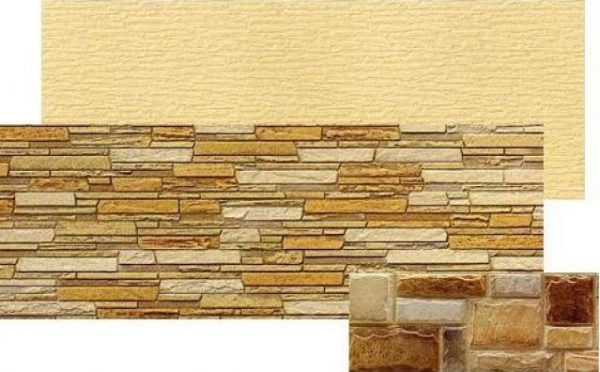

Material used for stone (brick) panels

Various materials are used for the production of cladding panels:

Steel or aluminum composite facade cassettes under the stone have high strength, long life, fire safety. The metal surface is produced with a stone imitation. The color of the polymer makes it resistant to ultraviolet radiation. Recommended for use when the manufacturability of the cladding comes out on top - they look ultra modern.

Pressed wood fibers with binders, from which wood panels are made for a stone - HPL-panels. They are lightweight, durable, frost-resistant. The material is inferior to types in terms of fire safety, but superior in its anti-vandal properties.

Fiber cement is a material based on a mixture of cement and fibers. It does not burn, is resistant to moisture, is durable, but it is heavy, difficult to process. Do-it-yourself installation of panels under a stone is difficult to do. Japanese fiber cement is popular, which does not contain asbestos, which makes it environmentally friendly. Such panels do not need to be washed - it cleans itself after atmospheric precipitation. It has no shine and effectively imitates natural material. The panels suitable for the plinth cladding are similar to those used for the façade. But the cladding itself has features, read here.

Surfaces that mimic panels:

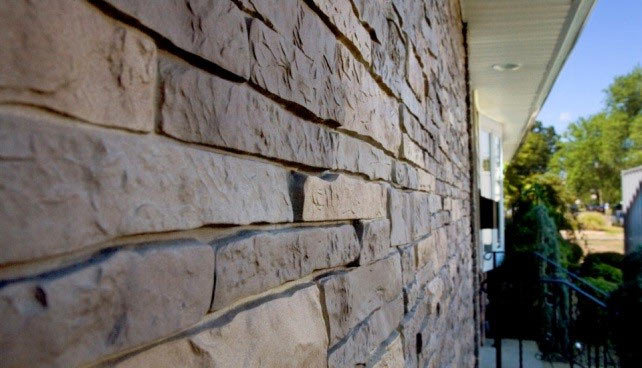

- Rock is a texture that is formed when chipping large pieces with a difference of 100 mm.

- Point - a flat surface with chips, which is used for cladding buildings in a classic style.

- Heat treatment - gives an old look with chips, peeling. Polished stone imitates a rough, even surface.

- Sawn stone is a surface with longitudinal grooves, suitable for plinth plating.

- Polished stone - repeats the mirror surface of artificial polished stone.

- Glossy - has a matte smooth surface.

Facade panels with imitation of natural stone

Facade panels for exterior decoration of a house with imitation of a stone surface reliably protect the walls of the house from negative environmental factors. They can be used for cladding a new home or for renovating the walls of an old building. Facade panels that follow the stone surface are easy to install thanks to the use of aluminum or other metal battens.

Typically, stone-textured panels include a polyurethane interlayer, a foam interlayer, stone powder and resin. These panels are manufactured by casting using polymer raw materials. This production technology provides the building material with a long service life.

The accumulated experience in the use of facade panels with imitation stone allows us to highlight the following advantages:

- the surface of the wall does not need to be pre-leveled;

- panels can be installed in any season;

- they have good heat and sound insulation;

- in terms of service life, they are not inferior to materials for finishing made of natural stone;

- the structure can be adjusted thanks to the steel or aluminum profile;

- withstand abrupt climate changes, high humidity, precipitation and sunlight.

- are not afraid of corrosion;

- resistant to mechanical damage;

- facade panels with imitation of stone are much lighter than finishing with natural stone;

- they are more unpretentious in care and cleaning;

- environmentally friendly and safe for humans;

- do not conduct electricity;

- easy to mount;

- reduce the load on the building foundation;

- the cost of such cladding is much lower than the cost of finishing with natural stone;

- a variety of shades and reliefs that imitate the surfaces of different natural stones.

Advantages and disadvantages of cladding materials

Whatever one may say, but not everyone has the opportunity to build a good solid house straight from brick. This is a rather expensive and heavy material that not everyone can acquire. And therefore houses are sometimes built from cheaper and simpler materials that are not distinguished by their beauty - just then the facade is cladding. Here special panels come to the rescue, which are fixed outside the house on its walls and quite cope with the task of imitating other, more expensive and beautiful materials than those from which the house was built.

Finishing the facade of a private house with brick panels

Undoubtedly, this option also has disadvantages compared to the same stone or brick, but it is not devoid of a lot of advantages. Why is the use of artificial facade cladding good?

-

Aesthetics. So, artificial panels that can imitate brick, after installation, may well give the house a beautiful and finished look, visually make it heavier, and make it more respectable.

-

Economy. The costs of building a house are high, especially if you build it from bricks. Using cheaper materials along with cladding panels will save a lot of money. And there is not so much waste from the panels during the finishing process (only 3-5%). The service life of the panels is quite long and is about 20-50 years. So it's not worth worrying that the house decorated with them will quickly lose its appearance.

- Good physical and technical properties. Thanks to the panels, the house can be additionally insulated, as they will increase the level of thermal insulation. Also, the panels are distinguished by high indicators of environmental friendliness and do not harm human health.

-

Protection. The panels perfectly protect the material from which the walls of the house are made from external influences. This is especially true for buildings made of aerated concrete or wood. The panels themselves are not afraid of moisture, wind or sun rays.

- Ease of work. Installation of the panels is quite simple - they are lightweight. In addition, work can be performed at any time of the year, even for beginners in the construction world. In fact, building a house with inexpensive materials and paneling it will be faster than building a brick building.

Facade panel

Facade panel

Naturally, the panels also have certain drawbacks.

It is important to know them before deciding on this type of finish.

- If the panels are made of plastic, they can be flammable and, in the event of a fire, will release a mass of toxic substances into the air.

- Some panels, when hitting them, can seriously and most importantly - irreversibly - deform.

- Some panels are quite expensive.

Additional elements

Additional elements

In general, it can be noted that the number of disadvantages pales in comparison with the number of advantages of the panels.

But nevertheless, they should be taken into account and paid attention to them before deciding on the installation of such material on the facade of the house.

House facade decor

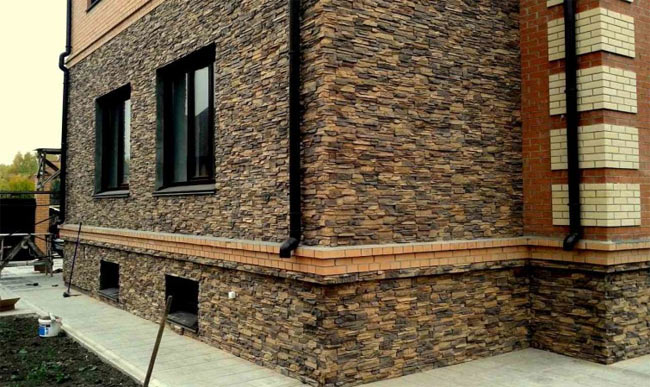

To refine the facade of the house, you can use simple design techniques. Decorative stone inserts in the plinth area:

Decor of the entrance group, corners and windows:

Contrasting plasterboard inserts plus stucco molding:

The most beautiful exquisite facade

The most beautiful exquisite facade

Fachwerk styled styrofoam decor:

Facade painting:

Decorative shutters:

You can decorate the entrance group with a handrail, a visor, interesting entrance steps.

A canopy over the entrance group decorates the facade

A canopy over the entrance group decorates the facade

Stone steps complete the facade

Stone steps complete the facade

You can equip the terrace and glaze it, trim it with wood or decorate it in a Mediterranean style.

When choosing how to sheathe the facade of a house, it is better to be guided by the climatic conditions of the area in which the house is located, the requirements for the stability of the finish, as well as individual stylistic preferences.

If you have made up your mind, it is not a problem to choose methods of facade finishing.

DIY installation

Facade panels for exterior decoration of the house are also popular due to the fact that even a non-professional can cope with their installation. Due to the large surface area of the wall, covered with just one panel, installation is done in no time. Special locks provided in the construction of the building material help to secure the panels to each other with high quality and firmness.

Assembly of facade panels for exterior decoration of the house can be done in one of the following ways:

- with the help of fasteners on a prepared crate made of metal or wood;

- using a special glue.

Installation of polymer-coated metal facades

To install such panels on the facade, a frame is created from vertically positioned guides. The panels are mounted horizontally on this structure. The vertical method of fastening metal facade panels is also allowed. But at the same time, the tightness of the joints suffers. The entire system of façade panels and supporting structure is designed so that the fastening elements are not visible after assembly. During the installation process, self-tapping screws or nails made of material that are not subject to corrosion are used. The assembly of metal facade panels for exterior decoration of the house requires additional elements that increase the cost of such work by about 30%.

Installation of a wood fiber facade

There is a perforation on the edge of such panels. Fasteners with staples and screws are carried out through this perforation onto self-tapping screws.

Installation of vinyl facade panels

The elements are attached to each other without much difficulty. They can be used to form sections of different sizes. The separate panel has a latch at the bottom, and an edge at the top, with which the panels are attached to the wall surface using self-tapping screws. There is also another latch. The bottom and top panels are held together by these locks, hiding the perforated top. Thus, the place of the fastener becomes invisible. The panels are overlapped. Start the assembly from the ground, covering the wall surface horizontally. The holes for the self-tapping screws have a gap to compensate for the swelling and contraction of the building material under the influence of temperature. Fastener nails are made of aluminum to prevent rust marks on the cladding.

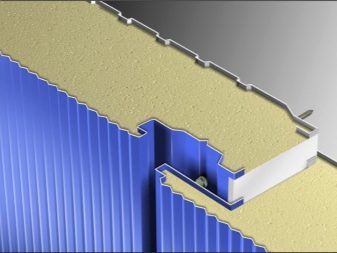

Installation of polyurethane panels

The assembly is carried out according to the "groove-comb" scheme. Installation takes place vertically. Fastening to the frame is made using stainless steel screws, which are invisible on the surface after installation.

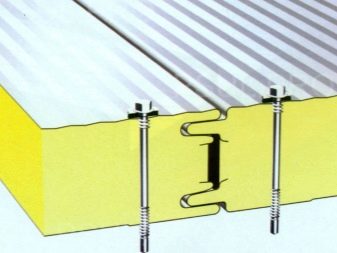

Installation of facade sandwich panels

Such panels are fixed to the crate with self-tapping screws. Self-tapping screws are suitable for both wood and metal. Dowels are used to fix the facade on concrete walls. The interconnection of sandwich panels is based on the groove-comb principle. This protects the outer surface of the building from moisture penetration and creates a reliable adhesion of the panels to each other. For the processing of joints, special mastic, polyurethane gaskets, tape or foam are used. The seams at the ends can be filled with both mounting foam and mineral wool. Then strips are applied to these seams.

Installation of fiber cement panels

External cladding of buildings with fiber cement panels is carried out with the use of clamps using the groove-ridge method. The structure is based on a frame made of wood or metal. Tiles need to be painted after assembly of the facade with high quality acrylic or polyurethane enamel. For fasteners, it is also permissible to use rivets, screws or nails.

Installation of a facade made of porcelain stoneware

The installation of a porcelain stoneware facade is carried out mainly with the help of a special two-component polyurethane-based adhesive. The tiles are glued to a cellular fiberglass surface, which will prevent the pieces of the panel from shattering in case of damage.

Facade decoration with fiber cement panels

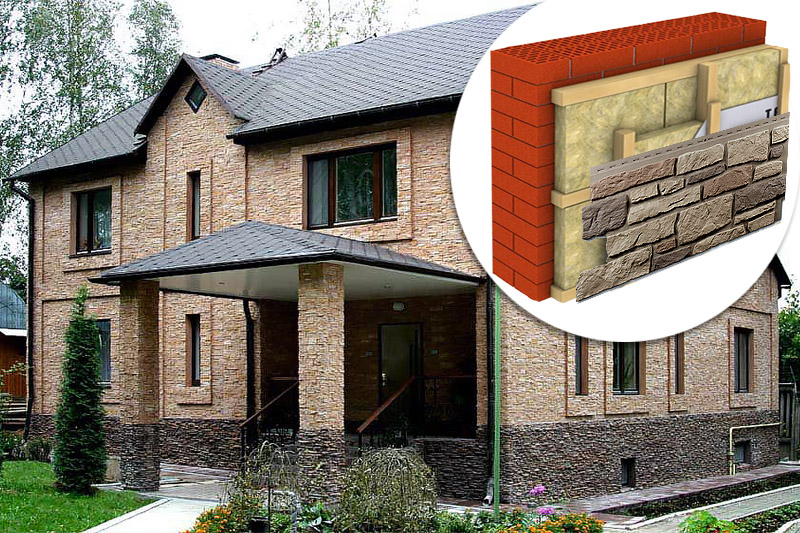

Fiber cement panels are considered an excellent alternative for decorating a residential building. They are used to insulate the facade of a house from the outside.

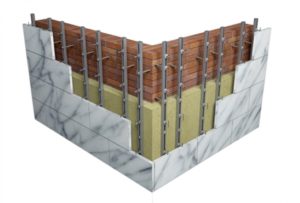

Each element is fixed on a pre-prepared metal frame. A layer of thermal insulation is placed between the slabs and the iron base.

Modern technologies make it possible to apply the texture of natural stone, solid wood to the surface of the slab. As part of such panels, 85% of cement and 15% of various fillers are used, which make it possible to imitate one or another texture.

To decorate the facade of country houses, plates from a domestic manufacturer are used. The most popular are:

- Latonite;

- Ldm.

They are attached to hinged metal structures. Metal screws allow fixing huge plates.

Stages of work

- As a rule, at the stage of preparation for installation with your own hands, you need to process the wall for attaching the facade panels. First, all the protrusions are removed, then the old cladding is cleaned, and then the wall is treated with an agent that prevents the formation of fungus. If the walls are uneven, then the panels will be mounted on a frame, wood or metal.

- The base should be checked for evenness using a building level. If the differences turn out to be more than 1 centimeter, then fastening the panels to the glue will be impossible. In this case, alignment is carried out. In addition, the walls must be primed, both brick and concrete, and the wooden ones are treated with an antiseptic.

- The installation of the lathing takes place in advance. The frame is constructed in a vertical or horizontal arrangement of all the constituent elements. The lathing should not follow the unevenness of the wall surface. A gap for ventilation must be left between the facing material and the wall. The cavity formed between the surface of the building and the panels is filled with insulation materials, foam or mineral wool. Before proceeding to the installation of the lathing, it is necessary to lay a rather thick and durable cellophane film.

It is important to correctly determine the level of the first row of cladding using the starter bar. Wall panels are usually fixed from ground level at a height of 30 centimeters

It is advisable to start the cladding from the corners. After the first row is ready, all the gaps between the wall and the material are filled with polyurethane foam. If in the process it turns out that the panel does not fit in a row, it is cut with a grinder.

Fiber cement panels are mounted on self-tapping screws. Metal plates are attached to the lathing after the facade of private houses has been insulated. Plastic panels are mounted on the frame using fasteners. Clinker, as well as fiber cement, are attached to self-tapping screws.

- Vinyl panels are connected to each other thanks to latches, one of which is located on the edge. Thus, sections of different sizes are assembled, which are then attached with self-tapping screws to the wall of the building. The panels are fixed with locks and in parallel cover the perforated fastener from the eye. Installation is carried out with an overlap from the ground, horizontally. Holes for self-tapping screws are cut with a certain gap, which will come in handy in case of swelling or compression of materials during temperature fluctuations. Nails are selected from aluminum or from other anti-corrosion material.

- The polyurethane panels are joined together like a "tongue" and "groove", and are mounted vertically. The facade coating is attached to the frame with stainless steel screws, which will be invisible upon completion of the work.

- Sandwich panels are attached to the frame with self-tapping screws in the case of wooden and metal battens, and on concrete walls - with dowels. The panels are also connected to each other according to the “tongue-and-groove” system. This scheme is chosen to prevent moisture from entering the walls of the house and to create high-quality adhesion of parts to each other.

- The installation of the porcelain stoneware facade is carried out with glue. It should be composed of two components, one of which is polyurethane. The tiles are glued to a cellular fiberglass surface, which will prevent fragments from shedding in case of damage.

Composition

For the production of slabs similar to natural stone, artificial and natural raw materials are used.

In accordance with the material of manufacture, facade cladding panels are of two types:

- fiber cement;

- polymer.

Fiber cement products are composed of silica sand and cement with the addition of cellulose fibers. They are characterized by fire safety, frost resistance up to -60 degrees, sound-absorbing qualities. The downside is the ability of the material to absorb water, making the structure heavier. A low level of impact resistance indicates a tendency to damage. Fiber panels do not have a pronounced deep texture of stone, as they are made by casting.

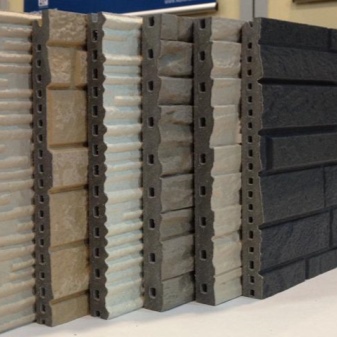

The composition of polymer panels includes polyvinyl chloride, resin, foam, stone dust. If a composite panel is being made, a polyurethane foam layer is added. PVC panels are able to clearly highlight the stone texture, highlight the rubble and wild stone. Plastic does not react to moisture, has antiseptic properties. The panels are resistant to impact and damage.

Varieties of facade panels

Facades for exterior decoration are divided into several classification groups.

- They are rectangular in format, in the form of an elongated narrow strip or a medium-sized module.

- In appearance, the panels can be simply painted or with imitation of the texture of brick, stone or wood.

- The panels are divided depending on the presence or absence of insulation.

- By the type of fastening, facades with locks and panels that are not fastened to each other are distinguished.

- According to the material of manufacture, they are subdivided into metal, stone, glass, polymer and composite.

Vinyl facades

PVC panels are one of the most popular materials for exterior decoration of houses. They are made on the basis of polyvinyl chloride. There is a wide variety of vinyl facades on the market with different surface reliefs.

Facade panels made of polyurethane foam

Manufactured using a special technology from porous plastic. The internal volume is 90% hollow cells with gas inside. A marble crumb is added to the polymer, which is reliably soldered with it under the influence of high temperatures. The outer layer of the panels is created from clinker decorative tiles.

Metallic

As a rule, aluminum is used to create such panels. Some models are made of galvanized steel. Metal panels are perforated or smooth.

Facade panels made of fiber cement boards

On the surface of these panels there is a special film made of inorganic material. This film tends to self-clean. The composition of such panels includes plastic, cellulose, cement, as well as stone chips. They can be covered with acrylic or polyurethane.

This building material is suitable both for renovating the exterior of old houses and for cladding new ones. Fiber cement facades can imitate the surface of wood, stone, marble or brick.

Wood fiber facades

To create these facade panels, wood fibers are used, compressed under pressure at high temperatures. Wood fiber tiles are easily bonded with glue. Veneer and polymers are used for their facing.The surface of the panels is covered with protective materials. Its texture is difficult to distinguish from natural wood. Facades can be additionally processed, drilled and sawed if necessary.

Facades from porcelain stoneware

Porcelain stoneware is made by mixing various minerals with white clay. To obtain ceramic granite of the desired color, a pigment is added to its composition. The material is made similar to all kinds of natural stones.

Facade sandwich panels

They consist of a plastic plate pressed between two metal layers. The plastic plate also has a thin vapor barrier layer. Sandwich panels are distinguished by good sound insulation. They can withstand abrupt changes in climatic conditions. The metal layers include manganese, magnesium and aluminum. Their surface is made similar to various traditional finishing materials such as wood, stone, plaster.

Facade panels made of stone

The latest developments in the field of building materials allow the inclusion of natural minerals in the composition of the finishing panels.