Installation process

The basis on which will

the glued panels must be flat. The installation process takes place in the following

stages:

Preliminary

preparation of the base, elimination of all cracks on the working surface;

Padding;

Markup;

Preparation of the solution

for masonry - it should be of such a consistency so as not to drain from the spatula;

If it is necessary to produce

trimming excess parts of the panels to fit the parameters of the wall;

applying glue in an even thin layer - here

it is important to take into account that the size of the layer does not exceed the panel itself and make sure that it does not

there were voids under the façade system;

Applying material

for cladding and smoothing;

Filling the joints with glue;

Drying process;

Removing the protective film

from the front side after drying within 48 hours or after complete

hardening of the adhesive solution. Moreover, it should be very easy to remove if

this does not happen, then you need to leave the object to dry for some more time.

AMK facade system installation technology

The AMK system is universal and is attached to almost any base - it can be used for finishing facades made of brick and concrete, wood, plywood, drywall, gas and foam concrete. The light weight of the elements does not make the structure heavier and does not require additional wall reinforcement.

For work you will need

the following tools and materials:

- Roller for

applying a primer; - Building

mixer; - Capacity

for mixing glue; - Serrated and

flat spatula; - Building

level; - Roulette and

pencil (for marking); - Building

knife; - Ground

solution; - Putty

(if necessary) to eliminate seams and cracks; - Water;

- Glue;

- Grout.

Facade fastening technology

the system is simple and consists of several steps:

Preparation

bases and its markings - the surface where the AMK will be attached must be

pre-cleaned from dust and primed, all existing cracks and seams

putty;

Preparation

glue - the glue solution is diluted according to the manufacturer's instructions - the mixture must

it will turn out to be moderately liquid, but at the same time not to drain from the surface. Specialists

it is advised not to mix the entire volume of glue at once, but to prepare the mixture in parts as

necessary, this will preserve the properties

glue and prevent it from drying out.

Application

adhesive solution - the glue must be evenly distributed over the surface

walls with a notched trowel at an angle of 90 degrees;

Mounting

AMK - start glueing from the lower left corner, protruding and unnecessary elements

cut with a knife before starting work. Each element of the facade system is tightly

pressed against the wall and smoothed with a flat spatula

It is important to ensure that

all the air has escaped from under the stove, there should be no voids under the material;

Grout

seams - after installing the panels, it is necessary to fill the seams between the sheets

the remaining glue or special grout. To do this, use a flat spatula,

which is positioned at an angle of 45 degrees relative to the base

You can not

they are afraid to stain or damage the panels, since they have a protective film;

Removing the protective

films - the film is removed only after the glue has completely dried, avoiding direct

sun rays. On average, it takes from 2 to 5 days, the lower the temperature

environment, the longer the glue will dry.

How to glue the AMK facade system

For work with AMK facades

strong adhesion glue is used for mosaics and porcelain stoneware, with high

indicators of moisture resistance and frost resistance.

The color of the glue does not play a big role,

but since it is often used as a grout for finished

surfaces, it is worth giving preference to neutral shades - white or gray

fit perfectly.

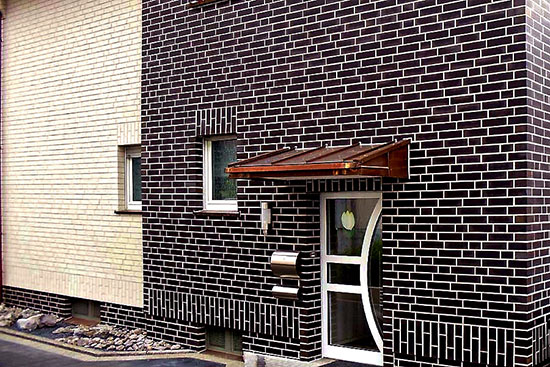

What is AMK facade system

AMK facades are

panels for finishing walls and partitions with imitation of stone or

brickwork applied over a reinforcing mesh with a thickness of 30 -33 mm.

Used in production

chips from natural marble and acrylic water dispersion, which is applied

on a polymer mesh base. Iron oxide is used as a dye

pigments, they are highly resistant to adverse external conditions,

including exposure to ultraviolet radiation.

Finished facade sheets are protected

film, which is removed only after the installation of the system. The film protects

panels during storage and transportation, as well as during assembly

works from the ingress of adhesive solution and grout.

Advantages

Release of this type of facades

began not so long ago, in 2015, but in a few years AMK managed to conquer

success among buyers and has become one of the most demanded materials for

exterior wall decoration.

The main advantages of the system

AMK facades:

- Strength

and durability - the service life is about 15 years; - Environmental friendliness

- in the manufacture, only safe materials are used that are not

emit toxic substances; - Availability

- the average price for 1 square meter is 500 - 700 rubles; - Moisture and

frost resistance; - Ease

and installation speed - the AMK facade system is attached to any flat surface

using glue, does not require special skills or additional

equipment; - Increased

resistance to external influences and natural phenomena; - Maintainability

- if one of the elements is damaged, it can be easily dismantled and replaced

on new; - Sustainability

to temperature extremes; - Fire resistance

- the material does not burn or melt; - High

vapor permeability level.

The strength of the material, its

resistance to external influences, ease of installation, affordable price and

aesthetic appearance - these are the main components of the success of the AMK facade system

among buyers.

Colors of the AMK facade system

Color palette for this

of the material is based on the natural shades of the stone and includes three

the main colors are sand, gray and brown, each of which is presented in

several types.

At the choice of buyers

more than 10 basic colors are presented:

- Brown

shades - light brown, brown, dark brown and brown mix

(several shades of a given color on one panel); - Shades of gray

- light gray, gray, dark gray and gray mix; - Sand

shades - light sandy, sandy, dark sandy and sandy mix.

Sheets with

several basic colors, such as a mix of sand and brown bricks.

Types of AMK facade system

There are three main

kind:

- Block - size

single element - 400 x 190 mm, sheet - 995 x 1250 mm; - Imitating masonry

brick - one fragment has a size - 250 x 65, and the whole sheet has

parameters - 1250 x 995 mm; - Clinker - measures

as in the previous version.

AMK for sale

packaging, which contains 10 sheets, ranging in size from 9 m2 to 9.4 m2.

You can buy panels in all regions of the Russian Federation and in the CIS countries at an affordable price from

500 rubles per m2. Approximate

calculation of the amount of required material and the price can be carried out on the sites

companies selling and installing AMK panels.

Features and Benefits

AMK is intended for the implementation of decorative and protective cladding of both external walls of the house and internal ones. It fits perfectly into any interior, effectively imitating brick or masonry. The system consists of slabs in the form of bricks made of marble chips and aqueous acrylic dispersion.It is analogous to marble plaster or flexible stone, but it is much cheaper. Such facades have high performance characteristics, they are durable and very strong.

AMK consists entirely of natural ingredients that are highly resistant to natural phenomena and almost any external influences. The big advantage of the system is its fire resistance, it is not flammable. Also, the tiles have a high level of vapor permeability. In addition to high quality, the system has a very aesthetic appearance.

Installation of AMK is simple and quick, repair work does not require professional skills. This item pleases men who have never done repairs on their own before. One of the main advantages of this type of finish is maintainability. If one of the plates is damaged, it can be easily dismantled and replaced with a new one.

Features and Benefits

Panels

AMK can be placed on top of any surface: drywall, mineral wool, aerated concrete,

plaster, foam concrete, penoplex, OSB, DSP, etc. The main thing is to be even. Facade

system - sheet decorating material located on a reinforced mesh.

It has the following advantages:

- The ability to imitate the laying of natural materials;

- ecological composition and does not harm people and nature;

- Simplicity in repair work - if it is necessary to repair or replace a separate element, then this section can be separately dismantled and replaced with a new one, indistinguishable from the rest;

- it is easy to carry out the installation - the installation process can be done independently and at the same time save on the cost of work, the price for installation is in the range of 250 rubles per m2, and by performing all the work without contacting specialists, there is a big financial saving;

- Long service life - if all conditions are met, the facade panels can serve people for 15 years;

- Aesthetic appearance;

- A light weight;

- Has such dimensions that it is convenient to transport in any car;

- wide range of applications;

- Not susceptible to environmental influences and ultraviolet rays;

- fire resistance;

- Vapor permeable - it has a vapor permeability coefficient of this kind - 0.13 to 0.36 and this property allows the walls of the house to breathe;

- Does not allow moisture to pass through;

- Does not make the facade of the house heavier;

- The ability to maintain its original shape and color for a long time.

- It does not require special skills and experience when laying, thanks to this it is not necessary to hire a team of specialists for installation, you can lay the panels on the walls yourself;

- There is no need to somehow wash the panels from the glue in order to remove all traces of the glue material, you just need to remove the protective film from the block;

- Installation technology saves time and money.

Store AMK panels

necessary in a warm and dry room. If the products were delivered to a cold

season, you do not need to immediately unpack, the packaging should be left in

warm room until it warms up to room temperature. And only then produce

opening.

In her interior

installed in fireplace areas, imitate stone and brick masonry. Also

this material is used in the hallway and in the living room to create

zest in your apartment. Also, the AMK system is used to mask and remove

various defects on the wall surface.

How to glue the AMK facade system

For mounting panels on

different surfaces apply glue with different shades of color to

the grouting joints were not very noticeable. Under normal ambient conditions

environment, the glue mixture dries within a day, at low air temperatures and

high humidity, the drying process can take up to 3-5 days.

Recommended to apply

adhesive mixture, which is used for the installation of porcelain stoneware and mosaic

compositions. It must be moisture-resistant, frost-resistant and have

strong fixing properties.It is also recommended to use dry adhesives. The glue consumption is as follows - for 10 sq. meters goes 1

bag of glue mixture.

So that the glue lines are

match the color with the system, then paint is applied over them and the protective film

a similar shade. To create a shade, various colors are added when

preparation of glue mixture.