Installation features

PVC membranes are considered to be durable. This is true, but only under the condition of correct installation.

The most important thing is to properly lay the material itself. It should overlap

Before starting work, you must have a correctly calculated plan for laying all the material.

The web is laid exclusively by hand using a special welding tool

It is important to remember about the temperature outside and weather conditions. The laying of the material should not take place with a wind force of more than 5 m / s

At the same time, the air temperature should not be higher than -5 and higher than +40 degrees C. Do not lay the membrane during rain or immediately after it.

It is advisable to lay the canvas on a cleaned homogeneous surface. All foreign objects must be removed from it in advance, especially plant roots, sticks, boards, glass and any other debris that can damage the material under pressure. The cleanliness and uniformity of the coating play an important role in the life of the coating to be produced.

The method of attaching a geomembrane to a concrete wall is fundamentally different from laying it on the ground. The fastening of the canvas to the wall is carried out using anchor bolts, which are closed from above with a polyethylene textured patch. All seams must be well soldered over a large seam width. The quality and durability of the entire structure depends on how correctly the installation of this type of insulation is performed.

When welding 2 sheets of geomembrane, you need to know some features.

- The sheets are joined together by high temperature welding. This method is called extruded and is performed with a special tool.

- After completing the main stage of welding, begin to fix the edges.

- The final consolidation takes place in prepared trenches.

- It is desirable that the overlap of the sheet is at least 10 cm from the edge. This will create a wide and secure seam. In this case, there will be a small overspending of material, but it is better to sacrifice 1 extra roll than after the completion of all work to look for one leak in multi-meter seams.

A video overview of the geomembrane is presented in the video below.

Installation tips

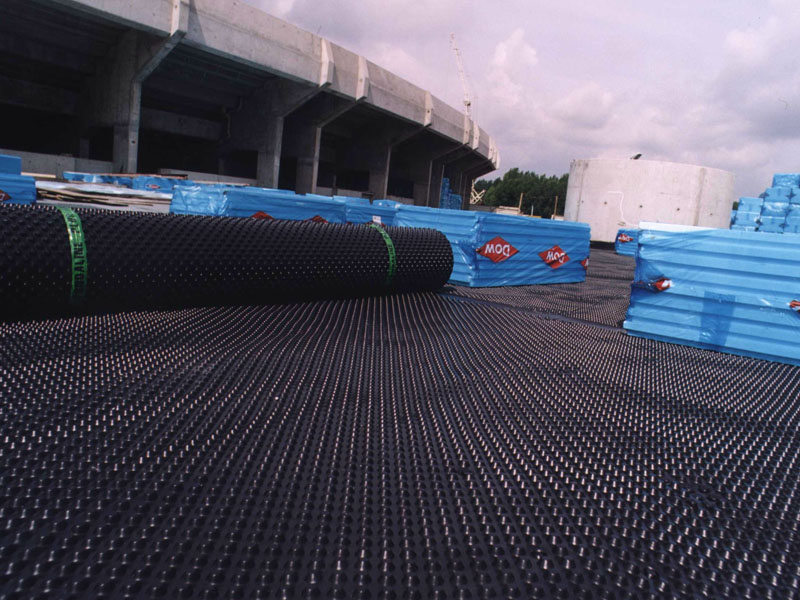

Geomembrane "Dreniz" is installed in layers in combination with a standard drainage and waterproofing system. Its installation is carried out simultaneously with the laying of tubular drains. Then it is placed on the surface of the soil (with a filter layer to the soil). In this case, the polymer part of the sheet turns out to be connected to the walls or floor. The geomembrane is laid in rows: vertically and horizontally, in a flattened form.

It is worth considering the following points:

- "Dreniz" is used in conjunction with pasting insulation or replaces it;

- in the wall-mounted application, the membrane is laid at a maximum depth of 8 m;

- it is possible to fix the protective layer at any type and level of groundwater.

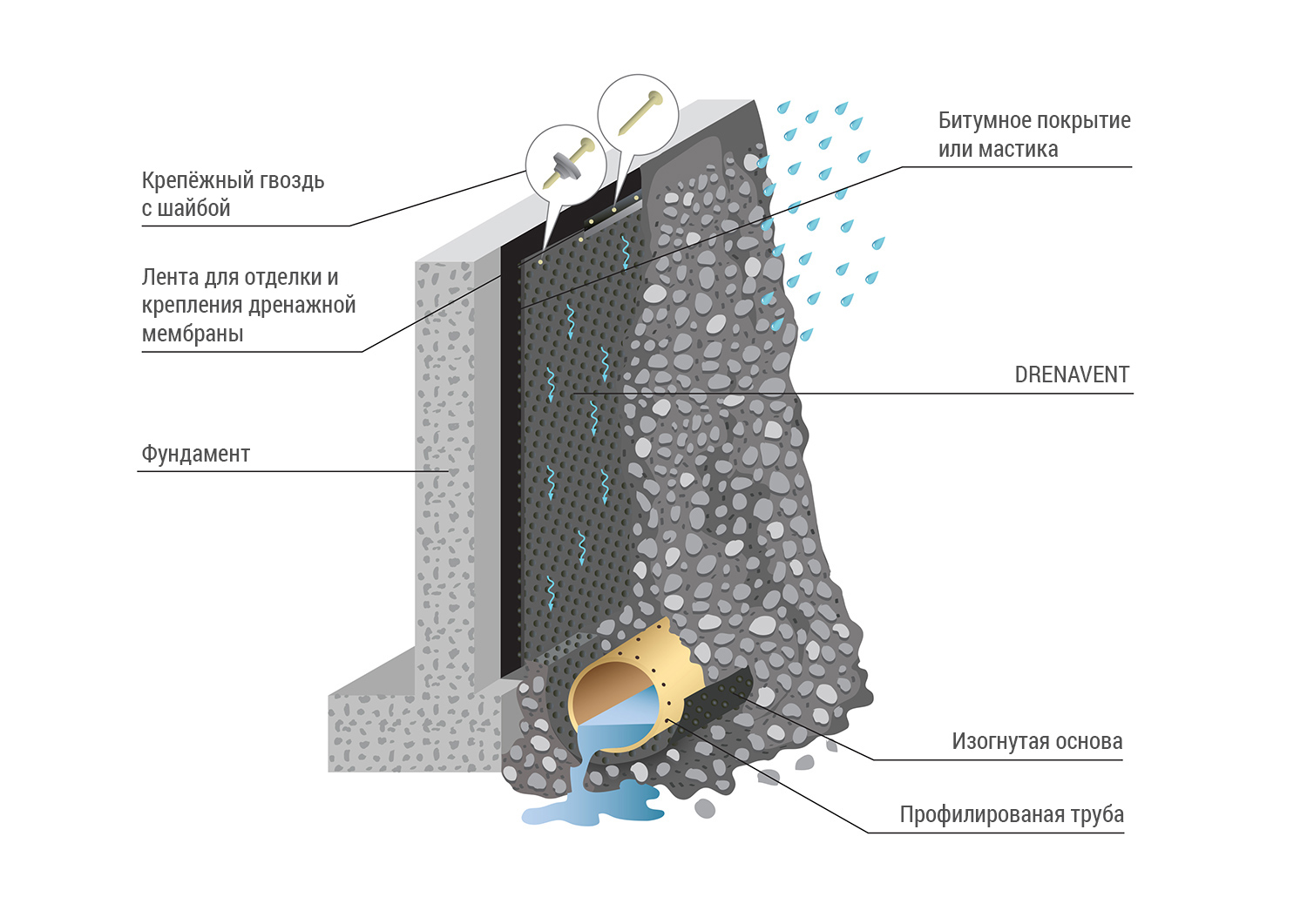

When draining the surface of the walls, work is carried out from the bottom up. Sheets of material are stacked directly on top of each other (overlapping, along a special contact strip). Its width is 15 cm; for installation, a hydrophobic composition is used that does not allow moisture to pass through. When joining, the layers of material are separated, the seam in the rows is displaced. On the wall, the geomembrane is attached using bitumen mastic or hydroglass (in a disposable version); when protecting the foundation, it is possible to use dowels, followed by fixing with chemical-based insulating compounds.

Ring drainage using a geomembrane is carried out to a depth of 5–8 m, the free space is filled with sand with a high filtration coefficient. Wall mounting is prohibited when the trench is flooded with water. It is first drained, and then "Dreniz" is fixed on the surface.

How to properly mount the geomembrane, see below.

Unique properties of Dreniz geomembrane

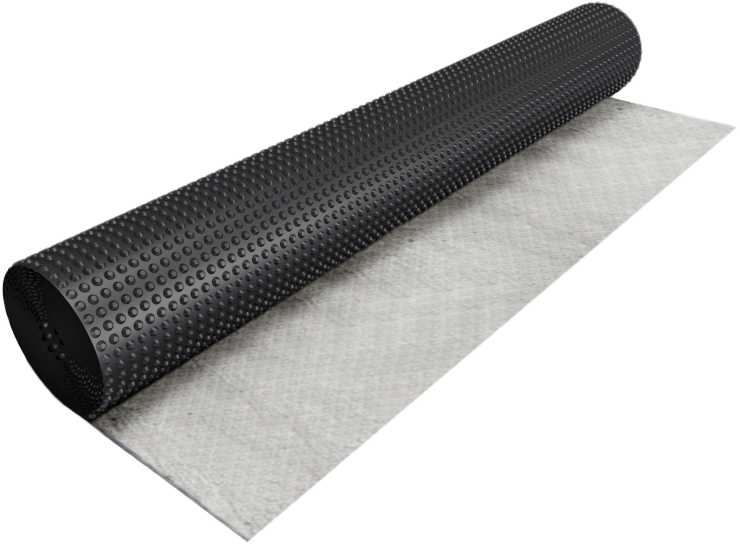

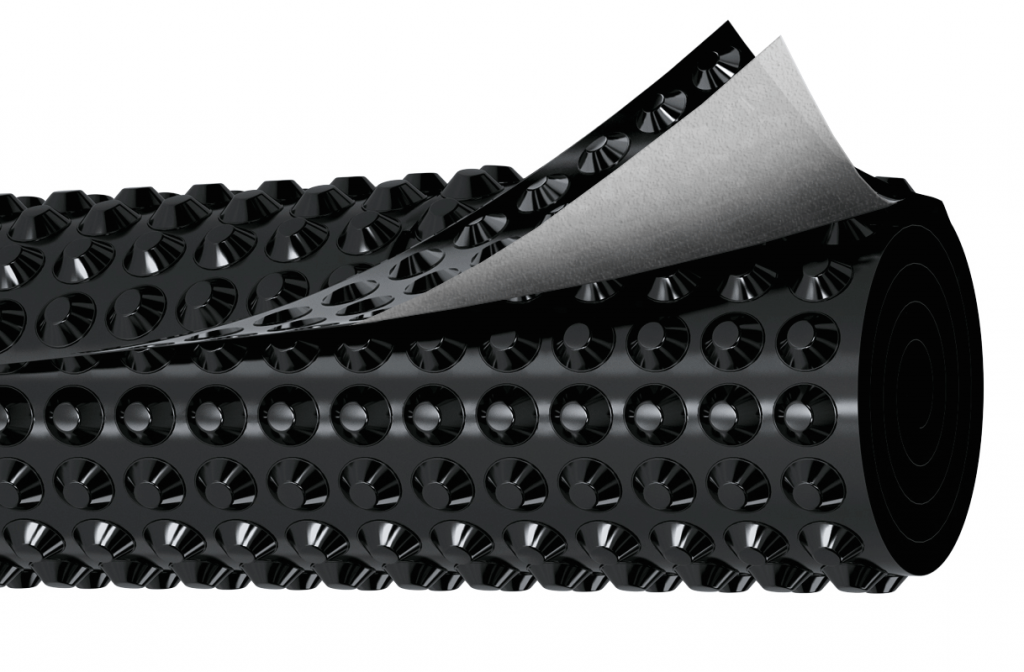

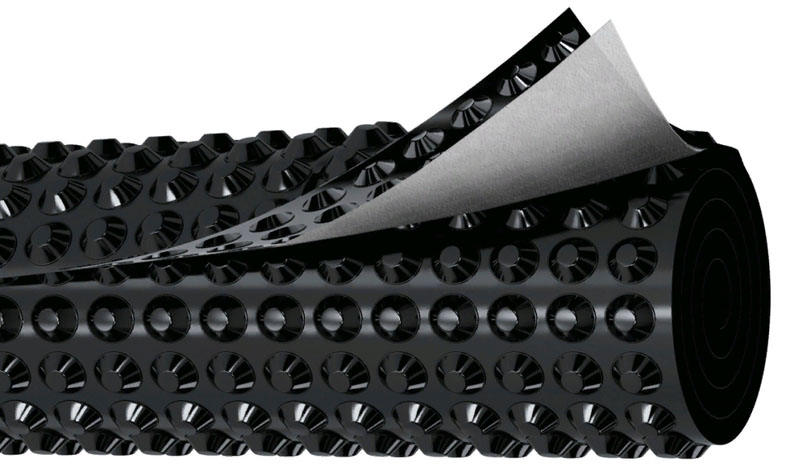

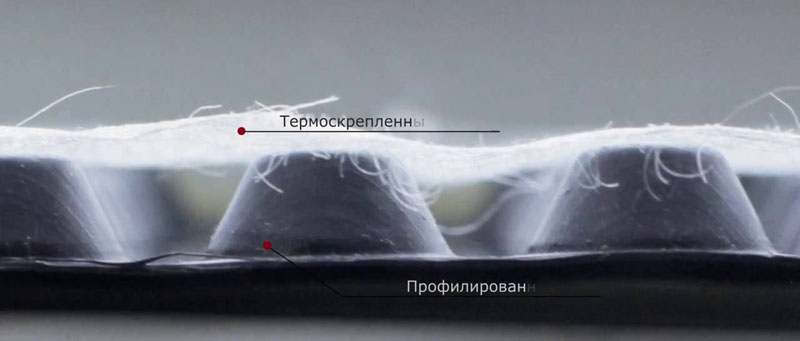

Geomembrane Dreniz consists of three main components: PVC film, Dornit non-woven geotextile and waterproof glue connecting them. Polyvinyl chloride (vinyl plastic) sheet has a special cellular profile. The product is durable, strong, chemically inert, perfectly resists deformations during ground shifts, resists well the negative effects of an acid-alkaline environment, does not lose performance in a wide temperature range, and is environmentally friendly.

Technical characteristics of Dreniz

| Description of characteristics | Index |

|---|---|

| Drainage capacity | not less than 1.1 l / s per 1 m2 |

| Compressive strength | not less than 0.245 MPa |

| Tensile strength | not less than 29.4 MPa |

| Dornit areal density | not less than 60 g / m2 / 250 g / m2 |

| Mass / m2 | about 1.05 kg |

| Roll width | 1.0 m |

| Roll length | 15.0 m |

| Roll area | 15.0 m2 |

Do you need a vapor-permeable membrane to protect building structures, the price of which will be beneficial to you? NPO Geotechnologii manufactures and sells a wide range of these products. In addition, the site catalog also contains a logicroof membrane, produced on the basis of high-quality raw materials.

Where is it applied?

The use of the Dreniz geomembrane implies several directions at once, in which this material can be useful. The drainage shell complements and enhances the properties of the waterproofing and drainage system. Let's note the most popular directions of its use.

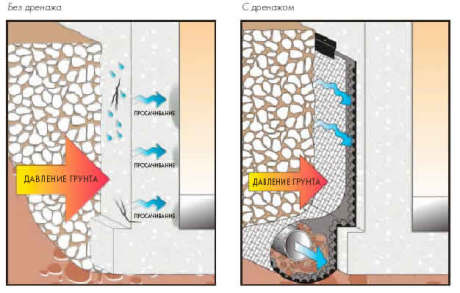

- Protection of the foundation and basement of structures, buildings, and other objects from the effects of groundwater. The geomembrane provides effective moisture removal and reduces the negative consequences of the rise in the level of underground liquid.

- Drainage of building and landscape structures. These can be parking areas, paths and driveways, operated roofing, floors in basements. Here, such an addition provides a more efficient moisture removal.

- Protection of objects where it is necessary to replace standard materials and technologies with more economical ones. First of all, this applies to classic waterproofing with wall drainage. This is where the membrane material will provide the best manifestation of its properties.

- Replacement of coating and pasting waterproofing. Due to its greater depth, Dreniz copes with the tasks much better than the usual mastics and waterproofing.

- Protection of existing waterproofing from damage. It turns out to be not subject to mechanical damage. In addition, the cellular structure of the geomembrane retains air access, which provides additional thermal insulation and ventilation of structures.

How much does a drainage membrane cost: price overview

Of course, the cost of membranes is far from democratic, but the installation of a new base or foundation will cost even more.

PLANTER Geo profiled membrane 2 × 15 m, spike height 8 mm

High strength polyethylene membrane. Suitable for the blind area of foundations and paths.

Geotextile collects water, and the membrane removes it through drainage channels to the outside

Geotextile collects water, and the membrane removes it through drainage channels to the outside

Membrane Planter Standard 1 × 20 m

Effectively proved itself in the organization of wall drainage. High strength material.

Can be used to organize sidewalks and country paths

Can be used to organize sidewalks and country paths

Drainage geomembrane Isostud GEO, 2 × 20 m

Drainage with a geotextile layer will ensure effective drainage of water from the ground, providing high strength and protection against ground sinking even in places with close groundwater contact.

The material protects the soil from waterlogging and waterlogging, protects the paths from grass germination

The material protects the soil from waterlogging and waterlogging, protects the paths from grass germination

And if you have experience in protecting a summer cottage from moisture using drainage membranes, share your knowledge with our readers!

Previous EngineeringKitchen sinks made of artificial stone: prices and reviews of the best models

Next Engineering

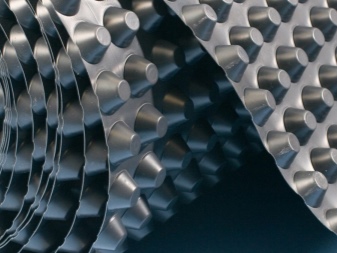

Profiled membranes: material features ↑

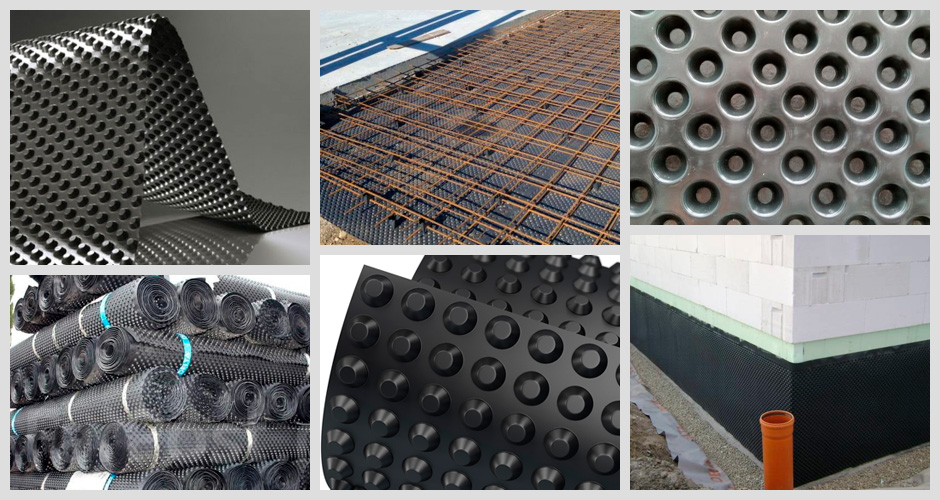

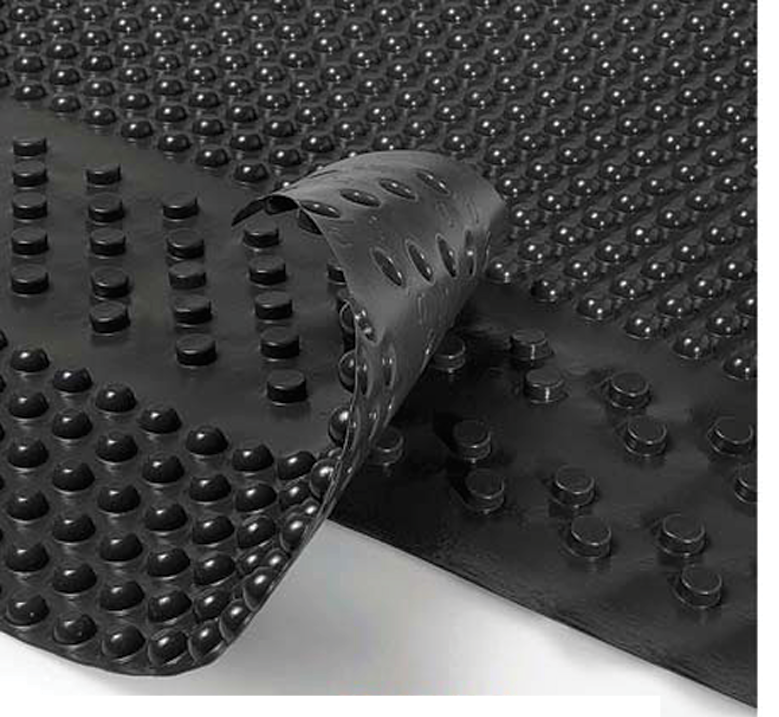

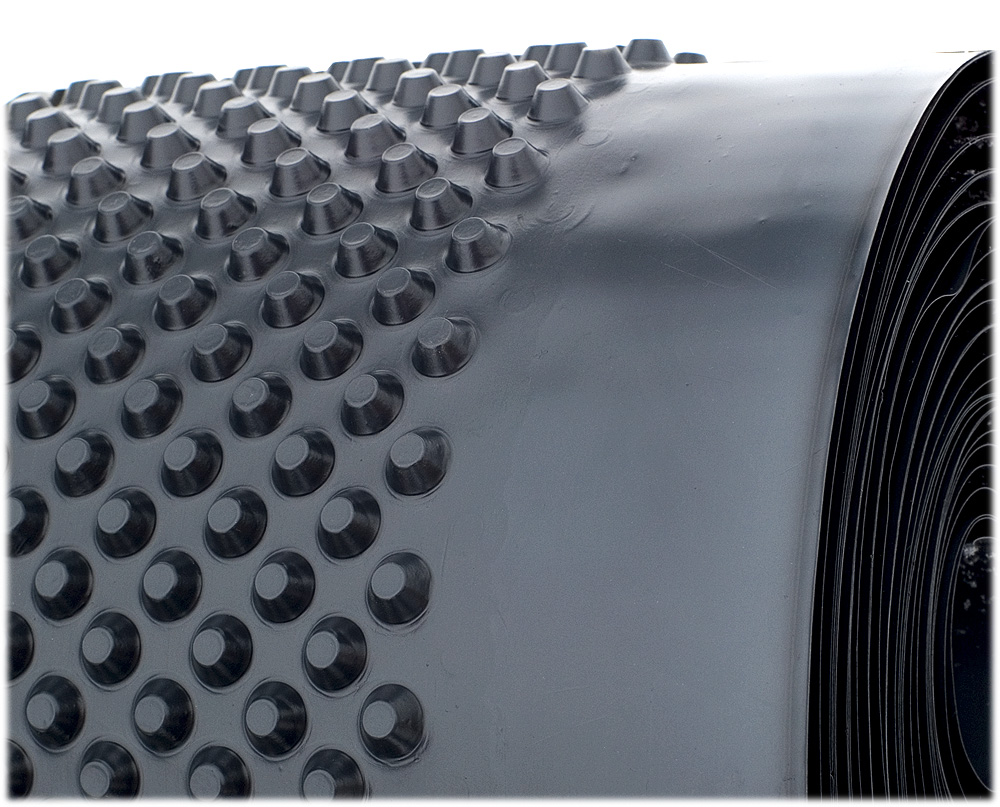

Membrane Planter is a roll-on synthetic protective material. Hollow spikes are extruded on the polymer canvas in a checkerboard pattern.

Automation and control: production facilities

Automation and control: production facilities

Manufacturing material - high density polyethylene. PVP is produced by extrusion technology. The production process is automated; compliance with technology is strictly controlled at each stage. For the manufacture of especially durable polyethylene, a special formula of raw materials has been developed. The canvases are integrally pressed, without seams.

Membrane Planter: a versatile product

Membrane Planter: a versatile product

Polyethylene for the manufacture of a planter is a high-strength fabric with a uniform dense inner structure, which has increased elasticity and resistance to any kind of damage.

Membrane fabric production

Membrane fabric production

Advantages:

Wide operating temperature range. The material retains its performance without loss of elasticity even at an air temperature of -45 °.

Durability. The manufacturer guarantees from 60 years of operation of the membranes, subject to the installation recommendations.

Elasticity. The material can withstand increased loads without the risk of tearing.

Resistance to aggressive substances. Polyethylene sheets are not destroyed when exposed to chemicals, they can be installed in aggressive soils.

Environmental friendliness. Protective membrane Planter - not only for outdoor use. The material can be mounted on the surface of walls and floors inside buildings, in residential premises.

Ease of installation. The universal material is mounted in two directions: horizontal and vertical. The edges of the canvases can be joined using a special fixing tape, without the use of hot-welding technology.

Features of installation and operation of Dreniz

The material is maximally comfortable to install, which is carried out by the filtering surface to the outside. The vertical or horizontal positioning of the diaphragm depends on the design. In the process of laying, the material does not lose its filtration capacity, since it was laid down at the manufacturing stage. The geotextile fabric does not reach the edge of the vinyl plastic sheet, since the geomembrane installation technology requires an overlap of 100 mm or more (fixation is carried out on dowels or bitumen mastic). The width of the web in a roll is 1 m, and the length is 15 m (although an increase in length is not excluded, taking into account the specifics of the project being implemented). The compressive strength of the material is 0.245 MPa, and the tensile strength is 29.4 MPa.

What is Dreniz?

Geomembrane "Dreniz" is a new generation multicomponent material with a pronounced characteristic relief. It is a membrane based on cellular PVC, supplemented with a layer of a special textile fabric. A geocomposite protective coating of this type can be combined into large structures using moisture-resistant bitumen-based mastics. The production of products under the trade name "Dreniz" is carried out in accordance with specially developed specifications.

The non-woven fabric is made of durable, tear-resistant, needle-punched polyamide. This material is a Russian development, which is not inferior in characteristics to foreign analogues. It is used to protect foundations and plinths from the effects of atmospheric or underground moisture.

There are several types of Dreniz geomembranes:

- "U" - reinforced version for deepening to more than 15 m;

- PF, without geotextile filtering layer;

- regular, two-layer.

The material is made in the form of an unbreakable web 1 × 15 m in size, rolled up into rolls.

The technology of laying protective membranes in TechnoNIKOL insulation systems ↑

The technology for laying Planter profiled membranes is quite simple. For fixing the canvases, when using the joint materials recommended by the manufacturer, the use of hot gluing methods and special tools is not required.

Installation of membrane protection is carried out both outside buildings and on the inner walls of wet rooms. For laying in private houses, choose a product of the Standard, Eco level. When it is necessary to connect the membrane to the wall drainage line, it is rational to use the material with geotextile.

Horizontal laying

Horizontal laying

Planter Standart membrane sheets, when fixed to a vertical wall, can be laid horizontally and vertically.

Laying the canvas with a geotextile layer

Laying the canvas with a geotextile layer

The upper edge of the canvas should be 15 - 20 cm above the waterproofing installation line. When installing a decorative coating, the excess material can be cut off. To fix the sheet, an edge clamping bar is attached.

Vertical alignment

Vertical alignment

The canvases are overlapped. The edges of adjacent strips should be aligned with an overlap of 3 to 4 projections. When laying, the seams of the joints are sealed with adhesive tape on a bitumen basis.

Fixing the canvas

Fixing the canvas

The canvases are fixed on dowels or on plastic fasteners, if it is necessary to connect the membrane to the bituminous layer.

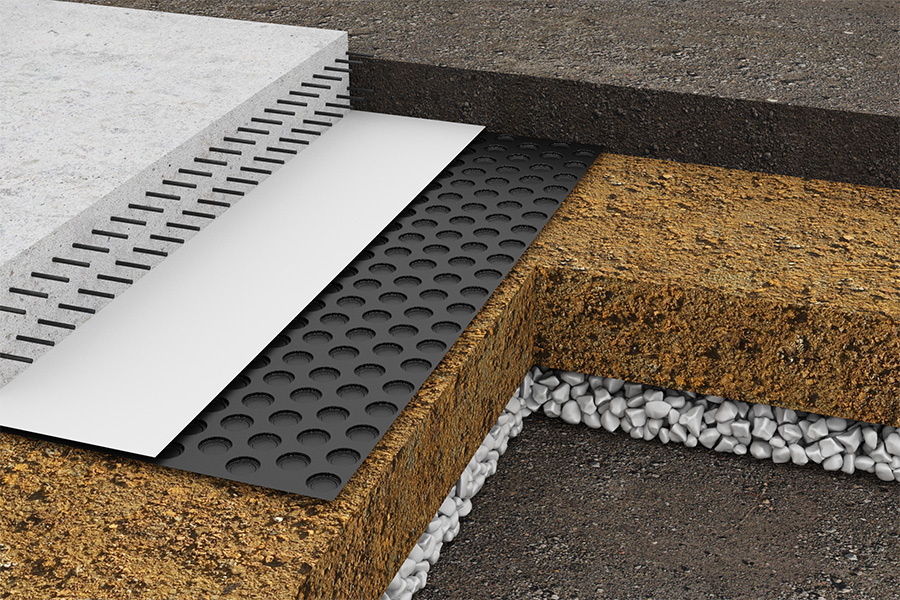

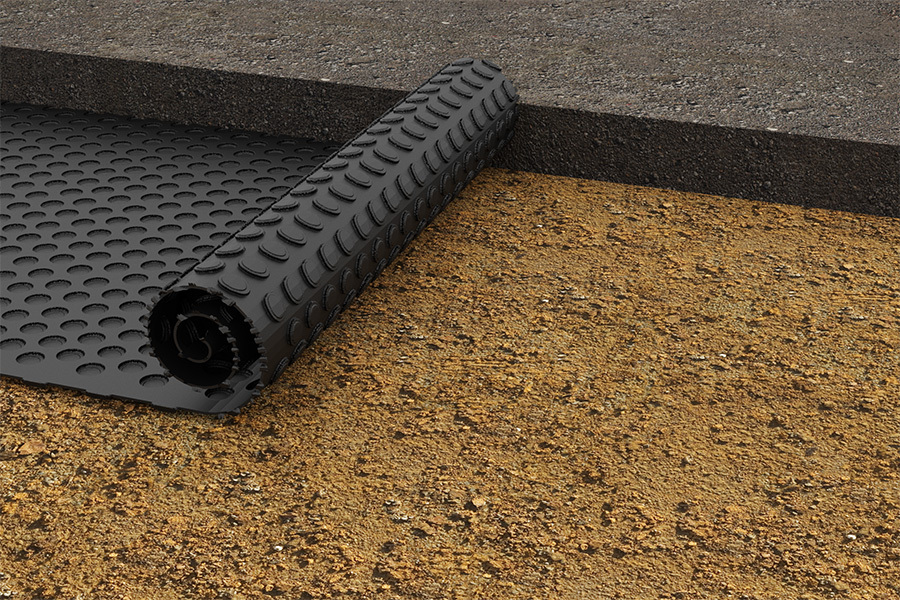

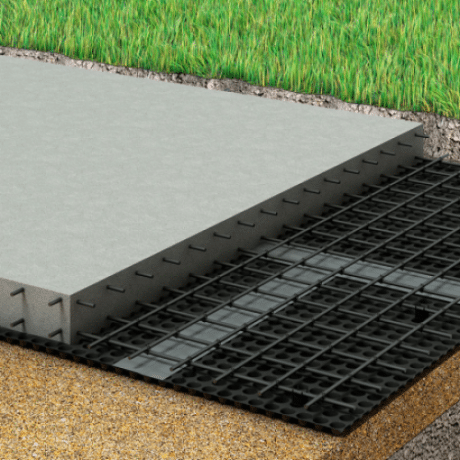

As a preparation for the foundation, Planter Standard is laid directly on the ground. The base must be flat, free from hard rocky inclusions. The soil must be compacted. It is allowed to create a gravel cushion up to 10 cm high.

Laying canvases under the foundation

Laying canvases under the foundation

The canvases are rolled out. It is imperative to check that folds and creases do not form on the strips. The first roll can be rolled out along the marked line, spikes down. The next strips are laid with overlapping edges.

Tape connection on an aluminum base

Tape connection on an aluminum base

The edges are connected with a reinforced tape on an aluminum base.

Joining strips with textile layer

Joining strips with textile layer

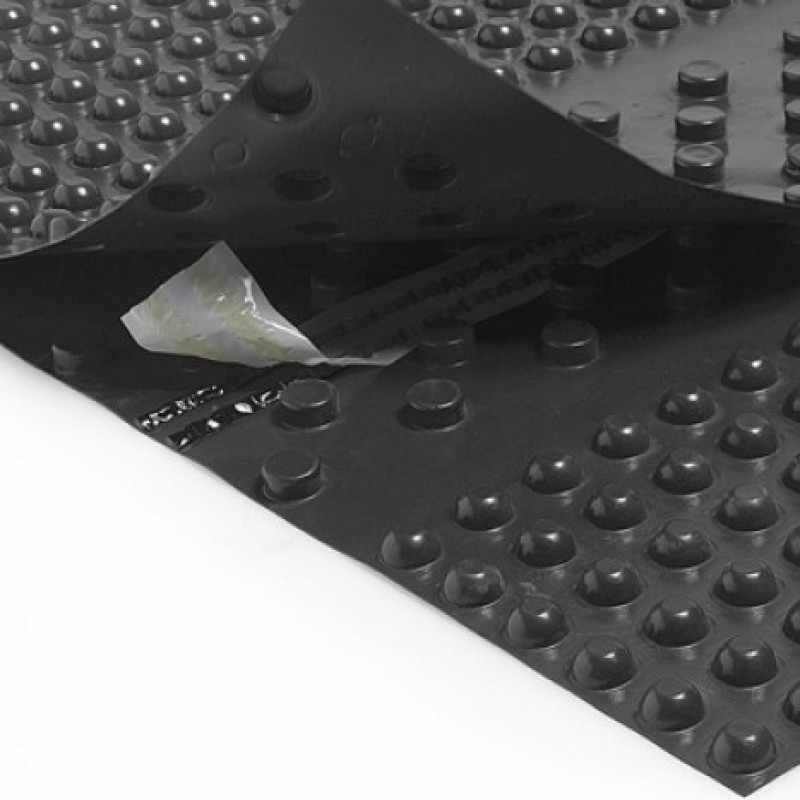

When using a sheet with a geotextile layer, the edges of the sheets are connected in two stages. Fold back the textile layer, connect the polyethylene base with adhesive tape, duplicate the connection after laying the edges of the textile.

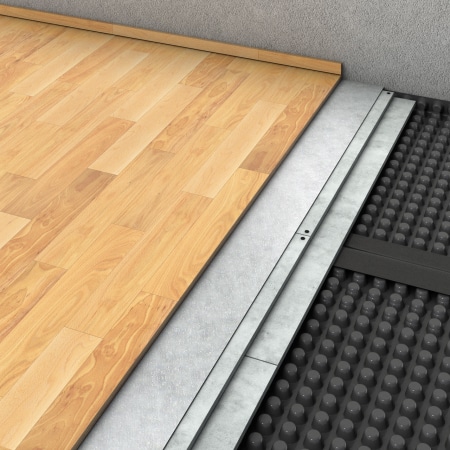

Installation under the floor

Installation under the floor

Inside living quarters, the membrane is laid with spikes up. The membrane performs the function of sound insulation and thermal insulation, protection against moisture seepage, especially on the ground floors. The canvases are laid end-to-end. The seams between the sheets are glued with polymer-bitumen tape.

Detailed instruction from the manufacturer on the use of the Planter Standart profiled membrane.

The use of membrane materials instead of classical concrete preparation in the construction of foundations is economically beneficial. The cost of equipping the base is significantly reduced. In order not to overpay, choose the optimal class of material: for private construction, it is enough to purchase budget Eco canvases

If you need to calculate the number of rolls and choose the type of membrane for a large construction site, contact the specialists, because the calculations take into account not only the area and number of storeys of the building, but also the features of the soil

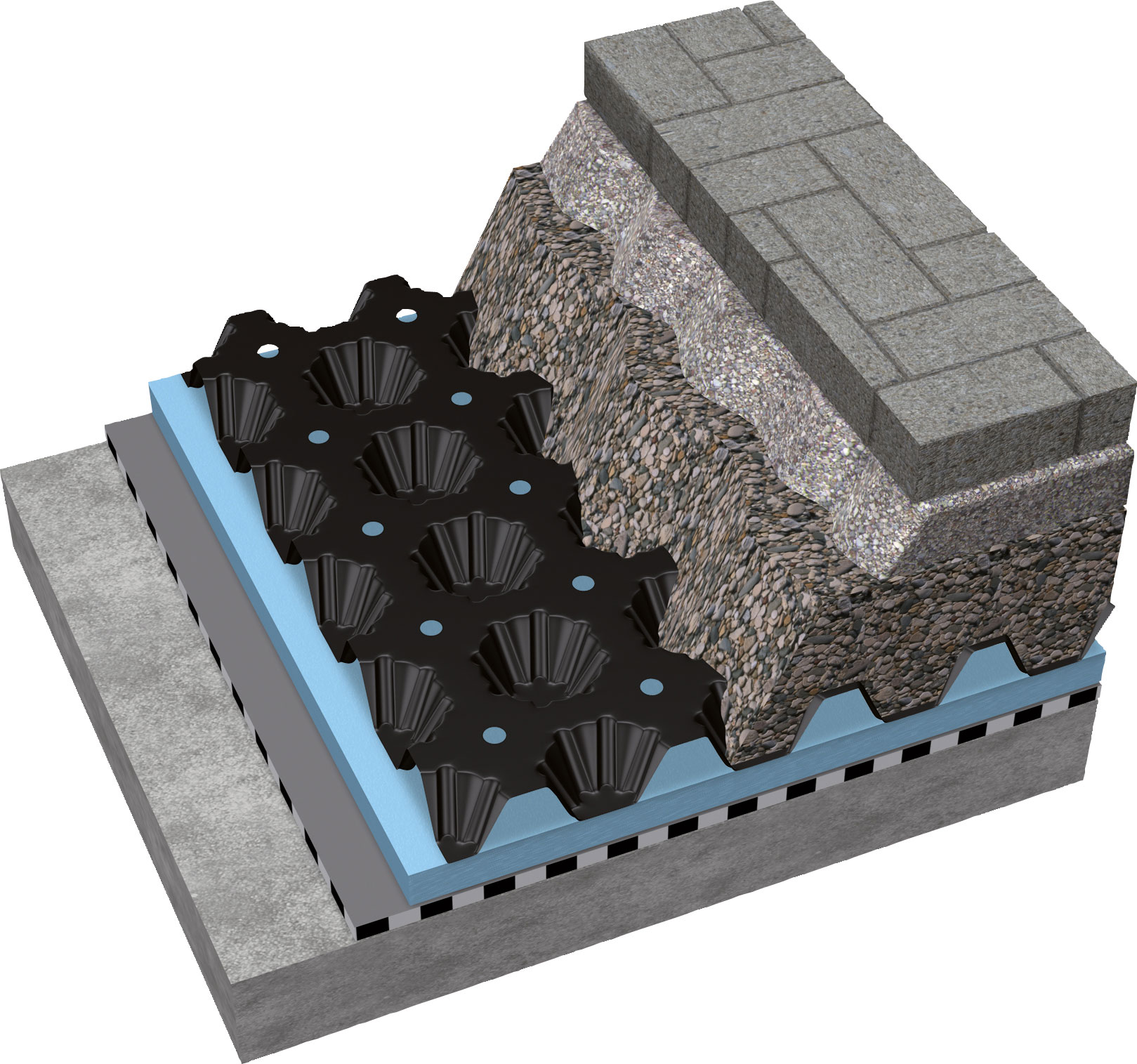

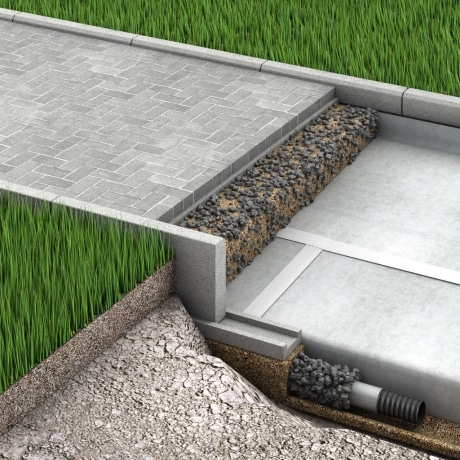

The principle of operation of drainage membranes

The innovative drainage system allows some of the water to be drained directly along the surface of tiles or paving stones. And remove moisture that has seeped through the seams with a drainage membrane. On the one hand, it acts as an effective drainage, on the other hand, it prevents the track from spreading under the influence of water pressure and the usual change in the base topography.No soil deformations occur with drainage membranes or gratings.

Due to special dense protrusions and recesses, the vacuum necessary for water drainage is created

Due to special dense protrusions and recesses, the vacuum necessary for water drainage is created

Such voids cannot always be provided with gravel, which, during operation, can crumble and clog geotextile membranes, thereby impairing the quality and speed of water drainage. The stability of the sand base in the innovative system of drainage membranes is provided by a filter layer in the form of a geotextile. Under the influence of temperature, it attaches itself to the rubberized membrane itself. It is interesting that such systems have found application not only in the device of garden paths.

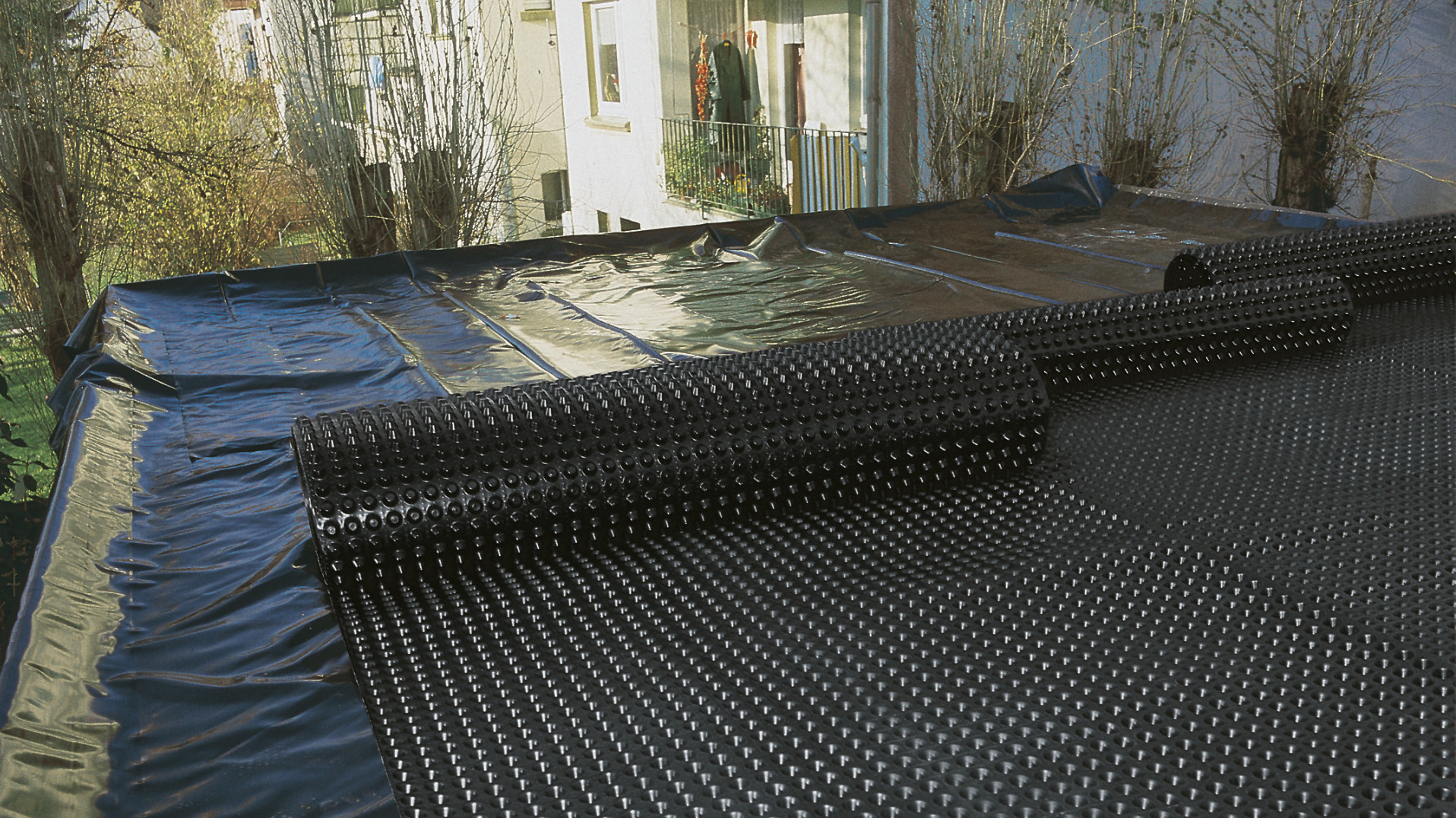

Such drainage systems are used as a waterproofing layer in roofing systems, in the construction of concrete structures, the operation of which will be carried out in difficult conditions.

Such drainage systems are used as a waterproofing layer in roofing systems, in the construction of concrete structures, the operation of which will be carried out in difficult conditions.

Also, such membrane systems are widely used to protect underground structures from ground movements and to waterproof them.

Areas of application of the profiled membrane

- profiled membranes are used in the following areas:

- protection of the main waterproofing of the foundation (from the root system of plants and trees, groundwater, soil shrinkage and mechanical damage during backfilling);

- wall drainage of the foundation (protects the foundation from groundwater and atmospheric precipitation, directing them into a drainage pipe);

- horizontal formation drainage (point structure provides protection against punching);

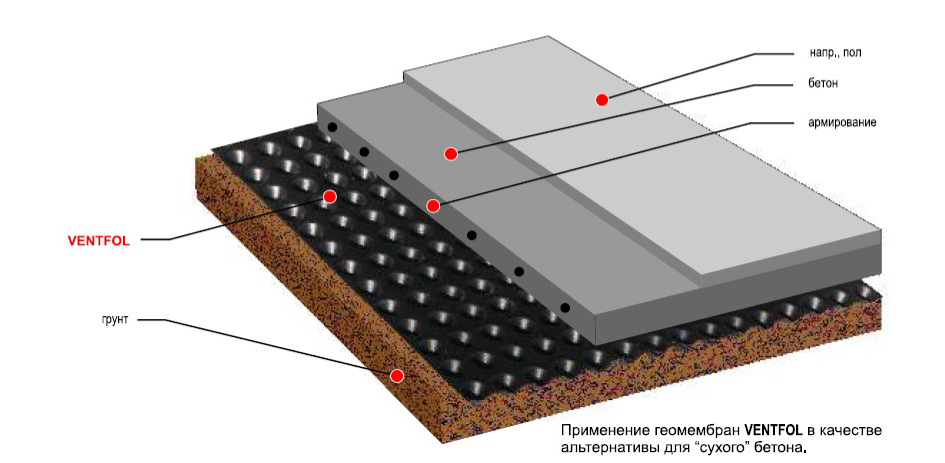

- replacement of concrete preparation (when building buildings on soil with a low water level, when only horizontal waterproofing of the slab from capillary moisture is used; does not allow "cement milk" to seep into the ground);

- ventilation of damp walls (when fastened from the inside of the building, it provides air circulation, when fastened from the outside - optimal temperature and humidity);

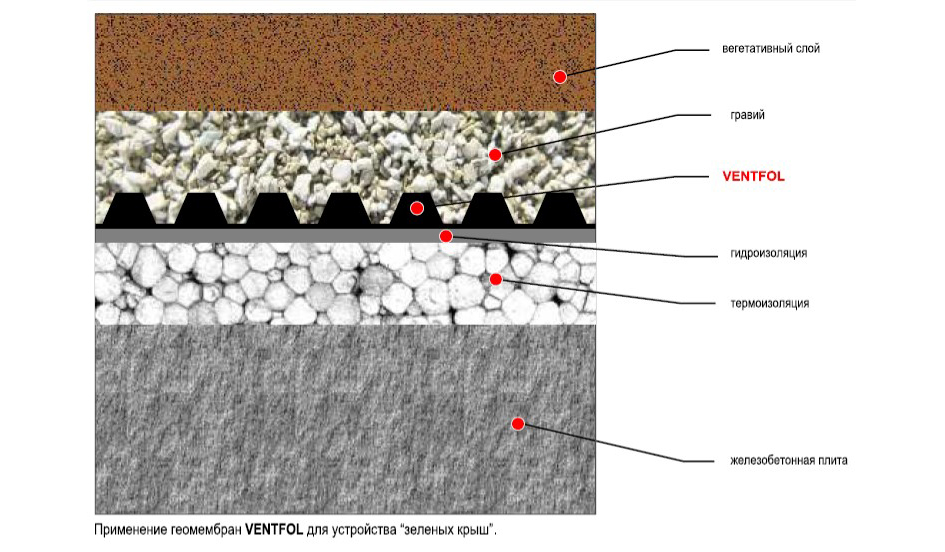

- inversion operated roof.

Profmembrane is used for the construction of such objects as:

- landfills for solid waste and software;

- ash dumps;

- square of the tank;

- sarcophagi of chemical waste;

- tail and sludge storage;

- open and closed water facilities, incl. cascading;

- irrigation canals and water conduits;

- road surfaces;

- port facilities;

- underground parking lots and garages;

- oil and gold mining industry waste storage sites;

- tunnels and underpasses;

- cellars and cellars;

- receivers of industrial and domestic wastewater;

- escalators;

- gas pipelines;

- agricultural structures (for lines for manure removal and storage of mineral fertilizers);

- cooling towers.

Methods for arranging garden paths and their comparison with each other

Drainage membranes are modern, but not the only way to organize garden paths and sidewalks. As mentioned above, some summer residents do not perceive this type of improvement as mandatory.

Arrangement of garden paths based on crushed stone

This drainage management system is common in many areas. However, it requires really serious material and physical costs. First, a pit is dug, the soil is tamped, then a layer of geotextile is laid, which provides protection from germinating roots, and then a layer of gravel or crushed stone is poured.

Usually, for arranging paths, a crushed stone fraction of at least 5 mm is used

Usually, for arranging paths, a crushed stone fraction of at least 5 mm is used

When organizing a trench at the bottom, it is necessary to maintain a slope of 10 mm per 1 m for better water drainage. Sand is usually poured over the gravel, followed by another layer of geotextile. Most often, it is simply laid immediately with a margin so that the top layer can be covered. And only then the tiles and paving stones are laid. The slabs are leveled, the seams are filled with sand or screenings. Quite a laborious, physically and financially costly project.

How to make garden paths based on a drainage membrane

The stages of work are quite simple. The first stage is leveling and cleaning the surface of the future location of paths and sidewalks.There are several variations in the location of the drainage spikes. If you are using drainage membranes without thermally bonded geotextiles, the spikes will point downward. If you are using a drainage membrane in conjunction with a geotextile layer, the spikes are directed upwards.

Membrane joints are usually laid with an overlap, usually 5 cm. The joints are sealed with self-adhesive tapes

Membrane joints are usually laid with an overlap, usually 5 cm. The joints are sealed with self-adhesive tapes

In order to save money, you should not use a conventional membrane and lay a layer of geotextile on top of it: when filling crushed stone, the geotextile will rinse, which will reduce the drainage capacity of the membrane.

In addition, to enhance the outflow of water, it is necessary to organize a slope at the rate of 1 cm for each meter of the path.

Why garden paths are best done with a drainage membrane

With the help of a profiled drainage membrane, moisture does not accumulate in the soil layers, but is removed through the drainage seams. There is no need to add an extra layer of gravel. You avoid waterlogging under the paving stones.

Why do you need a drainage profiled membrane when arranging garden paths

Water on the site is always the risk of waterlogging the soil. If the water is not properly drained, you will ensure rapid decay of the root systems of fruit and berry bushes and high humidity in greenhouses.

The standard solution is to lay geotextiles under the base of the paths.

The standard solution is to lay geotextiles under the base of the paths.

Modern technologies make it possible to simplify the process, to abandon complex stages, providing the same result. The drainage profiled membrane takes over the functions of the drainage layer, and the geotextile membrane is already attached to the base of the covering. Accordingly, it is not necessary to dig a deep pit and use additional gravel.

Geomembrane: technical characteristics and parameters

Geomembrane is an insulating thermoplastic material made of polyethylene. It is characterized by increased strength and a wide range of applications. Depending on the type of source material, geomembranes are subdivided into:

- LDPE (low density polyethylene), or LDPE (high density polyethylene).

- HDPE (high density polyethylene), or HDPE (low pressure polyethylene).

Comparative characteristics of the physical properties of various geomembranes are presented in the table:

|

Parameter |

LDPE (LDPE) |

HDPE (HDPE) |

|---|---|---|

|

Tensile strength, MPa |

13 |

23 |

|

Tensile elongation,% |

400 |

100 |

|

Density, kg / cu. m |

917-930 |

948-952 |

|

Compressive strength, MPa |

12 |

20-36 |

|

Impact strength (notched), KJ / sq.m |

Does not collapse |

2-50 |

|

Flexural modulus, MPa |

140-250 |

600-850 |

|

Hardness, MPa |

14-25 |

45-59 |

|

Working temperature, gr |

from -60 to +80 |

-60 to +80 |

|

Water absorption per day,% |

0,01 |

0,01 |

What it is?

Geomembrane is a synthetic fabric that is completely waterproof. With its help, an obstacle is created to the penetration of moisture. Simply put, the geomembrane is a dense polyethylene, which is very elastic, which allows it to be laid taking into account all the unevenness of the relief and buildings. It is highly durable and completely waterproof. These characteristics make it a versatile material that is used wherever waterproofing is needed.

The described canvas is very different from ordinary polyethylene. This is due to the substances and production technologies that are used in its manufacture.

The material of the described canvas is not ordinary polyethylene, but a composite, which is applied to a polyethylene base. The composition contains various substances that prevent the destruction of the material under the influence of the atmosphere and direct sunlight.

The canvas has a higher strength when compared to polyethylene. With a material thickness of 0.3 to 3 mm, it can withstand long-term vertical loads, stretching in the horizontal direction by 550% without damaging the surface. These indicators may vary depending on the brand and manufacturer of the canvas. The service life of the coating is 50 years or more.

In production, the technology of continuous extrusion is used, which makes it possible to obtain whole sheets without connecting seams. The dimensions of the rolls of this product are up to 2.7 m wide, and the length is the same for all and is equal to 50 m. For joining the canvases to each other, a welding method is provided using a special hand tool.

How is it used?

Waterproofing coating is used very often. Such a product is used for construction. The profiled membrane has proven itself very well as a basement waterproofing and protection from the roots of various plants, which are planted along the house. Due to its elasticity, ease of soldering 2 fragments and reliability from leakage of the connecting seams, it works as a full-fledged bowl to protect the basement from groundwater on the site and atmospheric precipitation.

In addition to protecting against the ingress of water into basements, it can be a good bowl for an artificial reservoir. If you have a desire to make an artificial pond at your dacha, then you cannot do without such material as an extruded geomembrane.

The small pond in the backyard is not limited to this material. With its help, you can create huge reservoirs and ponds. This material is a real find for fish farms. By digging a large pit in the ground and pouring water into it, you can avoid the ingress of substances that can negatively affect the health of pond fish. In addition to good performance, draining water from the reservoir, the membrane can be easily cleaned with a conventional high-pressure washer from accumulated contaminants.

In agriculture, this material is used to cover the walls of manure bins. The walls of fire reservoirs are finished with the same material. The drainage system is carried out with this cover. Extruded plastic membrane is used as a base for pouring a foundation to distribute a large weight of concrete.

Functions and advantages of the material

The profiled membrane is a LDPE geomembrane with a distinctive feature: the presence of many hollow protrusions on the surface. Their height ranges from 7 to 20 mm. The protrusions are arranged in an orderly manner on one side of the material and do not prevent it from bending.

Due to the presence of protrusions, the pressure is evenly distributed over the entire area of the membrane, which avoids point deformation. When used as ventilation insulation, the profiled geomembrane provides heat transfer inside the structure. Due to its characteristics, the professional membrane can replace granular drainage materials, which will significantly save money and effort.

The advantages of a profiled geomembrane:

- high strength;

- resistance to chemical, thermal and biological influences;

- durability (more than 50 years of guaranteed operation);

- ease of processing and installation;

- affordable cost.

It is difficult to overestimate the range of application of colored transparent plexiglass. Acrylic sheet is used for glazing vehicles, greenhouses, greenhouses, verandas.

Mirror plexiglass is actively used in interior design, furniture production and outdoor advertising. In this article, you will learn about the properties and advantages of the material.

What are drainage membranes made of for garden improvement?

Rubberized profiled drainage membranes do not contain unwanted components, keep their shape well, behave well in combination with any building materials: sand, cement mixture, reinforcement. A huge advantage is that they do not need to use additional waterproofing layers to organize them.

Drainage membranes are highly durable, they are resistant to temperature influences, they are not afraid of moisture, pressure, water flows

Drainage membranes are highly durable, they are resistant to temperature influences, they are not afraid of moisture, pressure, water flows

Typically, these materials have a complex microrelief, which is represented by rows of projections and depressions about 10 mm high.The base of the membrane is made of high density polyethylene, to which a geotextile fabric is glued on the reverse side. All materials are made using a special technology that ensures high strength and durability. They practically do not change under the influence of loads and chemical compositions (fertilizers, acids).

Performance characteristics of drainage membranes

Due to its special structure, the membrane provides a high flow capacity, while no deformations, ruptures or cracks occur. Geotextile itself prevents the reverse flow of water, acting as a kind of one-way canvas: it allows moisture to pass through, but only in one direction. In addition, such a membrane is significantly more profitable than all other options for arranging drainages, since it excludes heavy and financially costly work on the construction of pits and the purchase of a large amount of gravel or crushed stone.

For comparison: a drainage membrane with a thickness of 9 mm in its characteristics corresponds to an 800 mm layer of crushed stone

For comparison: a drainage membrane with a thickness of 9 mm in its characteristics corresponds to an 800 mm layer of crushed stone

There are several variations of membranes with different compressive strength: from 15 t / m² to 40 t / m². For the organization of summer cottage drainage systems, it is best to use membranes of normal strength, not exceeding 25 t / m². Drainage membranes can be used in the temperature range from -60 ° to + 60 °. At the same time, the coating does not change its properties and characteristics. In addition, the material protects buildings and soil from microorganisms entering it, is resistant to chemical reagents, the germination of plant rhizomes, as well as the ingress of ultraviolet rays.

Advantages and disadvantages

Let's consider the main advantages of the described product.

- Strength. It depends on the physical capabilities of the starting material that is used in the production of a particular roll. Based on this, we get a certain IPA indicator. In addition, the thickness of the material directly affects the degree of strength. Additional reinforcement of the web is provided by a reinforcing layer.

- Elasticity. The material stretches very well, especially if it is made of LDPE.

- Strength. These materials are capable of withstanding high ground pressure. They are not afraid of sharp stones and plant roots. This makes the geomembrane an excellent foundation protection. In this case, the likelihood of damage to the material during installation is extremely small.

- Chemical resistance. Materials made from polymeric substances are immune to aggressive chemical compounds (acids, oils, alkali). Due to this property, the described product can be used to isolate oil storage facilities, at toxic waste landfills.

- Environmental friendliness. This material is absolutely safe for human and animal health.

- Durability. As mentioned earlier, the lifespan of this material is very long. This is due to the fact that this canvas is not subject to destruction (corrosion, ultraviolet radiation, drying out).

- Temperature drops. The material is also immune to ambient temperatures. A wide range of operating temperature values allows the coating to be used both in tropical climates and in conditions of constant cold.

- Ease of installation. The film is not a heavy material, it is not difficult to work with it. The rolls are rolled out on the ground, and the material itself is very easy to cut. It is equally easy to install both in a small area and in large areas.

It is very difficult to single out the disadvantages of such material, and they can rather be attributed to the difficulties of installation and the peculiarities of the terrain, and not to the immediate disadvantages. For example, thick, high-density membranes are less elastic than their LDPE counterparts. It's harder to work with them. They are used mainly on relatively flat surfaces.

The main functions of protective profile membranes ↑

The Technonikol company produces Planter profiled membranes for use in private and industrial construction. Main functions:

Protection of external insulation systems from mechanical damage is necessary both at the stage of backfilling of pits and during operation.

Protection of the waterproofing system

Protection of the waterproofing system

- Primary water drainage when arranging wall drainage. Water drainage is provided by the cavities of the spiked blade. The minimum moisture removal is up to 5 liters per square meter.

- Preparation device for a monolithic or slab foundation. Membrane Planter Standard replaces the concrete layer, which is poured according to the traditional technology before the installation of the slabs.

- As a drainage base when arranging yards and paths, blind area.

Water drainage and wall protection against capillary moisture

Water drainage and wall protection against capillary moisture

- Sanitation of wet surfaces. Installation of canvases on damp walls is allowed: ventilation and free air circulation are provided by channels on the membrane surface.

- Protection and moisture removal from flat and maintained green roofs. It is used in combination with multilayer insulation. Protects the surface from the germination of plant roots, deformation of the insulating layers.

- Soundproofing. Installed for soundproofing living quarters: under the floor.

Profiled membrane manufacturers and estimated price

Based on the survey results, Planter and Tefond profiled membranes are the most popular among consumers. However, geomembranes produced under other brands are also quality materials. Below is an overview of manufacturers and prices. The cost is indicated in rubles per 1 m2.

Drizoro S.A. (Spain)

|

Name |

Number of layers |

Size (thickness * size of protrusions, mm) |

Price |

|---|---|---|---|

|

Maxdrain 8 |

1 |

0,55*7,5 |

125 |

|

Maxdrain P20 |

1 |

1*20 |

295 |

|

Maxdrain 8 GT |

2 |

0,6*8 |

168 |

TeMa (Russia-Italy)

|

Name |

Number of layers |

Size (thickness * size of protrusions, mm) |

Price |

|---|---|---|---|

|

Isostud |

1 |

0,5*7,5 |

99 |

|

Isostud Geo |

2 |

0,6*7,5 |

178 |

|

Isostud Plaster |

1 + fiberglass backing |

0,5*8 |

180 |

|

Name |

Number of layers |

Size (thickness * size of protrusions, mm) |

Price |

|---|---|---|---|

|

Tefond |

1 |

0,65*8,5 |

155 |

|

Tefond Drain |

2 |

0,9*8,5 |

240 |

|

Tefond HP |

1 |

0,65*9.5 |

209 |

Ondulin (Germany)

|

Name |

Number of layers |

Size (thickness * size of protrusions, mm) |

Price |

|---|---|---|---|

|

Fundalin Plus |

1 |

0,6*8 |

79 |

|

Fundalin Drainage |

2 |

0,6*8 |

139 |

|

Fundalin Plaster |

1 + fiberglass backing |

0,6*8 |

190 |

DorkenGmbh & Co.KG (Germany)

|

Name |

Number of layers |

Size (thickness * size of protrusions, mm) |

Price |

|---|---|---|---|

|

Delta MS |

1 |

0,6*8 |

112 |

|

Delta Drain |

2 |

0,6*12 |

300 |

|

Delta GeoDrain Quattro |

4 |

0,6*9 |

350 |

Planter (Russia)

|

Name |

Number of layers |

Size (thickness * size of protrusions, mm) |

Price |

|---|---|---|---|

|

Planter Standard |

1 |

0,6*8 |

80 |

|

Planter Geo |

2 |

0,75*12 |

135 |

|

Planter Active |

3 |

1*9 |

282 |

The profiled membrane combines the properties required to provide reliable waterproofing. The high resistance of the material to almost all types of impact made it possible to use professional membranes both for private housing construction and for commercial and industrial construction. A wide range of applications, reliability, various design options and an affordable price have made this material a leader in its segment.