is not “afraid” of temperature extremes, acids and oils.

- Silicone. It is the most common and demanded type of sealant. It is used at almost all stages of construction work. The material is also well suited for sealing facade glass, as it has high performance indicators. The popularity of this product is due to the fact that it is inexpensive and characterized by excellent quality.

Thanks to its unique characteristics and special composition, silicone glass sealant allows you to reliably seal joints and adhere materials. In addition, the product has found its application in car repair, as it can act as gaskets. The problem of sealing joints between glass and coatings such as metal, ceramic or brick is often encountered. Many adhesives cannot cope with this, but silicone glass sealant will ideally glue all objects, including elastic polymers, plastics, aquariums, and automotive parts.

In addition, the building product is used to seal joints between various glass objects. In a car, it can be used to strengthen headlights, fixed windows and sunroofs.However, when using this sealant, you must remember that it is not suitable for work in which glass must be combined with polymers. When interacting with fluoroplastic, polycarbonate and polyethylene, a chemical reaction occurs and the material loses its properties. In addition, this sealant can degrade when exposed to gasoline, synthetic oil and ethylene glycol.

Recently, such a new product as polysulfide sealant can be found on the construction market. It does not contain solvents in its composition, it is produced not in tubes, but in large cans and is used, as a rule, in the manufacture of insulating glass units. This sealant is obtained by mixing polymers with pigments and a structuring agent, resulting in a sealing material that has high resistance to gas, steam and water penetration. Typically, this product is used as a secondary sealant.

The sealant is easy to apply, it is not harmful to human health and does not require additional precautions

Advantages and disadvantages

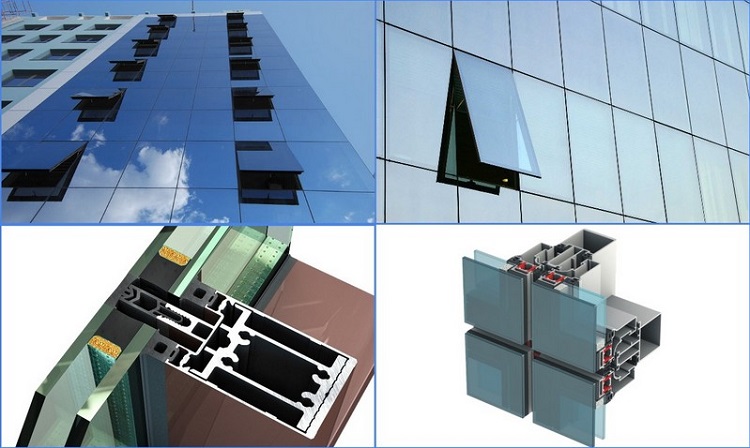

Finishing the facade of the building with glass has the following strengths:

- First of all, it is an original appearance, realized using glass of different shapes, colors and degrees of light transmission.

- The high level of natural light during the daytime allows you to significantly save on electricity, and besides, working in daylight is much more comfortable.

- Facade glazing is performed using high-strength types of glass and high-quality profile systems, which, together with modern installation technologies, allows us to implement reliable structures that are resistant to any natural phenomena.

- The use of energy-saving glass and the correct formula of the double-glazed unit provide high sound-absorbing and heat-insulating properties of the facade of the building.

- The design is easy to maintain and repair, if the integrity of one of the sections is violated, only the damaged element is replaced, without dismantling the units of the profile system.

Disadvantages of glass facades:

- Facade decoration with glass requires the participation of a team of experienced highly qualified specialists and sophisticated equipment;

- Compared to other design options, facade glazing is much more expensive, especially if you use high-quality branded profile systems and double-glazed windows;

- In order for the glass façade to retain its aesthetic properties, it must be cleaned regularly.

Confidential

Donkey

Burgundy Plug and socket).

Quick and dirty. Saucer 20-30 saucer (saucer)

Heart, heart, heart, heart, heart, heart Flare.

Bark, bark, bark, bark Quick and easy.

B & b, b & b, b & b, b & b Burgundy 8 bt

Cardinal table

Burgundy, burgundy, birch, burgundy, burgundy Open hearth (12-24 minutes).

Burgundy Bump (bump ± a bump).

Wedge-shaped trough 300-400.

Burgundy

Rose and Rose.

Donuts:

Delivery;

Bump (bump, bump) bump

Sweet spot

Burgundy and bark:

L & lt; l & gt; l & lt; / RTI & gt;

Rosewood Rosewood Rosewood;

Rose, Rose, Rose.

Good morning, good luck, good luck. 3-pitcher, 3-pitcher, 330-pitcher.

Bumpy:

100% contact;

Back and forth;

Good luck with a ball.

Gift:

Bridging;

Flashing.

Bump, bump, bump, bump, bump, bump, bump, bump Come on and on.

Â

How to Apply Liquid Window Sealants?

Each sealant comes with instructions on how to apply it to windows, where all stages are described in detail. It is necessary to install the sealant on a cleaned surface, therefore, before carrying out any work, it is necessary to clean the outer surface of the frame and the inner side of the window opening from dust and dirt. Sealing is the final finish of the window opening, therefore, it is first necessary to remove excess polyurethane foam and prime the joints. If there is an oily layer from any materials, the surface must be degreased. To keep the edges straight, take some construction tape and stick it over the seam. Purchased sealants are sold in special containers with a syringe. According to the instructions, you need to open the package and carefully apply the sealant to the mouths of the joints of the window opening with a uniform layer. The frame should be covered with a sealant 1-2 mm. Then you need to level its surface with a spatula. After applying the sealant, let it set and remove the tape. Depending on the type of sealant chosen, it will dry from 1 hour to several days.

Rice. 7. How to apply liquid window sealant?

For interior and exterior work

According to their physical and chemical properties, all sealants are divided into two categories - used for outdoor work and used indoors.

For sealants used for outdoor work, certain requirements are imposed that contribute to their effective resistance to an aggressive, external environment.

Sealing the outer seam with sealant

Sealing the outer seam with sealant

Requirements for outdoor sealants:

- Chemical resistance. Expresses itself in successful resistance to mold, water and chemicals.

- Successful resistance to mechanical stress. That is, such a sealant must be durable and not collapse from external forces.

- Elasticity.

- Good thermal insulation properties.

- Have a dye in its composition or have an easily dyed structure.

- When applied, to have such a state in which all hard-to-reach places are easily filled (to have fluidity).

- Easy to stick to surfaces (high adhesion).

- Wide range of temperatures for application and use.

Requirements for internal sealants:

- Lack of toxins. This is a basic requirement for sealants used in residential premises, preventing poisoning of people, animals and the development of allergic reactions.

- Counteracts biological agents, mold and bacteria.

- Moisture resistance.

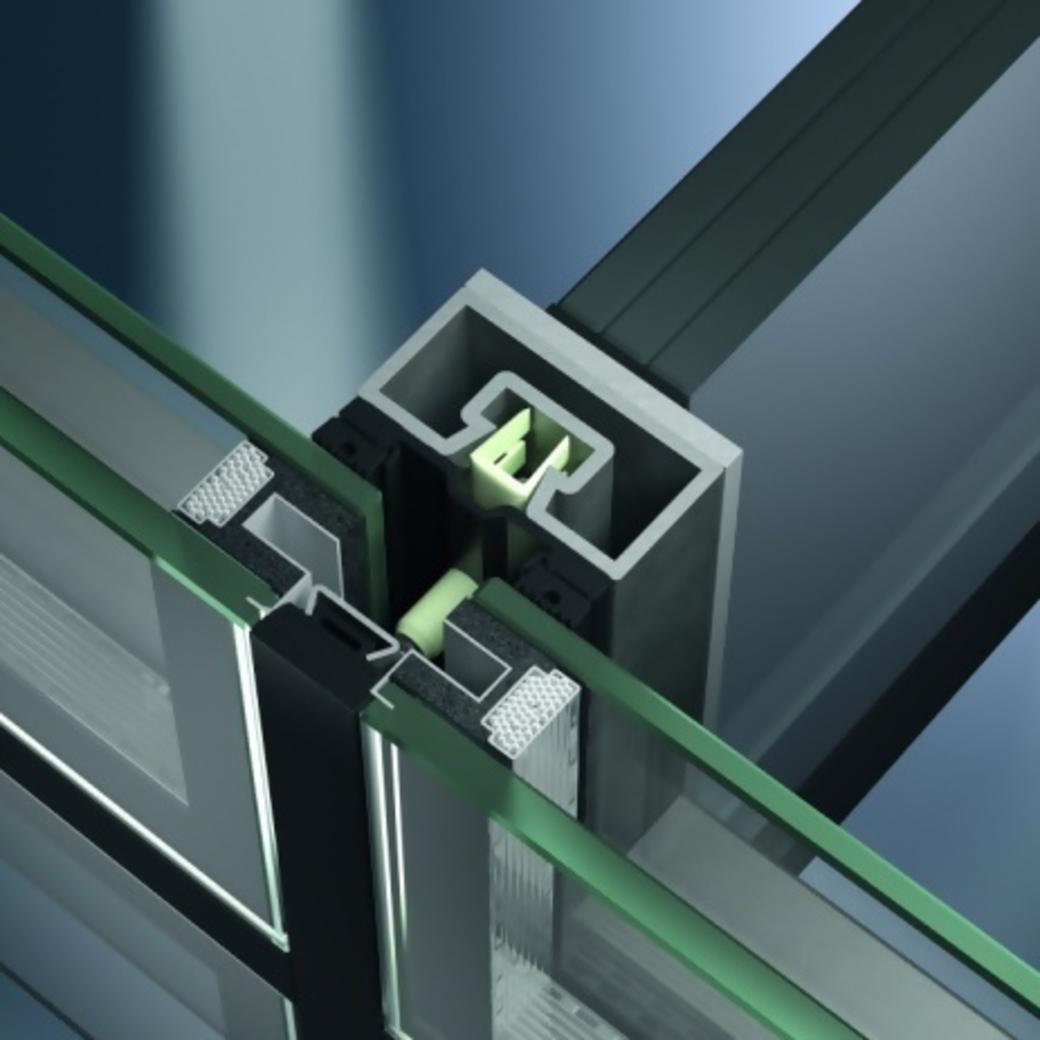

Mounting

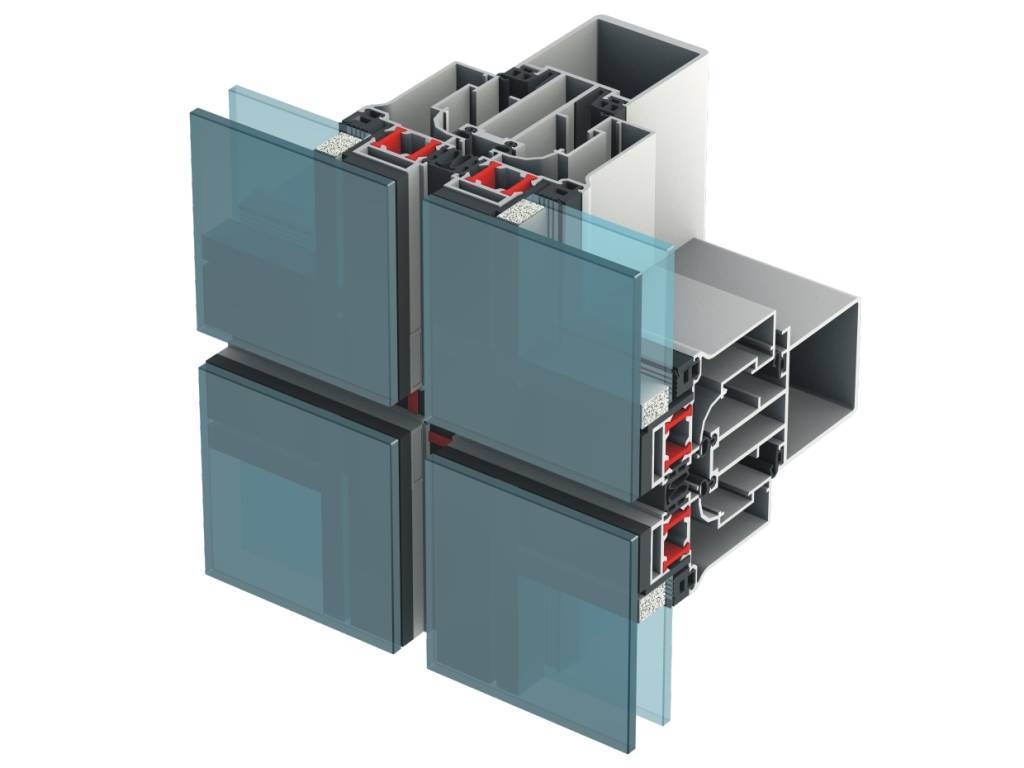

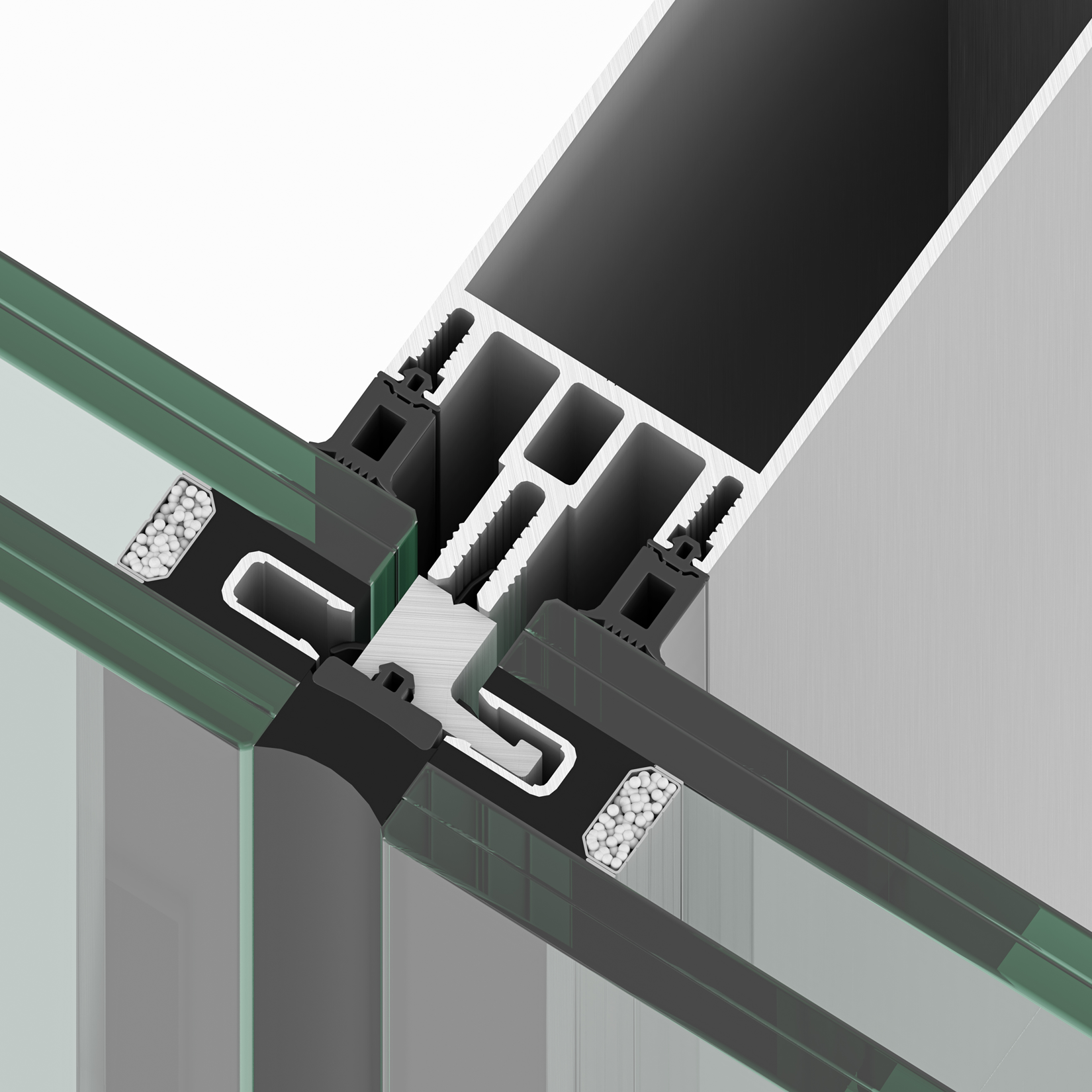

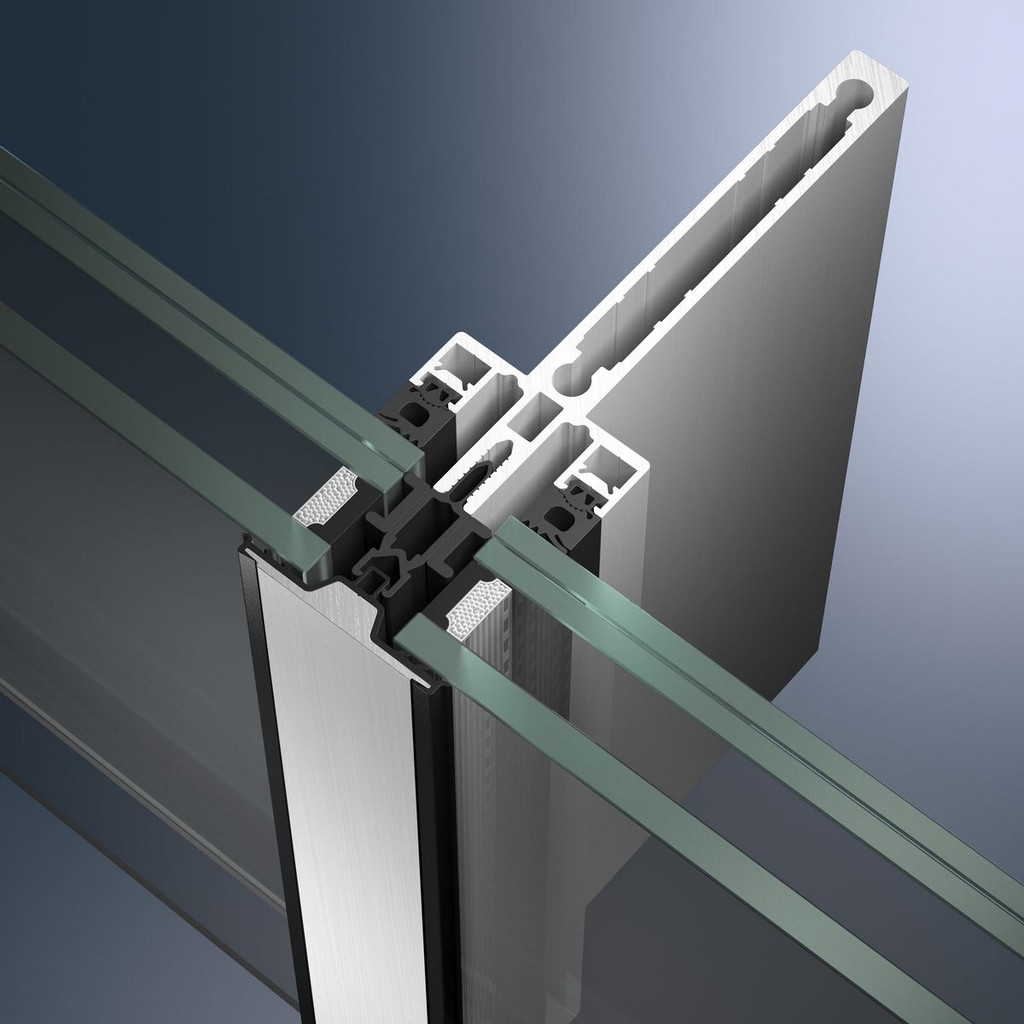

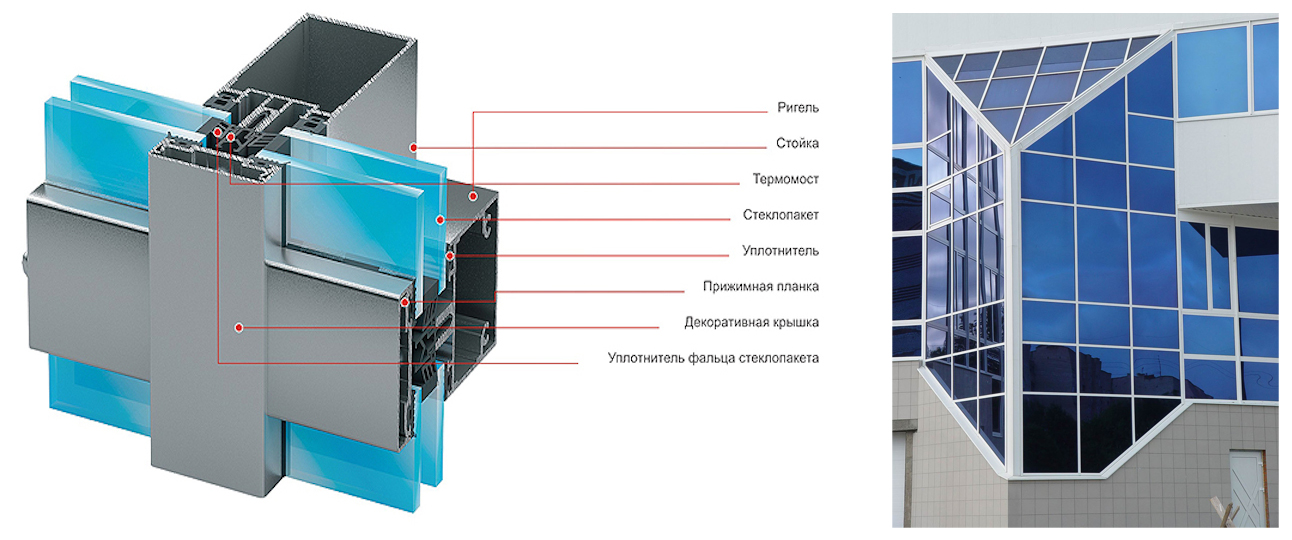

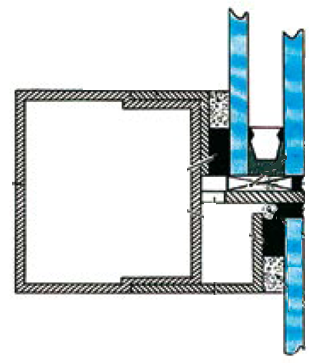

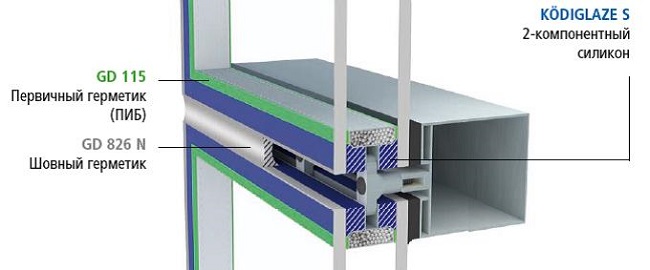

Structural facades are mounted either in a two-sided way or in a four-sided way. Two-way installation is performed according to the following algorithm:

- First, the rack-and-girder system is mounted. Install vertical elements, fixing them to the upper and lower floors, then mount the crossbars. Some systems are assembled without crossbars; transverse fasteners in such structures are only in the places where the glass adjoins the ceiling.

- Fasteners (clamps) are inserted into the U-shaped groove on the sides of the glass unit.

- Double-glazed windows are placed on support pads and fixed with self-tapping screws through the clamps to the outer end of the frame profile.

In addition to mechanical fasteners (clamps, self-tapping screws), double-glazed windows are attached to a sealant - they are coated with all joints. After installing the glazing, the seams of the structure are filled with thermal insulating materials and sealed with a decorative layer.

Four-sided mounting is done without any mechanical fasteners. A double-glazed window of owls on all sides is glued to the supporting structure with a sealant.

Sealant for double-glazed windows - the price is affordable for everyone!

Sealants for the manufacture of insulating glass units - should be selected taking into account their properties

It is important to choose the right sealant for each type of insulating glass unit. For example, in the production of frameless windows, it is better to use silicone sealant for insulating glass units, since it is resistant to sunlight.

However, for its hardening, high temperatures (not lower than + 12 °) and humidity are required.

To apply polyurethane and butyl sealant for the production of insulating glass units, expensive equipment is required.

A two-component polysulfide sealant for insulating glass units has a sufficiently high water and gas permeability, unlike other compositions.

Of course, the price for a two-component sealant for double-glazed windows is higher than for a one-component one.

In general, prices depend on the type of material used in their composition: butyl, silicone, polysulfide or polyurethane. And from the manufacturer or from the volume of the sealant, color, quantity in the package, delivery, etc.

You may also be interested in the article on double-glazed windows - see here.

Single glazing: cool too! - you will also find it on our website.

Two-component polysulfide sealant

And also on the website of the firm "GiFlex" (

One-component silicone sealants

And, of course, in the most famous online store "Price Pulse" (

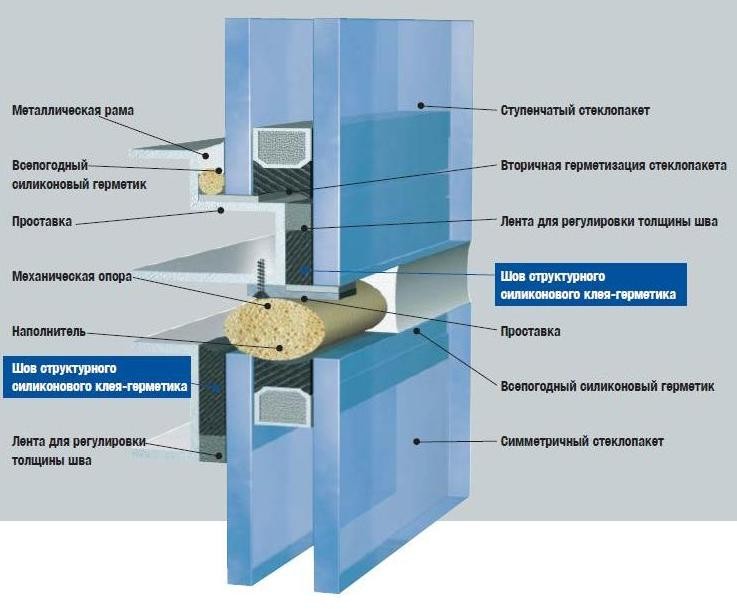

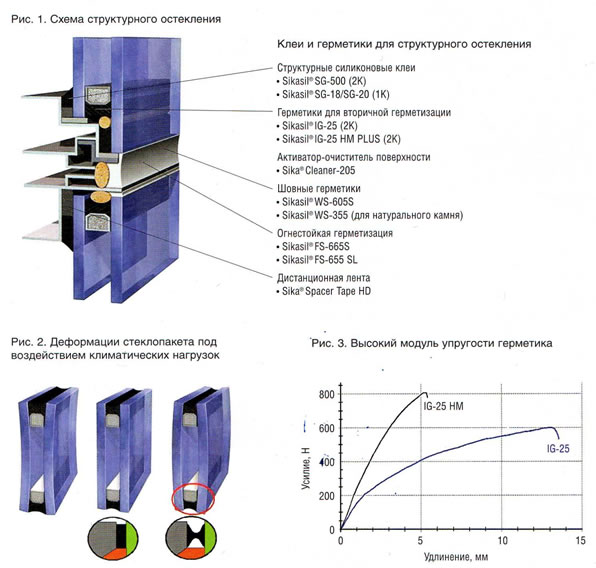

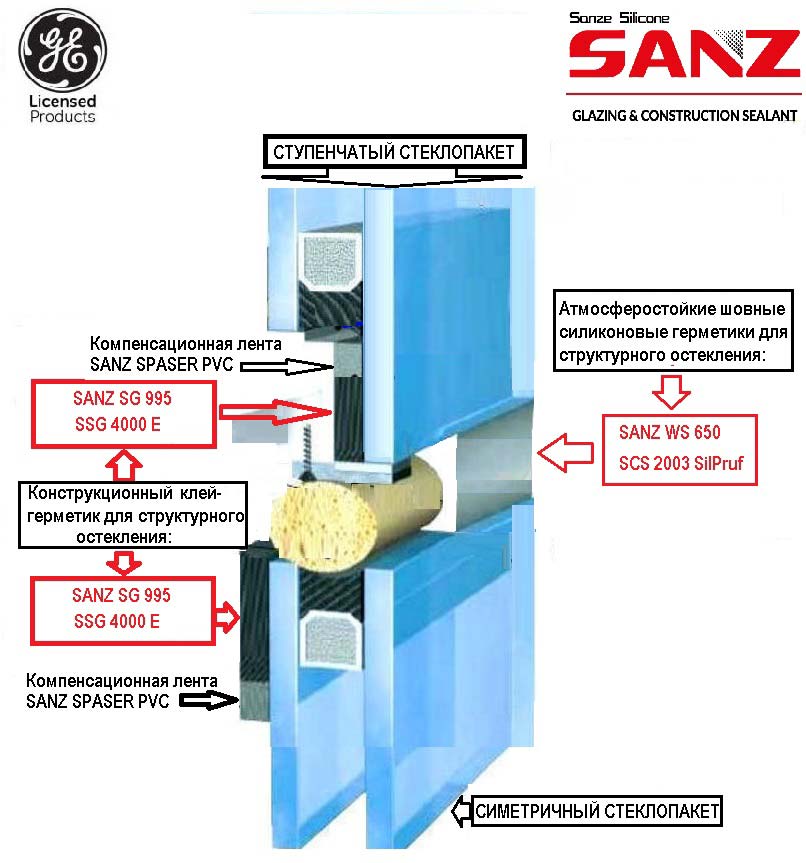

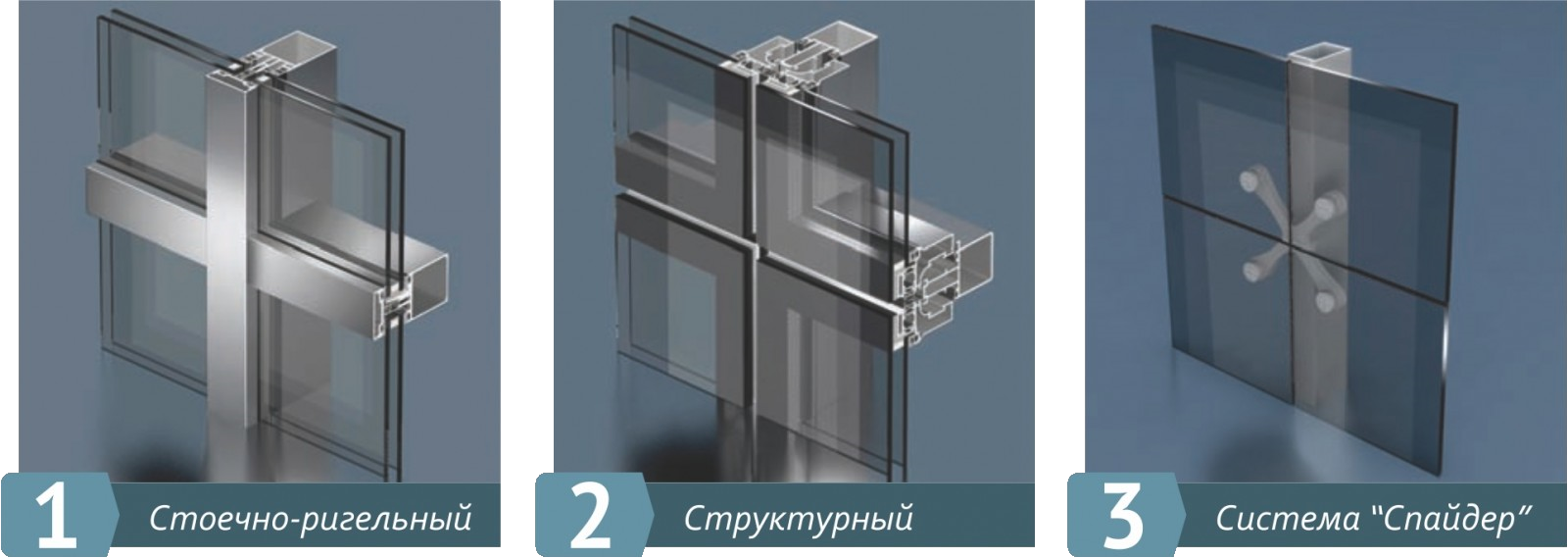

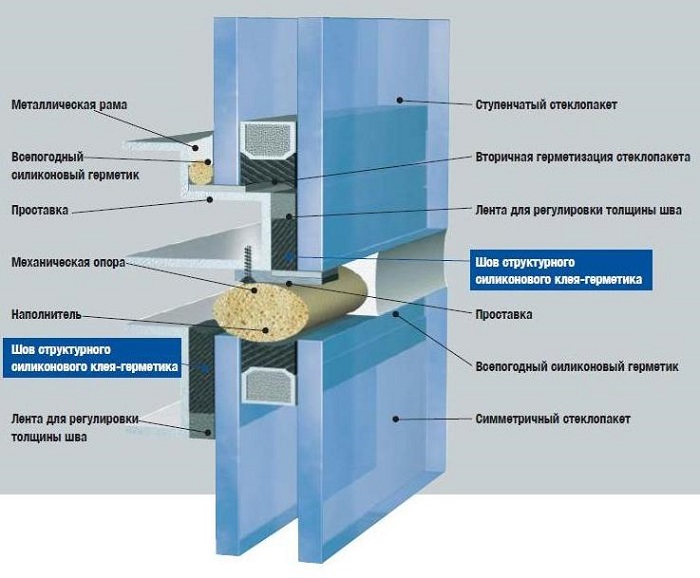

Structural glazing

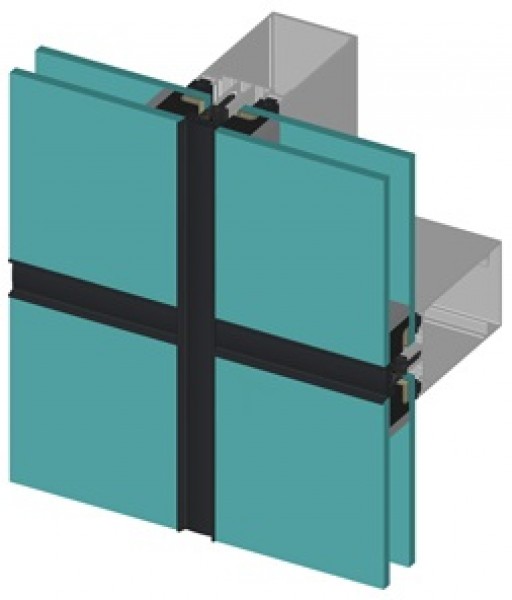

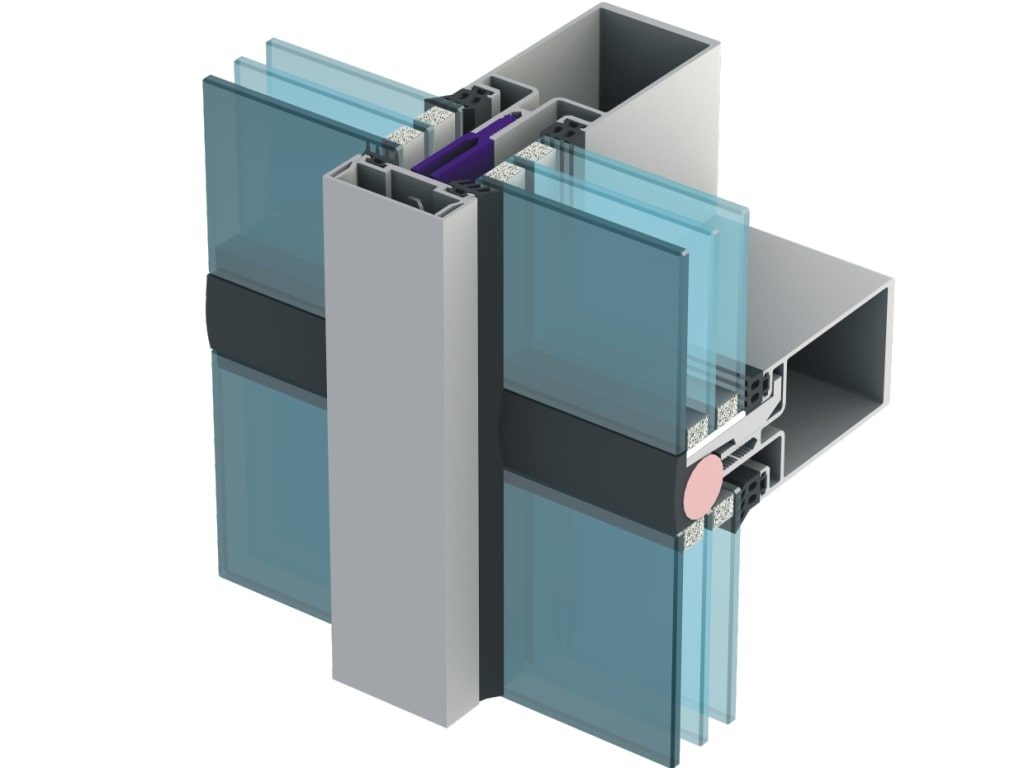

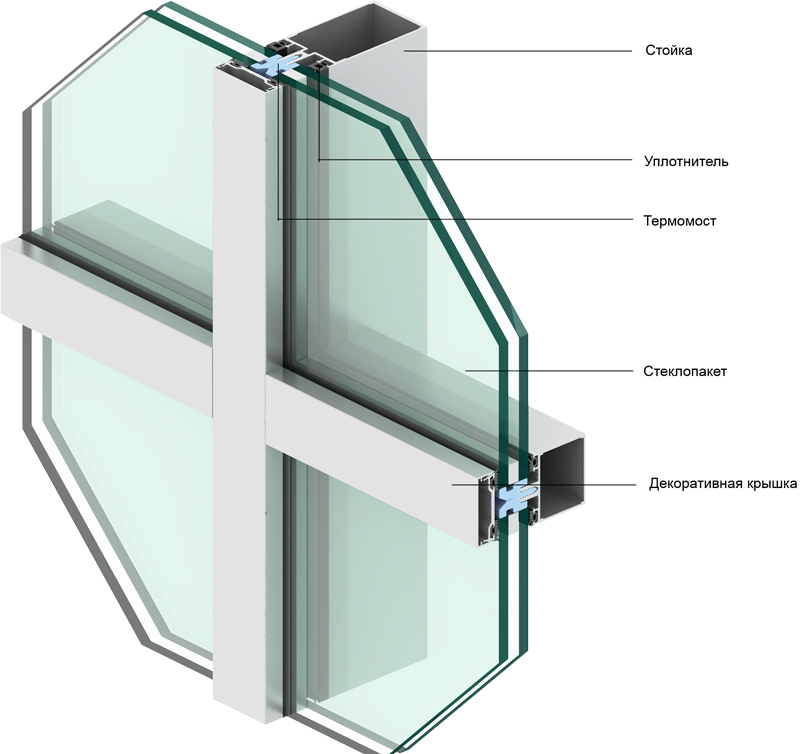

Structural glazing is a method of fixing glass elements without metal frames. They are replaced by a glue-sealant with unique adhesion and strength characteristics. It is matched to the color of the glass, which makes it possible to obtain a monolithic surface. There are two ways of fixing double-glazed windows:

- Double-sided. A variant of a translucent facade with structural glazing, when from above or from the sides the double-glazed windows are fixed on a mounting base, located vertically or horizontally, and between themselves on a sealant. This method is suitable for facades where one glass unit covers the height of the floor. Then fasteners are installed at the level of interfloor floors, into which double-glazed windows are inserted. They are glued together with silicone sealant along the entire perimeter of the floor.

- Four-sided - no fasteners are used. The connection of transparent glass elements is carried out only due to the adhesive sealant. With this version of the device, a monolithic surface is obtained, without visible assembly and butt seams. In this version, square glass elements look good.

The use of both fastening methods for structural glazing ensures complete tightness of internal visits from water, snow or blow-through.

The use of both fastening methods for structural glazing ensures complete tightness of internal visits from water, snow or blow-through.

The frameless system allows you to harmoniously and discreetly integrate sliding and hinged windows for room ventilation. It is almost impossible to visually determine their meta position.

Dignity

- Solid construction. The joint seams filled with adhesive sealant ensure that the entire surface works as a whole.

- Strength and durability. Structural glazing, or rather the glass junctions, can withstand changes in the geometric dimensions of the facade from seasonal temperature fluctuations from -30 to +40 C. The system is practically not destroyed by ultraviolet rays. The facade is resistant to atmospheric precipitation. Mixed glass bags add extra strength to the system.

- High performance in thermal and sound insulation of indoor visits. Achieved by using tempered glass on the outside and laminated glass on the inside. Such systems completely dampen impact noise with an intensity of up to 83 dB.

- Increased sunlight transmission. The width of the joints does not exceed 2-3 mm, which increases the usable glazing area, and therefore the amount of incoming sunlight.

- Tightness. Without artificial ventilation, air exchange between the street and the interior is zero.

- Environmental friendliness. The materials used for structural glazing of building facades have certificates of compliance with European environmental standards.

- Ease of maintenance. On the smooth surface of the façade, there are no gaps for dirt accumulation. It is quite easy to wash them.

disadvantages

Functionally, there are no shortcomings. Structural glazing cannot be designed on the knee. It is necessary to take into account many related factors: the intensity of the wind, the curvature of the building, the features of the heating and ventilation systems. All this increases the cost and time of work.

Regulations

The main provisions and technical requirements for double-glazed windows and the methodology for working with them are fixed:

- GOST 24866-2014 Glued glass units. Technical conditions.

- GOST 30779-2014 Glued glass units. Method for assessing durability.

- GOST 32998.4-2014 (EN 1279-4: 2002) Glued glass units. Methods for determining the physical characteristics of the sealing layers.

- GOST 32998.6-2014 (EN 1279-6: 2002) Glued glass units. Rules and methods of product quality assurance.

GOST 24866-2014 also describes 2 methods for testing the tightness of glass units.

==== Figure 1 - Scheme of the stand for testing the tightness ====

1 - top loading screw; 2 — pad; 3 — spring; 4 - dial indicator; 5 — double-glazed window; 6 - sliding supports; 7 - bottom loading screw

Test procedure.

1. By rotating the scale of the lower indicator 4 the arrow is set to zero division.

2. Load screw 7 load the lower glass so that the size of its deflection corresponds to the size of the deflection of the upper glass.

3. The glass unit is kept for 3-4 minutes to stabilize the readings of the upper indicator.

4. Re-set the readings of the scales of the upper and lower indicators to zero division.

5. The glass unit is kept under load (15 ± 1) min and the readings of the upper indicator are determined.

If the glass unit is hermetically sealed, the reading of the upper indicator should be no more than 0.02 mm.

When testing a two-chamber double-glazed unit, the tightness of each chamber is determined separately.In this case, for testing the second chamber, the glass unit is turned over on the supports 6 180 ° around the longitudinal axis.

6. Evaluation of results. The samples are considered to have passed the test if the readings of the upper indicator do not exceed 0.02 mm for all samples.

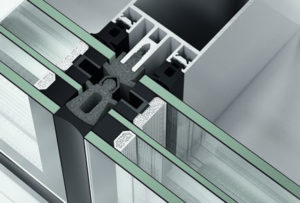

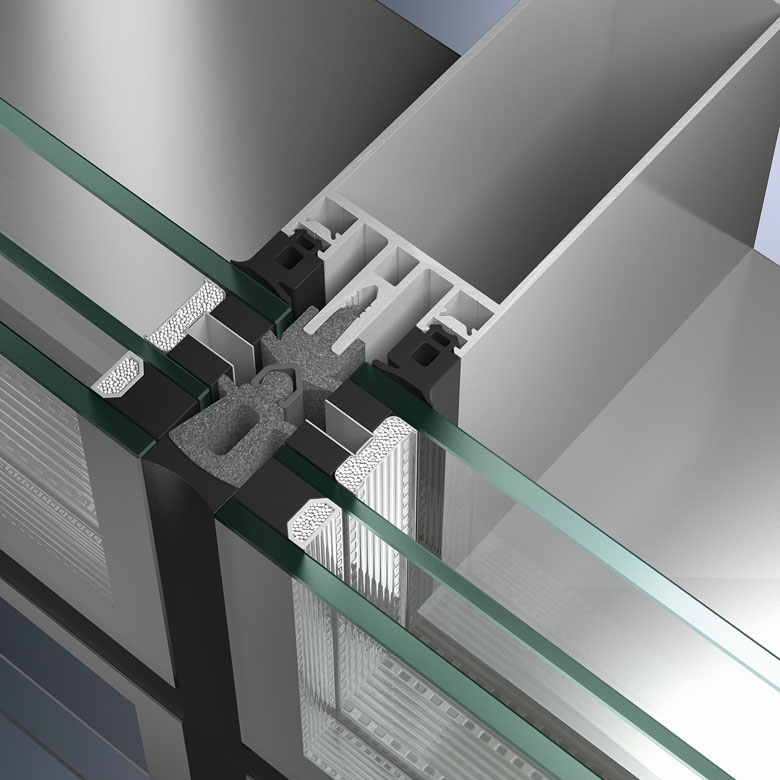

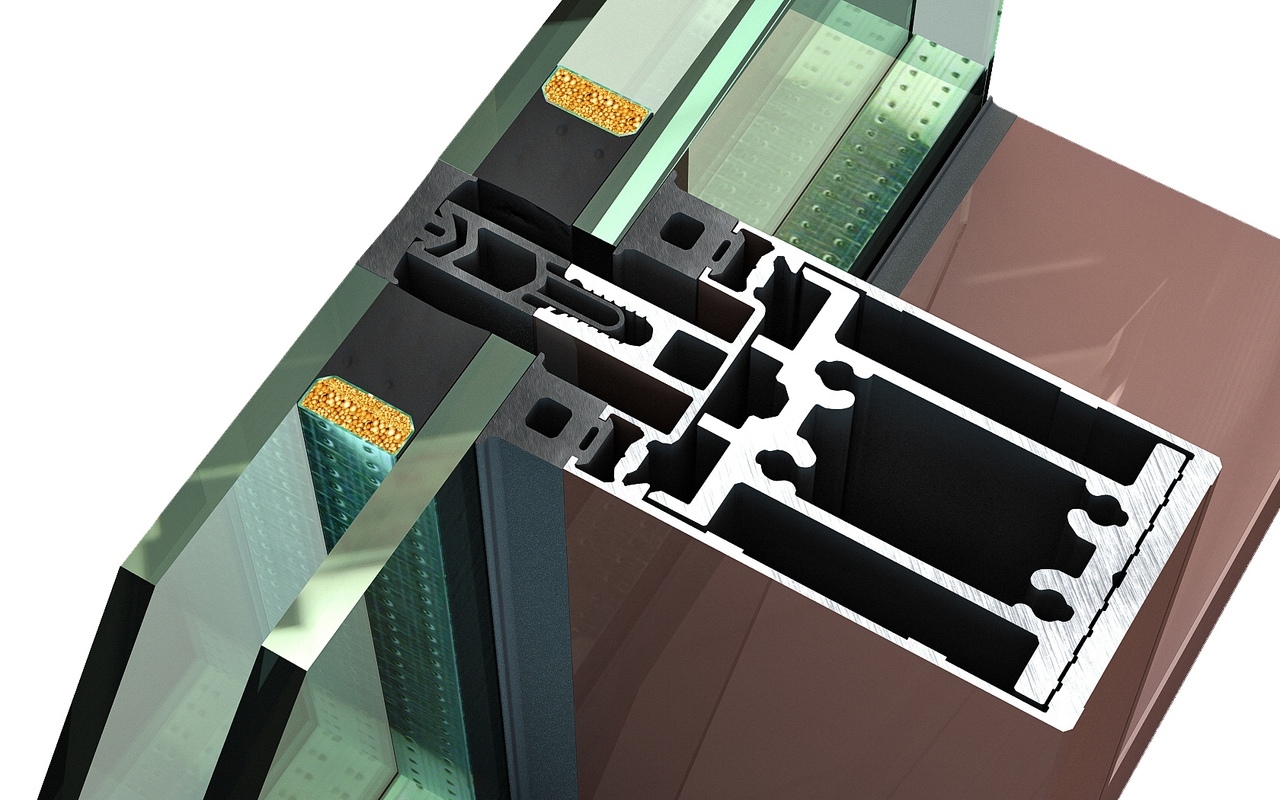

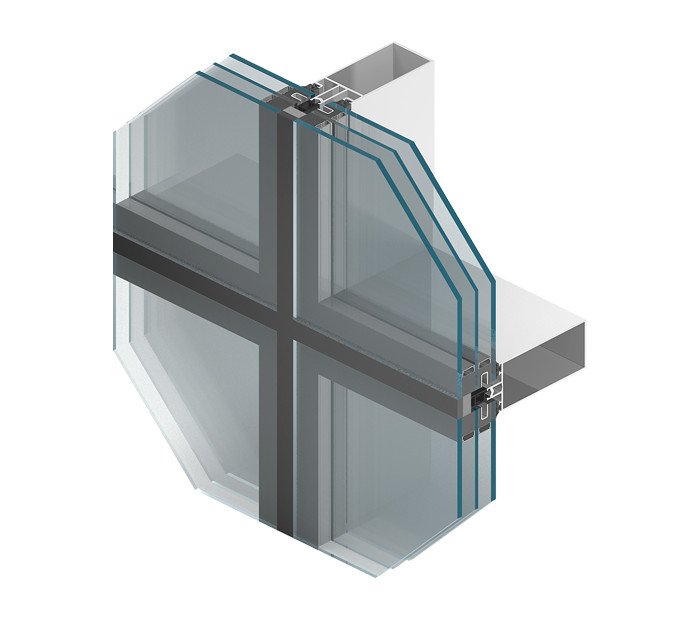

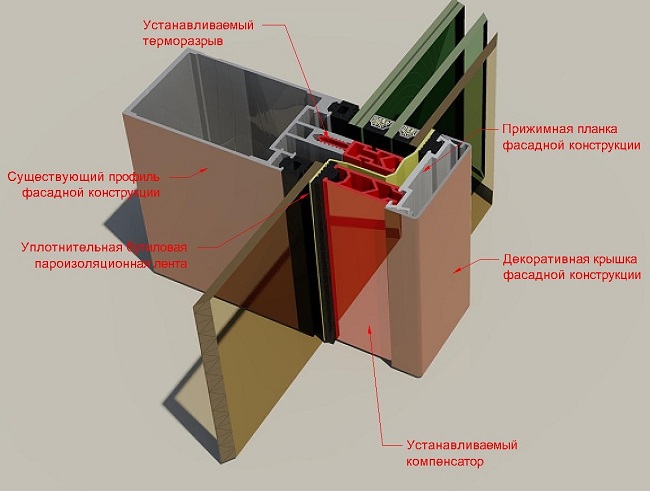

Features of structural glazing

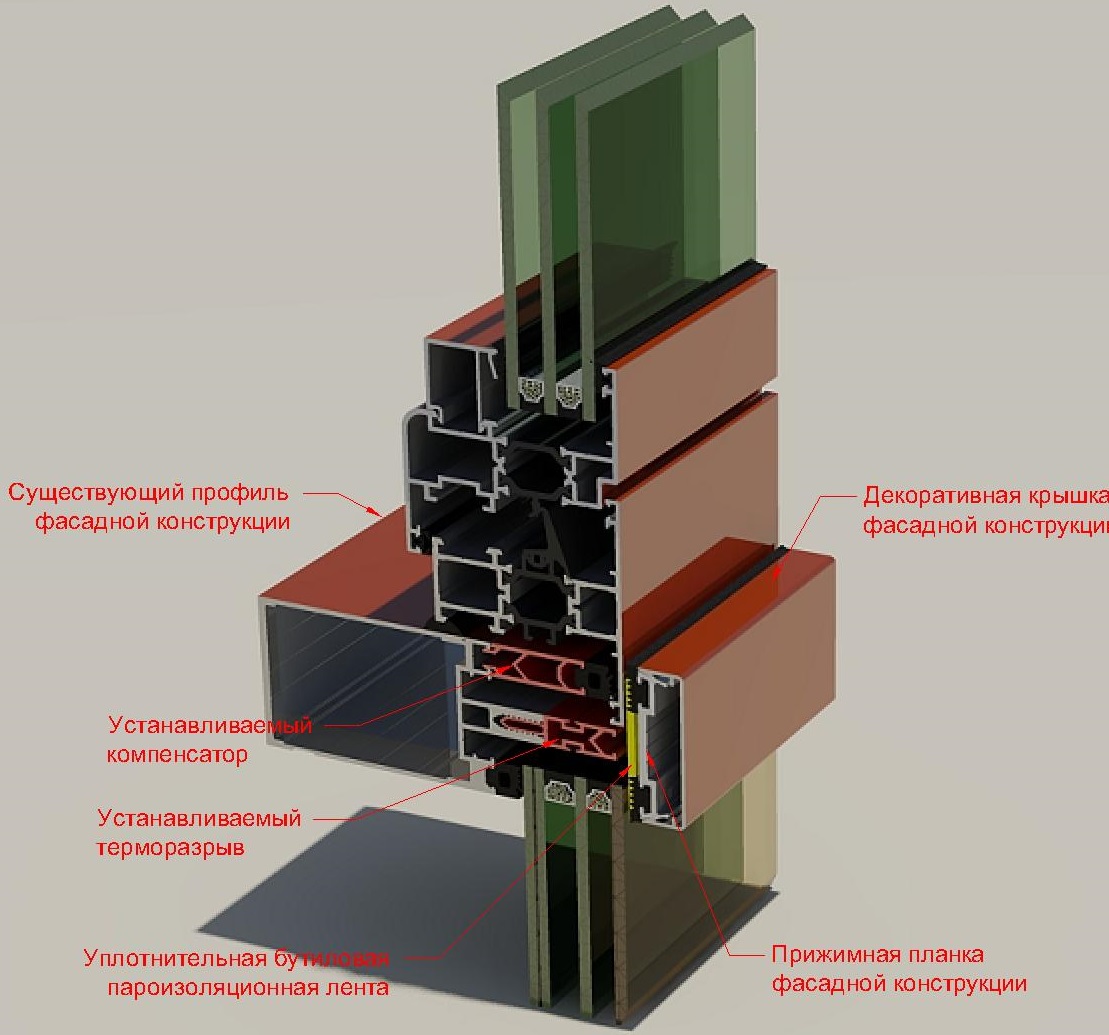

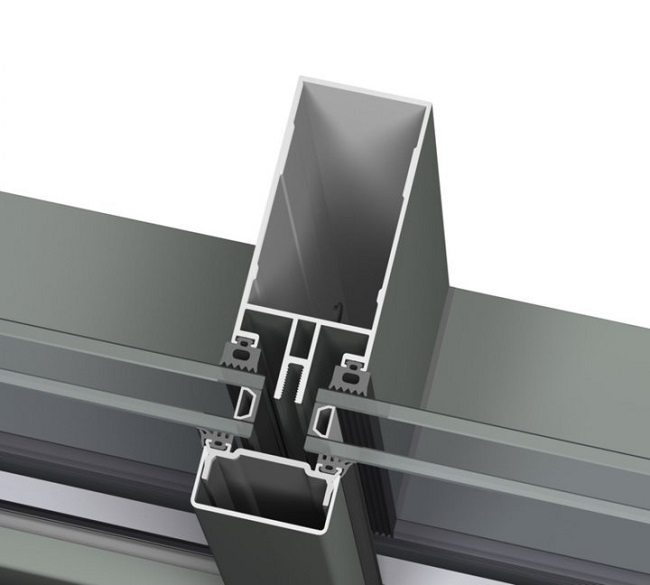

Structurally, structural facades are very similar to the post-transom glazing system, the main difference is the absence of a visible pressure profile from the outside.

Post-transom system

Post-transom system

Let's consider the main characteristics of structural glazing:

- The frame consists of vertically installed racks and horizontal lintels (crossbars);

- The profile is made mainly of aluminum, sometimes stainless steel, light-alloy metal elements or titanium are used.

- The frame is fixed between the storey floors, while the structure is visible only from the inside of the room. From the outside, only double-glazed windows are visible, the seams between which are filled with either a special sealant of a suitable color or a thin decorative profile.

Structural glazing

Structural glazing Drawing of a typical structural glazing unit - top view

Drawing of a typical structural glazing unit - top view

Visually, the structure of the system can be seen in our video:

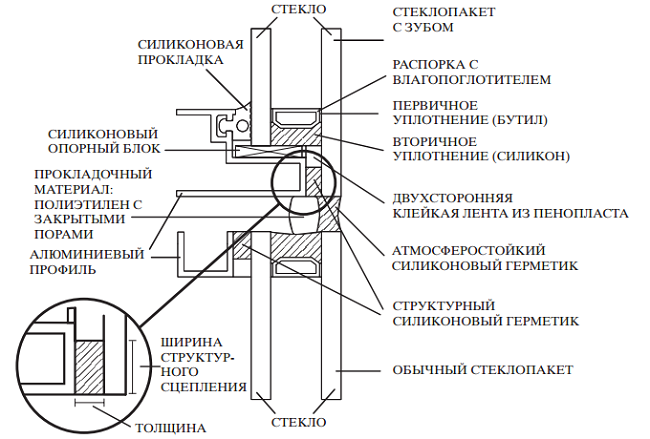

Insulating glass units for structural facades

The outer glass in such double-glazed windows is 10-15mm larger than the inner glass. This is necessary to minimize the external seam and secure the glazing to the frame. There are designs in which the distance frame is slightly recessed into the depth of the glass unit. This allows you to insert a metal profile into the resulting groove and through it to fix the glass unit on the supporting frame.

Outer and inner glass also differs from those used in traditional PVC constructions. The outer part is made of thick tempered glass - for the inner part, triplex is mainly used.

Another important point to consider when installing double-glazed windows is the assembly seams between them. A completely seamless structure cannot be assembled, since the structure will lose its integrity due to thermal deformations of the glass and the supporting profile. The minimum gap between the outer panes is 1cm. However, making seams larger than two centimeters is also undesirable - a facade with such gaps does not look entirely monolithic.

Structural Glazing Sealant

Methods of mechanical fixation of insulating glass units on the supporting frame differ depending on the manufacturer of the profile. However, in most cases, the outer glass of the insulating glass unit is held in the structure by the silicone sealant. In addition, this material seals all joints and abutments of the structure, compensates for temperature changes in dimensions, preventing damage to glass and deformation of the structure as a whole.

In structural facades, sealant is used for the following reasons:

- Reliable fixation of glass, metal, ceramics and most plastics.

- You can choose a material that matches the color or use a transparent one.

- You can work with silicone sealant at temperatures from -30 to +40.

For glazing structural facades, either neutral or acidic sealants are used. The use of the latter together with glass coated with decorative or energy-saving spraying has a number of peculiarities. The composition of such spraying, as a rule, includes metals, and the acid in the sealant can interact with these metals. Therefore, the places of contact between the acidic composition and the glass must be pre-cleaned.

Dow Corning Structural Glazing Sealant

Dow Corning Structural Glazing Sealant

Brief historical background

Double-glazed window (hereinafter SP) is a building translucent structure (SPC) made of two or more sheets of glass, interconnected by spacers and sealants. The joint venture dates back to the 60s of the XIX century.

However, many still remember the old double frames, which were insulated with cotton wool, glued with paper and fabric strips for better thermal insulation in cold weather conditions. Double-glazed windows and SECs assembled on their basis came to the space of the former USSR in large quantities in the 90s of the XX century. Twenty years before that, a double-sealed double-glazed window appeared and began to be massively used, as we are already accustomed to seeing it. Today, such a double-glazed window is used in 90% of the SPK.

In the 50s of the XX century, a double-glazed window was invented on the basis of an elastic sealant. The design is based on a hollow spacer frame, a drying agent inside it, and a sealant based on thiokol. Thiokol is a polysulfide rubber, highly resistant to gasoline and aromatic solvents, with good aging characteristics, high mechanical strength, elasticity and low gas permeability. Thiokol-based sealants are called polysulfide and are actively used for the secondary sealing of insulating glass units in our time.

Warm and cold facade glazing

Profile systems of cold facades are made either of plastic or aluminum, however, the latter option is more common, which is noticeably colder than PVC structures. Translucent filling in cold facades is, as a rule, single glass or single-chamber glass unit, in which ordinary glasses with low energy-saving characteristics are used, dry air is used as a filling gas.

The actual profile of cold glazing is rarely thicker than 5 cm, and the number of isolated chambers in it does not exceed four (usually 3).

Warm facades are constructed from a wide frame profile with a cross section of 5-10 cm. Plastic products contain at least 5 chambers, in which thermal insulation materials are additionally used. In aluminum structures, profile systems with thermal breaks are used, which helps to reduce heat loss in the cold season.

Energy-efficient double-glazed windows with two or three cameras, different thicknesses of glass and spacers are installed; an inert gas (argon, krypton) is used as a filler.