Manufacturers

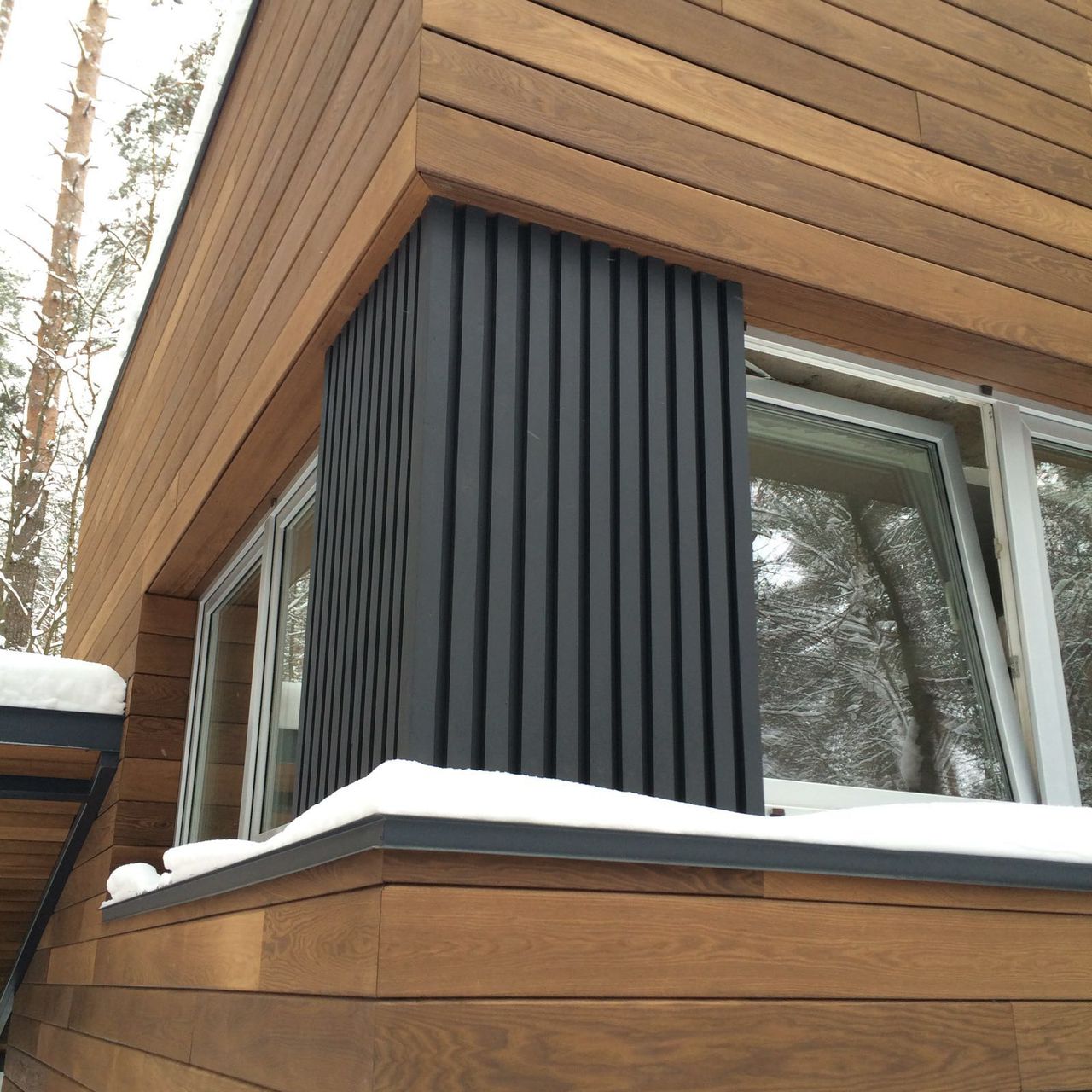

The popularity of the facade board is increasing every year. It is used not only for cladding facades, but also as decorative coatings for certain areas of the house. There are many varieties of cladding boards on the market today.

Among all this variety, there are several popular brands:

- Vetedy;

- Bruggan;

- Legro is a Hungarian-made product that stands out for its high quality and original design;

- PS-Wood is a domestic manufacturer of WPC boards, which are made using German technology;

- Revaldia;

- "Ekoles" - produces high-quality facing plank, which is suitable for various types of houses.

Features of the use of WPC boards

WPC board (wood-polymer composite) is a generalized material made of plastic and wood. The essence of the creation technology lies in the fact that shredded wood is heated to a high temperature and particles of polymers, that is, plastic, are gradually added to it.

When certain temperature indicators are reached, the WPC is given the required shape. The main advantage is that in essence the material is wooden (the inclusion rate of wood reaches 90 percent), but thanks to the inclusions of polymers, it acquires the useful properties of plastic, in particular:

- immunity to weather conditions;

- high mechanical strength;

- low water absorption;

- long service life;

- does not fade in the sun;

- provides sound insulation;

- helps to keep warm in the house;

- ease of installation;

- created from environmentally friendly materials;

- gives the surface an attractive and stylish look.

WPC boards are different in appearance, size and configuration, but they also differ in scope. The most famous and popular are terraced ones. They are frames made of wood, which are equipped with a convenient tongue-and-groove fastening and stiffening ribs. They are distinguished by the optimal ratio of quality and price.

Facade panels are more expensive, which explains their relatively small scope. Panels made of polymers and wood are heavy, but have the best technical characteristics (they keep heat well, do not transmit noise, are resistant to moisture and the sun, and look great). WPC is also used to create gazebos, fences and railings.

There are certain

features of the use of boards, because of which the material cannot be called

universal

Note that:

- it is impossible to clad buildings from hollow

materials; - it is necessary to store the boards under an opaque awning, in

horizontal position and dry place; - the color may be uneven, but when styling it

disappears; - for acclimatization, the material is placed for 72 hours in

natural environment; - stainless steel hardware is used or

galvanized; - a special steel frame is installed on

building; - cannot be used in rooms with increased

humidity; - before use, the material is checked for

strength.

From conditions

the temperature expansion of the material changes in the environment. It is calculated

according to the tables, depending on the average rates for their region of residence.

Peculiarities

Facade board is a finishing material used to cover the outer walls of residential buildings. Technically, it is a product based on natural wood that can be specially treated. Such influences are capable of changing even the structure of the material, which increases its technical characteristics.

Facade boards can have various sizes and shapes, but externally, the products are endowed with a structure that is completely identical to natural wood. This applies to varieties, the production of which involves the introduction of additional polymer components into wooden surfaces.

Facade board for outdoor decoration is widely used in construction. It differs from ordinary wood in greater resistance to external factors.

Particular attention should be paid to painted materials or thermal board

The main purpose of the facade board is to decorate the facades - it cannot be used as a protective material, since its characteristics do not allow creating optimal conditions for thermal insulation.

Short description

WPC facade board: the cut shows how it will be attached

WPC facade board: the cut shows how it will be attached

Wood-polymer composite is a modern material from which panels are made for finishing the facades of industrial, public buildings, as well as cottages.

Consists of finely chopped wood fiber and polymers like polyvinyl chloride.

The main components are mixed and then pressed under high temperature. Thus, a textured, durable material in the form of facade panels is obtained.

The successful symbiosis of organic and inorganic components gives it unique characteristics.

Scope of application

WPC facade board is successfully used in interior and exterior finishing works:

- Cladding of building facades. Main area of application. Acts as the main material.

- Finishing of verandas, terraces in country houses. Can be primary or secondary material.

- Facing of the inner walls of dressing rooms, hallways, rest rooms.

- Arrangement of fences. An alternative to the usual wooden picket fence.

Step-by-step instructions for installing a WPC facade board

Planks for facade finishing are laid by two people. This greatly simplifies the process and helps to avoid mistakes. Installation is carried out in several stages. Each of them is mandatory.

Preparation of tools and materials

In addition to buying the planken itself for the exterior decoration of the house, taking into account the area plus 10-15 percent, a number of necessary materials and tools are required. It will be needed from the materials:

- clips for installation;

- brackets;

- profiles;

- anchors, screws and dowels;

- corners, slats.

Toolkit list

impressive, you won't be able to get by with one drill. In addition to the tool available

must be:

- puncher;

- screwdriver;

- saw;

- scissors for metal;

- tape measure and ruler;

- square;

- level from 60 centimeters.

Surface preparation

Preparation

is carried out without fail, as this determines the effectiveness

process. Worn surfaces are removed, parts are cleaned and replaced.

The old coating is removed, pipes, window sills and other protruding constructive

elements.

Additionally

walls are wiped with disinfectants. They are already affecting

previously cleaned surface, clean and dry. Funds shield

the inner part of the wall from the appearance of the fungus.

Mounting

frame

The frame is an important part of a ventilated façade. The durability of the structure depends on the quality of its installation. The dimensions of the lathing are calculated using schemes. The work is started only after agreeing on the obtained calculations and checking them.

Installation of boards, as well as installation with your own hands from an edged board, is carried out in three ways. You must choose from the following options:

- aluminum profile and wood - the price is small, quite simple installation, but wet materials cannot be used;

- WPC - convenient and simple, installed using dowels;

- L-shaped profiles - applicable to all types of structures, fastened with clamps.

The frame for boards made of wood-polymer composite is mounted according to certain rules. First, the height of the facade is calculated (along the perimeter, horizontally and vertically). After marking the holes, the brackets are installed. Keep track of those that the distance between them does not exceed 50 centimeters. The extreme rows should not recede more than 2 centimeters from the slopes vertically, and horizontally - up to 15 centimeters. Directly the installation of the frame takes place according to the following algorithm:

- attaching the first profile;

- line alignment;

- fix the second profile;

- screw the profile over the entire surface, avoiding window

openings; - add each profile, while screwing it into the pre-

holes made.

End, docking

and corner planks are needed to frame other walls.

The lathing is made in a similar way, but instead of brackets, logs are taken.

Insulation installation

Insulation

eliminates cold bridges that are observed between the frame and the wall. Use

it or not is an individual matter. Depending on the type of insulation, the rules change

its use and installation. In particular, insulation:

- cotton wool is mounted using dowels on the basis that

you will need at least 6 of them per square meter; - expanded polystyrene or polystyrene is laid on

construction glue.

A separate

pay attention to the width of the insulation

It is important that it matches the height

only in this case the panels will not bend and deform

Installation of WPC boards

Mounting

is drawn from the bottom corner and continues horizontally. Algorithm of actions:

- make a hole at the bottom of the frame;

- fix the board with a self-tapping screw and a clip;

- tighten (the impact force varies depending on whether an eternal tree or larch models are used);

- pin the clip to the top and set the next board;

- using two screws to fasten the boards further;

- mount with a slight upward displacement of the seams - this will provide additional strength;

- cut the last row so that a gap of at least 10 mm is obtained.

Coating

Coating with protective oils in production conditions costs +1200 rubles / m2. The service includes: grinding, covering the underside in 1 layer, covering the front side in 2 layers. We use only proven materials Kreidezeit and Leinos, in our range of more than 50 possible shades to choose from.

Thermo ash

Thermos pine

Thermos pine

Any natural wood must be protected with high-quality tinted oils from:

BURNOUT. When exposed to sunlight, the tree begins to fade and, over time, takes on a dirty gray tint. At the same time, ONLY tinted oils protect against burnout. DIRT AND DUST. Various particles of dirt and dust, when they hit an unprotected surface, begin to destroy it. Also, dirt can penetrate deeply into the porous surface of the wood and leave unpleasant stains that will be very difficult or impossible to sand off. CRACKS. Once on a surface unprotected with oil, water is instantly absorbed into the porous surface of a living tree. When the temperature drops, moisture crystallizes and cracks appear on the surface of the wood, which spoils the appearance of the decking.It is also imperative to protect the ends, this is the weakest point in a living array. We recommend covering the planken not only from the top, but also from the bottom. Any cheap formulations can be used below. This inexpensive symbolic layer on the back of the deck will provide additional protection.

Mounting

The technology for installing cladding from a facade board consists of the following sequential operations.

Preparing the walls. This often involves strengthening the top facing layer. If the plaster has peeled off on the walls, then these places should be repaired so that the situation does not worsen later.

Fastening of thermal insulation.This layer is optional, but the facade board allows the use of insulation. Here you can use both mineral wool and other similar materials.

At the same time, it is important to take care of the waterproofing of the insulation - it is best to sheathe it on both sides with a special protective film.

Installation of the lathing. Either wood planks or a metal profile are used as a frame. The first option is suitable for planken and all types of natural wood boards. If composite materials are used, then it is better to use a metal profile that can withstand high loads. All guiding elements of the frame are arranged vertically.

Fixing the board. The fastening of the elements is simple. In the case of a wooden frame and planken, ordinary self-tapping screws are used - they screw the board to the base

It is worth noting that these types of material do not overlap - it is advisable to leave a small gap between them, which will allow the tree to expand. For composite boards, special fasteners are used, which are designed for metal

It should be noted that sometimes ordinary metal screws can be used here.