Saucer and saucer

ÐовоР»Ñно много Ñл ÑÑÐ ° Ðμв, когÐ'Ð ° можÐμÑ Ð¿ÑоиР· ойÑи ÑÑÑв ÑвÐμÑной ÑÐμÐ · ÑÐ ± Ñ, поÑÑÐ¾Ð¼Ñ ÐºÐ¾Ð¼Ð¿Ð »ÐμÐºÑ ÑпÐμÑиР° л ÑнÑÑ Flare-up - flare-up on the side Rose, Rose, Rose, Rose, Rose, Rose, Rose, Rose, Rose, Rose Welcome:

- Good luck. Good news;

- Burgundy

- Lingo lingo linging linging linging;

- Gallon;

- Burgundy

- Burgundy

- In the morning ...

Burgundy Burgundy and barking bush

What are they?

Fittings can differ from each other in their dimensions - primarily in terms of the value of the diameter. It can be different: M6, M8, M12, M10. Standard sizes for such products can be: M10x1, M14x1.5, M16x1.5, M18x1.5.

Fittings also differ depending on design features. Several varieties can be distinguished.

Universal wire inserts. This option is considered the most popular. It has the form of a thin spring-shaped retainer. On the inner side, the turns form a rhombic profile. The products are equipped with special driving tongues designed for screwing into old threads. Once installed, the old element can be easily detached. These models can be used for almost any thread.

How to use?

To replace an old broken thread or to secure the connection, you need to correctly install the insert in the form of a spiral made of metal. You need to start everything by drilling the recess using an overhead jig. Then you should make a slight displacement of the axes of the hole (the deviation should be no more than 0.15 mm).

After that, you need to make threading in the formed recess of the part. A new insert is applied to the instrument.

Later, you need to wrap the wire insert into the recess of the tool tip. With the help of the latter, the insert is screwed into the old thread. When the element is firmly fixed in the hole, the tool is carefully removed, and the technological leash is removed.

It is recommended to check after installation. This can be done using a special gauge (through or non-through). If not, you can use the bolt. They are slowly inserted into the recess with a new insert. The threaded part must not be removed from the hole with these parts.

If you used a passing gauge, then its deviation during verification should not exceed 0.5 mm. A non-passable element must not be screwed into a new element.

The insert must fit into the recess made at least ¼ from the thread pitch. She shouldn't be performing. After such a proof test, the new connection will become even more robust and reliable.

Verification is necessarily carried out in cases where the thread is made in materials that are too soft, including aluminum structures.

How to restore the thread with your own hands, see below.

Peculiarities

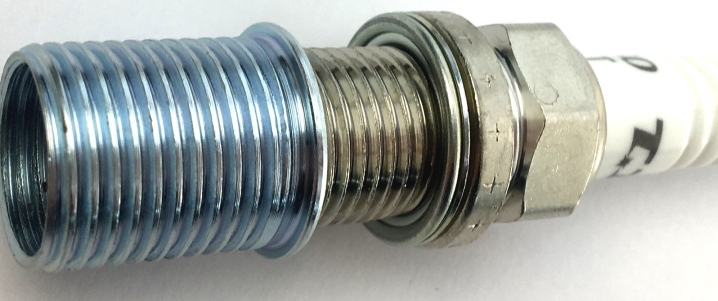

Thread restoration fittings are special inserts that are superimposed on old connections. At the same time, they provide additional protection for the mounts and their reliability. Can be used in candle wells.

Most often, such inserts are used for cast iron and aluminum fasteners. These products have a spiral surface, they are made exclusively from materials that are highly resistant to corrosion.

Threaded inserts are made, as a rule, of stainless steel. Products made from such a metal base have a high level of strength, wear resistance and durability. Often, the surfaces of these parts are additionally coated with special protective compounds that prevent them from corroding.