Specifications

Composition

Accent 125 is a non-viscous, thixotropic polyacrylate based paste.

The following ingredients are included in the sealant:

- Water dispersion of acrylic polymer.

- Special auxiliary substances that improve the properties of the material (to accelerate the film formation process, improve adhesion, extend the service life, etc.).

- Coloring pigments to give the sealant a specific shade.

- Filler to create volume.

Drying time

After applying the sealant, a film forms on the surface after an hour. It will take a day for a material with a thickness of 2 mm to harden. Full polymerization occurs within a week. The sealant can be applied at temperatures of - +5 - +35 degrees. Optimal weather conditions: temperature - +23 degrees, humidity - 60%. The sealant begins to perform its main functions already during the solidification period.

It is not recommended to treat the surface under the following conditions:

- temperature is below +5 degrees;

- humidity - above 80%;

- in very hot and dry weather;

- during the rain;

- in direct sunlight.

High humidity and low temperatures can lead to longer drying time and washout of the sealant. Too dry weather promotes accelerated film formation and the appearance of bubbles and blisters on the surface.

Consumption

Sealant consumption depends on a combination of three indicators:

- seam width;

- the thickness of the sealant;

- specific gravity.

So, with a material thickness of 5 mm and a joint width of 10 mm per 1 running meter. you need 100 g of sealant. The instructions provide a formula for calculating the material, as well as a consumption table for standard seam indicators.

The sealant is sold in 310 and 600 ml cartridges, as well as in 5 and 10 liter buckets. On average, one 5 liter bucket is enough to cover 70 running meters.

Service life and storage

The sealant forms a strong and durable coating that perfectly withstands any whims of the weather. The manufacturer guarantees the service life of the sealant for at least 20 years.

You need to store the product in a tightly closed container at t +4 - + 40 degrees. Expiration date - 2 years from the date of manufacture.

The sealant can be subjected to repeated (up to 7 cycles) defrosting / freezing, provided that the cycle is no more than one day. In this case, the limiting temperature should not be lower than -18 degrees.

One-time long (up to 7 days) freezing of the product is also allowed. Defrosting should be carried out in natural conditions without heating at a temperature of + 22 degrees.

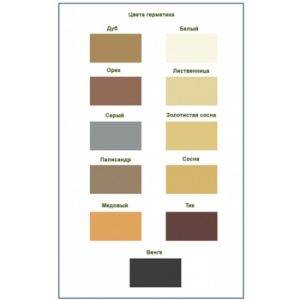

Color palette

The manufacturer offers 13 natural shades, from light larch to dark brown teak and wenge. A wide range of colors allows you to choose a tone for any design and color of the frame. If the buyer does not find anything suitable in the catalog, then you can order a custom tinting.

Log sealing services

The company "Master Srubov" offers professional sealing services wooden houses using the warm seam method... Our company has everything you need for high-quality performance of work - qualified craftsmen who are fluent in this technique, a sufficient stock of knowledge and experience, the necessary tools and readiness to start work at any time convenient for you.

We use only certified sealants, their price will be minimal for you, since we work directly with manufacturers. We apply a loyal pricing policy, which provides a variety of discounts for regular customers.You can contact us at the coordinates on the "Contacts" page.

Sealing instructions

High-quality insulation of a wooden house is possible only with strict adherence to the technology, which includes the preparation and the main stage for sealing the cracks.

Materials and tools

For work, you should buy a sealant in a cartridge or another form that works well for the assembly gun. You also need to prepare:

- foamed polyethylene in the form of a cord;

- narrow spatula;

- paint brush;

- water;

- rag;

- masking tape;

- soil for wood;

- spray.

You can also apply sealants manually, but using a gun will make your work faster and more comfortable. In addition, the assembly gun helps to squeeze out the product in a strictly metered, even and beautiful strip, while without it it will be difficult to achieve a similar effect.

Preparation

In older buildings, there is most often a rough caulk. It is better to remove it to reduce the risk of mold and insect nests. After the blockhouse is cleaned of dirt, dust, the old paintwork is removed, and in the presence of oil impregnation, the base is polished.

The wood is treated with degreasing compounds, then primed, allowed to dry well. If you ignore the preparatory measures, the sealant will lie unevenly and its adhesion to the substrate will decrease.

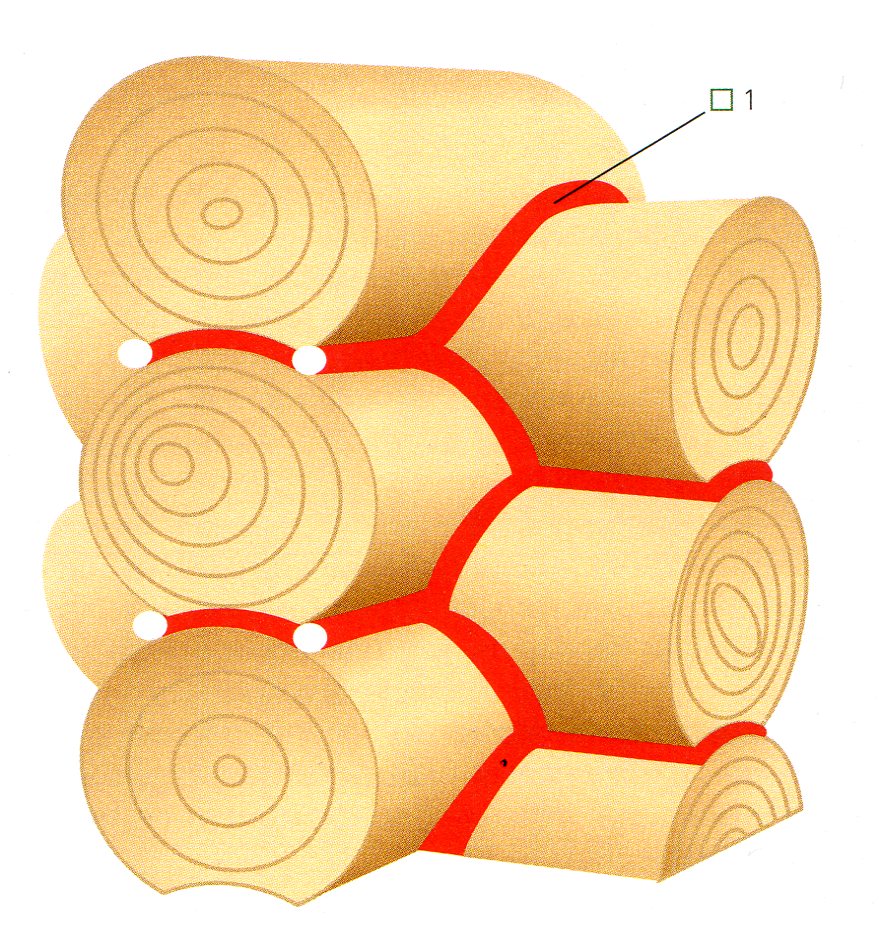

Further, a special polyethylene cord is laid in the seams between the logs. It is designed to fill the gap between the joints, since it is expensive and ineffective to completely seal the entire gap with a sealant. Too large joints are first caulked with tow, jute, then a cord made of expanded polyethylene is attached with metal staples. Both surfaces of the joints are pasted over with masking tape so that the sealant layer is even.

Sealing compound application

The warm seam creation agent is applied with an assembly (glue) gun. It is necessary to act in this way:

- cut the tip of the tube at an angle of 45 degrees;

- insert the tube into the pistol;

- pour the agent not packaged into cartridges into a special gun designed specifically for such sealants;

- press the "trigger", applying the sealant with a flat tape of the required thickness (the layer of the product should capture the logs by 0.5-1 cm on both sides);

- sprinkle the seam with water from a spray bottle, then level it with a spatula and remove the excess;

- moisten a small brush, finish the joint;

- remove stains, drips with a rag, then remove the masking tape without waiting for the sealant to dry.

Typically, for complete polymerization, the sealing compound needs from 2-4 days to 2 weeks, depending on its type, brand, weather conditions. Only after the end of this period can the seam be dyed.

Material consumption

Sealants are produced in tubes of 300 and 600 ml, as well as in plastic buckets of different sizes. Consumption varies greatly depending on the width and depth of the joint. For example, with a standard seam 5 mm deep and 20 mm wide, 200–250 g of the product will be needed per 1 running meter.

Drying time

It is necessary to work with sealants using the "warm seam" technology in dry weather at temperatures within the range of + 5 ... + 35 degrees. The optimum humidity for work is 60%, the temperature is + 20 ... 23 degrees. Under such conditions, the agent cures at a rate of 2 mm / day, and the primary film appears after 30-60 minutes. In wet, rainy weather, sealing a wooden house should not be carried out, as well as during snow. This will adversely affect the quality of the resulting seam.

Corners and cuts

The most difficult job of forming warm seams concerns the joints between wooden walls. To seal corners, overhangs, a polyethylene cord of the required thickness and length is inserted into the cracks, pushed through with a spatula. Usually this process is time consuming, laborious and painstaking.After the sealant is applied, its layer is leveled with a wet spatula.

If the corners were previously treated with oil impregnations or fire retardants, you will have to first grind the wood with a grinder, otherwise the sealing compound will not achieve the desired adhesion.

Storage conditions of the sealant

The product must be stored at temperatures within + 5 ... + 30 degrees without access to the sun, protected from moisture. The sealant can withstand up to 7 cycles of freezing and defrosting (the duration of each is no more than a day, the temperature is not lower than –18 degrees). Before use, the frozen composition is kept at room temperature for at least a day.

Views

There are several types of wood sealants, they are divided by area of application and are for indoor or outdoor use. Universal pastes are produced for a wide range of applications; there are also mixtures specifically for windows, roofs, log cabins. According to their special properties, waterproofing, heat-insulating and sanitary seals can be distinguished. In terms of composition, several main groups can also be distinguished.

Silicone sealant is not afraid of ultraviolet radiation, frost and surface heating, it works at temperatures from -50 to +140 degrees. It withstands deformation loads and perfectly compensates them, does not allow moisture and heat to pass through. This material is versatile, used for both internal and external work. The silicone joint sealant has the longest service life - up to 40 years. Due to its high elasticity and resistance to changes in conditions, this material is used as an inter-lead seal.

Silicone sealant is available in various colors, but it cannot be painted. A second coat or spot corrector after curing will not adhere to the first coat. Therefore, the silicone composition is applied once.

There are three types of compositions.

- acidic ones have increased strength and have a pungent acidic odor, which disappears as the material dries and polymerizes;

- neutral compounds are more environmentally friendly, but less resistant to atmospheric influences;

- Sanitary sealants contain special antiseptic additives that prevent wood from being damaged by fungi and mold.

Bituminous sealant is made on the basis of bitumen and rubber. Its waterproofing properties make it possible to use this material for sealing and repairing roofs, drains, and places with high humidity.

The polyurethane compound cures quickly and has excellent weather resistance, sealing and adhesion properties. The hardened seam can be painted over. It has excellent adhesion even when applied to damp substrates. Polyurethane sealant is available as a waterproofing sealant designed to work in high humidity conditions and sealing on dry and hard surfaces. Such seals are produced with various hardness indicators.

Professional insulation of houses

The company "Master Srubov" in a short time and at an affordable cost carries out work on the insulation of houses from a bar and any wooden buildings. We offer our clients a convenient service, high quality sealing of the seams of buildings, a phased payment of work. We also accept payment by card. We work on the territory of Moscow, Moscow region, as well as adjacent regions. We are ready to consider the possibility of cooperation with other regions of the country.

Master Srubov is the official representative of many premium sealant manufacturers - Ramsauer, Remmers, Wooden Wood, the domestic enterprise Oliva and other Russian and foreign companies. When choosing materials for work from those manufacturers whose dealers are our organization, we have the opportunity to offer you the most favorable prices for them. But at the request of the customer, we are ready to work with any materials, including VGT sealant.

Our masters have all the necessary knowledge and experience, have a lot of positive feedback about their work. But the specialists of our company do not stop there, constantly improving their skills, including on an ongoing basis attending practical classes and seminars from leading manufacturers, getting acquainted with new products and technologies for working with them.

For advice, clarifying information or ordering services for sealing your home, please contact our employee by phone. You can also leave a request in the "Contacts" section, and a specialist of our company will call you back in the near future.

Calculate the cost of painting and insulating your home right now

Do you have accurate measurements at home?

Measured by myself There is a project of the house The measurers came I want to call the measurer

By clicking on the button, you consent to the processing of personal data

How to properly grind the internal walls of a house from a bar

Preparation of materials and installation of a window sill when inserting windows in a wooden house

How to insulate a basement yourself

Sealant is an important representative of modern house building technologies.

Moisture-proof sealing of seams, holes, fasteners, carried out with sealants, greatly facilitates the work of builders of wooden houses. Modern sealants are elastic, adhere well to all surfaces, and are resistant to mechanical stress. Sealed materials are divided into three groups, according to the material that makes them up. 1 group. Polyurethane sealant. These sealants are characterized by very good elasticity and adhesion to any surface. Polyurethane is a good adhesive for wood, concrete and plastics. They have the longest lifespan

But working with this material requires caution, as it contains corrosive substances. Multi-storey panel houses contain many seams, which are sealed with polyurethane materials. Mainly outside, due to the resistance of this material to ultraviolet light and large temperature fluctuations

Most of them contain antifungal agents in the sealant, which is a plus for the tree. Group 2. Silicone sealant. Serves mainly for sealing the openings of windows and doors during construction and renovation. They have excellent grip on almost all surfaces. Such a sealant for work is often used for waterproofing house facades. It cannot be painted, but silicone sealed materials of any color are commercially available. The ability of a silicone mass to insulate a window opening in minutes is appreciated in construction. Therefore, the sales volume for silicone sealant is significantly higher than the rest. Silicone are acidic and neutral. Acidic sealants interact with cement, granite and metals and are therefore only used for plastics and wood. Neutral silicone sealants are suitable for all materials. Group 3. Acrylic sealant. Acrylics are mainly used to fill voids in seams and joints. These are harmless and you can work with them in closed rooms. The seizure of this material with the surface is slow, and the final hardening takes a day. Acrylic sealants cannot withstand severe frosts and therefore are not suitable for outdoor work at home in Siberia. Previously, the difference in quality between materials made by foreign and domestic factories was significant. Now domestic manufacturers have finalized their technologies, and their quality is almost equal to that of imported ones.

Mainly outside, due to the resistance of this material to ultraviolet light and large temperature fluctuations. Most of them contain antifungal agents in the sealant, which is a plus for the tree. Group 2. Silicone sealant. Serves mainly for sealing the openings of windows and doors during construction and renovation.They have excellent grip on almost all surfaces. Such a sealant for work is often used for waterproofing house facades. It cannot be painted, but silicone sealed materials of any color are commercially available. The ability of a silicone mass to insulate a window opening in minutes is appreciated in construction. Therefore, the sales volume for silicone sealant is significantly higher than the rest. Silicone are acidic and neutral. Acidic sealants interact with cement, granite and metals and are therefore only used for plastics and wood. Neutral silicone sealants are suitable for all materials. Group 3. Acrylic sealant. Acrylics are mainly used to fill voids in seams and joints. These are harmless and you can work with them in closed rooms. The seizure of this material with the surface is slow, and the final hardening takes a day. Acrylic sealants cannot withstand severe frosts and therefore are not suitable for outdoor work at home in Siberia. Previously, the difference in quality between materials made by foreign and domestic factories was significant. Now domestic manufacturers have finalized their technologies, and their quality is almost equal to that of imported ones.

Varieties of sealants

Choosing the right sealant is important

Sealants are divided into types by purpose and composition. First of all, there are household and professional sealants that differ in price, ease of use, and operating conditions. Professional products are not only more expensive, but also require certain skills in use, so it is impractical for home craftsmen to use them.

Any sealant contains fillers, polymer composition, hardeners and additional components that improve the properties of the material. Depending on the type of polymer used, they are divided into silicone, acrylic, polyurethane, bitumen and thiokol, but the first three are most often used for wood.

Silicone

Silicone compounds are acidic and neutral. The former contain acetic acid, and when hardened, they emit a strong characteristic odor. Acidic sealants are universal, have a low cost and are widely used in construction and repair work. True, they are incompatible with non-ferrous metals, natural marble and alkali-containing materials.

But for a tree, they are great. Neutral sealants are made on the basis of ketoxime or alcohol, so they can be used on absolutely any substrate. In terms of cost, they are more expensive than acid ones, although not by much. The general characteristics of silicone compounds are quite high: they are considered very durable (20-25 years), excellent for both outdoor and indoor use, and are water-repellent. After hardening, these sealants retain elasticity, withstand temperature changes, and are not exposed to atmospheric influences.

Sealant for wooden housing construction BARTON'S "Warm House"

The hardened layer has one more feature: neither paints nor repeated layers of the same sealant adhere to it. That is, in the event of a repair, it will not be possible to eliminate minor damage by spot application of a new composition, you will have to completely remove everything and seal again. As for painting, this problem is solved by purchasing colored sealants, the lines of which are available from almost every manufacturer.

| Specifications | The values |

|---|---|

| Polymerization time | from 6 to 12 hours |

| Life time | 3 years outdoor, 20-25 indoor |

| Application temperature | 5 ... 40 ° C |

| Shrinkage on curing | up to 15% |

| Density | 1-1.2 kg / l |

The quality of sealing depends on many factors, including the choice of composition.For log cabins, especially new ones, it is necessary to acquire a composition with the highest elasticity, since in such structures the deformations are stronger.

Elastic sealants are suitable for log cabins

For houses from laminated veneer lumber standard sealants are suitable: this material is less susceptible to shrinkage and cracking, which means there is no point in overpaying.

Check the expiration date and integrity of the packaging

Most sealants can be applied at subzero temperatures, but this should not be done during rain or snow. In the cold, the viscosity of the composition increases, which makes it difficult to apply, therefore, the sealant must be left at room temperature for a day before work.

You cannot dilute the sealant with water in order to save money, and also mix compounds of different brands with each other. This will reduce adhesion and may cause delamination of the material.

Sealants should not be diluted with water, the composition in the package is already ready for application

If the sealant in the container is frozen, it does not lose its properties, but it needs to be thawed only at room temperature. In no case should containers be placed near a radiator or other heating devices.

How to seal the seams in the bath correctly and accurately.

So you have come to the conclusion that it is time to build a bathhouse. The bathhouse has been built. But here a natural question is raised, how to cover up the seams in the already built bath, which are very visible. No matter how tightly the timber or frame is laid during the construction of the bath, the seams still remain. But through them just that precious heat will go, without which comfortable conditions for the visitors of your bath are impossible. It follows from this that in the winter period the heat in a log bath can be preserved only if all joints, cracks and seams between the crowns are sealed.

Wood, by itself, due to natural features, can deform, changing its volume and size. And in the bath itself, due to constant temperature changes, this will be especially noticeable, since cracks appear on the logs themselves, and gaps are most likely formed between the blocks. All this will lead to the fact that the bath itself as such becomes very unprotected from natural phenomena. This problem is completely solvable, and modern means for insulation will not require large material costs. But the insulation begins even during the construction of the bath, when the initial sealing and sealing of the joints of the bath is carried out. And from that moment on, a completely natural question arises: "How can you cover the seams in the bath and ensure its thermal insulation?" As thermal insulation, you can use traditional materials that are used when the crowns are laid: tow, moss. And also for sealing external seams in a bath, modern materials are suitable, which provide thermal insulation in wooden buildings.

Modern materials - acrylic sealants for wood.

Modern heat-insulating materials are resilient and elastic, therefore they are widely used. The peculiarity is that it is easy to work with acrylic sealants, they dry quickly and it is possible, if necessary, to apply several layers, which is very convenient and profitable. All modern hermetic materials have high adhesion, which has a positive effect on thermal insulation properties, they are not afraid of changes in air temperature and humid environment. But they have one more of the main properties - vapor permeability, which allows the tree to breathe. Acrylic sealants are used not only to seal the joints of the bathhouse, but also for any splits and cracks that form in the wood over time.

Among modern materials for keeping heat in a bath, special sealing tapes should be noted. They need to be distributed in the space between the timber. They are almost non-caking, which means that you do not need to use other hermetic materials, which creates additional savings.In addition, the sealant changes its shape when the logs begin to deform during the natural shrinkage of the bath.

- They include only natural materials, to which ecologists cannot make any claims.

- Moss and jute keep warm air out of the room and keep cold out.

- They have excellent absorbent qualities, which is very important in constantly damp bath rooms. Therefore, there is no need to worry about the walls starting to rot.

Sealing instructions

Effective insulation can only be obtained with strict adherence to the technology. Sealing includes several mandatory steps that must be performed in strict sequence.

Required tools

To complete the work, in addition to the sealant, you will need the following materials and tools:

- putty knife;

- construction gun;

- primer for wood impregnation;

- polyethylene cord for sealing wide gaps;

- an aqueous solution to moisten the spatula blade when leveling the seam;

- brushes;

- masking tape.

Preparatory operations

The walls of the log house must be thoroughly cleaned of dirt and dust. If the sealant is to be applied to a new home, the old paintwork must be removed. If the seams were previously smoked, you need to remove the old caulk.

The walls of the log house must be thoroughly cleaned of dirt and dust. If the sealant is to be applied to a new home, the old paintwork must be removed. If the seams were previously smoked, you need to remove the old caulk.

To improve adhesion, the surface to be treated is primed before sealing. The primer is made from a 10: 1 mixture of water and sealant. Then a brush or rag is moistened in the resulting solution and the joints of the logs are wiped. After all the preparatory measures, you must dry the surface well.

Preparation is an important step in sealing. An insufficiently cleaned surface interferes with adhesion, the sealant will lie unevenly and lag behind the walls.

It should be noted that wood preservative is carried out after applying the sealant. Antiseptic compounds dramatically reduce the adhesion of materials.

Sealant application

- To prevent the composition from getting on areas that are outside the application area, masking tape can be glued to the side edges of the logs. Usually this operation is done when the work is done by non-professionals. Experts apply sealant without adhesive tape exactly to the required places, covering an area of 1.5-2 m in one pass, but this accuracy comes with experience.

- In the gaps between the seams between the joints, a sealing polyethylene cord is laid with a chisel, which tightly fills the openings and at the same time serves to save sealant.

- A warm seam is applied with a pistol to the joints of the logs. It should grip the surface of the logs 0.5-1 cm on each side.

- Then the seam is slightly sprayed with water and leveled with a spatula, while removing excess sealant.

- After that, the final alignment is carried out. To do this, use a brush slightly moistened with water.

- Then, thoroughly wipe with a rag on both sides of the warm seam, removing the stains left after the water. If this is not done right away, the stains will harden and then it will be quite problematic to remove them.

- After the end of the work, the scotch tape is removed.

It takes two weeks for the sealant to dry completely, after which it can be coated with paints and varnishes. When using an acrylic compound, an acrylic colorant must also be used.