Types of facade structures

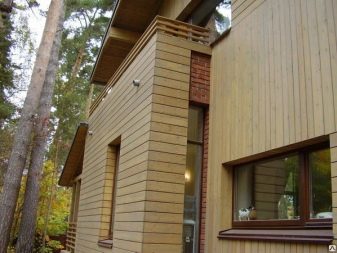

Among other things, when choosing a facade material, it is necessary to take into account what the building is made of, the principle of organizing the facade decoration may depend on this. For example, for wooden houses, it is advised to equip a ventilated facade.

It is customary to divide the facades into the following types:

- "Wet" are created with the obligatory use of building mixtures;

- "Dry" facades are equipped with mechanical fasteners (nails, screws, dowels, etc.). This method is more convenient, it allows installation at any time of the year, but does not provide the same integral structure as in the previous method.

Depending on whether there is a gap between the outer wall of the house and the finishing material, the facades are divided into:

- ventilated;

- unventilated.

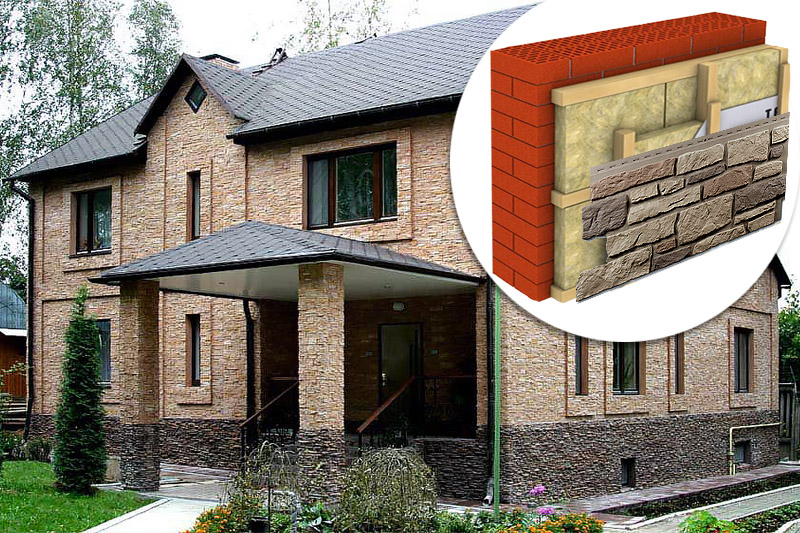

Ventilated facade

Ventilated facades require a ventilation gap between the facade material and the wall or insulation, if used. The gap is necessary for free air circulation and the removal of excess moisture that condenses or leaves the house through the walls. At the same time, the material of the ceiling wall remains completely protected from all atmospheric influences. It is better to equip such a facade when the walls are breathing. The non-ventilated facade involves the installation of the finishing material directly to the wall. Sometimes facades are simply classified into ventilated and "wet", although this is not entirely correct.

Now we can move on to materials that are widely used in the decoration of the facade of a private house.

Beautiful examples

Wooden panels familiar to everyone allow you to get unusual design solutions. It is enough to combine materials of different colors, changing their direction within the same facade.

The most popular options for cladding with wood or wood imitation are eurolining and block house (imitation of a log). Country houses and dachas designed in this way look cozy and noble, and under the cladding many building materials can be hidden (frame, brick, blocks or a pre-fabricated frame).

For country and Provence-style buildings, you can use a painted board or its siding imitation as a finishing material.

Houses finished with artificial stone or panels and siding with imitation of a stone surface look no less beautiful and even outwardly durable. Brick cladding is a classic. To create it, you can use not only brick, but also clinker tiles or siding with imitation of masonry.

Colored siding panels look original and allow you to create a unique exterior. Designers recommend combining 2-3 types of panels, similar in tone, or using contrasting solutions. The direction of the profile can also be different.

Vertical siding is able to visually "stretch the room", and the use of panels laid at an angle will add volume and expressiveness. It is not recommended to use horizontal single-color panels for cladding long, simple buildings. It looks monotonous and unattractive.

Using the same decorative plaster with a different method of application allows you to get completely different externally facades. Plastered in light shades of surfaces are familiar, this is an excellent solution for exteriors in a classic style, for example, traditional English or modern.

Colored plasters look no less interesting.

It should be noted that the greatest organicity is usually achieved by combining various textures.Wood and stone, brick and stone, stone and plaster harmoniously "coexist" within one facade.

For information on how to choose a design for home decoration, see the next video.

Features and Benefits

Facing brick is a type of material intended for facade decoration. In this regard, the brick is also called "front" and "front". Like any finishing element, a brick performs 2 main functions - protective and decorative.

The protective function determines the compliance of the material with the following requirements:

- high strength required to withstand mechanical stress, shock and wind load;

- low coefficient of moisture absorption, which means frost resistance, durability of the product, as well as the absence of mold and mildew in the room and on the surface of the facade;

- heat resistance, resistance to low temperatures and sudden thermal changes (a brick must withstand the most dangerous changes - jumps from low to high temperatures).

Given the laboriousness and considerable cost of installing a brick facade, a rare owner will agree to a structure's service life of less than two or three decades. However, subject to the masonry technology, such a facade has a 50-year or even more service period.

At the same time, the use of bricks for the facade opens up endless possibilities for its design. Different types of bricks, many options for masonry - all this makes brick cladding a real work of art.

In some cases, the use of this material as a finishing material is unacceptable. Let's dwell on this in more detail.

Brick, depending on the type, weighs 2.3-4.2 kg, respectively, brickwork with an area of 1 m2 made of material with dimensions of 250 * 65 * 120 mm has a weight of 140-260 kg. It is not difficult to imagine how much weight the facade of even a small house will have.

This necessitates a reliable foundation for the facade. It will be possible to use a brick only if the existing foundation protrudes beyond the walls by at least 12 cm (the width of a standard brick) and has a suitable bearing capacity.

In the absence of such, it is possible to arrange a separate foundation for the facade masonry, connecting it with the main anchors, but this is not always possible from a technical point of view. In addition, the process is quite laborious and costly. Additional costs will also be due to the need to remodel the roofing system and gables, since with the increasing area of the building as a result of finishing, they will not be able to fully protect the building.

When constructing a separate foundation for the façade, it is imperative to connect the load-bearing walls and cladding. As a bonding system, special flexible polymer bonds or stainless steel analogs are used, as well as galvanized steel wire. One end of the wire is mounted to the wall, the other to the facade. This allows you to maintain the location of the facing row, preventing its removal or "run over" to the supporting structures of the building.

An important requirement is the ability of the walls to "breathe", that is, to let the water vapor accumulating in the room into the atmosphere. Compliance with this requirement is ensured by maintaining a 2-4 cm ventilation gap between the facade and the walls, as well as equipping the first air vents, which are located in the upper and lower parts of the facade.

Airflows are carried out using special elements, or they can represent several unfilled vertical joints between bricks. The purpose of such elements is to ensure air circulation by sucking it in the lower part and outputting it in the upper part of the facade. Fresh air circulating inside the gap, as it were, blows through it, taking with it part of the water vapor.

Failure to comply with this requirement is due to the technical characteristics of the brick cladding (water vapor during freezing will destroy the brick, contributing to the appearance of cracks on it) and insulation (if any in the ventilation space), as well as the fallout of condensation on the surface of the walls and half-shelf inside the building.

Moreover, in the latter, a layer of heat-insulating material is often laid to increase the thermal efficiency of the building. In this regard, the width of the gap increases by 5 (or 50 mm) more centimeters, which entails an increase in the width of the foundation to 190-210 mm and the need to increase its bearing capacity.

However, today narrower material options are on sale - their width is 85 mm (eurobricks), and sometimes it can reach only 60 cm.When using such a brick, you can reduce the protruding part to 130-155 mm.

If it is impossible to fulfill the described requirements for the features of the foundation and structure of the building, it is not necessary to abandon the idea of living in a "brick" house. There are worthy analogs of brick finishes - clinker tiles, facade panels that imitate brickwork.

Requirements

In addition to the requirements that the owner of a private house is able to present, based on logic and intuition, there are also technical standards. All of them relate to two areas: compliance with GOST and compliance with SNiP.

GOSTs for each type of cladding are different. Compliance with them in the production of material is important, since the standard defines the minimum acceptable quality of the material. It regulates the composition of the substance, the permissible amount of resins and chemicals that are harmful to health, the strength of the material and methods of its verification, resistance to weather conditions and mechanical stress, storage rules and methods of transportation.

Also, building codes describe the permissible weight load on the structure of a building so that it remains safe for life and health. It will be different, for example, for one-story brick cottages and two-story frame buildings.

It is important to consider the requirements for a specific type of building.

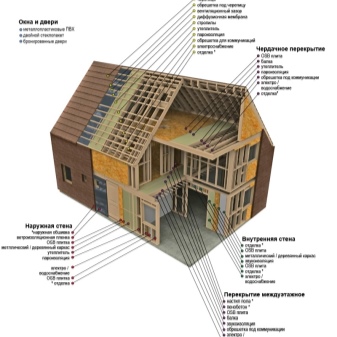

The competent use of materials is also in the area of building codes. It is not enough to decorate the facade of a cold house with mineral wool and sheathe it with siding on top. It should be borne in mind that when installing thermal insulation, waterproofing, vapor barrier and a ventilation layer are also required. If you do not follow these rules, the effect of finishing will be negative.

The facade decoration of the house affects the landscape design and the appearance of other buildings on the site, so the materials must be chosen so that they look harmoniously against the background of the surrounding objects. A Scandinavian-style house in the middle of a Japanese rock garden is an unfortunate combination, but finishing with natural materials for a chalet-style house surrounded by a country garden is a winning combination. The emphasis on naturalness and simplicity makes it correct.

Facade finishing materials

The facade of any building is its hallmark, evaluating which guests get acquainted with the taste preferences of the owners and their wealth. There are quite a few opportunities for decorating private residences, but this season the following are the most relevant.

Wood. This material is chosen by people who prefer eco-safety and reliability. The cladding made of wood panels is in harmony with the surrounding nature. Such elements are able to soften the aggressive industrialism of hi-tech and the clarity of the angles of minimalism.

Concrete wall surfaces can be painted, sewn up with plastic or covered with ceramic tiles. A novelty in the design of the house is the gray shades of the materials, giving the building an industrial stylish look.

Brick design remains in demand, as it is a guarantee of strength, durability and attractiveness.The facade can be covered with natural stone elements or analogues that are not inferior in quality and type.

It is typical for the 2020 season to use clinker brick, which, due to its dense structure and the absence of voids, perfectly protects the structure from the effects of external natural factors.

Siding panels and decorative plaster. Siding elements are very popular among users due to their performance and a wide variety of textures and shades. The most popular are elements that imitate wood, stone and metal.

People like plaster for their cost and the ability to often change the exterior design. This season, light colors are popular, thanks to which it is possible to visually increase the size of the building.

Decorative rock

The main disadvantage of this material is its high moisture absorption - this should be taken into account when planning repairs and should not be used in rooms with high humidity. Average service life is at least 15 years.

In addition to brick, the walls can be covered with decorative artificial stone, which imitates sandstone, shell rock, slate, tuff, basalt, etc. Despite the variety of textures, decorative stone is produced mainly from gypsum, sand, clay, cement and appropriate dyes. The advantages of this finishing option are the variety, which allows the most daring design fantasies to roam. Artificial stone is quite easy to install, it is hygienic, has a low weight, which can also be attributed to the advantages.

The advantages of this finishing option are the variety, which allows the most daring design fantasies to roam. Artificial stone is quite easy to install, it is hygienic, has a low weight, which can also be attributed to the advantages.

Decorative stone is used most often to highlight corners, openings, arches, fireplace framing, in other words, to create stylish accents. The service life with a careful attitude is up to 30 years.

Artificial facing stone

Decorative stone is an expressive way of exterior decoration of the building. Its artistic possibilities are very great - a variety of forms, patterns, textures and shades can become a powerful pictorial tool in skillful hands. Read here: Blind area around the house.

True, a surface lined with artificial stone may turn out to be too active, drawing attention to itself - for this reason, this material is often used in combination with some other.

Among the undoubted advantages of decorative stone are its strength, durability, resistance to various influences. And the obvious disadvantage is the relatively high cost.

Stone is an integral part of classic styles. It is a traditional material that has often been used in the past, in particular for cladding plinths. However, he found his niche in modern construction and is a component of many fashionable solutions.

Sheathing

House cladding, in contrast to cladding, performs 2 functions - decorative and load-bearing. The latter manifests itself primarily in frameless buildings. The outer cladding has a large load, therefore the materials used in this case are based on metal (more often steel), which necessarily has anti-corrosion protection. House cladding is usually done using special metal sheets or thermal panels.

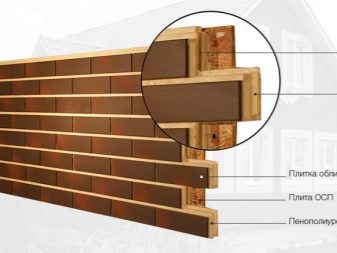

Thermal panels

They are a material consisting of a foil layer with a fastening system, insulation and a decorative layer. As a heater, polystyrene foam and its extruded version, as well as polyurethane foam, are used. Preference should be given to polyurethane foam products. The insulation in them contains the smallest air bubbles, which provides excellent thermal insulation performance with a low weight of the product.

Clinker tiles are usually used as a decorative layer.

The material is durable, 1.7 times warmer than many of the materials reviewed

It is quite simple to mount it, however, it is important to observe the fastening technology.The material should be fixed directly to the wall, avoiding the formation of an air gap between the panels and the facade

This is due to the vapor tightness of the thermal panels.

The walls should be leveled first, otherwise the skirting of the cladding cannot be avoided, which will lead to the loss of its operational properties. The service life of the cladding is up to 30 years.

Sheets

Steel is usually used as the basis for external cladding sheets. It is covered with a layer of zinc, which allows you to achieve decent anti-corrosion performance. Additional protection against environmental influences (primarily UV influence), as well as the decorative effect of the material is provided by applying a polymer coating.

The strength of the material and its wind resistance is ensured due to the peculiarities of the shape: a profiled galvanized sheet is used to create a ventilated sheathing. Similar sheets are used as roofing sheets for roof decoration.

This finishing method is applicable not only for residential buildings, but also for household buildings, garages. Profiled sheets are robust and durable, and new fastening systems ensure ease of installation and durability. By choosing this or that shade or direction of "furrows", you can create unique exteriors.

Installation is carried out on a prepared frame. For insulation, you can choose polystyrene, mineral wool materials or purchase a profiled sheet, thermally insulated at the factory. The latest models are 2 profiled sheets, between which a layer of insulation is laid.

Finishing of house facades with modern materials: sandwich panels

For a long time, sandwich panels have not been used in our country. But today the situation has changed dramatically. Among other alternatives, siding and stones, panels have taken pride of place. This material is multilayer, it consists of several layers: metal and insulation. The two layers are connected by hot pressing. The sandwich panels look great, the material is lightweight and non-combustible. Also worth mentioning is the remarkable sound insulation performance. With proper installation, the panels will last a long time. Insulation and high aesthetic qualities are provided. Also, sandwich panels are used to insulate balconies. In combination with plastic, PVC panels provide maximum comfort in the room.

Among other types of cladding of facades of houses, panels remain in demand and popular, they are often used in the process of decorating balconies and loggias. Facade panels can be purchased profitably in specialized stores in Moscow.