Applications

Reflective paint is used for marking or decoration purposes, respectively, where light reflection is required. A nice feature of this material is that it dries quickly even in harsh climatic conditions. In order for the reflective effect to be more pronounced and durable, a primer is usually used before paint is applied. If a reflective material is used for decoration, then it is recommended to additionally apply a colorless varnish over its coating - this will not only fix the effect of light reflection, but also give the surface a glossy texture.

The most widespread is aerosol reflective paint in cans. This is due to the fact that its application does not require special labor, special skills and serious time costs. The main advantage of aerosol varnish is that it is ready to use immediately after purchase. But regardless of the external shape, whether it is a can or a can, formulations with the "glow in the dark" property are used to solve many problems, including:

- creation of markings near schools and on the territories of enterprises;

- application of marking on the elements of cars;

- painting helmets or uniforms for motorcyclists and cyclists;

- decoration of facades, for example, tiles, panels or ordinary concrete surfaces;

- designation of road signs and track surfaces;

- decorating the premises of private houses, clubs, bars and various entertainment venues;

- creation of works of art - from paintings glowing in the dark to spectacular body art (in the latter case, special coloring compositions are used that meet a number of hygienic standards).

The growing popularity of reflective varnish is influenced by the flooding of roads with an increasing number of cars. Thanks to the varnish, movement on roads and near them in the dark becomes safer for both the pedestrian and the driver. Therefore, the reflective coating becomes not a luxury, but a concern for lives. In order to understand this deeper, it is enough to imagine how the situation will change if the road, its markings and signs cease to be noticeable.

Plus to all of the above is also the fact that a coloring mixture with a similar effect can be easily created with your own hands at home. And, of course, you can use it for your own purposes, not necessarily related to traffic. It's easy to paint simple portable objects like children's toys - this will give the child the opportunity to look at them under cover of darkness in a completely new way. The main thing is that, because of the interest shown by him, then it should not be difficult for you to send the baby to bed. Another option is to make a glowing drawing on the wall so that the child is not afraid to sleep in the dark.

Composition and characteristics

Any reflective varnish owes its "magic" properties to a special pigment in the form of a ball, which is mixed with a transparent varnish. The task of pigments is reduced to the following: beams of light, falling into them, are reflected, as a result of which the painted surface glows.

It is generally accepted that the ideal proportion of pigment beads and a binder in the form of a varnish for working with an aerosol spray gun is 1: 3 (where 1 part is pigment and 3 parts is dye).However, some people mistakenly believe that the more balls that return light, the better the glow effect. But this is not the case. There is a clear proportion, tested by the hands of professionals and many years of experience, which it is better to adhere to. If dilution is required, toluene or xylene is used.

It is generally accepted that the ideal proportion of pigment beads and a binder in the form of a varnish for working with an aerosol spray gun is 1: 3 (where 1 part is pigment and 3 parts is dye).However, some people mistakenly believe that the more balls that return light, the better the glow effect. But this is not the case. There is a clear proportion, tested by the hands of professionals and many years of experience, which it is better to adhere to. If dilution is required, toluene or xylene is used.

The composition of varnishes with a glow effect differs in the basis of each of them, and you should be guided by it before buying and carrying out work. The base of the varnish must be chosen depending on the type of surface to be coated: concrete, plastic, metal, wood, glass or roadway.

On the packaging of the coloring product, it should be written in detail about the composition and surfaces for which it is intended. For example, acrylic-based paint should be preferred for concrete processing, and alkyd-based paint when working with metal. For the reflective balls themselves, it does not matter with what base they are mixed, be it alkyd, polyurethane or acrylic varnish - their properties do not change from this.

The average consumption of coloring materials with a reflective effect is 250 grams per 1 square meter. The average drying time at 22 degrees Celsius, as a rule, does not exceed 60 minutes. Prices for both aerosol products and those that are applied with a brush vary greatly, which makes it difficult to give them an unambiguous estimate.

Manufacturers

There are many manufacturers of glowing paints on the market today, and many of them produce quality products.

One of the most worthy brands is Revell. This brand was created in America in 1943. At first, his products were plastic toys, doll furniture. The company expanded, merged with others, including European companies, and the company's product range grew. Revell began to produce prefabricated models of cars, ships and airplanes. The products were a huge success. In addition to the kits of the models, the company has established the production of all the necessary accessories for assembly. Among them were paints, brushes, sprayers.

Revell is constantly developing, studying world experience, modernizing and expanding production. Taking care of clients, she develops interesting programs with bonus points and promotions. You can use bonus points to pay for some purchases. The company's consultants are always in touch and help customers choose goods that will be delivered to any corner of Russia.

The line of luminescent paints is represented by water-based acrylic compounds. Environmentally friendly materials are used for their manufacture. They are suitable for decorating children's toys. When applied, a thin even layer is obtained, which dries quickly and makes it possible to apply the next layer.

The paint does not have a strong odor, is not subject to ignition. If necessary, you can easily mix different tones. Luminescent yellow, silk matte red, and matte orange paint look especially beautiful.

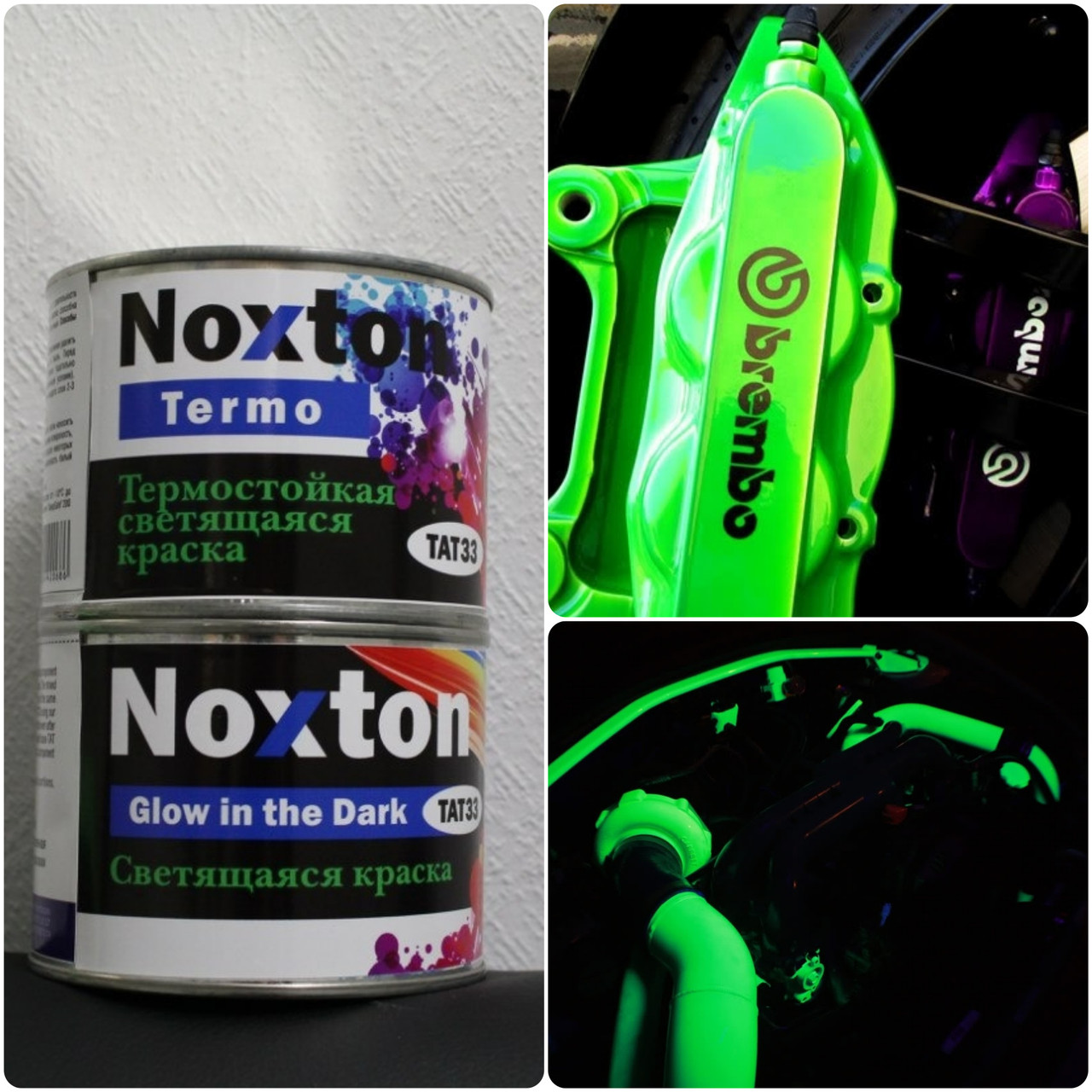

Some companies are engaged not only in the production of paint, but also produce luminous products. Among the leaders is Noxton. It offers the widest selection of colorants of various types (fluorescent, fluorescent, reflective) for a variety of surfaces and for a variety of purposes.

Noxton paints are economical and safe, have a very long service life, and high-quality dyes are used for their manufacture.

Noxton also offers a wide range of finished products (over 40 directions), among which you will find:

- luminous self-adhesive film;

- safety signs and vests;

- nail polish and hair gel;

- souvenir products;

- paintings;

- items for interior decoration;

- items for different areas of design.

The company "Nevidal", which has existed since August 2011, has proven itself well.The company produces and sells luminous paints and aerosols, special pastes and liquids for mirrors and glasses. The company also sells luminous products that can transform different rooms.

One of the directions of her activity is the production of luminous paintings. They are suitable for any interior, make it mysterious at night. "Fairy World", Magic Crow, "Leopard" are full of charm and magic.

Pictures can be charged by any light or heat source in a few minutes, and they will glow for 10-12 hours. The glow can be blue or green. Manufacturers promise that this function will work for up to 100 years.

See the video below for even more uses for glowing paint.

Peculiarities

Fluorescent paints also emit light in the daytime. However, in the dark, their light becomes 3 times brighter and richer. For this reason, this paint is often chosen for night decoration and various types of markings. To make surfaces covered with such paint look stylish during the day, you can use colored fluorescent products.

They can be white, blue, green, red, brown or light blue. Transparent paints will be almost invisible during the day. This dye will not glow on its own. When exposed to ultraviolet rays, its bright glow will increase tenfold.

If you don't know how a fluorescent paint differs from a luminescent analogue, it is worth taking a note: the latter has an independent illumination effect. The duration of this effect can last up to 10-12 hours. For the whole day, painted surfaces absorb light, and when darkness comes, they begin to glow autonomously. This difference allows you to accurately select the desired type of paint.

There is also a reflective dye. It acts as a backward reflection of the luminous flux: as soon as the light hits the painted surface, the rays are immediately reflected 200 - 250 m. This paint is selected to increase road safety.

Different types of fluorescent materials are suitable for coloring:

- metal products (they can cover car disks, signs on the road, various objects);

- different fabrics (to depict patterns on clothes, use for advertising purposes);

- glasses and ceramics (this can be tableware or stained glass painting);

- the human body (can be found in body art) and on the leaves of ordinary plants;

- wood (you can paint fences, decorate gazebos, openings of windows and doors);

- stone and concrete (painting of walls, garden paths, city alleys, building facades);

- plastic (products made of PVC, polystyrene and other plastic materials).

In addition to the ability to glow beautifully, fluorescent materials have other characteristic features. There are advantages and disadvantages among them. Let's consider the key points.

Low light fastness

Fluorescent paints can fade under the influence of light (if applied externally) in a matter of months. To make the dyes burn out more slowly, a modifier is introduced into the composition of the product, which absorbs UV rays. In addition, the coating with already applied paint can be painted over with transparent varnish. But the brightness of the glow of the paint will be reduced.

Loss of quality due to improper tinting

The fluorescent coloring product will become extremely unstable after unsuccessful tinting. To give the surface durability, it is better to buy ready-made material of the desired color right away.

Grain

Since the pigment grains are too large, they will not result in a fully glossy finish. To solve this problem, the dye is applied in 2 layers or painted over with varnish.

Fear of excessively high temperatures

Fluorescent paints and varnishes disintegrate at a temperature of +150 - 250 degrees C. They completely lose their ability to glow brightly.

It only takes 15 minutes of bright daylight or artificial light to charge the applied paint for 8 full hours of use. The light accumulation process is a completely continuous cycle. Product manufacturers guarantee that their glowing paints will last for at least 30 years.

Fluorescent paint

Many can answer the question of what kind of paints they are. Indeed, fluorescent paints belong to decorative paints and varnishes, which have a peculiar reaction to the effect of light flux. Products coated with such a composition are visible in any light. Moreover, at night they are much brighter than during the day. Professionals emphasize that the glow is almost twice as intense.

The high demand for similar materials was naturally due to the unusual effect and therefore the paints were quickly noticed.

Fluorescent glowing paint

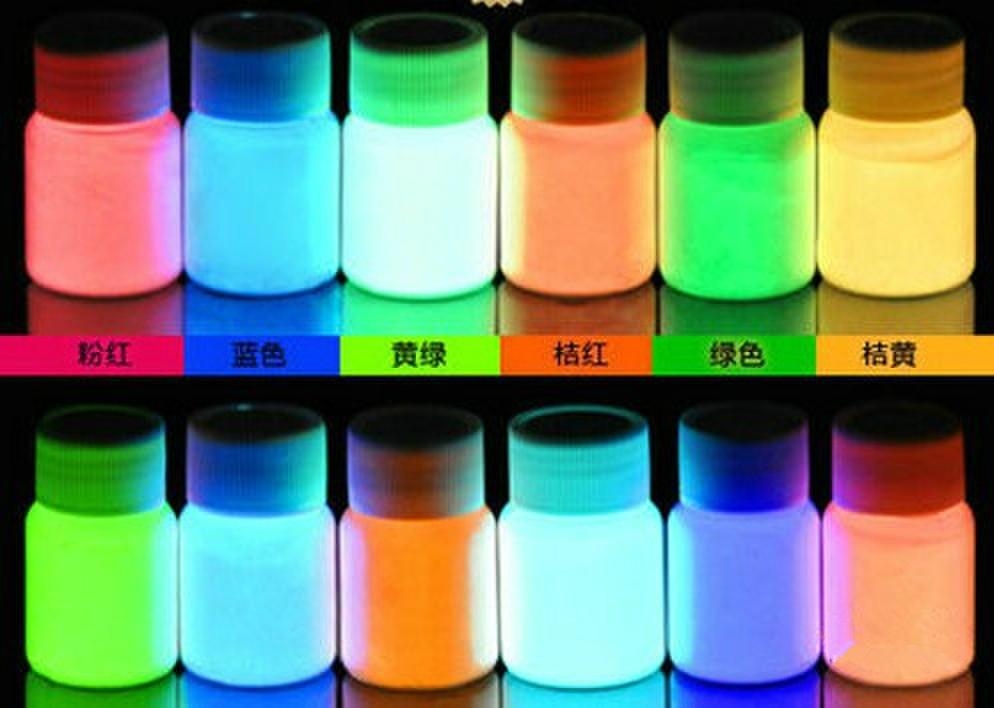

The variety of paints offered has a wide range. You can choose from white, brown, red, blue, yellow, green paints. Interestingly, they are visible and invisible. Invisible paint has a peculiarity - it is almost impossible to see it in the daytime. It will manifest itself only when exposed to ultraviolet rays.

Visible paint is easy to distinguish, however, when exposed to sunlight, the glow intensifies.

The predominantly common fluorescent dye composition can be called acrylic, the base of which is water. The composition includes a dye, a binding element (acrylic polymer emulsion) and water prepared in a special way. Those who have used this composition note the uniqueness of the product.

The advantages of the material include:

- Versatility - can be used both indoors and outdoors.

- Ease of use - when performing work, a spray gun, brush, paint sprayer or roller is enough.

- Saturation of the painted surface - you can additionally protect from adverse weather conditions with a polyurethane-based varnish.

- It fits well and economically on the surface.

- Dries quickly enough.

- Impeccable consumer properties - do not tarnish, the color does not lose color under the influence of sunlight.

- Do not harm human health.

- Diverse area of application - you can paint a paper base, natural flowers and wood, concrete and stone surfaces, plastic and metal.

The use of dyes with a fluorescent special effect is quite wide.

The unusual property of the material can be successfully used as:

- Marking - designation of signal lanes and signs on transport.

- Painting of various objects - equipment, road signs, "beacons".

- Marking of fragments of the pipeline, machine tool, inventory with hazardous areas.

Common disadvantages

Unfortunately, coatings cannot fluoresce forever, since they have rather weak resistance to direct sunlight. Fast burnout can be avoided by using protective equipment such as clear varnishes.

When purchasing such a composition, it is important to make sure that it does not have matting properties, in which the glow effect will be significantly reduced.

The texture of the fluorescent dispersion does not allow for a glossy surface finish. When such a need arises, you can resort to the method described in the previous paragraph.

The material does not belong to heat-resistant compositions.

It collapses at a temperature of + 100-150 ° C.

Views

Since there is no official classification, the type of paint can be determined not only by the active pigment, but also by the surface on which it is applied. Different formulations can be used for the same surface.

Phosphoric paint is suitable for coating various materials. She can apply drawings to metals, fabrics, glass, wood, concrete, plastic.It quickly accumulates light energy, and then releases it over long hours, providing a beautiful phosphorescent glow.

Because prolonged exposure to phosphorus can cause nausea and more severe poisoning, modern paints replace phosphorus with a phosphor that acts in a similar way.

The phosphor is a phosphorescent powder, therefore the paint with it is called phosphorescent.

Also, paints in which the pigment can accumulate both sunlight and electric light, and then give it away, are called luminescent. The night color may differ from the color that the paint has during the day.

The undoubted advantage of luminescent paints is their harmlessness. And since they are made on the basis of varnish, they have another remarkable property: by creating a film on the painted surface, they protect the object from moisture and other adverse environmental influences.

For some people, floristic glowing paints are of particular interest. They are designed to create a glowing effect on vibrant colors.

It can be used to process any parts of plants: petals, leaves, buds. And for cut flowers, it will even prolong the life.

You can apply it in any way. In the daytime, it will look like a light white bloom. Any light source will "charge" it.

A slightly different look is fluorescent paints. They can be of any color and look like ordinary paint. They do not differ from conventional coatings either day or night. A source of ultraviolet light is required for their glow. They can be used on wood, concrete, paper, metal or plastic. In order for their effect to manifest itself, one layer is quite enough.

The base for fluorescent compositions can be of any color, they can even be applied to other designs made by conventional means. Fluorescent paints are not harmful to health, so they can be used in homes and places where there are large numbers of people.

Some modern manufacturers are mastering the release of compositions in which the glow effect appears as a luminescent with a gradual attenuation and as a permanent one when irradiated with ultraviolet light.

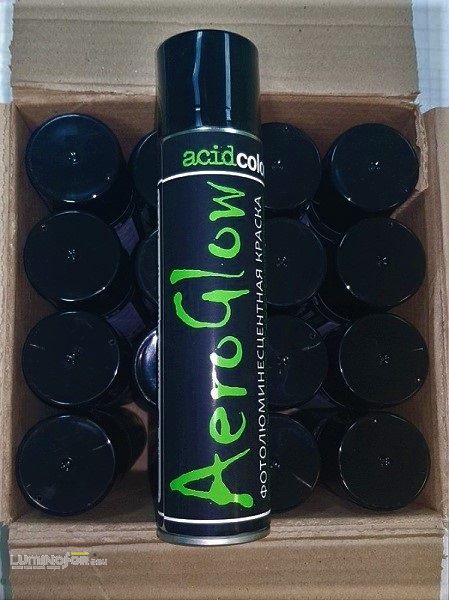

Manufacturers produce phosphorescent paints in different containers: in cans and cans.

Spray paint is more popular due to the following properties:

- it is easy to use;

- this is a ready-made composition; solvents and other substances do not need to be added to it;

- it can quickly paint a large surface;

- it dries quickly.

General guidelines for the use of fluorescent ink

The application of luminous enamels is no different from any other type of painting work. Of course, the composition, purpose and type of the painted surface affect the features of the application.

There are several general guidelines, these are:

- purchase of standard inventory and additional materials: brushes, rollers, spray gun, protective equipment, solvent;

- surface preparation: remove dirt, dry and degrease;

- paint preparation: stir the composition to a homogeneous mass, add a thinner / solvent if necessary (according to the instructions);

- material application: usually, it is recommended to apply the fluorescent composition in 2-3 coats to form a high-quality and durable coating. Each of the layers must be allowed to dry a little.

Conclusion

So, now you know the answer to the most popular question - does fluorescent paint glow in the dark or not. By choosing a high-quality source of ultraviolet radiation, you can create a unique interior, as well as give an unusual look to your own clothes, car or even hair. Go for it!

Application technique

Most often, such paints and varnishes are applied to facade parts and various protruding parts of structures. Reflective pigment is the main distinguishing feature of their composition, which removes the need for additional decorative layers.All that is required of liquid formulations is to pre-mix them. Before using materials in tubes or cans, even such a trifle is not required - they are ready for use from the very beginning.

But first, take care of the surface you are going to paint on. As with any painting and finishing work, any foreign elements such as dust, rust, grease and dirt must be removed from the surfaces.

If you are going to apply paint to the road surface, then pay attention to the pieces of earth and clay - they need to be removed to the ground

If the area to be painted is small, then it is advisable to use an aerosol reflective varnish in cans. Otherwise, you will need any of the most popular painting tools - a brush, roller or spray gun. In this case, the latter is used for work only with fairly liquid formulations. Further 3 options are possible:

- Mixing lacquer base with reflective beads and color scheme. This method is not designed for a thick consistency and can be effectively sprayed with paint;

- The base in the form of a varnish is applied to the surface separately from the entire composition, and from above, using a sieve, pigment balls of the desired color are scattered onto the varnished areas. Excess balls are removed (a jet of compressed air does an excellent job of this). Half of the remaining pigment is not painted over, that is, the previous layer of varnish serves as an adhesive base for it. This method is used in large-scale road markings;

- White varnish is applied to the surface like a primer, and after it dries, a colored reflective layer is applied.

All work with reflective paint is recommended to be performed at low air humidity and room temperature. To increase the resistance of the reflective coating to wear, quartz sand is additionally included in the composition (with a grain size of not more than 0.2 millimeters and in a proportion of up to 1/100 of the total mass).

Varieties of paints

Today, there are two well-known types of dye mixtures with the effect of light reflection. All of them, at first glance, are very similar, but each product has its own advantages, operating conditions and its own mechanism of the glow phenomenon. Before purchasing it, it is better to familiarize yourself with the information about each of these types.

Luminescent varnishes

Luminescent varnish accumulates the light of the sun and artificial illuminators, after which it displays it in the dark for 8-12 hours. It reflects soft, eye-pleasing light without even requiring additional UV exposure. Thanks to the luminophore, light energy is accumulated throughout the day, working autonomously in the dark and thereby allowing partial savings on electricity. Typically, the colors produced are green, blue, and milky.

Luminescent varnish accumulates the light of the sun and artificial illuminators, after which it displays it in the dark for 8-12 hours. It reflects soft, eye-pleasing light without even requiring additional UV exposure. Thanks to the luminophore, light energy is accumulated throughout the day, working autonomously in the dark and thereby allowing partial savings on electricity. Typically, the colors produced are green, blue, and milky.

Due to the fact that the pigments of such varnishes sometimes contain harmful substances, the use of luminescent compositions is limited. It is believed that they should not be used in bedrooms, children's rooms and kitchens. This is not always justified and relevant only if phosphorus acts as a storage device in the composition - in this case, it is better to use the coloring material only in outdoor decor, outdoors.

Fluorescent formulations

Paints and varnishes of this type work a little differently: their coating does not accumulate light energy, but exhibits a glow effect only when exposed to rays of sunlight or artificial light. An example of this effect can be seen in the dark on the road, where road signs, signposts and markings start to glow when the headlights hit.

Fluorescent dyes are used not only for roads, but also for clothing. For example, in some cases they are used to paint work overalls.Such paint is also in demand when decorating the premises of entertainment establishments, where, when the ultraviolet lamps are turned on, the painted interior takes on an extraordinary look.

Volume

For the job, spray paint is best suited: if all available material is not used up immediately, it will be stored in the can until the next use. At the right time, you can again implement new original ideas for the design of the glowing image. The volume of this paint in an aerosol can for use in different purposes can vary from 100 to 520 ml. You can buy paint in cans of 140, 150, 200, 240, 300, 340, 400 ml.

It is difficult to answer exactly what surface area can be painted over with one aerosol product of a certain volume: paint consumption depends on a number of factors

It is important which company produced the paint. Has the meaning:

- the coefficient of coverage of the product itself;

- original surface color;

- absorbency of paint;

- the presence of a primer;

- experience of using spray paint.

- uniformity of application.

- the tone of the paint (the lighter the shade, the greater the consumption of the dye);

The approximate consumption of such a can, according to the manufacturer's label, is 1 sq. m. about 200-300 ml.

Scope of luminous paints

There are many creative industries where glowing materials are used. Let's take a look at a few of them.

- Machine numbers. In order to embellish your car, you can use this material. The process of applying to the surface is very fast. The finished coating will glow for two hours after the end of the work. There are no guarantees for the operation of the material, since it cannot physically deteriorate. In daylight, the license plates will be of normal color, but only when entering a dark room will they acquire a beautiful green-blue color. The content of the number (numbers, letters) stands out well.

- Machine disks. This is the second way to make your car special. The work of covering the caps consists of a couple of stages. First of all, the surface is cleaned of dirt or dust, covered with a primer, glowing paint is applied to the dried soil. To protect the surface, you need to open it with a special varnish. After the end of the work, a day must pass to obtain the result.

- Glass decor. One of the most popular uses is the use of paint for glass, porcelain, and ceramics. Specifically, it can be vases, glasses, wine glasses or ashtrays. Such items will be a great gift or an unusual interior for a nightclub.

- Glowing paint for flowers, plants. Luminescent paint is a safe material for both people and the environment. To surprise a girl or woman, cut flowers lend themselves to coating. During the day they will look like ordinary ones, and at night they will pleasantly surprise you with their unusual color.

- Used in factories for textiles or fabrics, silk-screen printing.

- Design of a room, building, room. An old building or room can be transformed in an unusual way. It can be applied on ceramic tiles, wallpaper, painted walls with ordinary paint, plastic or wooden skirting boards. For example, you can paint a starry sky on the ceiling, or Christmas trees on the walls before the New Year. Popular are art murals, LED materials, watches, leather belts.

- You can complete a drawing (shapes, flowers) or just a contour through a stencil.

- They are also used for safety signs, clothing, decorative stones, children's souvenirs, nail polish, paintings, business cards, body art, tattoos. They can be used to draw stained glass drawings on paper or style. Used for makeup.

Glow in the dark paint

Glow in the dark paint

Views

There are four main types of fluorescent ink on the market today:

- Acrylic enamel for use in interior decoration.Often used when renovating or changing the interior.

- Acrylic enamel, which is intended for painting the facades of houses.

- Spray paint containing urethane and alkydane. It is a versatile paint and varnish coating. This type of coating is produced in cans that are convenient for use.

- Invisible paints. They are almost invisible on light surfaces, but this is during the daytime. In the dark, they acquire a whitish tint in the form of chaotic stains. They are often used by designers in exclusive projects. This paint was also used in highlighting road signs.

Enamel for decorating interior items can be applied to almost any surface, be it wood, plasterboard surfaces, paper, stone. Exceptions are plastic and metal surfaces.

The color shade of acrylic enamel is determined by its composition, which includes acrylic as a base and luminescent pigment particles. New shades are obtained by mixing the existing color scheme.

The paint does not have an unpleasant, pungent odor. It is not toxic. The disadvantages include low moisture resistance, so it is better not to use it in the bathroom, swimming pool.

Acrylic enamel, intended for painting the facades of buildings, is very resistant, withstands various temperature conditions. It does not lend itself to fading and is sufficiently resistant to cleaning and disinfecting agents. It is not difficult to wash a house painted with such enamel.

Facade paint is odorless. She has excellent vapor permeability. It fits well on a concrete surface, galvanized metal, which cannot be said about many other types of paints and varnishes.

Spray paint, which belongs to the class of universal coloring agents, has a wide range of uses. They are used for indoor and outdoor work. The process of applying such paint is simplified due to the fact that it is produced in small cans. Aerosol colorant can be applied to many types of surfaces:

- glass;

- plastic;

- wood;

- wall surface.

They are ideal for use in bathrooms, swimming pools, toilets, as they have the highest vapor resistance.

Invisible paint is a very popular type of paintwork. She has a wide range of colors. Ordinary white walls or ceilings during the day magically turn into masterpieces of designers and artists at night, gleaming with different colors. All this thanks to ultraviolet light.

conclusions

The painted base can be charged and glow at the same time under the influence of soft ultraviolet light. Clubs use this effect. But the powerful activity causes the luminous pigment to wear out quickly.

The luminous coating creates beautiful things. The property of phosphorus-pigment is used to accumulate light, glow is given in the dark without backlight for a long time.

In the construction market, phosphorescent paint is represented by well-known brands:

| Brand name | Main material for coloring | The basis of the glowing composition | Economical composition | Price, dollar |

| Noxtron, country of origin Ukraine | metal, wood, glass, plastics, flowers, textiles, body art. | influences the purpose of the material | from 10 to 14 l / m2 | from 6400 to 8320 rubles. |

| LumiNovator, Russia, phosphor-based spray paint | paper, fabric, plaster, natural stone, primed metal. | water dispersible acrylic | from 230 g / m2 | from RUB 2100 to RUB 3840 |

| Phosphor, Ukraine | metal, wood, textiles, PVC. | acrylic | from 10 to 12 l / m2 | from 3200 to 3840 rubles |