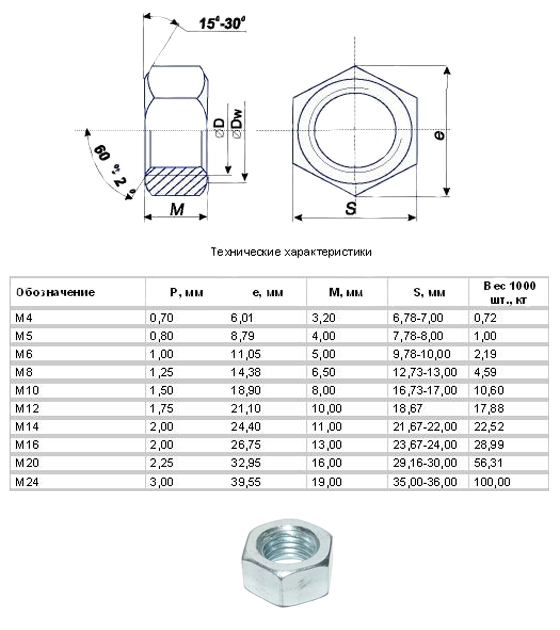

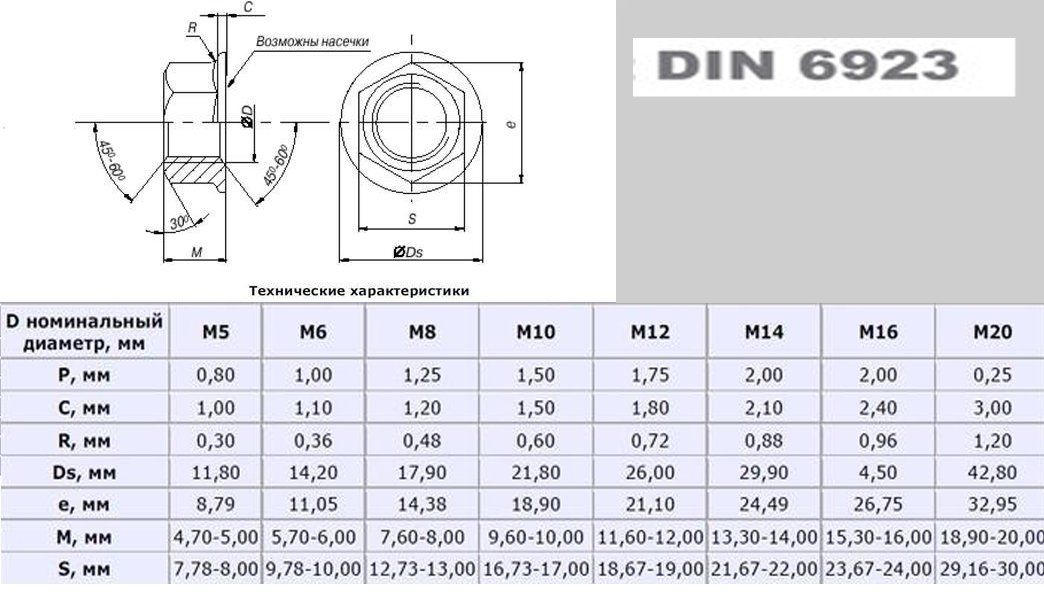

Dimensions and weight

It is most convenient to present the relevant information in the form of a table.

|

Brand |

Height (mm) |

Width (mm) |

Depth (mm) |

|

М4 |

120 |

65 |

10 |

|

M5 |

4,7 — 20 |

8 - 30 (turnkey) |

— |

|

M6 |

30 - 160 (most often 120) |

65 (turnkey) |

10 |

|

М8 |

8 |

17.9 (maximum width) |

10 |

|

M10 |

10 |

15 |

— |

|

М10х1 |

4 – 20 |

5,5 – 30 |

— |

|

M12 |

Before 18 |

Up to 25 |

15 |

|

M14 |

14 |

21 (turnkey) |

— |

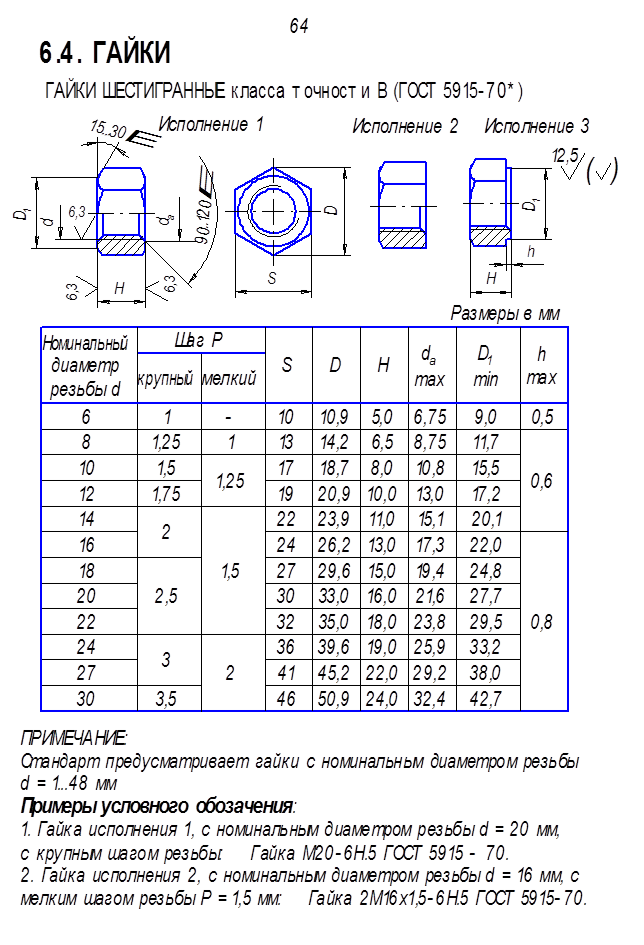

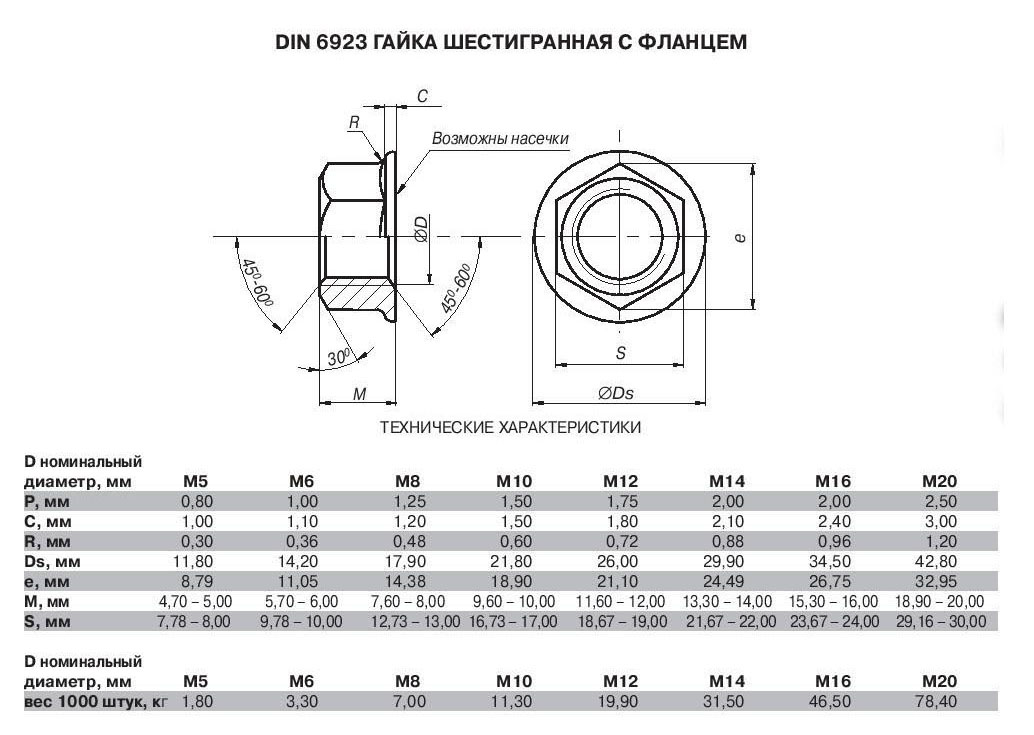

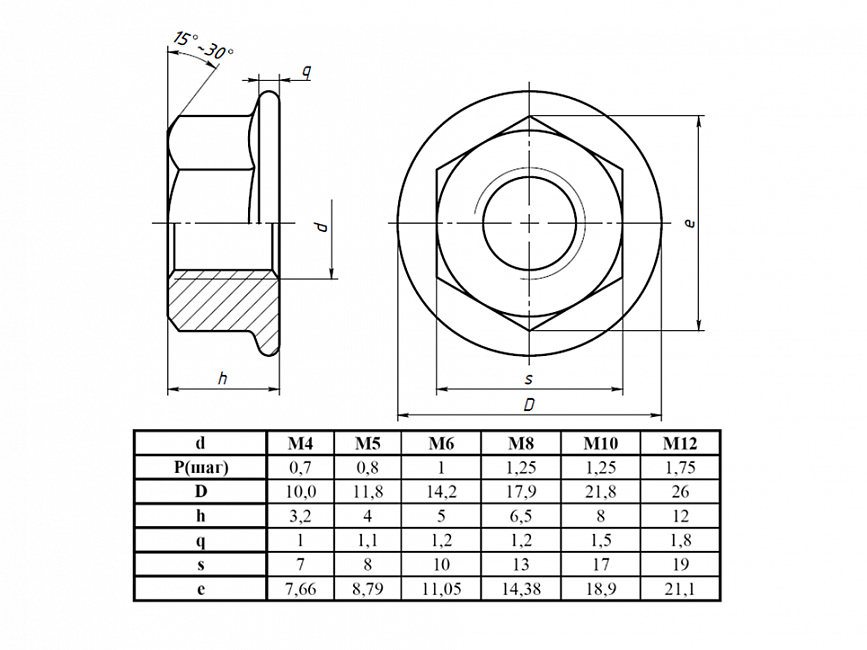

M16 flange nuts are usually made of high-quality steels. Carbon metal grades are predominantly used. Considered interaction with various types of metric fasteners. This nut has the following dimensions:

-

thread section from 5 to 20 mm;

-

cutting step from 0.8 to 2.5 mm;

-

height from 4.7 to 20 mm;

-

turnkey width from 8 to 30 mm.

Typical for M18:

-

cutting step 1.5 or 2.5 mm;

-

section inside from 18 to 19.5 mm;

-

head height - 14.3 - 15 or 16.4 mm;

-

wrench size 27 mm.

M20 nuts have the following dimensions:

-

height 2 cm;

-

turnkey size 3 cm;

-

flange section 4.28 cm.

According to DIN 6923, the weight of 1000 pieces of nuts is normally:

-

M5 - 1 kg 790 g;

-

M6 - 3 kg 210 g;

-

M8 - 7 kg 140 g;

-

M10 - 11 kg 900 g;

-

M12 - 20 kg exactly;

-

M14 - 35 kg 710 g;

-

М16 - 40 kg 320 g.

M4 flange nuts are designed to create some pressure on the joint surface. Typically, a household package contains 25 pieces. Such products are made of galvanized steel. As for the M6 hex nuts, they can be packaged in 0.581 kg. Basically, the right-hand thread predominates.

See the video about the flange nut below.