GKL seam finishing

Treatment of seams of gypsum boards with UK * and application of paper tapes (manual method):

- Put putty on the joint with a narrow spatula.

- We apply the tape and lightly, without pressure, fix the tape with a spatula. For best results, we recommend using SHEETROCK paper strips.

- We accelerate the putty under the tape from the middle to the edges. Thus, we glue the tape, remove the excess adhesive layer from under it and level the surface.

- We are waiting for the complete drying of the putty.

- Next, take a wider spatula and apply a layer over the tapes. This layer should be 5-10 cm wider than the previous one on each side.

- After the layer has completely dried, we can proceed to the continuous leveling of the surface into a plane.

* UK - thinned edge

You can find detailed instructions in the Articles section.

External and internal corners processing:

- Prepare in advance a piece of a corner or tape of the required size. For a perfect result, we recommend using SHEETROCK professional corners.

- Apply an adhesive layer of putty to the base on both sides of the corner with a narrow spatula.

- We fix the corner or tape on the surface.

- We accelerate the putty under the tape from the middle to the edges. Thus, we glue the tape, remove the excess adhesive layer from under it and level the surface.

- We are waiting for the complete drying of the putty.

- Apply a layer over the corner or tape using a 25-30 cm wide spatula.

- After the layer has dried, we proceed to the continuous filling of the surface.

You can find detailed instructions in the Articles section.

Technology

After proper installation of lighting, you should:

spray the plane of the wall with liquid and wipe thoroughly with a sponge to cleanse and increase adhesion;

Sponge cleaning

- create a mixture of glue with water and apply a primer;

- dial the finished putty into a narrow spatula;

- work in a vertical direction, apply the composition to the wall;

- carefully process the area of the plane;

- stretch the putty with an extensive spatula, from time to time wiping the spatula with a damp washcloth (the thickness of the cover should not be more than one and a half millimeters);

- cover the surface with a substance;

- the final putty must take hold and dry;

- using a fine-grained emery paper, get rid of all the bulges.

Grinding

Ceiling preparation

Ceiling preparation mainly depends on its condition. However, after bringing the plane into a uniform state, you need to putty the ceiling for painting or whitewash it.

For facing actions, various materials are used, of which there can be multi-purpose, initial and final mixtures. In addition, reinforcing meshes are used - this reduces the number of holes.

The final mixtures are the most watery. They should be applied after using the starting putty. So, the process of applying the final putty is quite simple.

For more information about ceiling putty, see the video:

Preparation of the plane for finishing

To acquire an attractive ceiling plane, without spending extra time, you can simply paint over it. Ceiling painting begins before priming and filling. First, the surface is carefully cleaned and primed.

Surface cleaning

In most situations, the best result is the use of deep invasion - a high-quality base is applied with a paint roller, and in inaccessible areas it is practical to use narrow brushes. There should be at least two layers.

As a result of the absolute drying of the special liquid, the plane is filled with the initial substance. For the base, the deepest cracks and voids are repaired.

Sealing cracks

For best results, a reinforcing mesh is used (smoothes the surface).

Reinforcing mesh application

The prepared starting putty is beaten with a spatula and applied to the ceiling with a thin layer.

It is not recommended to make a fat layer. The composition must be laid in the same way, trying not to leave marks from the scapula. After drying, the sanding stage begins and again needs to be treated with a primer consistency.

Primer

Application of the substance

The layer of finishing putty should be thinner than the past, the original. To apply it, it is more correct to use a wide spatula. The composition is prepared in accordance with the instructions printed on the package (before creating thick sour cream).

Then a fraction of the substance is collected from the container per blade and distributed in a layer of 2 millimeters. Then it is dried and leveled with P80 sandpaper.

P80 sandpaper

The second layer is superimposed on 1 layer, which is carried out with an overlap. With painstaking work, you can make a flawlessly flat surface.

Application

After drying and sanding the surface of the finishing putty, the painting stage begins.

Painting

The finishing putty for painting has the following price of work performed:

- wall decoration for painting (4 layers) 350r / m2;

- alignment of walls along beacons 350r / m2;

- putty of walls in 2 layers 200r / m2;

- gluing fiberglass (cobwebs) 120r / m2;

- finishing putty of walls and ceilings in 2 layers 200r / m2.

Types

What is the best putty for wallpaper walls? By purpose, putties are divided into the following types.

Starting

It is used for the purpose of premature alignment of the entire area on which the installation will take place. There is one significant difference between the starting and finishing putty.

Starting

Finish

The finishing putty for wallpaper is used already at the end of the work in order to fix the result and level the surface. This putty is applied only after the previous layer of the applied putty dries well. Here is about how much the putty dries.

Finish

In terms of composition, they are like this.

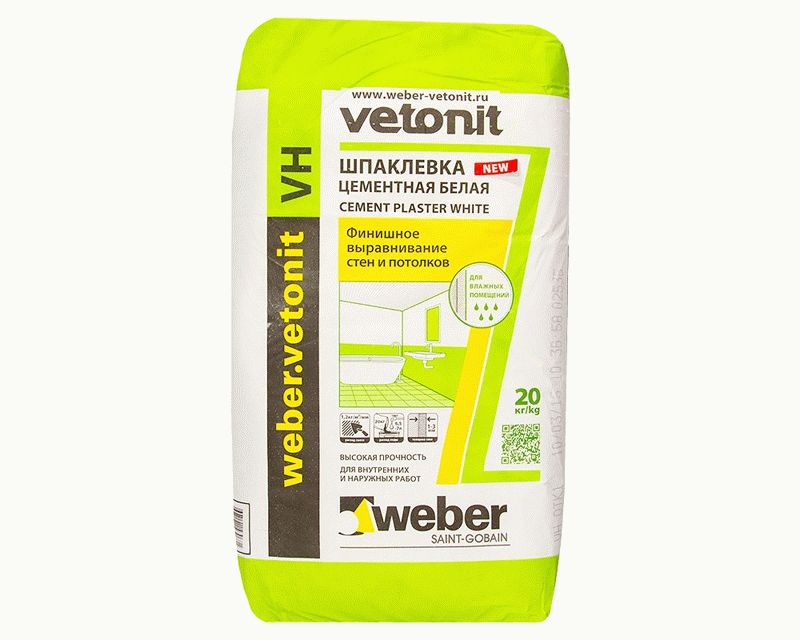

Cement

Used for repairs indoors for painting or outside. Here about the finishing putty for painting. The material is suitable for finishing rooms with high humidity levels.

Cement

Gypsum

May be used exclusively for completely dry apartments. If the gypsum plaster is used for rooms with high humidity, then the material will begin to crack instantly.

Gypsum

Acrylic

Acrylic filler is used to perfectly level the walls. Here about acrylic putty on wood.

Acrylic

Also, putties can be further divided into the following varieties:

ready-made, which are sold in stores;

Ready-made

dry, in powder form.

Dry mix

The advantages of the first type of putty are that after opening the package, the master can immediately start working.

Finishing putties can also be further subdivided into such subgroups.

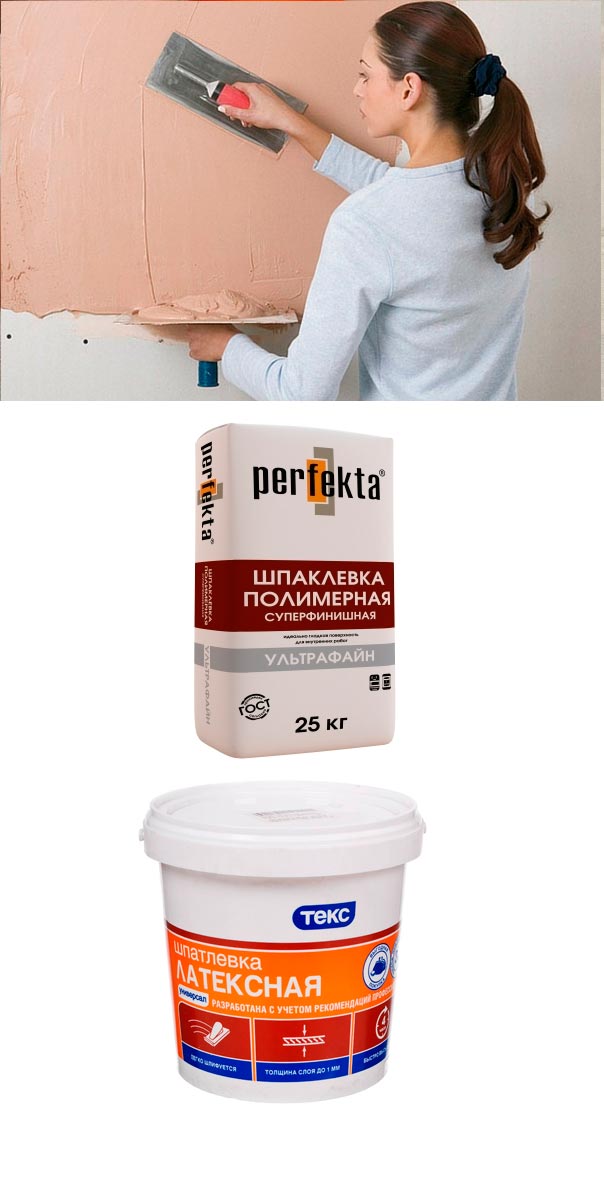

Latex

Latex acrylate mixture is one of the most demanded on the market.

Latex

But it should be borne in mind that latex putty is quite expensive. Usually, purchased packages contain twenty-five kilograms of putty.

Oil - glue

Oil and glue putty has been used for a long time. However, this method of application has not lost its properties today.

Oil and glue

If you allow the putty to harden for some time, the layer becomes very durable and of high quality. In stores, one packaging unit contains five hundred grams of putty.

PVA

Putty, which contains PVA, is usually used to finish those surfaces in which there is a risk of fungus or other bacteria.

PVA

You can buy the mixture in a hardware store in the form of a small bottle.

Best starter putty

This is the name of the mixture, which is applied as the first layer, and on top it is treated with a finishing putty and after that paint or wallpaper is used. Of the 10 options considered, the ratings included in this category have the best quality.

Danogips Dano Jet 5

Polymer putty mixture Danogips Dano Jet 5 is intended for leveling walls for wallpapering. A solution is prepared on its basis, which can be used within three days after that. To maintain its properties, the temperature in the room at this time must be at least + 13⁰С. The composition of the material includes marble fractions that reduce shrinkage and prevent the risk of microcracking. The composition is prepared quite simply by mixing water (0.28-0.31 l) and 1 kg of powder.

The finished mixture is homogeneous without much effort and can be applied both with a spatula and with airless devices. It is allowed to use the product within 5 minutes after the preparation of the components. It does not dry very quickly on the walls, within 24 hours, which allows, if necessary, to adjust the work results. Danogips Dano Jet 5 is used as a base coat in preparation for the application of the finishing filler. With its help, cracks in the walls are hidden, but there is no decorative function here.

Dignity

- Fairly white - 90%;

- Acceptable consumption of the working mixture - 1.2 kg / 1 sq. m;

- In the process of infusion, it does not thicken;

- It is not taken in lumps during finishing work;

- Does not require thorough surface preparation;

- Does not crack over time.

disadvantages

- Be sure to use sandpaper;

- The resulting coating is best treated with Dano primer.

The coating is made with a maximum thickness of 6 mm, due to which it is possible to achieve a smooth surface effect.

Volma Standard

This putty is based on gypsum and special additives that give the coating increased adhesion and resistance to cracking. It is available in 20 kg paper bags and requires dissolving in clean water with a temperature of +5 to + 20ºC. Powder consumption is quite economical - 1 kg per 0.45-0.55 l of liquid, with such proportions the mixture does not spread over the surface after application.

To create a smooth and durable coating, the finished composition must be mixed well with a drill with a nozzle or a construction mixer, and then kept for at least 3 minutes. The maximum time for applying the solution is 2 hours, after which it hardens and loses its astringent properties. The composition can be applied in a layer with a thickness of 1 to 8 mm, and if it is thick, then an h-shaped rule will be needed to align it.

Dignity

- Low consumption of the mixture - from 0.8 to 1.0 kg with a layer of 1 mm thick;

- Well hides cracks in the walls;

- Suitable for seams;

- Fits perfectly on the surface;

- Used for finishing concrete, plaster, plastered surfaces;

- The service warranty period is 1 year.

disadvantages

- The base must be thoroughly cleaned of dust, water, oil stains;

- The second coat should be applied immediately after the first.

Osnovit Econsilk PG35 W

Putty powder "Osnovit Econcilk" is designed for leveling ceilings and walls, sealing joints and small cracks in gypsum plasterboard sheets, in aerated concrete and brick foundations. It can be used wherever a thick coating is not required to give the surface a smooth finish. A solution is prepared from this starting mixture with the addition of water in proportions of 0.51-0.59 liters per 1 kg. This ratio guarantees the strength of adhesion to the base (≥0.5 MPa) and high resistance to mechanical and chemical stress.

Osnovit Econcilk PG35 W is suitable only for interior work, although the optimum operating temperature is from +5 to 40 ° C. This mixture is used to putty the surface for the subsequent creation of decorative coatings: wallpapering, painting, etc.The "viability" of the finished composition does not exceed 2 hours, during which it is required to fully develop it. Undiluted powder can be stored for up to six months in low humidity conditions.

Dignity

- Beautiful white color;

- Sold in three volumes - 5, 10 and 20 kg;

- The consumption of the mixture with a layer of 1 mm is not less than 0.8 l of the solution;

- Doesn't shrink over time;

- Plasticity of the material.

disadvantages

The next layer is applied 3-5 hours after the first one.

Reviews show that Osnovit Econcilk PG35 W putty is actively used for repairs in residential premises, but it is not suitable for baths and restrooms due to insufficiently high resistance to moisture.

No. 7. Major manufacturers of putties

The market for putties is oversaturated today - you can find a mixture of any composition, for any type of surface and, most interestingly, at almost any price. We all love to save money, especially when it seems that there is no difference at all between two similar products. When it comes to putties, saving does not seem such a sensible thing, because hardly anyone wants the putty layer to crack and fall off along with the paint after a few months. Trusting the products of large manufacturers is better:

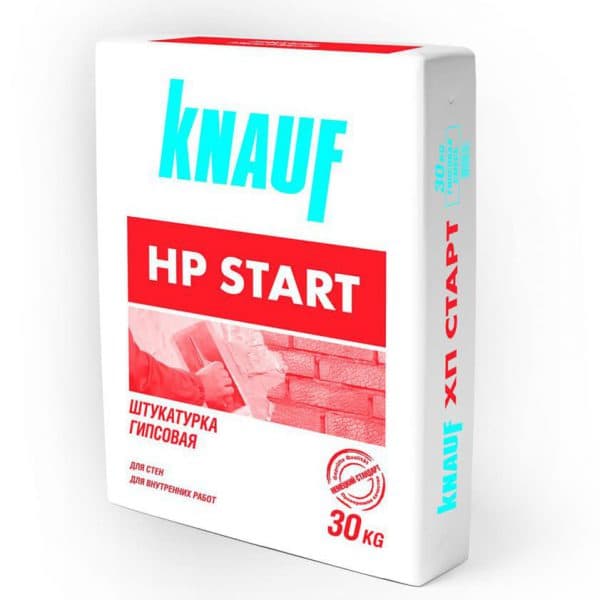

- Knauf is a large German company with factories located all over the world, incl. in Russia, which allows us to buy quality products at more affordable prices. Knauf putties are presented in cement, gypsum and polymer compositions, sold in dry and ready-made form. There are solutions for all areas of use. A special solution of the company is a gypsum plaster with components that protect against X-ray radiation;

- Ceresit is a product of a large concern that is very popular all over the world. Ceresit brand sells cement and polymer putties;

- Tikkurila is another well-known concern that produces putties, among other things. The company offers acrylic moisture resistant and gypsum compounds. Also in the assortment there is Euro Filler Light putty, which is distinguished by its ease of application and the absence of the need to sand - the surface itself becomes even. The color of the composition can be chosen from 15 offered. The company also offers Spakkeli wood putty, which is suitable for the treatment of doors, furniture and other wooden surfaces indoors;

- Vetonit offers polymeric, cementitious and organic bonded fillers. There is a composition that will not only align the seams on drywall, old painted surfaces and wallpaper, but also allow you to create a textured decorative surface;

- Kreisel is a German company with factories in 20 countries, incl. in Russia. Putties are represented by cement and gypsum compositions;

- "Prospectors" - home-made putties. The quality is not bad, the prices are reasonable. The assortment is represented by gypsum, cement, polymer-cement and polymer compositions, which are suitable for starting and finishing works in dry and wet rooms, as well as for outdoor work;

- Volma is another domestic manufacturer that has proven itself well. The range of compositions is very wide. There are gypsum and polymer putties with different particle sizes. There are solutions for any situation.

You can also recommend the products of "Ural building mixtures", "ARMstrong" and "Eurogypsum".

When buying, do not forget to inspect the integrity of the packaging, pay attention to the expiration date and, if desired, ask for certificates of conformity - any responsible manufacturer and seller should have them

Views

Putty materials are divided into types according to several criteria.

According to the composition, the following types of putties are distinguished:

- cement - the main component is cement and sand, and reinforcing fibers, gypsum, marble powder are used as additives;

- acrylic - based on acrylic polymer;

- acrylate - contains acrylic and latex;

- oil - the multicomponent composition includes drying oil, glue, acrylates, chalk;

- silicate - has a base of silicate liquid glass;

- silicone - the main component is silicone.

The most common composition is cement, as it has an affordable price and adequate quality. Cement-based putty is applied to all types of mineral surfaces: concrete, plaster, lime, gypsum and brick.

This composition has the following positive qualities:

- frost resistance - withstands more than 100 freezing cycles, operates at low temperatures from -60 degrees;

- strength and durability;

- fire resistance, refers to non-combustible materials;

- water resistance - resistant to atmospheric precipitation;

- environmental safety - contains natural mineral additives;

- good hiding power - it is able to close up base defects up to 1.5 cm.

Acrylic compounds are waterproof and do not crack. They create a durable elastic layer that can be further processed. Acrylic-based putties are only suitable for finishing with a layer of up to 50 mm, they are not able to fill deep irregularities due to their fine structure. When grinding, protection for the respiratory system is needed, since the composition is very dusty.

The addition of latex to the acrylate putty imparts increased moisture resistance, plasticity and durability. It is easy to apply and does not require pre-mixing with water. But the price for such a product is much higher than for cement compositions.

Oil putty is used for leveling wooden facade elements. It has its own peculiarities in application, which limits its use. The oil putty layer must be protected with oil paint, since the components do not tolerate high humidity. Putty in a thin layer up to 2 mm with multiple repetitions, which gives strength.

Silicate compounds fit well on aerated concrete, foam concrete, shell rock. Strict adherence to the application technology creates a protective vapor-permeable layer. Used as a decorative finish.

When using a silicone-based putty, a durable vapor-permeable protection is formed. The silicone layer repels dirt. There is a possibility of tinting in different colors, while the composition will be the final decorative layer on the facade. The high cost of the material becomes a limitation in application.

By purpose, the facade putty is divided into the following types:

- Basic. The granular structure is intended for leveling and restoring facades with cracks and dents up to 150 mm.

- Finish. Liquid fine structure is used for finishing with a layer of up to 0.4 cm.

- Decorative. With its help, they give various textured effects. A textured putty is used for the facade.

- Compositions for wood. For wooden structures, the vapor permeability index is important so that the outer layer of the putty does not delay the release of water vapor.

Depending on the readiness of the putty, two types of products are distinguished: dry mix and ready-made composition. Dry putty is in the form of a powder, which requires preliminary mixing with water to a certain consistency. After mixing, the components of the mixture react, ripening occurs, after which you can begin to putty. Available in bags from 5 to 30 kg.

The finished putty is a fully prepared product suitable for direct use on the surface. It only needs stirring the mixture until smooth. Ready-made polymer compositions are produced, which are poured into buckets from 2.5 kg.

Making a starting putty with your own hands

In the modern market of finishing materials, there is a huge assortment of various putty compositions, including basic varieties.However, in some cases, large hardware stores are not available.

In the modern market of finishing materials, there is a huge assortment of various putty compositions, including basic varieties.However, in some cases, large hardware stores are not available.

For example, when a house is being renovated, located somewhere in the rural outback. The table below shows recipes for making starter putties at home.

№

Name

Application area

Preparation

1

Gypsum-chalk

Leveling concrete and plasterboard walls in dry rooms

Mix 1 part gypsum and 3 parts chalk in a dry bowl. Gradually, while stirring, pour the mixture into a container with a 5% solution of wood glue and stir until smooth. Use immediately - the solution hardens quickly.

2

Oil

Wooden surfaces subject to temperature extremes (wooden facade cladding, window frames).

Mix 2 kg of chalk with 1 kg of drying oil, add 0.1 kg of desiccant and put the mixture on fire

Bring gently to a boil and cool. Use warm.

Rating of the best putties

The basis for compiling this TOP was customer reviews and advice from repair specialists. We have carefully studied them for safety, quality, versatility, ease of use of putties.

The following parameters were used in the selection of suitable nominees:

- Type of putty - starting, finishing, universal, decorative;

- Material type - polymer, gypsum, etc .;

- Available volumes for sale;

- Method of preparation - whether dilution with water is required or the filler is already liquid;

- Smell, texture and consistency of the finished solution;

- Suitable surfaces for processing - concrete, drywall, wood, glass, brick;

- The minimum and maximum possible layer thickness;

- Economical consumption;

- Setting speed on the base;

- Acceptable application method is manual and / or automated;

- Fraction color and size;

- The duration of the preservation of the astringent properties of the solution;

- Resistant to moisture;

- Purpose - work with seams, filling gaps, full coverage of walls and ceilings;

- The temperature of the composition, surface and air in the room, acceptable for finishing;

- Recommended operating conditions - inside and / or outside buildings, whether suitable for use in the bathroom.

Also, when selecting good putties for walls for wallpaper and paint, we paid attention to their shelf life, value for money, durability of the finished coating. Best glue guns

Best glue guns

How to properly putty the facade

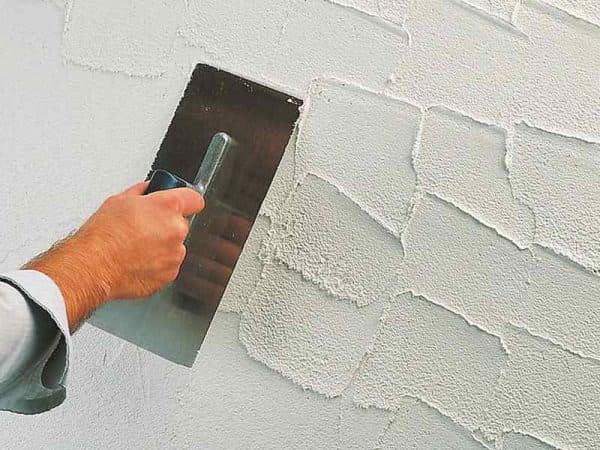

Let's make a reservation right away, there are two ways to putty the facade: manual and machine. The machine is used to work with large volumes to increase the speed of work. For a private house, of course, this is irrelevant. By the time you get used to the device, the facade will already be finished, and the material will take twice as much as with the manual method.

Therefore, it is advisable to apply the material on your own, using a spatula or a float. Regardless of the method of applying the material, first of all, the base must be prepared: the surface is cleaned of dirt, dust and oil stains, then the priming is performed, which is necessary to ensure the adhesion of the materials.

Ready putty material is mixed before work. If there are significant defects on the surface, they must first be eliminated by filling cracks and cracks with putty. After the patches are completely dry, a continuous layer of material can be applied. Multiple coats should be applied if necessary. It is recommended to sand the finished surface to achieve an excellent result.

Advice. Do not putty the facade in high humidity or in hot weather, when the surface is very hot - this greatly reduces the quality of the finish. Because the putty takes a certain time to dry.

Front putty consumption per 1m2

In order to correctly calculate the consumption of facade putty, you need to decide what composition of funds you are going to purchase. There are two options:

- Starting and finishing putty.

- Universal putty.

Consumption per 1m2 of starting and finishing putty

Starting putty is needed to seal cracks, level out small drops. Its consumption cannot be accurately calculated, since it is necessary to build on the state of the wall. But to grout a medium crack, you will need a layer of approximately 3-4 mm per square meter. Perhaps you won't have to cover all the walls with starting putty, so it makes sense to estimate the area of the putty.

The consumption of the finishing putty per square meter is less than the starting one. Largely due to preliminary priming of the surface. You can navigate by 1 mm.

Consumption per 1 m2 of universal filler

The declared consumption of universal putty by manufacturers is lower than the combination of starting and finishing putty separately. Usually, it is 1.5 kg per square meter for a layer of 1 mm. Manufacturers always indicate consumption on the package.

How many mm thick layer you need, everything will depend on the condition of the surface to be coated. Let's focus on the 2mm middle layer.

The universal putty is justified to use on more or less smooth and not prone to cracks surfaces.

Stages of work

It will be impossible to manage with one layer, even a qualified specialist will not be able to cope with such a task. The best temperature for outdoor work is from 9 to 20 ° C, the permissible air humidity should not exceed 80%.

The process of applying the putty is as follows:

The surface is cleaned of excess dirt and old finishes. A primer is placed on the cleaned surface; it must dry before starting the further operation. It is better to prime the surface in two layers. Next, depressions, dents, and cracks are removed. After which the material is allowed to dry out. The putty is applied evenly to the walls, and then gently leveled. As improvised means, it is better to use two metal spatulas of different sizes and a construction float.

Functions and features

The finishing putty is a dry mixture that is used for the highest quality leveling of the walls. In addition, thanks to this solution, you can quickly hide small defects in the wall surface and increase the strength of the leveling layer.

A distinctive feature of the finishing putty is that it includes special components that ensure the plasticity and ease of use of the material.

Among the main advantages and distinctive characteristics of the finishing putty are the following:

- Impressive adhesion properties, thanks to which the mortar adheres firmly to the wall surface.

- The putty is free from lumps and other flaws that are inherent in other mixtures.

- Ease of use. Any person who has not previously carried out any finishing work can handle the application.

- No cracks appear on the surface after drying.

- The ability to apply high-quality paint that will lay evenly.

The application of a conventional building mixture is the initial stage of finishing work to improve the condition of the wall covering, but the use of the finishing is the final stage of finishing, the purpose of which is to increase the strength characteristics of the wall.

Views

Plaster.

This type of putty practically does not shrink and evens the surface well. Since the color of such a mixture is always white, it hides dark spots well. The disadvantages include high moisture permeability, therefore, it is used only for finishing dry rooms. Suitable for drywall, plaster, concrete base.

This type of putty practically does not shrink and evens the surface well. Since the color of such a mixture is always white, it hides dark spots well. The disadvantages include high moisture permeability, therefore, it is used only for finishing dry rooms. Suitable for drywall, plaster, concrete base.

Cement.

An inexpensive, fairly plastic mixture made on the basis of white cement, not afraid of moisture, which is often used as a topcoat in bathrooms, toilets and outdoor work.Unlike the starting cement putty, it does not contain sand, and the size of the fractions does not exceed 0.2 mm. However, its graininess is still higher than that of acrylic or gypsum compounds, so the surface after puttying turns out to be less smooth.

An inexpensive, fairly plastic mixture made on the basis of white cement, not afraid of moisture, which is often used as a topcoat in bathrooms, toilets and outdoor work.Unlike the starting cement putty, it does not contain sand, and the size of the fractions does not exceed 0.2 mm. However, its graininess is still higher than that of acrylic or gypsum compounds, so the surface after puttying turns out to be less smooth.

The disadvantages include the tendency to shrinkage and cracking. Due to its high strength, the surface should only be sanded semi-dry after its application - after complete drying it will be impossible to do this.

Polymer (acrylic, latex).

Both of these compositions are largely similar due to the content of polymer components. But:

Both of these compositions are largely similar due to the content of polymer components. But:

- Latex is stronger and more durable; it is less prone to cracking than acrylic, gives a perfectly flat surface and improves adhesion (adhesion); such a putty is very economical - it is allowed to apply it in the thinnest layer less than a millimeter; used mainly before painting; high-quality putty with a similar composition is vapor-tight, does not require intermediate priming and sanding; can be used for the restoration of wooden surfaces with further varnishing; the disadvantages of latex putty include, perhaps, the high cost and the inability to use at low temperatures due to a decrease in elasticity;

- The acrylic surface is strong enough, does not absorb moisture, is resistant to low temperatures, it is impossible to wash it, unlike gypsum, therefore acrylic is widely used not only for interior, but also exterior decoration; similar to liquid rubber, has good adhesion, however, it is undesirable to apply too thin a layer, so it will be less durable.

Polymer compositions fit well on any substrate, be it aerated concrete, plaster, wood or drywall.

Types of finishing putty

For the final putty, polymer, acrylic, cement and gypsum mixtures are used, each of which has its own advantages and disadvantages. Let's consider them in more detail.

Cement

Cement mixes are the simplest and cheapest, but also the most popular option for finishing wet rooms, such as kitchens, bathrooms and toilets. Also, this material can be used before painting the walls in the entrances and in the decoration of facades. A cement-based mixture is not afraid of moisture, it makes the coating durable, strong and resistant to various external factors. As disadvantages, there is a high risk of microcracks and shrinkage of the mixture after drying. It is necessary to sand the cement putty before it is completely dry, after drying it will be almost impossible to do it.

Gypsum

Gypsum plaster provides an even white surface and masks dark spots on the walls, so it is ideal for light, thin or textured wallpapers.

Gypsum can be applied to walls in a layer thicker than 2 mm, it is best used for finishing dry heated rooms, bedrooms, corridors and rooms where decorative coating is expected.

Gypsum compositions for puttying are characterized by low waterproofing and water-repellent properties, which somewhat limits the scope of application. However, such disadvantages are offset by ease of use and affordable material cost.

Polymer

For beginners in repair, a polymer finishing putty will be the best option - a ready-made mixture will not make you worry about how to correctly make a solution of the desired consistency. The material is produced ready-made, so it only needs to be thoroughly mixed, after which it can be applied to the walls with a thin layer. This type of putty creates a perfectly smooth plane on any surfaces, but the high cost of the material is a significant disadvantage, especially when processing large rooms.

The polymer mixture adheres well to the wall and reliably adheres to the surface.Superfinish mix has the finest structure and is considered the best option for decorating walls and ceilings where delicate decorating work is required. The material based on polymers does not shrink, eliminates the possibility of cracking, is highly plastic and moisture resistant, and also guarantees a long service life of the final finish.

The surface texture after the application of the polymer putty depends on the particle size - the smaller the particles, the smoother the finish layer. Superfinish mixtures consist of fractions with a diameter of up to 0.15 mm, which allows you to create a mirror-smooth surface structure.

The importance of alignment

It's amazing, but many people sometimes sincerely ask the following 2 questions: “why align the walls under the wallpaper? " and "do i need to prime the walls before gluing the wallpaper? ". Imagine a situation when brand new wallpaper is safely glued to the wall - and the owners meticulously examine the result. The drawing is slightly skewed in several places, in others it perfectly reflects the features of the relief of the capital surface. "Just think, completely imperceptible! " - the owners will say and take up their favorite things. And soon they will be rearranging furniture in the apartment and, too intensively pushing the chair against the wall, pierce the freshly pasted wallpaper. Who knew that there was a hole in this place, you ask. And we will answer: the owners knew - but they did nothing about it. So, puttying is mandatory in cases where there are irregularities, depressions, depressions, cracks or any other defects that can later spoil the impression of the repair results. It should be understood: if the walls in your room are dancing pretty well, allowing discrepancies at different points more than 3 centimeters, do not expect anything good even from the most spectacular wallpapers. They will: