What is required for door installation

To install the door, you need to prepare all the necessary tools:

To install the door, you need to prepare all the necessary tools:

- level;

- marker;

- glue;

- polyurethane foam;

- accessories for the door.

Before installation, the walls must be leveled. This will help in eliminating distortions.

Be sure to pay attention to the floor and slopes. After removing the old door, it is necessary to correct the opening, reinforce the loosened structures with a wooden bar

This will avoid distortions.

If the doorway is decorated, then the hinges are attached and the door leaf is fixed on them. The drilled holes are closed according to the veneer color with plugs. Handles and locks are installed. The threshold is finalized. The shape of the panel should be perfectly rectangular and the corners should be straight.

If you are faced with the question of choosing a material for doors, then you must proceed from practical considerations. Take a closer look at the eco-veneer. This high-quality, durable and beautiful material will decorate your home for many years.

Today the assortment of eco-veneer is constantly expanding. This allows customers to successfully choose a model to their liking.

Advantages and disadvantages of interior doors made of eco-veneer

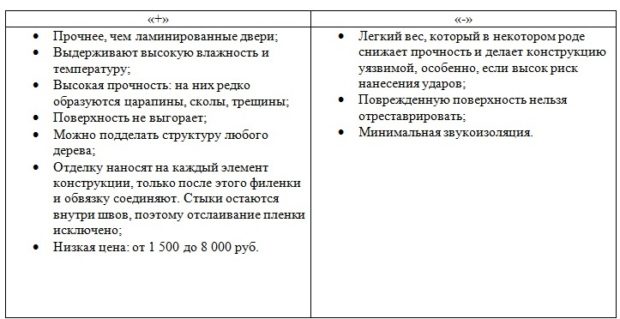

An interior door covered with an eco-veneer has its pros and cons. Consider in detail the positive and negative aspects of these joinery products.

pros

These include:

- low web weight simplifies the transport and installation of the door. In addition, injuries from getting fingers in the doorway will be less significant, especially for young children;

- wear resistance. The synthetic adhesive polymers that make up the eco-veneer prevent the appearance of scuffs, chips, and also protect the coating from the harmful effects of ultraviolet radiation;

- high moisture resistance... The presence of a polymer film prevents moisture from entering the wooden elements of the canvas. Due to this property, the eco-veneered doors can be installed in bathrooms, kitchens and other rooms with a high degree of humidity;

- resistance to amplitude fluctuations in temperature... Even a sharp drop will not lead to the destruction of the structure;

- wide range of products. Nowadays, you can easily choose a canvas that matches any interior, from Hi-Tech to classic;

- unpretentious maintenance... The door leaf can be easily cleaned of stains and dirt with a cloth soaked in a solution of any detergent;

- environmental friendliness... Both wood and polymers do not emit toxic substances and do not cause allergic reactions in humans. Door panels covered with eco-veneer are allowed to be installed even in children's and medical institutions;

- high accuracy of imitation of natural wood... It is quite difficult to visually distinguish an eco-veneered door from a natural one;

- affordable price of products... The cost of products covered with eco-veneer is much lower than natural ones, or processed with natural veneer of valuable wood species.

The list of advantages is quite impressive, but there are also disadvantages.

Minuses

The most significant disadvantages are:

- poor sound insulation... The corrugated cardboard used to fill the canvases does not interfere with the propagation of sound waves;

- low rates of thermal insulation... Despite the presence of air in the inner cavity, the thermal conductivity of eco-veneered structures is quite high;

- low strength of door leaves... A strong punch or kick is sure to leave a mark. It can also happen when hitting furniture or other hard objects;

- low maintainability... In the presence of serious damage (deep scratches, dents and other defects), it is almost impossible to restore the damaged surface;

- low vapor permeability... Due to the high density of the eco-veneer, the doors impede natural air circulation, which negatively affects the microclimate. Only regular ventilation of the room can save the situation;

- gloss and repeating texture... By these features, it is easy to distinguish eco-veneer from natural veneer or solid wood.

Despite the disadvantages listed above, eco-veneered door panels are becoming more and more popular. This is evidenced by the reviews published on the Internet.

Repair of doors made of eco-veneer

Even such doors sometimes have to be repaired. There may be several reasons for restoring the integrity of the coating:

- swelling of the coating;

- the appearance of scratches and chips.

The first reason is the most harmless, all you need is a slightly heated iron, which is applied to the problem area for 5 seconds.

Elimination of scratches can be entrusted to a wax pencil, matched to the color of the canvas. Pre-clean the problem area, warm up the wax crayon and cover the scratches. After hardening, remove excess material and cover the restored area with varnish.

For more serious damage, patches are indispensable. The damaged area is cleaned. The necessary fragments are cut from individual veneer sheets, identical in texture and color with our door leaf. After they are carefully glued, smoothing the docking places. The recovered coating is also varnished for durability.

The choice of interior door leaf:

What is eco-veneer doors

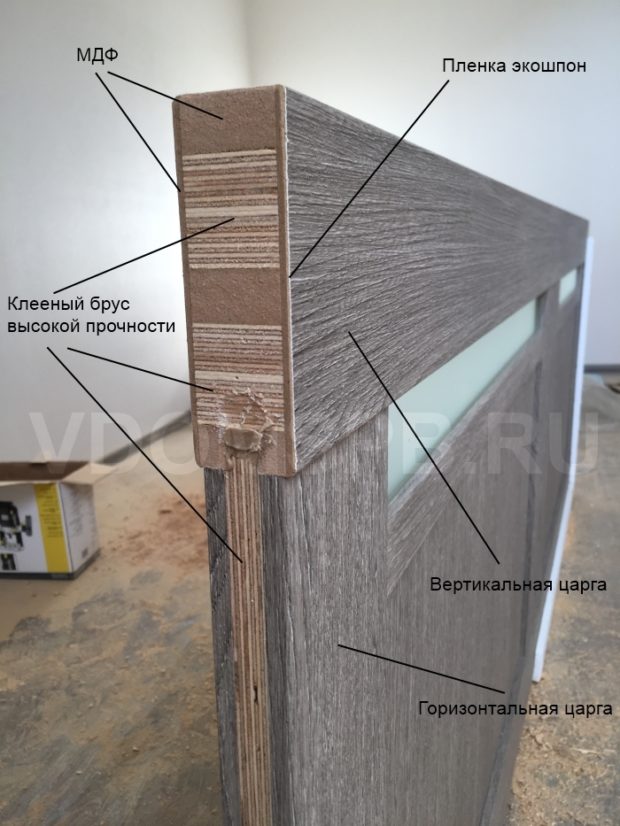

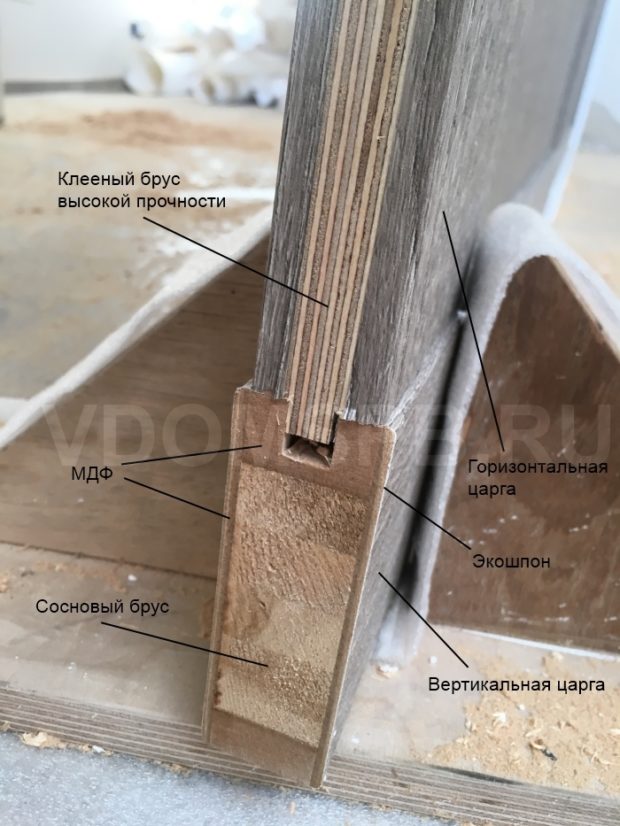

Eco-veneer is on the agenda. First, let's imagine what the cutaway models look like. Such a construction turns out to be multi-layered, where:

- Base - solid pine or high strength glued beams;

- Upholstery - MDF panels;

- Decorative finishing - eco-veneer.

Almost all doors with an eco-veneer coating are side-by-side structures. 4 drawers (2 horizontal and 2 vertical) form a solid frame, which is filled with MDF inserts or glass, depending on the design of the model.

Why don't eco-veneer doors fade under the bright sun?

In finished form, the finishing material is a film, the same as PVC or other rolled analogs. Why, then, is the word “veneer” in the title?

The fact is that wood is used here as a raw material, or rather, the most "waste waste" left after woodworking. They are mixed, and then several times, layer by layer, subjected to pressing. The result is a thin film with a textured surface.

Yes, as far as color is concerned - the material is painted not with a brush over the surface, but in bulk. Before the substance is sent to the press, it is thoroughly mixed with the addition of dye. Then the adhesive polymer is poured here. The technology makes it possible to obtain a material with a homogeneous structure. Shades on the inner and outer sides of the model are excluded. To obtain absolutely any color and the desired relief, exactly imitating all types of wood, up to oak and exotic wenge, a huge collection of dyes is used.

We saw the abbreviation CPL in the description of the model - it means that you have the same eco-veneer in front of you. Apparently, these doors are produced abroad, and they have their own designations.

Please note that materials with a very low cost are used for production, therefore, pretty doors made of eco-veneer cannot be expensive.

"Eco" means safer than natural veneer?

Yes, you can say that. Nevertheless, the point is, of course, relative, because in this case it is not the materials themselves that have to be compared - veneer and eco-veneer, but the compositions with which they are attached to the canvas.

To glue natural veneer to the surface, glue is used.It is good if the manufacturer is responsible for the choice of consumables. And if not, then at least a persistent chemical odor and toxic fumes are provided to you. In the case of eco-veneer, you do not run the risk of getting into this kind of trouble, because in this case both the film itself and the MDF have sufficient adhesion and stick to each other without the help of binding intermediaries.

Eco-veneer is bought, if you need it inexpensively, but on the damage of the array

Everything is correct. Actually, this class of interior doors was created with the goal of making spectacular, modern, stylish models, exactly repeating the relief structure of natural wood, more accessible. The surface of the eco-veneer gives the same tactile sensations as when touching wood. Add to this a great design, a great variety of options, colors, styles, compatibility with all types of accessories - and all this is several times cheaper than absolutely the same elite class doors.

Pros and Cons - Which Wins?

Interior doors made of eco-veneer are found in all directions of classifications by style, color, type. The film is flexible, bends easily and is used for finishing embossed surfaces. This opens up new design possibilities. Canvases sheathed with eco-veneer imitation oak, mahogany, ash, with two panels and a flat crossbar in the middle - a common option for a classic living room. For dark rooms, you can choose doors with glass and light eco-veneer trim. If you want more elegant - order glass with an ornament.

See what element in the room you would like to combine the door with: the range of inexpensive models is one and the most diverse, so you can choose a product for parquet, skirting boards, furniture facades.

Advantages and disadvantages of eco-veneer

After determining what an eco-veneer is, you need to get acquainted with its (or, rather, their) properties, because unfounded statements that they are the best, insufficient evidence. Any material is learned in comparison with competitors, therefore, one cannot do without a list of advantages, as well as a search for shortcomings.

Dignity

Several wonderful qualities can be attributed to this category at once. Moreover, they apply to all types of artificial analogs.

- Durability, wear resistance. The most important advantage of eco-veneer is resistance to abrasion, any mechanical stress, including the attacks of four-legged household researchers. Successful resistance to humidity, as well as temperature extremes, the absence of fear of sunlight are also among the advantages.

- Environmental friendliness is the reason the material owes its growing popularity. Its safety is confirmed by special certificates. Doors with such a coating are allowed to be installed in child care facilities.

- Great resemblance to natural veneer. Such cladding can successfully imitate the structure of any wood, and even an experienced person is not always able to distinguish it from ordinary material without getting close.

- The ability to choose a material that imitates the structure of almost any wood.

- Low price when comparing artificial veneers with natural rivals.

- The unpretentiousness of the coating, which does not require any special care.

Another plus is the integrity of the door covering: in this case, gluing the edges to the ends of the products is not required, since they are simply wrapped in material.

disadvantages

Without the above list of minuses, the assessment will be incomplete, biased, because it is possible to make a decision about the expediency of a purchase only if the advantages still prevail over the disadvantages. These include:

- Low sound insulation characteristics. The reason is the hollow door leaf, with MDF inserts. In some models, corrugated cardboard is used, which also cannot boast of soundproofing qualities.

- Insufficient air exchange.Synthetic substances, used as a binder or base, impede air circulation. The result is not the best indoor climate, so more frequent ventilation will be needed.

- The inability to restore the coating after severe damage. Such products cannot be repaired or restored.

- The fragility of the coating to break is a minus of the product made of wood fibers.

This is not to say that materials have a large superiority of advantages over disadvantages. The former are not too exceptional, the latter are not so scary. The only thing that can alert you is the presence of the "eco" prefix. Such veneer is still not a completely natural product, so its safety, seemingly confirmed by various certificates, is still capable of raising doubts.

What are modern doors made of?

This article is for people who are not involved in door making. The article will be useful to those readers who want to buy MDF interior doors in Mogilev.

One of the most important questions that the buyer must decide for himself is what material his future doors should be. In the selection process, sellers provide their customers with a large amount of information, often using terminology that is incomprehensible to most people. Let's try to tell you in simple words what this or that name of the material from which the interior doors are made.

What is MDF?

MDF is a very environmentally friendly material. MDF is a fine wood chip that is pressed under high pressure at high temperature.

What are MDF doors?

MDF doors are made as follows: a pine frame is filled with compressed cardboard honeycombs. This structure is then faced with MDF boards. Various coatings are applied to MDF boards, for example, a finish film, laminate, laminate or paint.

What is MDF doors laminated with a finish film?

What are laminated MDF doors?

Laminatin (synthetic veneer) is a textured paper impregnated with synthetic resins. It has a thickness of about 0.4 to 0.8 mm and is called by another synthetic veneer. Laminatin has high aesthetic characteristics and improved mechanical resistance. Also among the advantages it is worth noting the environmental friendliness of the material and its resistance to moisture. Among the shortcomings, it can be noted that the surface is too smooth to the touch and the high price for such doors.

What is MDF laminated doors

Laminate (artificial veneer) is a decorative coating that has a corrugated wear-resistant surface that imitates natural wood veneer in color and structure, but due to the use of artificial materials in the manufacture of doors of this type, they are much cheaper than wooden doors. These doors are environmentally friendly, practical to maintain and operate, suitable for installation in bathrooms.

Veneer is thin cuts of valuable wood species. The structure of veneered doors consists of a pine frame finished with MDF sheets and glued on top of them with a layer of veneer by hot pressing. The veneer in combination with the varnish gives the door additional moisture resistance. The veneered doors are not afraid of such factors as drying and corrosion. The disadvantages include sensitivity to sunlight.

What are PVC coated doors?

PVC (PolyVinyl Chloride) coating is a durable polymer film material that is resistant to temperature changes, which is an important factor in changing climates. Unlike veneer, PVC film does not dry out, has excellent moisture resistance and is resistant to mechanical stress. PVC doors can be easily cleaned using cleaning agents. The advantage of this coating is increased wear resistance, a variety of colors and a relatively low price.The main disadvantage of this coating is the release of harmful chemicals when exposed to high temperatures, for example, from heating by sunlight.

What is Eco Veneer coated doors?

The construction of Eco-Veneer doors is similar to that of veneered doors. All the difference is that instead of natural veneer, a new generation of polymer coating is glued to the MDF board - Eco-Veneer (polypropylene). This material does not contain substances harmful to health, it is resistant to chemical attack, i.e. doors can be cleaned with detergents, including bleach solution. Eco-Veneer is resistant to sunlight - its tone and color remain unchanged.

What are solid pine (alder) doors?

Solid wood doors are durable and surprisingly strong. The pattern of the natural wood material is visible even through the top coat of varnish. Solid wood doors are resistant to mechanical stress and have a solid appearance. The main advantages of such doors are environmental friendliness, strength and durability. Doors made of solid wood must be protected from intense sunlight and moisture.

Perhaps, after all that I have read, it became even more difficult for some of the readers to decide on the choice of an interior door, but this problem is easy to solve. If you want to buy interior doors and live in Mogilev or the Mogilev region, you can contact the specialists of Exact Hod LLC by phone +375 44 583 44 82, +375 29 743 35 99 and get professional advice.

Doors from which array is better

The production of interior doors has become so massive today that some agencies are trying to compile ratings of companies involved in this area. The market is really oversaturated with offers. It would seem easier to buy the right product under these conditions. In fact, choosing an interior door from so many options, taking into account the variety of colors, textures and prices, is not an easy task, even if we are talking about a specific category of structures.

Doors from which solid wood is better, what to look for during inspection, what is primary and what is secondary - we suggest discussing these and other issues in our material

The struggle for the quality of an interior door begins long before its production. Before getting into the hands of the manufacturer, it must go through several stages of preliminary preparation:

- The stage of selection of high-quality, ecologically clean forest;

- Drying;

- Dissolution into lamellas;

- Bonding into a single sheet.

Taking into account the chosen style, paneled structures and doors are produced from re-glued solid wood.

Choice of wood

Here we mean not only the type of wood, but first of all its quality. A simple buyer is not able to control the selection process for logging, but you can inquire about the origin of materials from the manufacturer and check the availability of certificates.

Correct drying

Only dry wood is used for the production of interior doors, in particular the massif, brought to the minimum moisture content - on average 8%. This level can be achieved in two ways:

- Drying in vivo;

- Processing in drying chambers.

As a rule, manufacturers use the second drying method because it is faster. The rocks are dried in different ways, taking into account the peculiarity of the variety, strictly maintaining the temperature and pressure.

Splitting into lamellas

There are no interior doors made of a solid tree trunk. Immediately after drying, the workpiece is cut into small bars, which are then glued together and get a door leaf of the required size. Thus, manufacturers are struggling with internal stress arising during operation due to changes in temperature, humidity, and pressure.If you just cut out a door from a single piece of solid wood, it will be very sensitive to changes in the environment, which means it will quickly dry out, crack, and become unusable.

Wood protection

The protective properties of the future structure are given in two ways - by impregnation with some special compounds and by applying others to the surface of the canvas, molding. The materials used for external protection are also decorative. On sale there is a large collection of primers, stains, waxes with antibacterial and antifungal properties, as well as varnishes, paints, enamels with various tint options.

Coating advantages

Glass door models

Artificial veneer has a number of advantages that distinguish it favorably from both its natural counterpart and other synthetic film coatings. Let's list the main advantages:

Excellent wear resistance. In terms of its safety margin, eco-veneer is much superior to laminating film. This means an interior door covered with eco-veneer has the best resistance to short-term mechanical stress (shock), copes with significant changes in humidity and temperature without any problems (suitable for installation in a bathroom). In addition, this material does not change its original color under prolonged exposure to sunlight, it is resistant to scratches (of course, within reasonable limits).

Ecological cleanliness. Each regional dealer selling door systems with an eco-veneer has certificates of conformity confirming the environmental safety of each door model with an eco-veneer.

Accurate recreation of the woody structure. This material is capable of accurately repeating the structural features of wood of any species, which, together with a wide range of colors, allows the manufacturer to make a door that, both in appearance and in structure, would practically not differ from a door made of original wood.

Affordable price

It's no secret - it is important for the buyer to get a quality product at a lower cost. When planning the purchase of interior doors, you can be sure - models made of eco-veneer will cost a little cheaper than similar products, which include natural veneer.

Easy care

Due to the fact that the surface of the eco-veneer is very resistant to the effects of potent substances, which are present in excess in modern detergents, now it has become easier to take care of the cleanliness of the door leaf, and, therefore, more pleasant.

In addition to the listed advantages, it can be noted that the eco-veneer applied to the door, unlike other materials, does not flake off at the ends. This quality has become achievable due to its tight fit to the door leaf.

Properties of eco-veneer door leaves

The described interior doors will not change colors with prolonged exposure to the sun, and the installation of structures can be done in a room with high humidity, as for bathrooms, kitchens and bathrooms. Products are not afraid of exposure to high temperatures. Among the features of eco-veneer doors, one can single out their long service life. The material is not prone to chipping on impact.

In addition to elevated temperatures, the material easily copes with frequent and significant temperature fluctuations, and these phenomena do not become the reasons for the appearance of cracks. The production of canvases does not imply the presence of edges on the uprights and drawers. These parts of the doors are completely covered with a film, which eliminates the possibility of flaking, characteristic of the edge. As a result, the end face looks aesthetically pleasing and is characterized by durability during the entire service life.

In addition to elevated temperatures, the material easily copes with frequent and significant temperature fluctuations, and these phenomena do not become the reasons for the appearance of cracks. The production of canvases does not imply the presence of edges on the uprights and drawers. These parts of the doors are completely covered with a film, which eliminates the possibility of flaking, characteristic of the edge. As a result, the end face looks aesthetically pleasing and is characterized by durability during the entire service life.

Interior doors based on eco-veneer have found their application in premises of any purpose: apartments, houses and offices.This is due to the fact that the models can be chosen from a huge variety of shades, textures and textures that are very reminiscent of real wood. Such interior doors are quite easy to clean, for this it is enough to wipe the surface with a rag slightly moistened with soapy water.

The material is made by vacuum pressing, and in the process natural wood fibers are glued together with a substance based on polypropylene. Unlike polyvinyl chloride, which is better known as a PVC film, polypropylene does not contain substances harmful to humans, which allows it to be widely used in pharmacology and even in the food industry.

If polypropylene catches fire, then the products that will be released at the time of its melting will not be more harmful than the substances released during wood burning. Eco-veneer doors will not change their linear dimensions and become stained when exposed to moisture, they will not act as a surface that will be a favorable environment for the formation of mold or mildew.

The appearance of eco-veneer products deserves positive reviews, because they can be matched to any interior, unlike wood doors. Thus, doors made of eco-veneer, corresponding to the shade of bleached oak, can have a color from dark gray to white. But the wenge eco-veneer is distinguished by darker tones and is able to fit into the interior with predominant light shades, which is welcomed by those owners who want to create a contrast in the interior of the room.

White wood does not exist in nature. For this reason, if the design requires the use of white, then this requires the purchase of products that have been dyed. The advent of eco-veneer made it possible to resolve this issue. White interior doors eco-veneer cannot be distinguished from natural wood products. And the low cost of the described products is due to the fact that wood chips have a very low price, this also applies to polypropylene. Pros:

- practicality;

- environmental friendliness;

- abrasion resistance;

- imitation of different types of wood;

- does not change color when exposed to the sun;

- not afraid of exposure to high temperatures;

- wide range of applications;

- ease of care.

Manufacturing features

What does “eco-veneer” mean and what are such doors remarkable for? Eco-veneer is a multilayer material consisting of wood fibers glued together with environmentally friendly synthetic resins. This material does not contain hazardous substances for humans or animals. Manufacturers produce and deliver it to factories in rolls. Later it is cut and pasted over the door leaves.

During the production of the material, the finest wood fibers are dyed separately, which gives it a significant resemblance to natural solid wood. Then the fibers are glued together, pressed under conditions of increased pressure and vacuum. The raw material for production is usually coniferous wood. A special technology excludes the possibility of delamination of the material, its separation from the door frame. Thus, the service life of the products is quite long.

Despite the fact that this material is made from natural wood fibers, it has a more stable shape. Thanks to the advanced manufacturing technology, it is less susceptible to deformation in comparison with natural solid wood. In addition, eco-veneer is distinguished by high moisture-resistant properties, and in terms of strength it significantly surpasses natural wood.

Interior doors eco-veneer

Interior doors eco-veneer

To understand which doors are better to choose: veneer or eco-veneer, you should evaluate all the advantages and disadvantages of the new generation material.

What are the advantages of eco-veneer:

- The material will not lose the brightness of color and texture even when exposed to sunlight.

- It does not crack, it is resistant to mechanical stress.

- Doors can be installed in rooms with high humidity.

- The eco-friendly material does not cause allergic reactions in the human body, unlike some paints and varnishes used with natural materials.

- Does not emit harmful substances even when exposed to direct sunlight.

- The material is resistant to moisture, easy to clean by any means, does not leave greasy stains on the surface after washing.

- Well imitates the color and texture of any natural wood. In addition, modern production technology completely eliminates the possible difference in shades in different batches.

- More affordable cost in comparison with natural wood.

Like any material, eco-veneer has its drawbacks:

- Interior doors made of eco-veneer are an order of magnitude lighter than those made of natural solid wood. If exposed to significant physical force, the canvas can be damaged.

- Damaged sections of the door leaf are almost impossible to restore.

- Eco-veneer has low sound insulation properties.

- Rooms with interior doors made of eco-veneer require more frequent ventilation. The synthetic adhesive does not promote sufficient air exchange, as a result of which it negatively affects the microclimate.