Aerated concrete blocks D500

Aerated concrete blocks of the D500 brand are made from cement, quartz sand with the addition of lime and water. The creation of high-quality and corresponding to the characteristics of the blocks is possible only in the conditions of the plant. First, cement, ground quartz sand, lime and water are kneaded in a special mixer, then aluminum paste is introduced in the required volume (it is responsible for the appearance of pores in the structure of the material).

In a humid warm chamber, the solution increases in volume due to the formation of a large number of pores, gaining initial strength. Then the solidified mass is transported to the cutting equipment, and blocks with ideal geometry are formed. The material gains its final strength in an autoclave oven, where it is exposed to a high pressure of water vapor and a temperature in the region of + 175-200 degrees.

Thanks to the use of high temperature in production, it is possible to obtain high-quality and durable gas blocks, ensuring that they will demonstrate all the declared characteristics.

Views

There are two types:

- with a smooth surface;

- with comb and groove.

The former are used for interior and exterior walls, stairs, partitions, lintels and ceilings in residential buildings and industrial buildings, as well as in restoration work. Has strict geometric dimensions and a uniform surface. It is an excellent platform for wallpapering or laying any other finishing material.

Aerated concrete block of the ytong brand with a ridge and a groove is used for the same purposes as smooth, but has more advantages:

- thanks to the tongue-and-groove design, it is possible to connect the elements without the use of glue, thereby shortening the construction time;

- U-shape provides a snug fit, thereby reducing heat loss;

- can perform the function of formwork in the manufacture of stiffeners and reinforced lintels.

Maybe it's all about ecology?

Last but not least, the parameter of the YTONG blocks is environmental safety. YTONG blocks are awarded the Ecomaterial Absolute certificate, confirming that the products have passed the voluntary certification. From the explanations of the organization that issued the certificate, it follows that "the product complies with the standards, the emission of harmful substances and toxicity are at least 40% lower than the MPC, and advanced technologies and equipment are used in the production of products that minimize the impact on the environment", i.e. ... partly the certificate is issued in recognition of the environmental safety of products, partly for the safety of production processes, thanks to which the products were released.

Among the blocks we are considering, only YTONG and Porevit products have a certificate of the Ecomaterial project. Porevit blocks are rated Ecomaterial Green, which is lower than Ecomaterial Absolute. The Teplit blocks have a certificate of conformity of the materials and products produced in the category of environmentally friendly "green" building materials from the Union of Construction Industry Enterprises of the Sverdlovsk Region.

Since each certification company is guided by its own standards and criteria, for a more adequate comparison of the blocks under consideration, we will compare them in terms of the specific effective activity of natural radionucleides (NRN) or natural radiation. Since the level of natural radiation can negatively affect the state of human health, the sanitary and epidemiological surveillance services very carefully determine it for all construction products entering the market.

| Norm | YTONG | INSI | Warmth | Shipblock | Bang | |

|---|---|---|---|---|---|---|

| Activity index ERN, Bq / kg | 370 | 199,3 | 77,5 | s / n | 39,77 |

s / n - corresponds to the norm, the exact value is not specified.

In the battle for ecology, YTONG blocks have almost the worst indicators in terms of natural radiation. At the same time, they are still much safer than the norms prescribe, and therefore can be used for the construction of walls even in children's institutions.

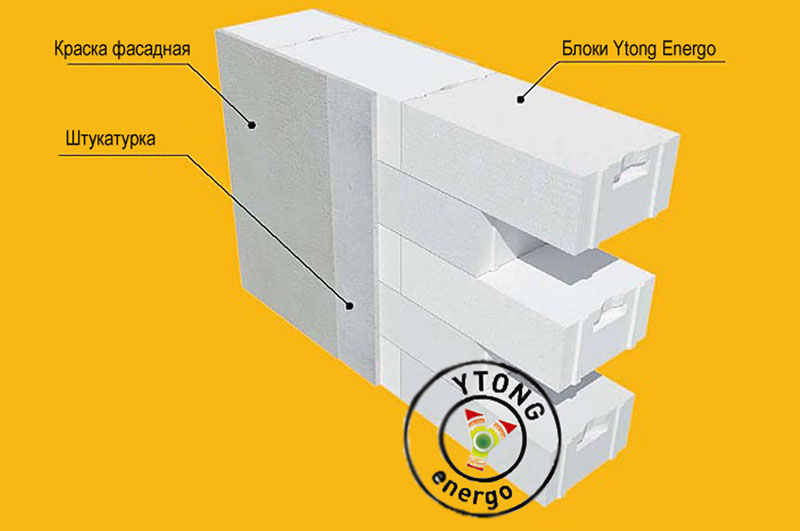

What is the optimal wall structure in terms of cost and risk minimization?

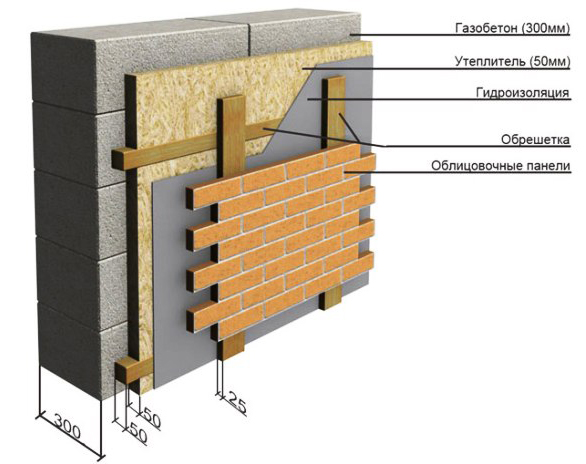

Despite the assertions that the gas block does not need insulation, residential buildings are usually made with a layer of thermal insulation, on which the facing layer is attached from above. This option makes it possible to save on heating in the future and be confident in the strength and reliability of the building, which will not collapse from moisture. The most popular insulation options are mineral wool and expanded polystyrene.

Mineral wool insulation

Mineral wool is a fiber insulation of inorganic origin. The material is made from various rocks, binder and glass. Due to the fibrous structure of cotton wool, air is retained in the thickness and thus insulates the room from the cold, acting as a high-quality and relatively inexpensive insulation.

The main advantages of mineral wool as insulation:

Long service life - 25-40 years.

Environmental friendliness and safety for human health due to the absence of hazardous synthetic components in the material.

Non-flammability and lack of smoke formation under open fire, which is extremely important for residential buildings.

Low level of hydrophobicity - cotton wool does not absorb moisture at all, but brings it out.

Chemical and biological resistance, inertness.

Low level of deformation - the insulation does not lose its original shape over time.

Good vapor permeability (which is important for aerated block walls, which cannot be finished with impermeable materials, thereby provoking moisture retention inside).

Versatility as an insulating material - not only retains heat, but also prevents sounds from passing through.

Mineral wool for insulation has been used for a long time and has managed to establish itself as an excellent material that fully copes with its tasks, inexpensive and easy to install.

What is the best way to insulate aerated concrete walls:

- D300 (wall thickness 20 centimeters) and mineral wool 5 centimeters thick.

- D400 (20 centimeters) and mineral wool 10 centimeters.

- D400 (30 centimeters) and mineral wool 5 centimeters.

- D500 (20 centimeters) and 15 centimeters of mineral wool.

- D500 (30 centimeters) and 10 centimeters of mineral wool.

- D500 (40 centimeters) and mineral wool in a layer 5 centimeters thick.

These are options that are relevant for central Russia. For the southern regions, the values are less, for the northern ones, more.

Warming with expanded polystyrene

Extruded expanded polystyrene (aka expanded polystyrene) is supplied in the format of plates made of a material of a dense cellular structure with a closed type of pores. This gives the polystyrene strength and the ability to resist moisture. The material is usually used to insulate foundations, roofs, basements, but it is better not to cover the outside with this heat insulator, as it will cause moisture to accumulate.

Despite the peculiarities of the material, it is still used for aerated concrete due to such advantages as durability, incombustibility, high heat-saving characteristics, the ability to take the dew point beyond the walls, simplicity and ease of installation, low cost. You can insulate aerated concrete walls with expanded polystyrene with your own hands: installation involves calculations, the purchase of sheets, their cutting and fastening to self-tapping screws.

The thickness of the expanded polystyrene is 2-10 centimeters, if necessary, the sheets can be fastened in half. It is also possible to order panels of the required thickness from the factory on an individual basis. For the D500 brand with a thickness of 30 centimeters, sheets 10 centimeters thick are enough: the insulation will provide all the necessary indicators of thermal insulation.

Varieties

Today, Ytong produces two types of gas blocks:

- smooth;

- tongue-and-groove.

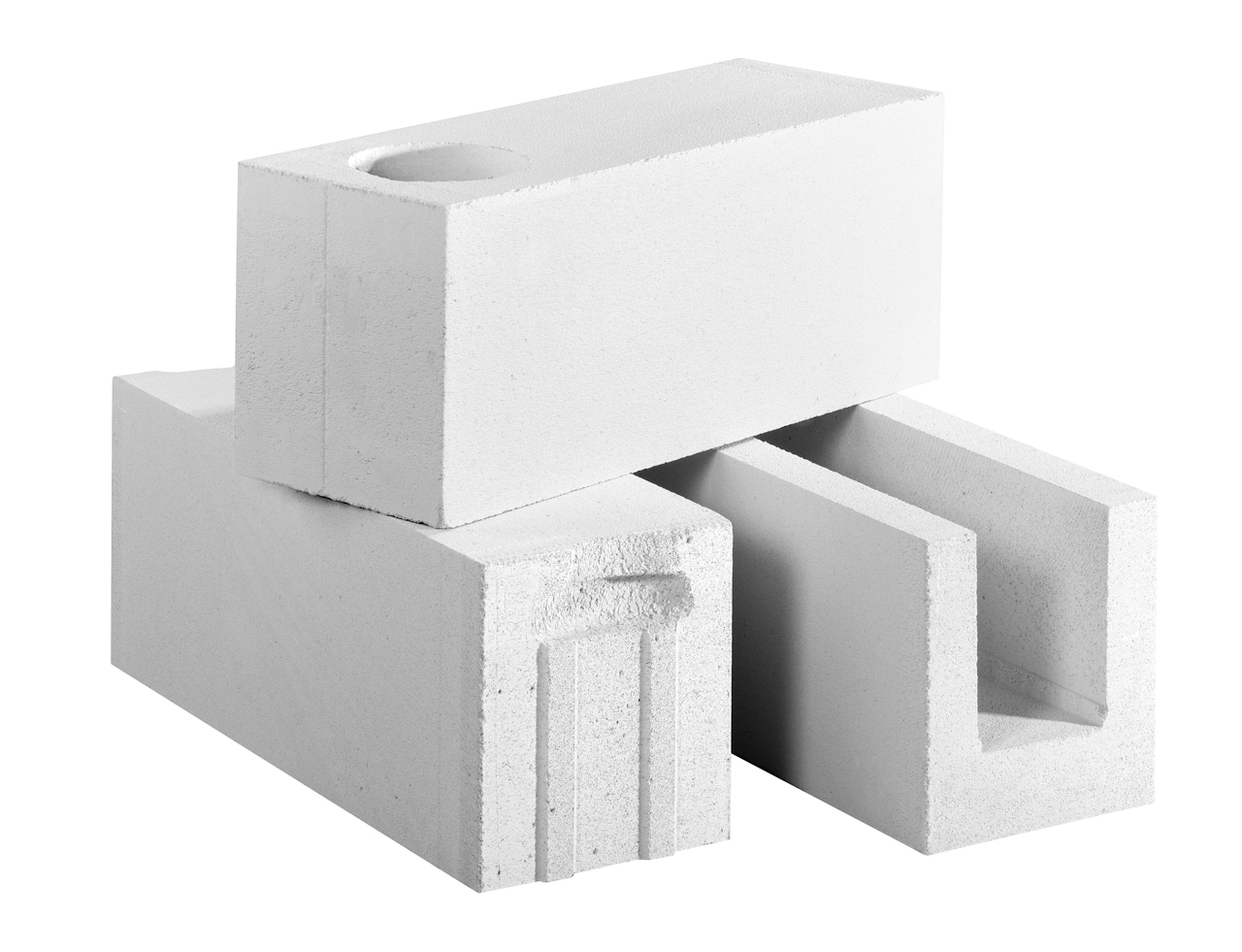

Tongue-and-groove

Such blocks are used for external and internal decoration (for partitions, walls, lintels, ceilings, restoration work). With the help of a tongue-and-groove structure, you can easily connect all the parts to each other, without using adhesives.

This type of material is u-shaped. It provides the tightest connection, as a result of which heat loss is significantly reduced. Often this variety is used as a formwork during the manufacture of reinforced lintels and stiffeners.

The D400 model belongs to the tongue-and-groove blocks (its dimensions can be 375x250x625, 300x250x625 mm). As a rule, it is used to decorate external walls without insulation. The density of this variety is 400 kg / m3. Water vapor permeability is 0.23, and frost resistance is 35.

Smooth

Such blocks, like the previous ones, can be used for a variety of purposes (exterior and interior decoration, construction of partitions, ceilings, stairs, walls). They have strict geometric shapes and a uniform surface. Also, this material often acts as a launching pad for laying finishing coatings, gluing wallpaper.

The smooth variety of Ytong aerated concrete includes D400 models, the size of which can be 150x250x625, 200x250x625, 240x250x625, 250x250x625, 300x250x625, 375x250x625, 400x250x625, 500x250x625 mm. The density of such building gas blocks reaches 400 kg / m3. Their technical characteristics are the same as those of the D400 material with a groove-ridge (vapor permeability is 0.23, frost resistance is 35).

Also, this type of material includes D500 samples with dimensions, 625x250x100, 75x250x625, 50x250x625, 100x250x625 mm (blocks 625x250x100 mm are most often used for the construction of partitions). The density of this material reaches 500 kg / m3. All technical characteristics are the same as for the D500 with tongue and groove.

Ytong also produces reinforced aerated concrete lintels that provide excellent thermal insulation even in the absence of an additional layer of insulation. For load-bearing internal and external walls, as a rule, take the PN250 model with a height of 249 mm or PN 125, the height of which is 24 mm. For internal curtain walls, use PP250 with a height of 49 mm. Also, this manufacturer manufactures prefabricated monolithic floors. They consist of beams with free reinforcement. Such elements are made of reinforced concrete or steel. The length of the parts is determined depending on the spans to be covered. Another component is T-blocks, which are in the form of bushings sandwiched between two side slots. They rest on beams

Ytong also creates arched aerated concrete blocks. With their help, you can bring to life the most daring design ideas. They make it easy to make semicircular interior partitions. Such elements are installed on a thin-seam mortar of the same manufacturer.

YTONG blocks - GOST - not a guideline!

An explanation needs to be given after the loud headline. Xella declares that YTONG gas blocks are manufactured according to the organization's standard (STO 73045594-001-2008 - ZAO Ksella-Aeroblock-Center Mozhaisk), which imposes higher requirements for finished units than state standards (GOST 31359-2007 and GOST 31360 -2007), which all manufacturers must adhere to. We were unable to get a copy of the STO for YTONG blocks, so we cannot confirm or deny the company's statement. Very often, releasing your own standards is just a publicity stunt. In the service station, you can overestimate some unimportant indicators or overestimate important ones only by a tenth of a percent. And this will give the company the right to loudly declare technical characteristics exceeding all standards.

For an unbiased analysis of the characteristics, let us refer to the test reports of YTONG blocks, which are easy to find on the Internet. Let's compare the values stated in the protocols with the data on other gas blocks.

| Physical and technical properties | Unit measurements | YTONG | INSI | Warmth | Shipblock | Bang | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Density grade | kg / cu. m | D400 | D500 | D600 | D400 | D500 | D600 | D400 | D500 | D600 | D400 | D500 | D600 | D400 | D500 | D600 |

| Concrete strength class | – | B2.5 | B3.5 | B5.0 | B2.0 | 3.5 | B3.5 | B2.5 | B2.5-B3.5 | B3.5-B 5.0 | – | B2.5 | B3.5 | – | B2.5 | B3.5 |

| Coefficient of thermal conductivity in dry. condition | W / m ° C | 0,088 | 0,099 | 0,112 | 0,1 | 0,12 | 0,14 | 0,1 | 0,12 | 0,15 | – | 0,12 | 0,14 | – | 0,13 | 0,143 |

| Frost resistance | cycle | F100 | F100 | F100 | F100 | F100 | F100 | F100 | F100 | F100 | – | F150 | F150 | – | F50 | F50 |

| Fire resistance | hour | NG | NG | NG | NG | NG | NG | NG | NG | NG | – | NG | NG | – | NG | NG |

| Vapor permeability | mg / m hPa | 0,24 | 0,21 | 0,17 | 0,2 | 0,2 | 0,16 | 0,24 | 0,21 | 0,18 | – | 0,2 | 0,16 | – | 0,20 | 0,16 |

| Drying shrinkage | MMM | 0,45 | 0,4 | 0,35 | n / a | n / a | n / a | 0,56 | 0,56 | 0,59 | – | 0,56 | 0,56 | – | 0,56 | 0,59 |

| Geometric deviation | – | – | ||||||||||||||

| - by lenght | mm | 0,3 | 0,3 | 0,7 | 2 | 1-2 | – | 0,3-0,8 | – | 3 | ||||||

| - by thickness | mm | 0,3 | 0,4 | 0,5 | 2 | – | – | 2 | ||||||||

| - in height | mm | 0,7 | 0,8 | 0,3 | 1 | – | – | 1 |

As you can see, there are not many differences. Let's take a look at what you can overpay for.

YTONG blocks - heavy-duty

First of all, the difference in strength class is striking. Only YTONG and INSI D500 blocks have a declared strength class B3.5. All other manufacturers under consideration guarantee only B2.5. Recall that the strength class shows us the ultimate ability of a material to withstand compressive loads - that is, what is the maximum weight, laid on top, the material can withstand. In suburban construction, unless, of course, you are building a house higher than three floors, with a helipad on the roof, there are no such heavy loads, and therefore the strength class B3.5 is an excess value.

YTONG blocks are the first among even

Dimensional accuracy is something that YTONG block manufacturer can really be proud of. For all measurements - length, thickness and height, the deviation from the declared values does not exceed a millimeter. This is proven by the test reports and is commendable. Among the competitors, only the Kurgan plant, which produces Porablok blocks, declared similar characteristics, but we could not find an official confirming document.

Now let's try to figure out whether it's worth overpaying for perfect geometry. Thanks to precision, the blocks fit more closely to each other in the masonry, which guarantees higher thermal insulation properties of the wall and its even surface. What are the blocks attached to? For special glue or cement-sand mortar, however, the latter is not the best option. Manufacturers recommend maintaining a joint thickness of 2-3 mm when laying on glue and 10-15 mm when laying on mortar. As you can see, the dimensions of the joints can easily compensate for minor, 1-2 mm, deviations in the geometry of the blocks. Of course, the more ideal the material, the more mediocre a bricklayer can be, but you will not specifically call such a person. And from the outside and from the inside, the wall will still not remain bare. Insulation (if necessary), cladding and plaster will "forgive" and slightly larger irregularities.

Comparing other characteristics, too, one does not see serious discrepancies. Yes, YTONG blocks have a lower thermal conductivity coefficient, and a higher one - vapor permeability. But the difference with other blocks is at the level of tenths and hundredths, and all this is likely to be leveled out by other components of the wall cake.

In the dry residue, the blocks of Russian manufacturers do not have critical flaws in comparison with the YTONG blocks, all comply with the requirements of GOST, which does not differ much from the requirements of the service station of Xella.

Application

Currently, aerated concrete blocks of this manufacturer are widely used in construction for various purposes. They are often used for the construction of foundations and basements. After all, groundwater often gets on them, and this material does not allow moisture to penetrate inside. Also, aerated concrete blocks are used in the construction of external walls, since coatings made of this material have an increased level of steam permeability and strength. At the same time, they can be erected using only one layer of aerated concrete.

For internal partitions, gas blocks are also taken. They are lightweight, which greatly simplifies installation and reduces the load on the supporting structures. At the same time, the assembly of even the most intricate shape will be simple, because all the connecting elements have perfect geometric shapes and are easily fixed.

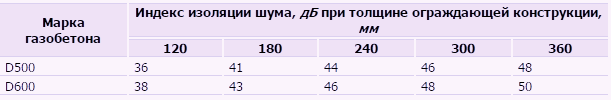

No. 5. Soundproofing qualities

Aerated concrete is an excellent sound insulator, but the ability to damp external noise varies depending on the density of the material, construction technology and wall thickness. So, for example, a D500 gas block with a partition thickness of 120 mm provides noise insulation at a level of 36 dB, and with a partition thickness of 360 mm - 48 dB.Similar indicators for aerated concrete of the D600 brand are 38 and 50 dB. Normative acts regulate sound insulation between rooms at a level of 41 dB, between a room and a bathroom - 45 dB, between different apartments, an apartment and a staircase, a lobby, a corridor - 50 dB. Even a gas block of a structural and heat-insulating type allows you to achieve the required sound insulation values.

Composition

Gas blocks of the German company Ytong consist of a special mixture, which includes several elements.

When they are mixed, a special porous structure of parts is formed. It:

- quartz sand;

- Portland cement;

- aluminum powder and suspension;

- crushed lime (it can be slaked or quicklime);

- water (only approved by Gosstandart).

The basis of the gas block is quartz sand. Aluminum powders and suspensions also play an important role. They form alumina and hydrogen, which imparts porosity to the material. At the same time, experts say that all the characteristics that the material possesses will be the same for both vertical and horizontal installation of the structure.

Ytong aerated concrete blocks must be sent to special autoclave ovens, in which they are strongly compressed at a set level of moisture and temperature. After that, heavy-duty construction products are obtained that can withstand almost any chemical reaction.

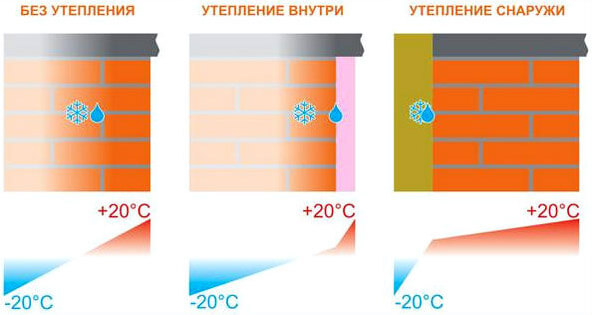

Calculating the dew point for the walls of your cottage

The dew point calculation is very important: we are talking about a temperature indicator, thanks to which you can determine the exact point at which the steam will reach maximum saturation and begin to turn into water droplets. Thanks to the correct calculation of this value, it will be possible to correctly determine the thickness of the walls and the optimal insulation.

You can also see dew drops with correct calculations in a well-built housing: these are drops of water on the windows, which appear with sudden changes in the air temperature outside the window. When the apartment is +20, and outside the window is minus, such a drop provokes the appearance of condensation on the windows. In addition, the level of humidity in the room is of great importance (comes from breathing, cooking, humidity outside, etc.).

The moisture that accumulates on the glass can be wiped off, but when, due to incorrect calculations or mistakes in the choice of materials, dew collects inside the aerated concrete, it is impossible to remove it from there and destruction cannot be avoided. When there is minus outside the window, somewhere in the wall there will be a temperature at which the steam begins to condense and turn into water

It is important to find the dew point and build the walls so that it is not inside the wall, but outside.

Dew point calculations take into account parameters such as indoor humidity, indoor and outdoor temperatures, material grade and wall thickness. They also remember about the partial pressure (vapor pressure) - in cold weather in the external environment, this indicator is low, and where it is warm, it is higher. The steam wants to get out - where the pressure is lower. Therefore, in winter, in a D500 with a thickness of 40 centimeters, the dew point will be in the wall closer to the outside.

When mineral wool with a thickness of 10 centimeters is used with the same initial wall data, a vapor-tight film is laid inside the room and so it is possible to exclude the possibility of freezing due to moisture. If the insulation is chosen correctly, the dew point will be in the thickness of the insulation, not in the wall.

You can calculate the dew point using special online calculators or using formulas, the values of selected materials. But it is much easier to simply take into account the basic rules and advice of the masters: for the middle strip, a wall of 400 millimeters is enough, for a wall of 300 millimeters, insulation is needed.

The northern regions require mandatory insulation, the southern ones allow not to use it or reduce the thickness of the walls (if there is thermal insulation).

No. 8. What to consider when examining the block?

To be sure of the durability and reliability of the constructed building, special attention must be paid to personal inspection of gas blocks.Please pay attention to the following details:

- accuracy of geometry. Responsible manufacturers, which will be discussed below, offer blocks with exact dimensions, without deviations (allows 1-2 mm) and chips, because this is a guarantee of simplicity and cost-effectiveness of installation. Moreover, thick joints, which become inevitable with insufficiently accurate geometry, can create cold bridges;

- Colour. A good autoclaved gas block has a uniform light gray color. If the blocks of the same batch differ from each other in color, have streaks, then we are talking about products of inadequate quality. The presence of oily stains and cracks is unacceptable;

- package. The material must be hermetically sealed, and on each pallet with the material there must be information about the batch number, and a quality certificate must be attached to each batch.

No. 2. Advantages and disadvantages of aerated concrete

Regardless of some features of production, all aerated concrete blocks can boast a decent set of advantages:

- excellent thermal insulation due to the porous structure of the material;

- large dimensions, light weight and ease of processing greatly simplify and accelerate the construction of buildings from a gas block;

- good vapor and air permeability. According to these indicators, aerated concrete blocks come close to the tree. In practice, this means that a house built from such material will always have an optimal microclimate;

- fire resistance;

- environmental friendliness and safety. Hazardous synthetic substances are not used in the manufacture of gas blocks;

- resistance to damage by rodents, insects and microorganisms;

- frost resistance. On average, the gas block can withstand up to 50 freeze / thaw cycles without losing its basic operational properties;

- relatively low cost.

Among the main disadvantages of aerated concrete, we highlight:

- high hygroscopicity. This main drawback of the material is associated with its structure and ability to retain moisture inside. Water absorption can be up to 35%. When moisture is absorbed, the thermal insulation properties deteriorate, and serious deformations of the material may occur. This drawback can be circumvented by arranging reinforced waterproofing, building a reliable drainage system and window drains. In addition, the facade needs mandatory finishing, for which decorative tiles are excellent;

- the possibility of cracking if the foundation is incorrectly installed. Cracks can appear both along the lines of the masonry, and in the blocks due to the shrinkage of the foundation, to which such large aerated concrete blocks are very sensitive. So that the advantage does not turn into a disadvantage, you need to pay maximum attention to the correct installation of the foundation;

- fastener problems. Only self-tapping screws can securely hold in aerated concrete. Nails and screws easily enter the aerated concrete wall and just as easily fall out of it, so special fasteners will be required.

No. 7. The size and shape of the gozoblocks

Gas blocks on the market may vary in size and even shape. Depending on the purpose of use, one or another material is chosen. The most common option is rectangular blocks, which can be divided into several types:

- wall or masonry. They are used for the construction of load-bearing walls, less often for partitions. They have a standard length of 600 mm and a height of 200 mm, but different widths - from 200 to 500 mm;

- the gas block for partitions has the same length and height parameters, but a smaller width - from 75 to 150 mm;

- not all manufacturers produce a gas block for lintels. The length of such blocks is 500 mm, the height is 200 mm, and the width is from 250 to 400 mm.

In addition to smooth rectangular blocks, the following types of material are also produced:

- U-shaped blocks are usually used for the arrangement of hidden building elements. With their help, you can create monolithic stiffening belts, while the internal space is filled with reinforcement and concrete;

- tongue-and-groove blocks at the ends have protrusions and depressions for the most accurate and strong connection of adjacent elements. There is no need to use an adhesive solution for processing vertical joints;

- blocks with grips are distinguished by the presence of cutouts on the sides of the block for ease of handling;

- hh-type blocks, due to their structure, allow laying a layer of thermal insulation between the partition plates.