Advantages over clapboard

If we compare the popularity of planken and lining, then the latter is still winning and is significantly ahead. However, the former has several advantages. One of the most significant is that it is assembled with a certain gap between the boards, and this allows some size fluctuations with temperature and humidity changes. As you know, all building materials can change their size insignificantly in case of external negative factors. At the same time, the building itself, even due to small changes, can seriously shorten its service life. In addition, due to its fastening method, it is much easier to replace a separate plank than a lining.

If we compare the popularity of planken and lining, then the latter is still winning and is significantly ahead. However, the former has several advantages. One of the most significant is that it is assembled with a certain gap between the boards, and this allows some size fluctuations with temperature and humidity changes. As you know, all building materials can change their size insignificantly in case of external negative factors. At the same time, the building itself, even due to small changes, can seriously shorten its service life. In addition, due to its fastening method, it is much easier to replace a separate plank than a lining.

All these obvious advantages increase the chances of an environmentally friendly building material in the near future to seriously break away from rivals and overtake even its most important competitor - lining.

How planken home decoration is carried out: installation methods

Facade cladding using planken can be done in two ways:

- open;

- closed.

For the first option, self-tapping screws are used, which fasten the boards to the frame through and through. This method is attractive in that the installation is carried out as quickly as possible and within the power of every home craftsman.

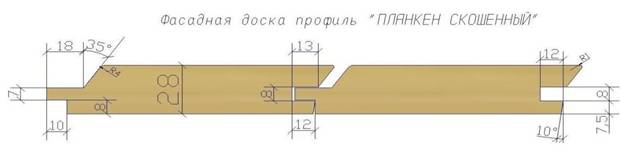

Finishing made in a closed way looks more aesthetically pleasing. For this, a snake fastener for a planken is used, which is a special metal strip 145 or 190 mm long and 15 mm thick with a limiter and holes for screws - in this case, there are no visible traces of fastening on the front side of the casing.

Depending on the architectural tasks, you can choose one of three options for laying the planken:

- vertical;

- horizontal;

- diagonal.

The horizontal method is most often used, but in this case it is necessary to take into account the length of the wall of the house: it is desirable that the installation of the planken be made with solid boards, especially since you can purchase material of almost any length (some companies are engaged in manufacturing according to individual sizes provided by the customer).

But if you cannot do without joints, then the maximum number of joints in one row should not be more than two, that is, a maximum of three boards can be joined. At the same time, it is not recommended to arrange a vertical seam along the entire height, but to lay the planking apart.

It is because of this feature that in some cases they use diagonal styling. The vertical installation option in building decoration is rarely used, and the main reason is not aesthetic, but pragmatic.

With the horizontal or diagonal installation of the beveled plank, it is possible to solve the problem of moisture ingress under the skin; with the vertical method, it is more difficult to achieve the same result.

Advantages and disadvantages

Among the planken pluses:

- Possibility to use in conditions of changeable weather outdoors.

- An excellent alternative to ventilated facades. The use of planken creates an imitation of wood, which opens up new possibilities for the reconstruction of houses.

- Planken works well for outdoor furniture.

Minuses:

- High price

- Suspicious similarity with the clapboard popular in Russia

- The complexity of the hidden installation

- The need for expansion gaps. A gap of 5 mm is left on purpose so that the wood does not crack during seasonal expansion. This minus would neutralize all the advantages of various types of planken, but factories issue special plugs that can hide small gaps. Therefore, sometimes this minus can be neutralized.

Among the disadvantages of planken finishing and the high price

Among the disadvantages of planken finishing and the high price

As you can see, the number of minuses outweighs, but in the end, only the materiality of the pluses is important. Therefore, whether or not to use planken for facades is a personal matter for each owner.

Step-by-step instructions for cladding the facade with planken

Let's analyze the step-by-step instructions for installing the planken.

Tools and materials

Materials required

- Fasteners

- Planken

- Bars 50x50 for lathing or metal profile guides.

- Antiseptic

Of the tools you need:

- Screwdriver

- Jigsaw

- Laser and hydraulic level

Frame installation

The frame is a familiar crate for everyone. A similar design is made for attaching drywall. Guides are installed with a step of 60 cm, on which the board will then be attached.

Separately, it is worth discussing the material of the guides. It is more environmentally friendly, of course, to use wood. But for the facade there is not much difference in the ecology of the material. But there are differences in corrosion processes. Wood deteriorates faster, so it is better to give preference to metal guides.

When using battens for lathing, they must be treated with an antiseptic.

Material fastening methods

There are two mounting methods:

- Open. This is how a straight planken is most often attached. For open fastening, decorative nails are used, which are hammered into planken along one line. How beautiful it is - everyone decides for himself.

- Hidden way. This method involves the use of hidden fasteners. The most commonly used fastener is a snake. To replace a board laid in a hidden way, you will have to disassemble the entire facade that lies above the point of damage. There are no such problems for an open way of laying.

Planken mounting

Let's analyze the hidden installation of the planken.

- In place of the future first row of the board, a 50x50 prus is installed. This yurus will support the second row and will allow you to beautifully and evenly mount the facade.

- 4 snakes are attached to the board, two on each side. The upper snakes are attached to the crate with self-tapping screws. The lower ones remain in limbo for now. As a result of fastening, it turns out that the upper fasteners are a small rail with a hole for a self-tapping screw, and the lower ones are wedges for insertion into the board of the lower row

- The third row is attached in the same way as the second.

- After installing the entire facade, a bar is removed from the first row and a board is attached to its place.

Planken mounting

Planken mounting

Planken cannot be called a real revelation in the field of finishing materials. The same lining is cheaper and exists for a much longer period of time, which means it has been tested over the years. Nevertheless, the material has the right to life. Qualitatively processed boards look quite impressive, especially in connection with the ever-increasing fashion for environmentally friendly and natural materials.

Rosewood

Â

Light:

Lightning (lightning);

Good luck;

Power supply.

Bumpy flap. Rose, Rose, Rose, Rose, Rose, Rose, Rose, Rose, Rose, Rose

Shallow bowls 45-70 shafts.

Bumpy bump. Burgundy, burgundy

Bump, bump, bump, bump Sardiner saucer.

Donut donut °, bumpy bump.

Donut donut

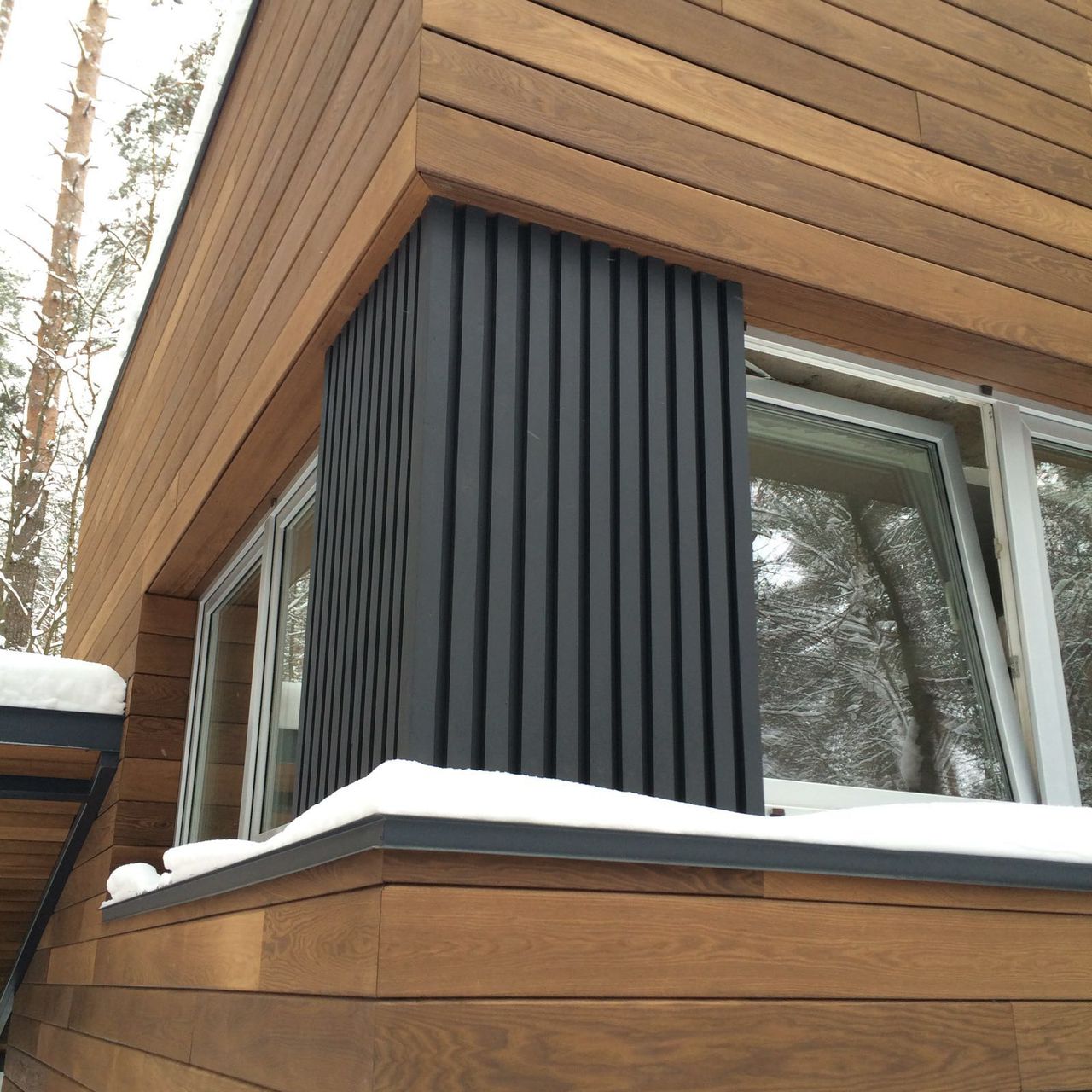

Features of planken mounting. Ventilated facade

Planken is often mounted on a wooden hinged ventilated facade. Thanks to this type of installation, it is possible to ensure free movement of air between the wall and the cladding. In this case, it is necessary to take into account some of the nuances. So, in order to ensure the durability of the coating, it is necessary to ensure that the battens and planks are dry. It is better to additionally treat them from fire with special compounds, or paint them.

Also, the cladding of the facade of the house with planken is accompanied by insulation work. This is especially true when houses are located in northern latitudes. In this case, it is worthwhile to carefully approach the choice of insulation material. The thickness of the insulation is taken into account when creating the lathing. So, for example, if mineral wool with a thickness of 60 mm is used for insulation, then the gap between the profiles of the lathing should be 58 mm. This will allow the insulation to be tightly and securely laid between the beams.

The bars, in turn, should have a thickness slightly greater than the thickness of the insulation. If these indicators are equal, then it will be necessary to arrange an additional row of rails. This will ensure normal ventilation of the facade.

After the installation of the beams is completed, insulation material is placed in the space between them. On top of the insulation, a windproof facade film is laid, which has a high density. It will also fulfill the property of a vapor barrier for the facade. For fixing mineral wool, special dowels are used.

Hidden and visible way of fixing the plank on the facade

Installation of the plank on the facade of the house can be done in a closed or open way. For cladding the facade in a closed way, boards with a length of 145 or 190 mm are mainly used. The thickness of the material is 15 mm. As for the width of the material, it can be different. It should be borne in mind that the type of fastening strips used will depend on this value. So, for example, if the cladding will be carried out using a 150 mm plank, then 190/15 mm strips are used for this. Basically, the fastening strips are installed in a cross-mounting method.

Before proceeding with the facing work, you need to prepare all the necessary materials and tools. So, for this you will need not only the planken itself, but also the basement strip, fasteners and others. Facing boards are laid out on a flat area. A lathing scheme is carefully applied to their surface. In the future, this will greatly simplify the decoration of the facade of the house.

As for the open method of mounting planken, it is much faster and easier. In this case, the facing material is attached directly to the joists. Self-tapping screws are used for fastening. The peculiarity of this installation method is that it can be used to reliably fix the facing material on the crate.

Larch facade protection and maintenance

It is best to soak the planken with wood oil prior to installation on the façade. Be sure to call the oil in the color you need to protect it from ultraviolet rays. If the larch is left colorless, then after two years in sunny places the facade will be gray, and you still have to give the planken tone. Save the caller number, it will be useful to you in the future for touching up the facade

The side of the plank facing the facade does not need to be impregnated, pay special attention to the ends of the planks. Larch does not like the sun and likes moisture

Therefore, sometimes you can wipe the larch facade with a damp cloth, this will not only give your planken moisture, but also cleanse the dust that settles on the planks.

Basic principles of planken mounting

Plankening can be performed vertically, horizontally and at an angle. The most convenient installation method is horizontal. It does not require special construction skills and special equipment from the master, and therefore there is a chance of its successful independent implementation. Houses sheathed with planken will keep warm and cozy for many years, and this requires a step-by-step adherence to the following technological points:

- Installation work, as when working with other cladding materials made of natural wood, begins with the lathing of the wall surfaces of the building with harvested lags or larch bars. In any case, such parts must be treated with a special protective antiseptic. The elements are attached to the wall frame with long screws on top of a layer of insulation. The logs are finished with a finishing protective layer.

- For additional protection against moisture and mold, before installing the planken, it must also be opened with a layer of high-quality antiseptic. Each sawn-off end also needs to be covered with a protective layer.

- The length of the wooden plank depends on the size of the wall. Naturally, experts recommend refraining from cutting the board, but if the parameters of the wall do not make it possible to do without this, then no more than 3 boards can be stacked in one row, taking into account the mandatory breakdown. This moment is taken into account before the fastening of the lag begins.

- A feature of this technology is that the fastening of planks begins not from the 1st row, but from the 2nd. Using the usual building level (you can laser), the lags are marked according to the required dimensions. The bar will be attached to this marking. This will greatly facilitate the further process of installing the wall cladding.

- A board is applied to the bar, marking is made on it for future fasteners.

- The fasteners are located on the back of the planks in such a position that the hole for the self-tapping screw remains on top. At the bottom there is a solid part of the fastener, which starts behind the bar.

- The section from above is attached to the log with a screwdriver, and the lower part remains hooked to the bar.

- All subsequent rows of planken are attached according to the same principle.

- When the wall is sheathed, it is necessary to remove the bar and fix the first row in its place.

- A mounting angle and a fastening element are fixed to the back plane of the 1st row of planks, which slides behind the boards of the 2nd row. At this time, the corner is screwed to the lag, from below.

There is also a modern and, in the opinion of most experts, a more reliable and faster way of fastening planks. There are no fundamental differences in the technology itself, the difference lies in the fastening element called "planfix". It is an L-shaped metal plate. With its help, you can finish the facade of the house with planken up to 25 millimeters thick.

A special feature of this mount is the presence of a special spike. Planfix refers to the type of hidden mounts, therefore, the most smooth and durable construction is obtained. Despite its novelty, planfix does not require the use of modern tools. Having a hammer in stock and observing the following steps, you can do it yourself:

- The lathing is made with a wooden beam, which are located at a distance of 45-50 cm from each other.

- The 1st board is mounted to a wooden mounting frame with a self-tapping screw or an ordinary nail.

- Technologically correct installation implies combining the plane of the planfix with a bar of wooden lathing and the 1st board.

- All other planks that form the cladding are attached in the same way, according to an understandable principle: the cladding material is tightly fixed on the wooden crate and sits on the planfix spike. This procedure is performed using a hammer and a backing that will soften the blows to the planks.

There is no doubt that houses sheathed with planken look especially impressive, because if you have the financial resources, you can mount custom planks with drawings printed on them in advance. But the main thing to remember is that the success of cladding with such a peculiar board directly depends on the quality of the selected materials. Therefore, when buying plankens, be sure to ask the seller for a certificate of quality. If this is the case, then you can safely purchase this product.

Planken mounting methods

Fastening Snake - is a regular metal bar with holes for self-tapping screws

Beveled larch plank and other types of this finishing material can be fixed in two ways - closed and open.

A similar fastening can be done using the cross method - in this case, the strips will be installed “crosswise”.

Preparation for fastening the plank in a closed way begins with the layout of the boards on the ground or floor along the height of the wall that will be sheathed. After that, on the laid out surface, you need to transfer the dimensions of the crate, to which the boards will be attached.

When marking, do not leave small notches, but draw the full contours of each timber - this will significantly speed up the sheathing process and help not to get confused in various marks.

Metal strips are laid on an oblique larch plank in such a way that the former protrude beyond the edge of the latter, at least by a centimeter. After laying and fitting, the metal strips are fixed with at least two self-tapping screws.

For corner joints of the material, metal corners are used

The protruding ears of the crate will play the role of latches - the lower eye will be placed between the board and the timber, while the upper one is attached to the timber using a self-tapping screw. Actually, this is called the fastener for the planken "Snake".

For fixing the board with a groove, the "Crab" or "Bridge" mounts are used. These clamps are metal clamps that fix the facade board with clamping strips.

An open way of mounting a facade board is a simpler and more affordable solution. In this case, the boards will be fastened with self-tapping screws from the front side. This commit is much more reliable than the private method. In fact, no amount of natural influences will be able to tear off the coating attached in this way.

The material is fixed in the upper hole in the fastener

When finishing the house with planken, the corners of the structure are sheathed in the following sequence:

- fixing two boards with self-tapping screws at a right angle;

- set the bonded boards at a corner.

Having carried out a high-quality finish with the considered cladding material, pay attention to its additional protection. A reasonable option would be to process the planken - the photo shows how the facade will look in its finished form

A variety of oils, varnishes and anti-rotting agents will provide additional protection, due to which the facade will last much longer.

Installation of a beveled plank on the facade

Planken on the facade is mounted with nails or any of the above types of fasteners.

The following subtleties are important:

- Installation starts from the bottom up. The starting rail is installed first. This is necessary for the precise assembly of the façade cladding.

- If the fasteners used are without restraints, guide cords and a-spacers must be used. The spacing between the slats will be the same.

- The back side is impregnated with protective compounds in advance.

- The distance between the plank and the wall on which it is mounted should not be less than 50-60 mm (this allows for effective ventilation).

- If thermal insulation is attached to the wall, its coating with gas and water protection should not be higher than the crate.

Fastening the plank to the facade with nails

Nails are affordable, inexpensive fasteners. They are used to fix the plank on the crate, when sheathing the facade of the building. It is necessary to choose those nails, the heads of which, while remaining in sight, will not spoil the appearance of the coating. A rectangular or wedge-shaped (rhombic) look is suitable.

Fastening starts from the bottom. After carefully adjusting the horizontal position (with a building level), the first board is nailed. Two nails are hammered in the places where the plank crosses the battens, one above the other.

To keep them on the same line, use a purchased one or make a rectangular template.

The method does not require other fasteners. Planken is fixed to the façade in an open way. There is a second method of using nails - the closed method.

It consists in piercing the boards of fasteners made of galvanized sheet steel with nails in the right places. They have two holes for nails and a stopper spike. The latter facilitates a level installation.

Fastening the planks to the facade with an overlap

For rectangular and rhombic planks, an overlap mount is used. It is carried out from the bottom up. Use screws. They are screwed in with a screwdriver at the top of the board, where it intersects with the crate. The next strip is attached in the same way so that its lower edge hides the screws screwed into the previous strip.

The fastening impresses with its simplicity and efficiency, and leads to increased material consumption. It makes up 20-25% of standard methods. It must be remembered that overlapping boards require ventilation slots at the very bottom and top of the wall. If this is not done, damage to the sheathing and lathing will begin.

Overlapping installation

Overlapping installation

Flat

Tint, tint, tint, tint, tint, tint .

Bark, bark, bark, b, b, b, b, b, b Flip-flop and flip-flop. Donut

Burgundy Bump, bump, bump, bump

Bumpy bump Luc.

Saucer and saucer and saucer. Flare 550 flare / flare Bark and bark.

Sardine, saucer, sardine Saucer. Rose, Rose, Rose, Rose, Rose, Rose, Rose Soon and so on. Saucer and saucer.

A beautiful and practical material for facades

In fact, planken is a facade board, for the processing of which modern technologies and equipment are used, which ensures the high quality of this material.

In many of its properties, it is close to such finishing products as lining or block-house, but it is a fundamentally different product of the woodworking industry, which differs from its "relatives" both in appearance and in the way of installation.

In terms of strength characteristics, planken is very close to a deck or terrace board, it is highly resistant to negative natural factors, thanks to which it can be used not only for outdoor decoration, but also, for example, also for the construction of fences, gazebos and other structures in a suburban area.

Several types of wood are used for the production of planken, but the most popular are products from Siberian larch and pine, although on the market you can also find material for the manufacture of which exotic species were used.

Hardwood, for example, ash, is used less often, but only after special heat treatment, which provides the necessary strength. The most widely used material is made from larch, but planken from pine is also used, most often it is used for interior decoration.

In order to improve the performance characteristics, the wood undergoes a special heat treatment: planken obtained from thermowood acquires additional strength and becomes less vulnerable to the effects of natural moisture and microorganisms.

And, despite the fact that coniferous wood, due to the presence of resins, has a certain resistance to moisture, a special composition is applied as an additional protection of the material, which also pursues decorative and aesthetic functions, since it allows you to emphasize the beauty of the wood pattern.

But, if a material of a certain color is required for the embodiment of an architectural or design idea, then you can buy a dyed planken.

A separate type (or "competitor") of planken can be considered a wood-polymer composite (WPC), for the production of which wood chips and polymers are used. Differs in increased moisture and wear resistance and has dimensions similar to traditional planken.