Peculiarities

Soudal sealants have a number of valuable characteristics that underline their high quality and reliability. These are resistance to ultraviolet rays, good tolerance to moisture and other external influences, ease of use and long service life.

Any sealant contains polymers. Depending on their type, the characteristics of the product itself are determined. One of the best known is the Soudaflex sealant. It is based on polyurethane, is characterized by good adhesion to other materials and elasticity after application. Its application does not cause problems and does not require special skills.

Soudaflex polyurethane sealant (Soudaflex)

Soudaflex (Soudaflex) is a high-quality, elastic, one-component polyurethane-based sealant.

Advantages

- Very easy application

- Remains elastic after polymerization

- Very good adhesion to many materials

Soudaflex 14 LM

A polyurethane sealant with a low modulus of elasticity with thixotropic properties (i.e., does not run off), intended for sealing vertical expansion joints. High adhesion to most building and industrial materials: concrete, metals, polyesters, artificial materials, etc. It can withstand high dynamic loads, inhibit vibration, and absorb vibrations. Can be painted.

Application

- construction: seams subject to large deformations (change in the gap);

- assembly seams between door / window blocks and walls;

- expansion joints between different construction materials.

Instructions

Surfaces (any traditional building materials, except glass) must be degreased, free from dust and dirt.

Porous surfaces should be treated with Primer 100. Non-porous surfaces do not need primers, but can be activated with Surface Activator. Some plastics and colored substrates may require a primer. It is recommended to carry out your own compatibility tests before using the adhesive.

- minimum width: 5 mm

- maximum width: 30mm

- minimum depth: 5 mm

- width = 2 x depth

When painting with paints fixed by oxidation, paint drying problems may occur. Due to the wide range of paints used, it is recommended to carry out your own tests before using them.

It should be noted that the sealant is elastic, unlike most paints, so the painted surface can crack when deformed.

Colour

White, light brown, concrete color, dark brown, dark beige

Package

Sausage 310 and 600 ml

Price

Sealant Soudaflex 14 LM (310 ml) - 253.00 rubles / piece

Sealant Soudaflex 14 LM (600 ml) - 334.00 rubles / piece

Soudaflex 40 FC

Permanently elastic polyurethane adhesive sealant designed to seal vibration-resistant joints and for expansion joints in industrial floors. Excellent adhesion to most building and industrial materials: concrete, metal, polyester, artificial materials, etc. It can withstand high dynamic loads, absorb vibrations. Can be painted.

Application

- any gluing and sealing tasks in construction;

- structural bonding in vibration-resistant structures;

Peculiarities

Excellent chemical resistance. Specially designed for concrete.

Instructions

Surfaces (any traditional building materials, most metals, polyester materials and plastics, except glass and PVC) must be degreased, free from dust and dirt.

In very warm and humid climates, it is recommended to use Primer 100 on porous surfaces.No primer is required on non-porous surfaces. Non-porous surfaces can be activated with Surface Activator. It is recommended to carry out your own compatibility tests before using the adhesive.

- minimum width: 2 mm (bonding), 5 mm (gap)

- maximum width: 10mm (gluing), 30mm (gap)

- minimum depth: 5 mm (gap)

- with a gap of 12 mm: width = depth x 2

When painting with paints fixed by oxidation, paint drying problems may occur. To verify the correct product selection, it is recommended to carry out adhesion tests.

Colour

White, gray, black

Package

Price

Sealant Soudaflex 40 FC (310 ml) - 262.00 rubles / piece

Sealant Soudaflex 40 FC (600 ml) - 330.00 rubles / piece

Views

Household and professional sealants are available in one-part and two-part. One-component is most often produced in tubes and cylinders. Such materials are completely ready for work, and for their use you need a mounting gun, which does not require any special skills.

Two-component sealants contain two components that are mixed right before use, as they do not last long. Therefore, they are used more by professionals.

Soudal sealants differ from each other in their composition, performance and application.

Consider a description of their properties and technical characteristics.

There are special means for sealing glass products (for aquariums and glazing of window frames). Seams made with silicone sealants must not be painted over. But this is not scary, since sealants are available in different colors or completely transparent.

- Polyurethane. Soudaflex 40, Soudaflex 40 FC, Soudaflex 14 LM - contain resins. They are the fastest drying, so you will not be able to store an open package for a long time. Used for sealing joints between panels, window frames and double-glazed windows, waterproofing and for roofing. Their properties allow gluing materials of different composition without losing the quality of the seam. Seams made with such sealants can be painted and varnished.

- Bituminous and rubber. They do not allow water to pass through, and therefore they are often used to protect the roof from rain, snow and other atmospheric phenomena. These sealants are perfectly combined with wood, metal, brick and many other building materials. Another advantage is that such formulations can be applied to a damp surface.

Seams made with bitumen and rubber sealants are strong, durable, flexible and weatherproof. Small disadvantages of such materials - they cannot be used at low temperatures. In addition, seams made with bituminous and silicone materials do not allow them to be stained.

Acrylic sealants. "Instant", "Parquet" - contain a plasticizer, ammonia solution, fillers and safe antiseptic additives. Compatible with all building materials (especially wood). They are actively used to seal cracks in a timber, when installing a wooden floor, parquet, laminate board, installing baseboards, sealing door and window openings. But it can also be used to seal pipes for various purposes, tile joints and repair cracked furniture.

The seams made with these sealants prevent the penetration of cold, which is important when insulating a house.

High temperature sealants. A special group of silicone building materials

They are able to withstand temperatures up to 350 degrees, therefore they are used in the manufacture of stoves and fireplaces, chimneys, and sealing joints on boilers.

Choose only those products that are suitable for the operating conditions of your stoves and fireplaces. High temperature sealants are acidic and neutral. Neutral materials are compatible with all materials, but acidic ones cannot be used to seal materials that are prone to corrosion, as well as in cement and concrete surfaces.

Heat resistant sealing pastes.Fix All Classic - SMX polymer hybrids. This type can be attributed rather not to sealing agents, but to adhesives. Such materials are capable of withstanding temperatures no more than 200 degrees Celsius. But they have their advantages - they are chemically neutral. They dry quickly, but the speed of their solidification is the higher, the higher the temperature in the working room. They can be used in saunas, showers, bathrooms.

Types and technical characteristics

There is a wide variety of sealants on the market that are suitable for a variety of applications. They are packaged in tubes of various sizes and shapes. There are universal, fire-resistant, silicone, sanitary, aquarium products. The most commonly used types are acrylic, silicone and polyurethane.

Silicone sealants have gained the widest popularity. As the name implies, the basis of the product is silicone. The product is presented on the market in a wide variety of colors - transparent, white, black, beige and bronze. It is the color of the material that affects its basic properties. The product is used for external and internal work.

Silicone sealants are divided into neutral and acidic. They can be used for work carried out in high humidity. They stretch up to 250 percent, do not lose their properties when the temperature fluctuates from -40 to +100 degrees, when exposed to pressure and other atmospheric phenomena. Also, such funds perfectly tolerate mechanical stress. Sealants of this group are in good contact with a large number of surfaces. They can be used when working with concrete, brick, glass and other substrates.

The next type is acrylic sealants. They have a lot in common with silicone, but they also have distinctive features. The products are available in different colors, and are often used for indoor work. These materials can be used in rooms with high humidity, they do not change their color under the influence of moisture. They are also resistant to mold and mildew.

Non-moisture resistant sealants of this group have excellent aesthetic properties and are often used in furniture assembly. They are ideal for working with wood products (door and window frames, flooring, etc.). The products dry out in a short period of time. For example, the fast-drying acrylic sealant Soudal Acryl Express can be processed and coated with paints and varnishes 10-15 minutes after application.

The most resistant, reliable and durable polyurethane sealants are recognized. They are used mainly for external work, they are suitable for sealing the seams of building objects. Like silicone, these products can stretch up to 250 percent. They are resistant to temperature fluctuations from -40 to +80 degrees, they tolerate most natural phenomena, high humidity and ultraviolet radiation well.

One example of a commonly used sealant from this manufacturer is Soudaflex 14 LM. It is available in 310 and 600 ml volumes. The product is produced in white, gray, light and dark brown, dark beige colors. It interacts well with most materials, it is used to seal vertical joints, because due to its consistency, it does not flow out of them. The product does not lose its properties when coated with paints and varnishes, it can withstand loads well.

Another popular brand is Soudaflex 40 FC. This sealant is available in the same quantities as the previous one, and can be black, white and gray. Its elasticity allows it to seal vibration-resistant seams, as well as to perform many other tasks during construction work. The product interacts well with a large number of materials, is often used when working with concrete. It perfectly tolerates even serious loads, it is easy to paint.

Fix All Classic can be used for both outdoor and indoor use. Its distinctive feature is the ability to interact even with wet materials. The product is chemically neutral, interacts well with most surfaces (from plastics to metals).The product is resistant to weak alkalis and solvents.

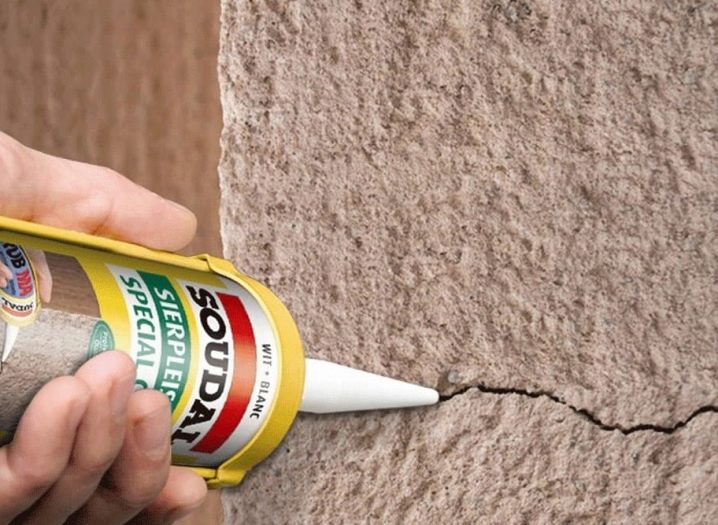

Instructions for use

- First of all, the surface is prepared. It must be cleaned, degreased and dried. To prevent the sealant from getting on the outer part of the coating, it must be sealed with masking tape.

- When working with sealants, it is recommended to use protective clothing and gloves.

- It is more convenient to apply the composition using an assembly gun. How to use it is usually indicated on the label. The composition must be applied at an angle of 45 degrees. For faster drying, it is recommended to avoid the formation of a thick layer. Excess sealant is removed with a spatula.

- Drying time depends on both the type of sealant used and the thickness of the applied strip. Usually this process takes about a day, but the material begins to harden after half an hour.

Scope of application

It is clear that the composition of the sealing materials significantly affects their properties, which means that their scope of application is different.

- If you need to seal joints in concrete or foundations, use silicone or bitumen.

- For sealing houses from a bar, laying parquet, laminate boards, installing baseboards, use acrylic sealants.

- For roofing work, polyurethane is perfect.

- A silicone or polyurethane sealant is suitable for window frames.

- Use silicone to seal cracks in a brick wall.

- Use acrylic sealants to seal joints during plumbing work and seal cracks in pipes.

- For stoves and fireplaces, select only high temperature sealants.