Peculiarities

Aligning the walls is an essential part of a major overhaul. To make high-quality work on leveling the surface, you will need a starting and finishing putty.

Finishing is used for the final stage of leveling the walls and creates a perfectly flat and white surface. Although a wide range of putties from different manufacturers is presented on the modern construction market, many buyers prefer the products of the German company Knauf.

This brand offers ready-made blends that are convenient and easy to use. Ease of work is an indisputable advantage. Anyone can make perfectly smooth walls using Knauf putties, without having any special knowledge or skills. It is sold in paper bags. The large package contains about 25 to 30 kilograms of the mixture for ease of use.

The Knauf finishing mix includes cement, gypsum and lime. After its application, it is not necessary to use additional mixtures for grouting the surface. This mixture is used as a ready-made fine finish. It is enough to read the instructions, stock up on the necessary tools and you can go to work.

Knauf on the packaging of each product indicates its characteristics, as well as the expiration date. On the putties, the maximum permissible layer thickness is always marked. The warranty period for it is only one year. The mixture should be stored in dry and dark rooms in a closed container. If the package has already been opened, then it must be used within 24 hours, otherwise the material will become unusable.

Best starter putty

This is the name of the mixture, which is applied as the first layer, and on top it is treated with a finishing putty and after that paint or wallpaper is used. Of the 10 options considered, the ratings included in this category have the best quality.

Danogips Dano Jet 5

Polymer putty mixture Danogips Dano Jet 5 is intended for leveling walls for wallpapering. A solution is prepared on its basis, which can be used within three days after that. To maintain its properties, the temperature in the room at this time must be at least + 13⁰С. The composition of the material includes marble fractions that reduce shrinkage and prevent the risk of microcracking. The composition is prepared quite simply by mixing water (0.28-0.31 l) and 1 kg of powder.

The finished mixture is homogeneous without much effort and can be applied both with a spatula and with airless devices. It is allowed to use the product within 5 minutes after the preparation of the components. It does not dry very quickly on the walls, within 24 hours, which allows, if necessary, to adjust the work results. Danogips Dano Jet 5 is used as a base coat in preparation for the application of the finishing filler. With its help, cracks in the walls are hidden, but there is no decorative function here.

Dignity

- Fairly white - 90%;

- Acceptable consumption of the working mixture - 1.2 kg / 1 sq. m;

- In the process of infusion, it does not thicken;

- It is not taken in lumps during finishing work;

- Does not require thorough surface preparation;

- Does not crack over time.

disadvantages

- Be sure to use sandpaper;

- The resulting coating is best treated with Dano primer.

The coating is made with a maximum thickness of 6 mm, due to which it is possible to achieve a smooth surface effect.

Volma Standard

This putty is based on gypsum and special additives that give the coating increased adhesion and resistance to cracking.It is available in 20 kg paper bags and requires dissolving in clean water with a temperature of +5 to + 20ºC. Powder consumption is quite economical - 1 kg per 0.45-0.55 l of liquid, with such proportions the mixture does not spread over the surface after application.

To create a smooth and durable coating, the finished composition must be mixed well with a drill with a nozzle or a construction mixer, and then kept for at least 3 minutes. The maximum time for applying the solution is 2 hours, after which it hardens and loses its astringent properties. The composition can be applied in a layer with a thickness of 1 to 8 mm, and if it is thick, then an h-shaped rule will be needed to align it.

Dignity

- Low consumption of the mixture - from 0.8 to 1.0 kg with a layer of 1 mm thick;

- Well hides cracks in the walls;

- Suitable for seams;

- Fits perfectly on the surface;

- Used for finishing concrete, plaster, plastered surfaces;

- The service warranty period is 1 year.

disadvantages

- The base must be thoroughly cleaned of dust, water, oil stains;

- The second coat should be applied immediately after the first.

Osnovit Econsilk PG35 W

Putty powder "Osnovit Econcilk" is designed for leveling ceilings and walls, sealing joints and small cracks in gypsum plasterboard sheets, in aerated concrete and brick foundations. It can be used wherever a thick coating is not required to give the surface a smooth finish. A solution is prepared from this starting mixture with the addition of water in proportions of 0.51-0.59 liters per 1 kg. This ratio guarantees the strength of adhesion to the base (≥0.5 MPa) and high resistance to mechanical and chemical stress.

Osnovit Econcilk PG35 W is suitable only for interior work, although the optimum operating temperature is from +5 to 40 ° C. This mixture is used to putty the surface for the subsequent creation of decorative coatings: wallpapering, painting, etc. The "viability" of the finished composition does not exceed 2 hours, during which it is required to fully develop it. Undiluted powder can be stored for up to six months in low humidity conditions.

Dignity

- Beautiful white color;

- Sold in three volumes - 5, 10 and 20 kg;

- The consumption of the mixture with a layer of 1 mm is not less than 0.8 l of the solution;

- Doesn't shrink over time;

- Plasticity of the material.

disadvantages

The next layer is applied 3-5 hours after the first one.

Reviews show that Osnovit Econcilk PG35 W putty is actively used for repairs in residential premises, but it is not suitable for baths and restrooms due to insufficiently high resistance to moisture.

How to apply the putty correctly

Before applying any type of finishing putty, the surface should be carefully prepared. Before applying the mortar, it is necessary to make a primer. This will eliminate the presence of moisture in the base coat. If you skip this step, the likelihood of mold formation will increase several times. The acrylic primer is applied using a roller.

To complete the work, you will need the following tools:

- Putty knife. It is better to use spatulas of different widths.

- Level.

- Plumb line.

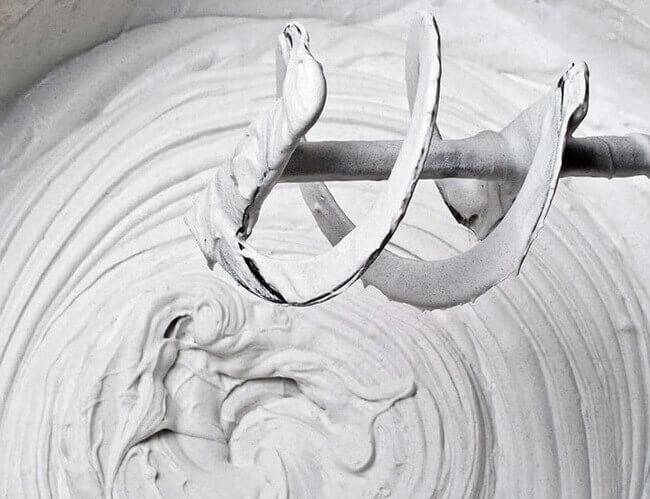

- Mixing tools. The ideal option would be a mixer or a drill with an attachment.

- Sandpaper for sanding walls.

- Mixture dilution container

- Separate tray.

Before preparing the solution, carefully read the instructions. Add the required amount of water. Next, stir the mixture well until a homogeneous mass is obtained. A small amount of the mixture is placed in a separate tray. Cover the rest to avoid drying out.

Stir the solution frequently and thoroughly. When the mixture is ready, you can start finishing. For wall application, use a narrow trowel. With a wide spatula, you can evenly distribute the material around the perimeter of the surface. There can be several layers.The process is laborious and painstaking, but the paint fits well only on perfectly aligned walls.

After the finishing putty is dry, you can safely start sanding. Usually the walls are sanded with sandpaper. This should be done manually. The grit size of the sandpaper should be P220-P280. Avoid using high grain paper.

For clarity, you can study the videos available on the Internet. This will help you understand the technology of applying the material and the fineness of grinding.

Professional finishers are more likely than others to work with a finishing putty. They know all the intricacies of the choice and use of material.

Here are some tips from the pros:

- The thickness of the finishing filler should be no more than 2 mm (maximum 3 mm).

- Each new layer of putty must dry completely.

- If light colors are chosen for decoration, then the thickness of the finishing layer should be greater.

- It is possible to process the surface using sandpaper only after it dries out (no earlier than two hours later). The waiting time depends on the composition and the manufacturer's recommendations.

After the walls are perfectly flat, they must be treated with a primer. Before painting, dry and sanded walls are recommended to be viewed in daylight. You can also use any lighting fixture

Putties according to the degree of readiness

According to this parameter, 2 types of wall putties are distinguished: dry mixes and ready-to-use. They are different, so let's take a closer look at their features.

Dry

Looks like ingredients put together in the right proportions. The solution itself is prepared before starting construction work. These types of putties are sold in bags, which indicate the expiration date and instructions for preparation.

Most often, dry mixes are used in puttying. To obtain a high-quality putty material, you should strictly follow the preparation instructions and adhere to the proportions of the components and water. When working with a large area, it is not recommended to immediately harvest a large volume of mixture. This is explained by the fact that after a certain time the plastic properties of the composition are lost, and it begins to "set". Several batches are recommended.

There are practically no drawbacks, except that the dry powder leaves behind dust, the mixture itself does not retain its properties for long after mixing and requires clear proportions during preparation.

Ready-to-use putties

The convenience here is that they do not need to be prepared - they are ready-made, for which special factory technologies are used. An additional advantage is that they, in comparison with dry mixes, do not lose their properties after a certain time. If necessary, in the course of work, a break is simply made, and the container in which the mixture is stored is closed. Thanks to the component that does not allow the mixture to set, it retains its properties for a long time. First, the first layer is applied, after it dries - the second, with a finishing putty. The only thing is that the cost of ready-made mixtures is higher compared to dry ones, but in the process you will not have to fiddle with dust and dirt.

Manufacturers

At present, a relatively large selection of gypsum putty can be noted, but not all of it is popular and of high quality. Unfortunately, all materials produced in Russia and the CIS are of very dubious quality at an unreasonably high price.

Some of the best putties are Knauf products, produced in various modifications. Often, when requesting "gypsum plaster", a photo of the products of this company comes out. But there is no classic starting product in their assortment, but there are finished products (after opening the bucket, you can start puttingty) for each of the goods in the assortment.

Ceresit putties, produced as starting and front ones, have proven themselves quite well.Perfectly combined with Knauf products. Also, some types of putty are produced by the well-known company Tikkurila, but it is known for its paints. But the putty of this company is of high quality.

The Polish firm Alpol, specializing in bulk materials, presents a starting (S20) and finishing (S22) putty. Almost all builders who can buy this company prefer it. But since Alpol does not produce universal, another Polish manufacturer, Acryl Putz, gained its popularity in the segment of universal gypsum putty and rightfully occupies its own niche.

Rating of the best putties

The basis for compiling this TOP was customer reviews and advice from repair specialists. We have carefully studied them for safety, quality, versatility, ease of use of putties.

The following parameters were used in the selection of suitable nominees:

- Type of putty - starting, finishing, universal, decorative;

- Material type - polymer, gypsum, etc .;

- Available volumes for sale;

- Method of preparation - whether dilution with water is required or the filler is already liquid;

- Smell, texture and consistency of the finished solution;

- Suitable surfaces for processing - concrete, drywall, wood, glass, brick;

- The minimum and maximum possible layer thickness;

- Economical consumption;

- Setting speed on the base;

- Acceptable application method is manual and / or automated;

- Fraction color and size;

- The duration of the preservation of the astringent properties of the solution;

- Resistant to moisture;

- Purpose - work with seams, filling gaps, full coverage of walls and ceilings;

- The temperature of the composition, surface and air in the room, acceptable for finishing;

- Recommended operating conditions - inside and / or outside buildings, whether suitable for use in the bathroom.

Also, when selecting good putties for walls for wallpaper and paint, we paid attention to their shelf life, value for money, durability of the finished coating. Best glue guns

Best glue guns