Varieties of facade paints

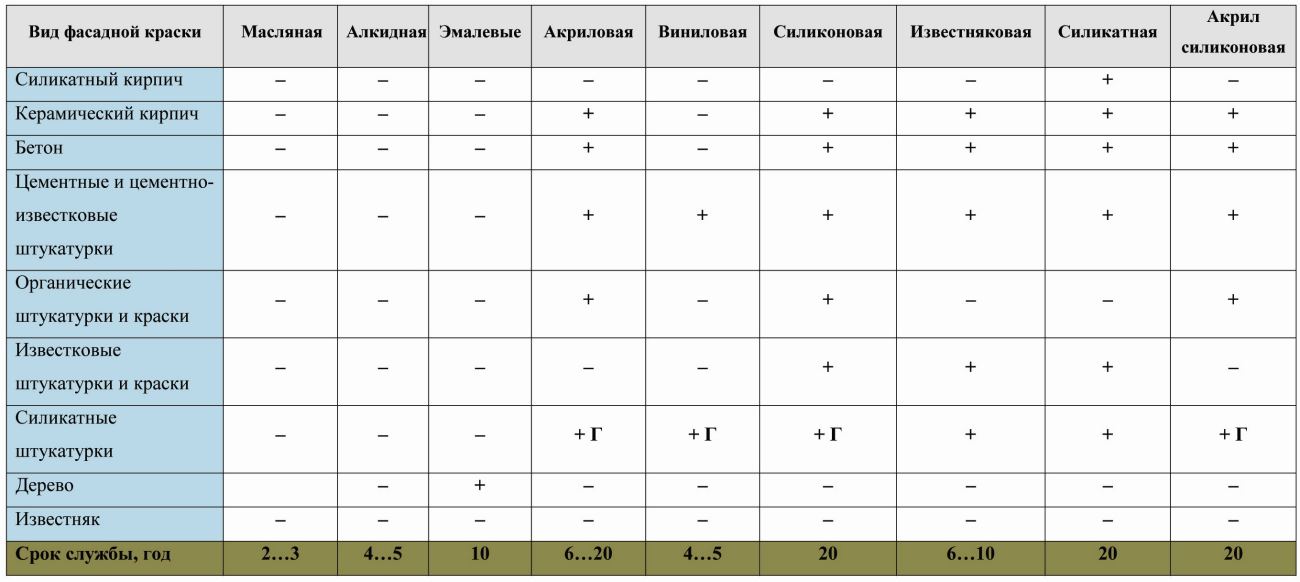

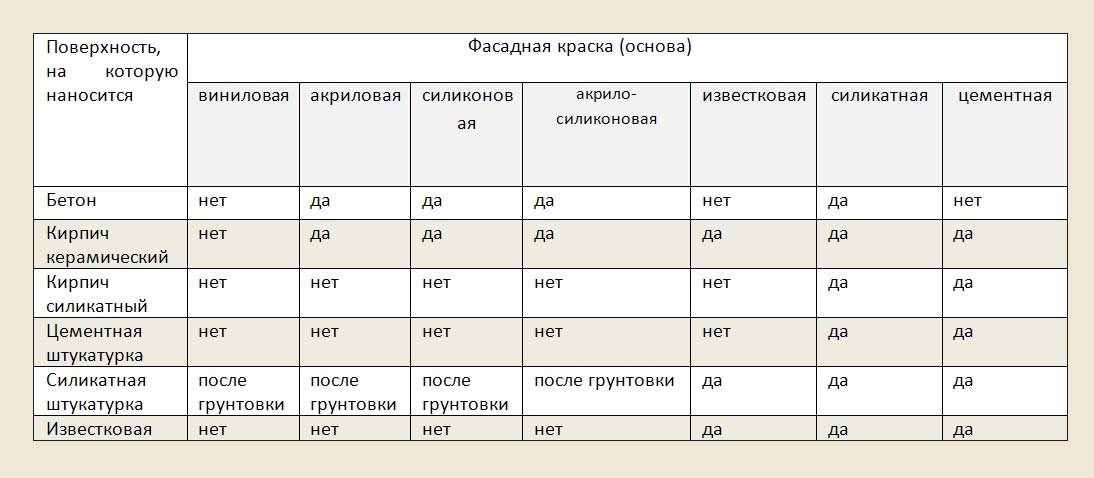

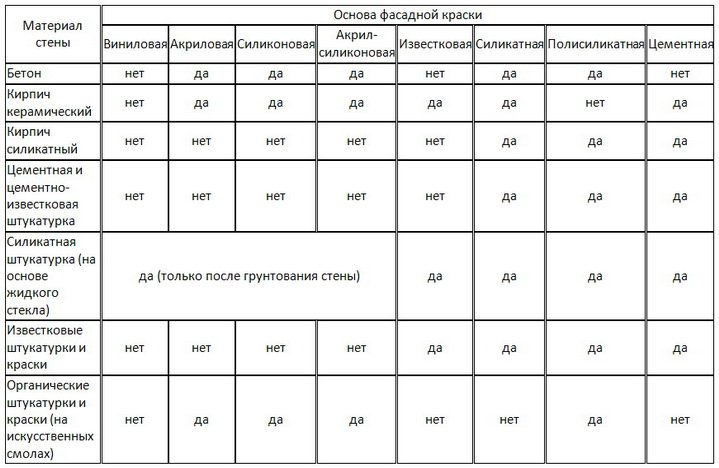

Paint for facade work is divided into types according to the composition and amount of the binder. Enamels are produced on the basis of lime, drying oil, silicone, acrylic. The first dye is used to restore buildings. Buildings with limestone cladding are painted with enamel. Buildings with a limestone base are covered with acrylic paint. These are buildings made of bricks, concrete or plastered walls. Silicate bricks or walls, which were previously treated with organic dyes, are coated with silicone compounds. Varnish-based enamels are used to protect against decay and destruction of wooden surfaces.

For the facades of houses, it is recommended to use latex, water-based, rubber, silicone, textured, silicate, acrylic special materials.

Silicate

The rating of facade paints is headed by this special material, which is developed on the basis of liquid glass. This is a mineral composition that is made on the basis of natural dyes, which ensures the safety of its use. After application, the composition retains its original appearance for many years. The paint is characterized by:

- Biological resistance;

- Resistance to impacts

the environment; - Resistant to deformation;

- Water vapor permeability.

Lack of paint is additional

wastage during application, as protective agents are used. Special material not

washed off and unstable to mechanical influences.

Lime

Paints are produced on the basis of slaked lime. The enamel is resistant to mold, vapor permeable. It has a low cost, which guarantees its availability. Before choosing a special material, it is recommended to determine its shortcomings. Enamel lends itself to rainfall and gets dirty, which shortens its useful life. Lime paints are limited in color. Tinting of special materials is not a way out of the situation, since when exposed to precipitation, stains appear.

Cement

Special materials are produced based on Portland cement, to which a coloring pigment is added. The technical characteristics of the special material are similar to those of lime enamel. An additional disadvantage of the cement composition is the instability to the effects of bacteria. The advantage of cement-based paint is that it resists precipitation.

Acrylic

Enamels are produced on the basis of acrylic resins and

characterized by a variety of color solutions. They are resistant to

mechanical stress and do not wipe off, therefore they retain aesthetic

quality for a long period. The elasticity of the composition guarantees its simplicity

application. They have a low level of water absorption, which excludes

the occurrence of mold and mildew. Enamels have a low level of vapor permeability

and have a high cost.

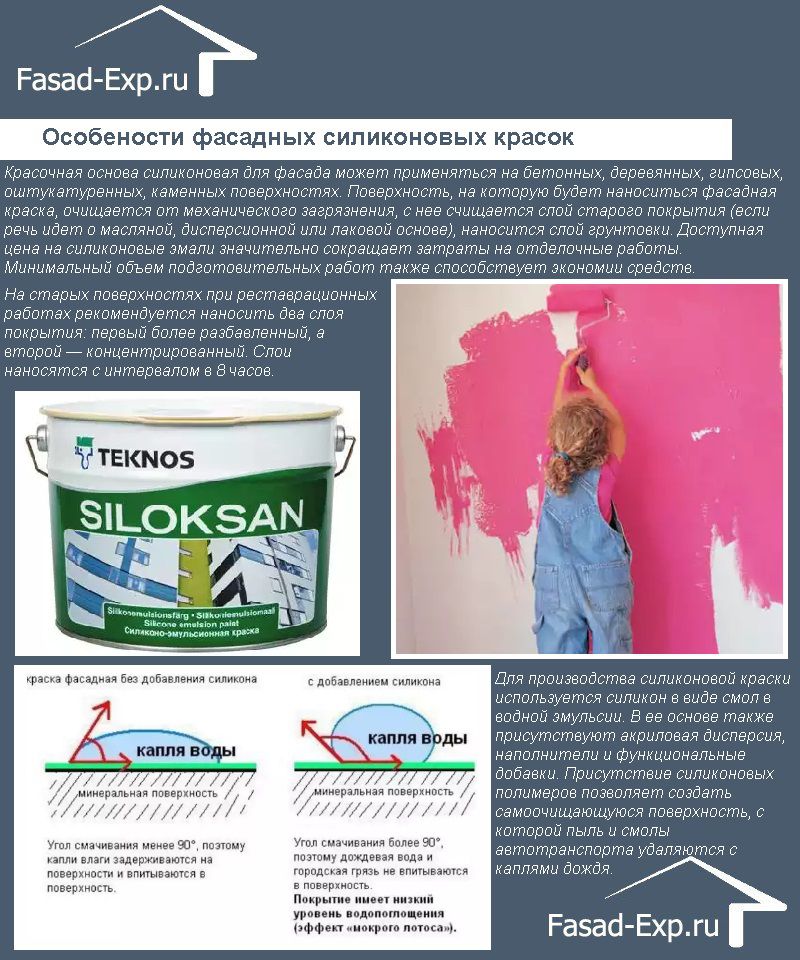

Silicone

The structure of silicone compounds

water emulsion. Silicone-based enamel is being developed, therefore it has

water-repellent properties. It is characterized by:

- Vapor permeability;

- Resistant to precipitation;

- Elasticity;

- UV resistance;

- Lack of statistical

attraction.

With the use of silicone composition, professional painting of building facades is carried out. The disadvantage of special material is its high cost, which is justified by the duration of its operation.

Consumption

- Calculate the total area for painting - first, the area of each wall is determined using the following formula: (length × height) - the area of all windows and doors. If the facade has complex geometric shapes, then they are divided into simple rectangles and the area of each of them is calculated. The results are added up.

- Multiply the area of the facade by the standard consumption for 1 m2 indicated on the package.

- The total is multiplied by the number of layers (most often, by two).

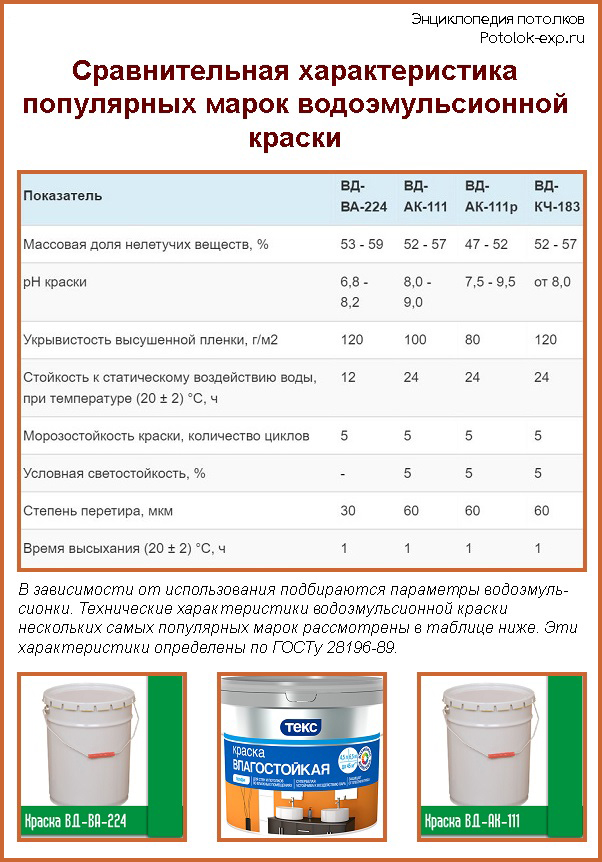

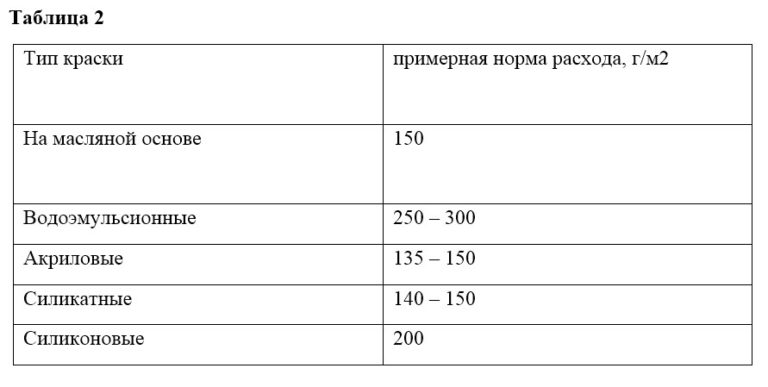

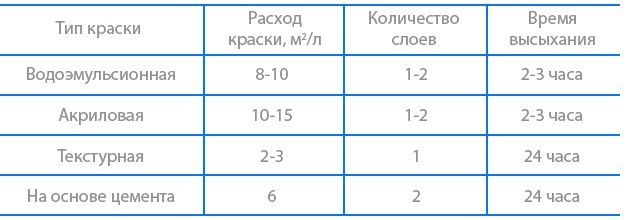

On average, the consumption for typical types looks like this:

- 0.1-0.14 l / m2 - silicone and latex;

- 0.1-0.16 l / m2 - water dispersion;

- 0.5-0.7 l / m2 - acrylic.

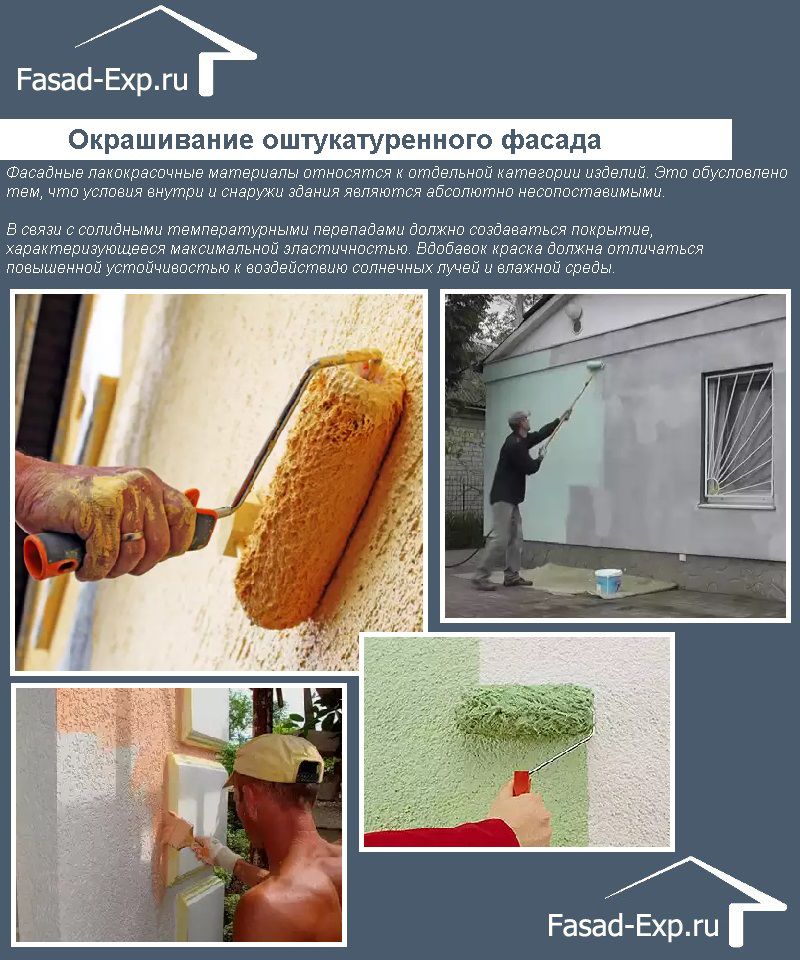

Instructions for painting external walls

In the work, you will need such tools and devices: spray gun (pneumatic or electric), container, roller with medium-length pile, wide brush, spatula, metal brush, scaffolding, step-ladder.

Preparation:

- Remove old cladding from the work surface, fill cracks with putty and smooth out irregularities.

- Places affected by fungus or mold should be cleaned with a wire brush.

- Rinse the walls with water and dry.

- Cover the façade with a penetrating primer to harden the surface and improve adhesion.

According to the technology, it is recommended to additionally process the external walls with a special impregnation that prevents putrefactive processes. It is done in 2 layers with an interval of 6-7 hours.

According to construction experts, work is best planned for late spring or early fall. Usually, at this time, the air temperature stabilizes within the required range, and solar activity decreases and does not harm the painted surfaces when it dries.

Staining:

- Stir the paint with a mixer.

- Cover the wall with a base coat. Apply strokes horizontally, vertically and diagonally, constantly alternating directions, this ensures uniformity.

- Leave the facade to dry.

- After 6-8 hours, apply a fixing layer.

According to the instructions, all mixtures are applied 2 times. The exception is lime-type solutions - they are applied three times.

The cost of facade paints

Consumption of oil paint per 1m2

Before naming specific numbers, I would like to say that the calculation of the consumption of oil paint will largely depend on the conditions for its application. Moreover, this difference can be very significant. That is why, to begin with, I will give an approximate figure for the general case, when there are not a large number of factors that strongly affect both the increase and decrease in consumption. On average, from 110 to 130 grams of paint per 1 square meter is spent in one layer for painting a surface. And then I will tell you in more detail what conditions are needed to reduce consumption, and which ones can lead to its increase.

The consumption of oil paint per 1m2 has its own norms. When calculating the average consumption rate, it is necessary to take into account such factors as: the viscosity of the paint, the quality of the surface and even its original color, the method of applying the paint (spray gun, roller or brush), as well as the place of work (room, street, weather conditions).

Oil paint on metal is consumed the fastest due to environmental losses. For example, more paint is consumed per m2 indoors than in dry, warm weather outdoors. But at the same time, if the weather worsens, then the loss of paint on the street increases many times over. In strong wind, rain, fog, paint is consumed faster than indoors.

As an example, we will consider the PF 115 paint.

PF 115 paint: characteristics and consumption

PF 115 paint is used for both exterior and interior work. It is an enamel paint designed mainly for metal work. The paint box indicates that it is weather resistant, resistant to wind, moisture and solar radiation. But is it? Partially yes. The fact is that paint acquires such properties only after application and complete drying.In the process of application, the paint is influenced by all environmental conditions and its consumption increases most of all in strong winds and bright sun.

Consumption will vary for this type of paint. Depending on the color of the enamel, 1 liter of paint can be painted:

- black: 17 to 20 m2

- blue: 12 to 17 m2

- brown: 13 to 16 m2

- green: from 11 to 14 m2

- white: 7 to 10 m2

- yellow: 5 to 10 m2

This type of paint, which has not yet dried, literally evaporates in the sun. And the consumption can increase significantly.

In concrete figures, these will be very large indicators, you may need twice as much paint as when working indoors, or, say, in calm cloudy weather. A smooth glossy uniform coating is formed only when the paint is completely dry. At the same time, if you apply too much paint in the sun, the coating will be sloppy and rough, and subsequently may begin to flake off.

Best of all, such an enamel paint is suitable for painting galvanized iron, ferrous metals. But it can be successfully applied to non-ferrous metals. True, in the latter case, paint consumption increases.

Painting tool

A lot also depends on what kind of material is applied to the surface. A paint brush, whether natural or artificial, consumes more paint than a roller. This is easily explained - the brush is literally soaked in paint. On the contrary, a roller, especially one based on silicone, is an ideal material for painting metal surfaces.

If you have followed all the recommendations, and the paint consumption still exceeds all conceivable and inconceivable norms - think about it - maybe it's the paint itself? This sometimes happens with cheap, low-quality paint. The manufacturer sets the price lower in the expectation that the consumption of this paint will be colossal, and in the end it benefits from this. Therefore, make sure that the paint is really high quality, and only then proceed to painting.

”

Similar homemade products

Filling the floor in the garage: do it yourself and save money

Laser level: do it yourself

How to make a floor screed with your own hands

DIY oil heater

Foam gun flushing device: do it yourself

Vacuum cleaner nozzle: a useful homemade product for repairs

Varieties of paints and varnishes for painting facades

Each type of paint intended for painting a facade contains an adhesive, color additives and a solvent. In addition to the mandatory components, manufacturers of paints and varnishes are trying to supplement the composition with something special in order to emphasize the originality of the product. Such an addition can be both the technology of ease of application and reliable protection from the external environment. In this case, the basic difference is the content of the sticky substance in the composition.

Acrylic facade paint

Paints and varnishes based on acrylic additives are the most common and popular types of dyes for the facade of the house. These paints have an adhesive called acrylic polymer. It allows you to protect plastered walls from weather and natural influences. In addition, the coloring of acrylic-based products is easy to change, so you won't have any problems with tinting.

Acrylic-based facade paints for home are either organic or with the presence of a solvent (water-dispersed, white spirit).

Organic paints are designed for use in cold seasons, even at low temperatures, as they have the property of fast curing. They come in both glossy and matte types.

Water-based paints have good adhesion to the plastered coating and do not have an unpleasant odor. In addition, they have a fairly low cost compared to other types of paints.

Silicate facade paint

This option is suitable if the facade is planned to be painted in light color shades and without textured coating. Liquefied glass, alkali-resistant additives and calcium borate act as an adhesive in silicate paint. They are designed to penetrate plaster and create internal protection by gluing any cracks. But this tightness does not allow steam to pass through, which is a disadvantage. The application of such a paint implies a good treatment of the plastered surface. In addition, silicate-based paint lacks a wide range of colors, as it contains chemicals.

Silicone facade paint

Silicone-based paint is the most modern type of paint for facade coating, which has incorporated the main advantages of other types of paint and varnish products. It contains silicone resins, which create a reliable water-repellent coating on plaster, the consumption of which is well correlated with the technological properties of analog solutions.

Silicone paint has excellent adhesion even to rough surfaces, including chemical coatings. At the same time, the dried paint does not absorb moisture, but tends to let steam through at almost the same level as that of silicate paints. Its elastic characteristics allow it to bond even wide cracks, which will never unstick under the influence of high temperature, in contrast to acrylic and latex analogs.

Despite the high cost, silicone-based paint is in demand in the field of facade decoration. The reason for this is ease of application, lack of odor and safety for humans.

Other types of facade paints

PVC paint has also found its niche in the market due to its low cost. It has a fairly bright color palette. In addition, the facade can be painted with perchlorovinyl paints and varnishes during the cold season. It protects the surface of the walls from corrosive effects and atmospheric precipitation, showing high resistance to biological and chemical threats.

The disadvantage is that it is easily flammable due to its chemical basis, it is quite toxic and has an unpleasant odor. In addition, PVC dye is short-lived, with a maximum service life of 4 years.

To give the facade an additional decorative effect, many people use structural facade paints, since they have a thick consistency due to the presence of plasticizers in the composition. This type of paint is used as an alternative to decorative plaster.

Paints are divided into a large number of types, so the choice must be made with an orientation to material capabilities and taste preferences.

How much paint do you need?

To correctly determine the consumption of the coloring composition, you need to know the area of the room. For example, a bathroom needs to be painted. Measure the width and length of each surface to be painted and calculate the area from them. The result obtained should be multiplied by the estimated paint consumption per 1 m2.

In most cases, about 1 liter per 10 m2 is spent on the ceiling. Sometimes the consumption is reduced, and the same amount of dye is enough for about 15 m2.

Paint consumption for walls is 1 liter per 10 m2. It can be reduced by pre-coating the surface with an acrylic-based primer.

The consumption of water-based silicone paint is largely determined by the nature of the painted surface. Smooth, perfectly flat or primed surfaces will take much less money. When working with concrete or untreated wood, consumption will increase.

An important role is played by the tool that will be used during work. Highest consumption when using long-haired or foam roller. Therefore, it is recommended to use a tool with medium bristles.

Do not forget about the quality of the dye.If you buy a high-quality water-based paint, you can get by with applying it in 2 layers.

Consumption depending on the varieties

Consumption is almost always indicated on the packaging along with data such as dye density, color and drying time. Here are some examples.

- Silicone water emulsion of the highest quality. It is applied on a mineral base, natural stone, wood or old coatings made of acrylic, acrylic-silicone and structural dyes. In order to paint 1 m2 of surface in one layer, you will need about 160-180 ml of the product.

- Acryl-silicate-silicone with ceramics in its composition. Like the previous type, it is applied to mineral bases, wood and old coatings from various types of dyes, including structural ones. More suitable for outdoor use. Consumption - 180 ml per 1 m2.

- High quality silicone with water repellent properties. It copes well with the effects of moisture, for example, in the bathroom. Protects facades and wood products from mold and mildew. About 160 ml of dye will be consumed per 1 m2.

Classification and properties of facade paints

Before answering the question of how to choose a facade paint for outdoor use, you need to consider the classification of tinting mixtures.

The first level of gradation is the type of solvent used:

- Water;

- Organic liquids (solvent, white spirit, xylene).

Water-borne facade paints are more popular with developers. Their assortment is much richer than that of tinting mixtures dissolved with organic liquids. The main motivations for choosing are the lower price and minimal toxicity of water-based paints.

The second, no less important classification factor is the type of binder that forms a protective film. The service life of the decorative coating depends on its mechanical strength, adhesion (strength of adhesion to the base), elasticity, resistance to frost and sun.

There are several types of binders used for facade paints:

- Cement.

- Lime.

- Liquid glass (silicate).

- Acrylic.

- Latex (rubber).

- Silicone.

- Siloxane.

All types of facade paints have common criteria for evaluating operational and technical properties:

Water absorption (absorption capacity)

Facade paint should not absorb much moisture. Otherwise, the walls will get wet, creating conditions for the development of mold and mildew. In addition, on a damp wall, the process of the release of salts from the solution (efflorescence) is activated and the plaster does not adhere well.

The degree of absorption capacity of facade paint is indicated by the coefficient of water absorption, denoted by the Latin letter W. Manufacturers indicate its value in digital form (kg / h / m2 hour 0.5). For high-quality colourants, this parameter should not exceed 0.05-0.1 kg / kg / h / m2 hour 0.5.

Vapor permeability

This indicator is of great importance for the comfort of living in the house. The paint should not block the exit from the premises to the street with water vapor.

To assess vapor permeability, three equivalent values are used:

- The mass of water vapor (gram) passing through 1m2 of the painted wall during the day.

- Vapor permeability coefficient, denoted by the symbol Sd.

- Diffusion resistance coefficient (µ).

High-quality facade paints pass from 110 to 140 grams of water vapor through 1m2 per day.

The second parameter of vapor permeability Sd is calculated using complex formulas. For us, only its numerical expression, indicated in the technical description of the paint, matters (optimum 0.3-0.05).

If we focus on the third criterion, then the dye composition in which the coefficient µ is in the range from 1400 to 1500 is considered good.

If the facade paint does not allow steam to pass through well, then the plaster becomes damp and falls off

Solar UV resistance

It depends on it how quickly and intensely the coloring composition burns out under the influence of sunlight. This parameter has no numerical value.Laboratory tests can be considered the only objective criterion. According to their data, silicate (polysilicon), acrylic and acrylic silicone facade paints are the most resistant to the sun.

For frost resistance, manufacturers have not come up with a digital equivalent. This indicator can be indirectly judged by the declared service life of the painted coating.

Consumption

When deciding what paint to paint the facade of the house, you should pay attention to the consumption. This is the main economic parameter.

It depends not only on the quality of the paint, but also on the texture of the wall surface and the absorbency of its material. In this regard, the amount of consumption of facade paint varies in a wide range from 0.18 to 0.7 l / m2. Manufacturers indicate the average flow rate over a smooth, primed surface (application in 1 layer).

The amount of paint consumed per 1 m2 of the facade should not be confused with another indicator - hiding power. It shows the amount of decorating compound required for continuous and uniform coloring of 1 m2. This effect is achieved only when the paint is applied in 2 layers.

Drying time

Drying time (in hours) is important for multi-layer painting. Its manufacturers are designated by two numbers

The first indicates the time after which the next layer can be applied (2-5 hours). The second digit determines the time required to achieve operational readiness (at least 24 hours at an air temperature of + 20 - + 23C).

Abrasion resistance is important only for those areas of the painted surface on which people walk. This parameter is measured in cycles of friction that a paint layer can withstand until it is completely abraded.

Varieties

The modern paint market is represented by a huge assortment; there was also a place for facade paints. The most common are such dye mixtures as acrylic, silicate, silicone, latex and textured.

Acrylic is the most popular and inexpensive option for painting outside walls. Interacts with almost all materials from which a building can be erected. After drying, it creates a durable protective film that protects against environmental influences. Does not fade, is abrasion resistant and does not form cracks. These paints are not suitable for lime plaster and sandstone walls.

For such surfaces, silicate paint is more suitable. It is produced on the basis of silicate glue, to which mineral pigments and fillers are added. The service life of this type of glue is 25 years. It is waterproof and provides a secure grip on the material to which it is applied. Resistant to any weathering. This mixture is suitable for use on concrete and brick. Its weak side is that it is susceptible to mechanical stress and is not elastic enough, therefore, it may crack after drying.

Silicone paints are considered one of the best for painting plastered facades. In terms of their characteristics in terms of elasticity, resistance to mechanical damage and prices, they lag behind acrylic compounds, and that is why they have not received such widespread use. After applying this type of paint, the plastered surface does not absorb moisture, but has a high level of vapor permeability and is resistant to temperature extremes. Once dry, the coating is dust-repellent and not exposed to sunlight.

Latex or water-dispersion mixtures are made on the basis of polymer components. The combination of latex and acrylic made it possible to increase the operational capabilities of the formulations and increase the scope of their application. They can be used for interior and exterior decoration, but the surface should be well primed before application to avoid further mold and mildew growth.Any type of surface can be painted with this composition. It does not have a pungent smell, is environmentally friendly, air-permeable and fireproof. Water-based paints can be diluted with water. They dry quickly and are resistant to moisture. The only drawback is that there is no way to tint them in bright and saturated colors.

Textured or structural coloring compositions are suitable for creating decorative coatings not only on facades, but also on other elements of buildings. They do not require careful surface preparation and can be applied to cracks and chips at corners. The composition of the paints contains special plasticizers that help to create a unique protruding pattern. The composition is highly frost-resistant, resistant to ultraviolet rays, insensitive to moisture, dust and dirt-repellent properties. Does not crack due to its high ductility. It can be applied to any surface - both brick and wood.

In addition to the above, there are still cement and cement-lime mixtures, but due to some shortcomings in production, they are of little demand, since they have poor moisture permeability, a simple color scheme and insufficient bactericidal protection. After application, fungi and mold often appear on them.

Calculation depending on the type of material

The most important parameter that must be taken into account when calculating the required paint and varnish composition for facade work is the type of paint. The paint and varnish material is selected depending on the features of your facade. In this case, the consumption for each type will be individual.

Water based paint

The basis for water-based paint is water, which contains an insoluble emulsion in the form of a pigment. After applying such a composition to any surface, the water evaporates and only the pigment base remains in the form of a colored layer.

If you decide to purchase a composition of this type, then you should know that for facade work it is applied in two layers. The time interval between painting two layers should be more than one and a half hours.

Advantages:

- frost resistance;

- low water permeability;

- lack of reaction to exposure to ultraviolet rays;

- acceptable cost.

The calculation in this case should be based on the fact that about 300 grams of the composition is usually spent on 1 m2 of the surface of the facade walls. That is, if you need to paint 10 m2 of the facade, you will need to purchase at least 3 liters of paint and varnish material.

Acrylic paint

Facade acrylic paint retains its color well over time

Acrylic-based paints and varnishes are ideal for facade work. Advantages of acrylic painting:

- the duration of the preservation of the bright color and protective properties of the coating;

- resistance to aggressive atmospheric factors such as high humidity, wind or direct sunlight;

- ease of maintenance, for which conventional detergents are sufficient;

- fire safety;

- absolute safety for human health;

- versatility that allows you to handle any surface of the facade, from brick or concrete to solid wood.

As a rule, the consumption of acrylic paint is less than water-based paint. Usually it is from 150 to 200 grams per 1 m2. More accurate facade paint consumption per 1m2 depends on how bright you want to make the painted surface. Finally, you can only decide when directly applying the composition to the surface.

If in one or two layers you get the required shade, then for 1 m2 you will need about 130-170 grams. If you need to get a more saturated color, you will have to count on 200 grams per 1 m2.

Oil paints and varnishes

Oil paint consumption depends on the desired color brightness

The oil composition consists of drying oil, color pigments and all kinds of fillers.At the same time, fillers can be sold both as part of a paint and in the form of separate solutions. If you are dealing with thick-grated oil formulations, then they will have to be diluted a little before application.

The calculation of the consumption of oil paint, like acrylic, also depends on the desired color brightness. For example, if you apply a small amount of red compound to the surface of the facade walls, it will look pink. The standard consumption for painting on plaster is usually 150 grams per 1 m2 and may vary depending on the required color.

Alkyd paint

Alkyd paints and varnishes are based on alkyd resins that are used in production. Its peculiarity lies in the fact that for facade work, the composition must be diluted with turpentine, kerosene or drying oil. When diluted with each of these components, there will be an individual consumption of material per 1 m2 of the painted surface. Therefore, in order to more accurately calculate the flow rate, one should take into account the amount of additional mixtures that are used to obtain a brighter shade.

Traditionally, the consumption of facade paint per 1 m2 of wall surface is small here and amounts to about 100 grams. That is, only a liter of paint will need to be spent on 10 m2. A distinctive feature of the alkyd composition is the creation of a stylish and original appearance. In addition, this paint will protect the facade surface from the appearance of fungi and mold.

Thus, now you know the approximate consumption for each type of paint. At the same time, when choosing a composition for facade work, you need to take into account a number of nuances associated with its consumption. This will save you time and will not buy missing paint. At the same time, you will not have an extra amount of paint and varnish composition.

Tools for the job

Having chosen what to paint the walls with, consider what kind of tool you need for this. In addition to the paint itself, you will need:

- brush or roller for priming;

- two brushes for applying paint - one wide, for the main surface, the second, narrow, for hard-to-reach places; a wide brush can be replaced with a paint roller;

- to create a decorative surface (for example, grainy or patterned), you can use rollers with nozzles;

- if necessary, a color shade of the desired shade for diluting a white base;

- a grater for grinding small irregularities;

- large capacity (tray);

- ladder;

- personal protective equipment: gloves, a respirator when using a spray gun, a hat when painting ceilings.