Stamps

| Name | Description |

|---|---|

| Contact | It is effectively used in rooms with high humidity. They can seal pipes, showers, bathtubs, toilets. |

| A moment from Henkel | Two-component glue "Moment Super Epoxy" is produced in tubes or syringes with a volume of 5 g or more. Also, the composition of Epoxylin is sold in 30, 48, 100 or 240 g. The product is reliable, durable and easy to use. |

| Super Grip | It is an equal component epoxy adhesive containing mineral fillers that increase the strength of the joint. Glues almost any material. |

| Bison | Transparent gel consisting of two components. They can fill voids, cracks, chips, restore the original shape of parts. |

| Class | The tool is similar to the previous one. Bonds metals, alloys, car repairs, pipes or sinks. |

| Second | Bonds all surfaces in just three minutes. |

| Novocolor station wagon | Slightly shrinks, has high adhesion to various substrates. The tool can be used to glue large cracks, chips. |

| Metal bond | Initial coupling in just 5 minutes. You can glue metal to wood, plastic or other substrates. |

| Compound K-153 | For joining metal structures exposed to constant moisture or petrochemicals. |

| Ultima (two-component adhesive) | It is used in decorative and cladding works. They can repair vehicles, boats, boats, household appliances or plumbing. |

| Poxipol | It crystallizes within 10 minutes after mixing, so you need to work with it quickly. |

| EAF | Bonds any surface, from glass to metal. Has a good value for money. |

| Epoxy steel | A tool for all foundations. Refers to auto chemical goods, as it is more often used in car repairs. |

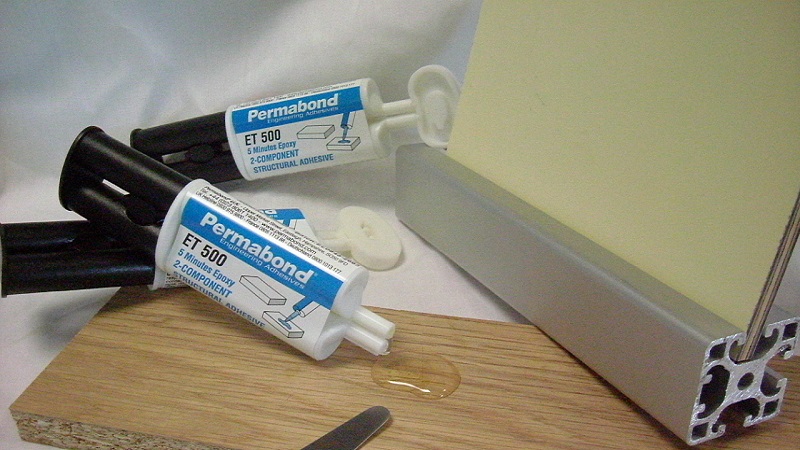

| DoneDeal Epoxy Adhesive | 2-component epoxy adhesive, available in syringes. Creates a tight, sealed, waterproof seam. |

| BisonEpoxy 5 min | Reliably adheres to any surface, has a high polymerization rate. |

| Abro | This is a cold welding that joins substrates of any material. It can be produced in white and black. |

| Novol Plus | Resin based product combined with hardener and fiberglass. Large chips, cracks or defects can be glued together. |

| Uhu | Connects plastic, metal, or used as a fill. |

| Defense-EK | Epoxy resistant to chemical reagents. Available in 10 kg buckets. It is more often used in production. |

| Epoxy Titan | Equal component product. Has increased strength and shock resistance. Sold in blisters of 20 and 200 ml, in 2 liter buckets. |

Epoxy adhesives from Moment

EAF

What is epoxy?

Two-component epoxy or epoxy compound is an adhesive that is prepared from two components. Buying packaging, you will find in it:

- a large bottle with a viscous transparent or yellowish liquid - the actual epoxy resin;

- small bottle of liquid - hardener.

If the proportions of epoxy glue are selected correctly (and we will learn how to do this a little later), then at the output (after mixing the two components) we get a viscous mass, which after 12 - 48 hours becomes solid like a stone. Moreover, transparent, which is a big bonus from the point of view of the aesthetics of the jewelry!

The answer to the question of where to buy epoxy is also good news: the miracle glue is sold in all hardware stores. In total, there are about 50 of its varieties (recipes), but, despite the chemical composition of the components, the principle of working with epoxy is the same.In addition, each manufacturer provides detailed instructions.

The most common construction epoxy glue is suitable for attaching a flower decoration to fittings. It costs about 1 - 2 cu, and the pack is enough for many times. I won't lie, but 10 hairpins will be enough for sure!

For making jewelry from epoxy or red currant, it is appropriate to use a jewelry compound. This resin is perfectly transparent, it has fewer bubbles and haze. We will consider the cheapest glue "EDP universal epoxy compound".

Types and characteristics of glue

According to the number of bottles included in the package, the glue is of the following types:

- One-component. It is a ready-to-use mixture of epoxy with solvents and plasticizers. It begins to harden after opening the sealed package. Usually, such adhesives perform a small amount of work, they can glue minor defects, seal seams, close up gaps. The funds are widely used in everyday life, needlework.

- Two-component. It is sold in a package in the form of two containers. One contains epoxy in the form of a paste, plasticine, and the other contains a hardener. They need to be mixed in a certain proportion, quickly used for their intended purpose. Most epoxy adhesives are two-part adhesives and can glue almost any object.

By consistency, adhesives are liquid and in the form of a plastic, thick mass. Liquid materials are sold in tubes and do not require dilution. It is recommended to repair chips, pits, and other defects with a plastic-like mass. Before using it, you need to knead it in your hands, mix it.

According to the method of curing, materials are classified as requiring heat treatment and not requiring it. The former are heated before the introduction of the hardener, the latter must be kept at room temperature.

Common brands

On sale you can find a huge variety of epoxy adhesives, among them there are imported and domestic brands:

- "Contact". Well suited for rooms with high humidity, suitable for sealing pipes, baths, toilet.

- "Moment" from Henkel. Implemented in every hardware store, the most popular. It is packed in different packages - weighing from 5 g, convenient and reliable.

- "Super-Grip" is an equal component epoxy. The composition contains mineral fillers, which increases the adhesion strength. Has no restrictions on processed materials.

- "Bison". Two-component colorless gel, used to fill voids, cracks, chips, helps to restore the shape of the product.

- "Class". An analogue of the previous composition. Ideal for use on metal and various alloys, helps to repair cars, sinks, pipes.

- "Second". A quick bonding effect is a distinctive feature of the product; it completely hardens in 3 minutes.

- "Novokolor epoxy universal glue". Differs in low shrinkage and high adhesion to various substrates, allows you to glue products with large cracks and chips.

- Metal Bond. 5-minute glue for all types of metal, can also glue metal surfaces to wood, plastic, and other materials.

- "Compound K-153". Black product, used for metal structures exposed to water, petrochemicals.

- Ultima ("Ultima"). A two-component agent used to join most of the known materials, including decorative facing. Suitable for repairing cars, boats, household appliances, plumbing.

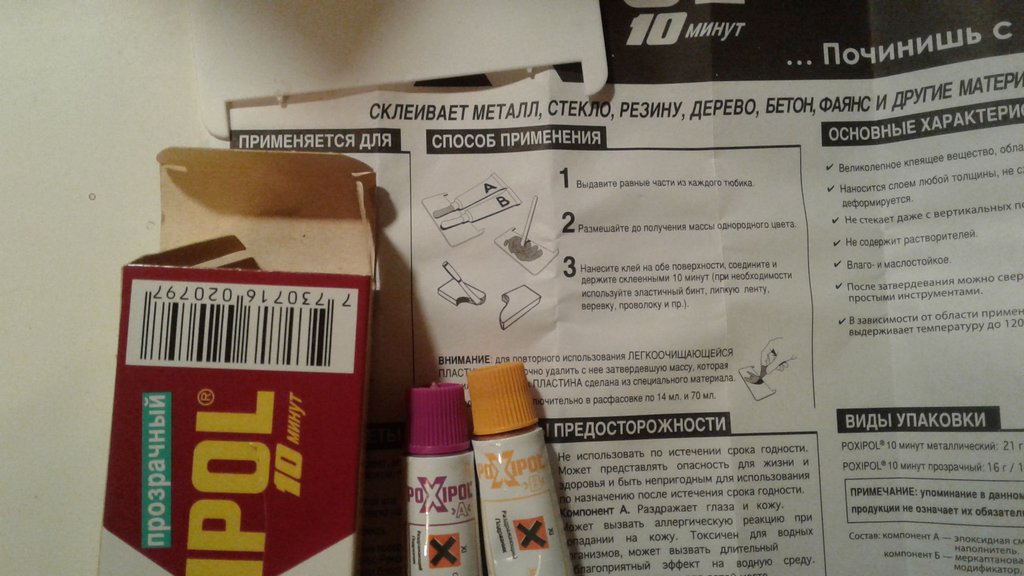

- Poxipol ("Poxipol"). Fast drying composition, will set in 10 minutes after preparation. You need to work with him very quickly.

- EDP. Ideal for all surfaces from metal to glass. Optimal in terms of price-quality ratio.

- Epoxy steel. Great for any type of metal, it is often referred to the category of auto chemistry and is recommended for car repairs.

- DoneDeal "Epoxy Adhesive" in a syringe.Two-component adhesive that gives a completely water-tight bond.

- BisonEpoxy 5 min. Differs in fast polymerization, super-reliable adhesion of surfaces.

- "Abro" (Abro). The glue of this article is available in two colors - white, black, and is a "cold welding" for all types of surfaces.

- Novol Plus 710. This is a repair kit consisting of resin, hardener, glass mat (fiberglass). Suitable if the product to be glued has significant defects, cracks.

- Uhu. It is used to join different types of plastics and metals, and can be used as a filling agent.

- "Defense - EK". Chemically resistant epoxy glue, sold in large containers (10 kg each), is mainly used in production.

- Epoxy Titan. High strength material, shock resistant, equal component. Packaged in blisters of 20 and 200 ml, in buckets of 2 liters.

What you need to know when using epoxy adhesive

The question of how to use epoxy glue is of interest to many. You should know that epoxy shows its declared qualities only after polymerization, the catalyst of which is a special hardener. The whole process of work is as follows:

- Work surfaces are prepared (degreased, cleaned and polished).

- An adhesive substance is being prepared.

- The glue is applied to the surface of the material and fixed.

- After the end of polymerization, the product is ready for further use.

How to prepare glue for work

In order for the repair to come out of high quality, you should know how to glue it with epoxy glue. Of course, all the nuances of how to mix the hardener to the adhesive are prescribed in the attached instructions. In the classic version, 1 part of the curing agent-catalyst is taken for 10 parts of resin. Moreover, a hardener is gradually added to the resin, and not vice versa.

When a hardener is added to it, the resin begins to harden (this process is irreversible). Therefore, the finished substance should be used immediately, it cannot be stored for a long time, otherwise the glue will deteriorate. Experts advise not to prepare too much of the composition, but only the amount that is required for current repairs.

Mass breeding rules

Knead the adhesive mass very carefully, keep in mind that the epoxy, when the hardener is added to it, begins to generate heat. Stir the substances. A spatula or stick made of wood is very thorough and long. But sometimes the resin is too thick. For these purposes, you can use a special solvent for epoxy or slightly heat the mass with steam at a temperature of + 55-60⁰С.

The resin must be prepared for use before use.

Other weak solvents will also help to dilute a substance that is too thick. For example:

- acetone;

- nail polish remover;

- alcohols;

- xylene.

Other organic substances can also be used. However, make sure that the volume of solvent used does not exceed 4–5% of the total resin weight. Otherwise, the composition of the adhesive will lose its qualities.

Drying time

The polymerization period is different and depends on many factors. For example, the type of glue used. So, cold welding will completely harden after 10-25 minutes. But for liquid substances it takes several hours, and completely such mixtures harden after 1-1.5 days.

You do not need to work with epoxy glue in the cold, at sub-zero temperatures. Optimum time for surface setting: + 10–30⁰С.

Consumption rates

The consumption of the adhesive substance directly depends on the thickness of the applied layer. On average, this figure is 1.1 kg of glue per square meter of surface when applying a layer of 1 mm. But the consumption increases when working with various porous surfaces (wood, concrete, etc.).

Safety engineering

Epoxy adhesives become completely safe for humans only after complete curing.When working with a liquid substance, certain safety rules must be observed:

- work in a room that can be thoroughly ventilated after the end of the process;

- use personal protective equipment: respirator, gloves, glasses;

- wear work clothes made of dense material, there is a long sleeve;

- everything that came into contact with the liquid mixture (sticks, dishes), after finishing work, throw it away, and ventilate the room well.

Gloves should be used for work

Existing varieties

The central component of the glue is epoxy resin. The material is a synthetic oligomer, which is used without additional substances. Epoxy resin is an indispensable component of paints and varnishes and finishing materials. The consistency of the resin depends on the material it is part of.

By composition

The epoxy adhesives market is represented by two groups:

- one-component;

- two-component.

The one-part epoxy adhesive is ready to glue after opening the storage container. The composition, in addition to epoxy resin, contains organic solvents that prevent polymerization. The one-component composition is used for gluing small parts, sealing plumbing joints and connecting pipes. Another area of domestic use is needlework. Do not store the glue open, since it dries quickly, which is the disadvantage of one-component epoxy glue

Among the advantages of the material, it is important to note:

- reusable use;

- ease of application;

- affordable price;

- ease of storage;

- non-toxicity;

- strength after polymerization.

Solidification of a one-component composition occurs at room temperature, so no heating devices are required. The two-component formulation is supplied in two separate tubes. One tube contains epoxy resin and the other contains a curing agent. The hardener is available in liquid or powder form. The advantages of the composition are:

- gluing two different materials;

- strength and elasticity of the connection;

- ease of application;

- no harmful secretions.

A two-part epoxy adhesive for fixing metal, wood, plastic and glass parts. Materials are combined in any sequence, which does not affect the adhesion strength

The connection retains elasticity, which is important under vibration loads. The glue is applied with a small spatula or stick. Mixing of the two components is required before applying to the damaged area.

A correct calculation of the amount of hardener added to the base composition is required. If there is an excess of hardener, then the "vitality" of the solution will be low, polymerization occurs quickly, which complicates the gluing. Lack of hardener prevents the build-up of strength, which will lead to an unreliable connection of parts

Mixing of the two components is required before applying to the damaged area. A correct calculation of the amount of hardener added to the base composition is required. If there is an excess of hardener, then the "vitality" of the solution will be low, polymerization occurs quickly, which complicates the gluing. Lack of hardener prevents the build-up of strength, which will lead to an unreliable connection of parts.

By consistency

Adhesives differ not only in composition, but also in consistency. Depending on the viscosity of the glue, there are:

- gels;

- liquids;

- plastic masses.

The gel is less fluid than liquid, so it is easier to apply on areas with more damage. Adhesives with gel formulations are consumed more economically than liquid formulations. Deep lesions require intense fluidity of the composition to envelop the fracture site. Liquid adhesives are easier to apply and self-cover the area to be treated. The polymerization time of liquid adhesives is longer than that of gel-like ones.Plastic masses of epoxy adhesives are a substance similar to plasticine. The components are supplied in separate packages or in one package. If it is one package, then the curing agent is on top of the epoxy component.

To start polymerization, the hardener and epoxy are thoroughly kneaded by hand. The components are mixed until smooth. After that, there is fifteen minutes for the glue to be applied to the damaged area. Another name for two-component elastic compounds is cold welding. The flexible adhesive is suitable for gluing wood, metal and plastic surfaces. The disadvantage of this method is the protruding mass of glue after polymerization.

Composition and properties

Epoxy adhesives from different manufacturers may contain different components, but the basic composition is always the same, it corresponds to GOST, attached certificates. Two main substances are strictly required in the composition:

- the actual epoxy resin;

- liquid or pasty hardener.

Polyamines, carboxylic acids, aminoamides are used as a curing compound. One-component adhesives always contain solvents (acetone, xylene, alcohols), which prevent the mass from solidifying before contact with air and evaporation. As modifying additives and fillers for glue can act:

- synthetic rubber;

- formaldehyde resin;

- fiberglass;

- clay, chalk;

- aluminium oxide;

- powders of vanadium, nickel, zinc;

- silicone resins.

All of the above binders provide the epoxy adhesive with the desired properties:

- optimal density;

- seam strength;

- high speed of curing;

- resistance to oils, gasoline, water, atmospheric factors;

- resistance to cracks, shrinkage.

It is also worth noting that the glue does not conduct current - it is a dielectric, so it is often used to isolate electricity.

Types and characteristics of glue

According to the number of bottles included in the package, the glue is of the following types:

- One-component. It is a ready-to-use mixture of epoxy with solvents and plasticizers. It begins to harden after opening the sealed package. Usually, such adhesives perform a small amount of work, they can glue minor defects, seal seams, close up gaps. The funds are widely used in everyday life, needlework.

- Two-component. It is sold in a package in the form of two containers. One contains epoxy in the form of a paste, plasticine, and the other contains a hardener. They need to be mixed in a certain proportion, quickly used for their intended purpose. Most epoxy adhesives are two-part adhesives and can glue almost any object.

By consistency, adhesives are liquid and in the form of a plastic, thick mass. Liquid materials are sold in tubes and do not require dilution. It is recommended to repair chips, pits, and other defects with a plastic-like mass. Before using it, you need to knead it in your hands, mix it.

Common brands

On sale you can find a huge variety of epoxy adhesives, among them there are imported and domestic brands:

- "Contact". Well suited for rooms with high humidity, suitable for sealing pipes, baths, toilet.

- "Moment" from Henkel. Implemented in every hardware store, the most popular. It is packed in different packages - weighing from 5 g, convenient and reliable.

- "Super-Grip" is an equal component epoxy. The composition contains mineral fillers, which increases the adhesion strength. Has no restrictions on processed materials.

- "Bison". Two-component colorless gel, used to fill voids, cracks, chips, helps to restore the shape of the product.

- "Class". An analogue of the previous composition. Ideal for use on metal and various alloys, helps to repair cars, sinks, pipes.

- "Second". A quick bonding effect is a distinctive feature of the product; it completely hardens in 3 minutes.

- "Novokolor epoxy universal glue". Differs in low shrinkage and high adhesion to various substrates, allows you to glue products with large cracks and chips.

- Metal Bond. 5-minute glue for all types of metal, can also glue metal surfaces to wood, plastic, and other materials.

- "Compound K-153". Black product, used for metal structures exposed to water, petrochemicals.

- Ultima ("Ultima"). A two-component agent used to join most of the known materials, including decorative facing. Suitable for repairing cars, boats, household appliances, plumbing.

- Poxipol ("Poxipol"). Fast drying composition, will set in 10 minutes after preparation. You need to work with him very quickly.

- EDP. Ideal for all surfaces from metal to glass. Optimal in terms of price-quality ratio.

- Epoxy steel. Great for any type of metal, it is often referred to the category of auto chemistry and is recommended for car repairs.

- DoneDeal "Epoxy Adhesive" in a syringe. Two-component adhesive that gives a completely water-tight bond.

- BisonEpoxy 5 min. Differs in fast polymerization, super-reliable adhesion of surfaces.

- "Abro" (Abro). The glue of this article is available in two colors - white, black, and is a "cold welding" for all types of surfaces.

- Novol Plus 710. This is a repair kit consisting of resin, hardener, glass mat (fiberglass). Suitable if the product to be glued has significant defects, cracks.

- Uhu. It is used to join different types of plastics and metals, and can be used as a filling agent.

- "Defense - EK". Chemically resistant epoxy glue, sold in large containers (10 kg each), is mainly used in production.

- Epoxy Titan. High strength material, shock resistant, equal component. Packaged in blisters of 20 and 200 ml, in buckets of 2 liters.

Instructions for use

The prepared composition hardens quickly, therefore it is recommended to use small portions for mixing. All products that need to be glued should be prepared in advance. To enhance the effectiveness, you can use a cloth - its impregnation will improve adhesion. The fabric is usually gauze, other thin material or fiberglass.

Preparation for gluing

The surface must be washed, cleaned, degreased with alcohol, acetone. For cleaning, you can use a fine-grain emery sheet. As a result, the base should be dry, free from dirt and dust. If a cloth for impregnation will be used, it must also be prepared, dried in air.

Adhesive preparation

The instructions for use state that the EDP glue must be prepared immediately before use. The proportion is 10 parts of epoxy from the first package to 1 part of the hardener from the second. How to dilute the adhesive composition? Here is a description of the technique:

- put a bottle of epoxy in water with a temperature of 50-70 degrees;

- hold for 10 minutes;

- take all the components in small volumes, based on the indicated proportions (for one division of the hardener in a measuring cup, there will be 10 divisions of resin on the paper label on the jar);

- mix the resin and hardener well (within 3-5 minutes);

- leave to release air bubbles for 10 minutes;

- apply in 2 hours, later gelatinization will begin, and the application of EDP glue will be ineffective, the quality of the seam will deteriorate.

Excipients

Various fillers are introduced into the composition to correct, improve its properties, they will have to be bought separately. These can be plasticizers, pigments, and all of them are introduced only in dry form. Even a drop of water can ruin the glue. You should carefully read the characteristics of the fillers in the instructions for them and add only to the permitted amount. Typically, no more than 10-20% fillers are added to maintain fluidity.

Glue application

The technique of applying glue to the fabric is as follows. A suitable cut is applied on top of the product, which will act as a reinforcing layer, after which glue is applied. If necessary, after 12-20 minutes, you can lay another row of mass.

Without cloth or gauze, the product is applied in a thin layer to both glued surfaces. After they need to be connected, press firmly. Better to use a vice or heavy objects. Excess glue must be removed immediately, after hardening - this will be very problematic. Leave the product pressed until it hardens completely.

Curing time

Curing of EDP glue lasts 24 hours, the time is indicated for operation at a room temperature of 20-25 degrees. With its increase, the indicator decreases, with a decrease, it rises.

Features of the use of epoxy glue for different surfaces

Epoxy adhesives adhere excellently to various surfaces, and future bonding does not lose its reliability and strength at any temperature. But there are some peculiarities of working with epoxy when gluing some surfaces.

For ceramics

The epoxy will help to reliably seal breakage or damage to ceramic products. All parts of the ceramics are preliminarily degreased. Their surfaces are treated with glue and attached in place. When gluing glass products, you should try to collect even small fragments. For work, it is better to use a transparent substance, having previously added a certain coloring pigment to it - in this case, the gluing points will be invisible.

For concrete

When working with concrete surfaces, specialized compounds are used, for example, Ceresit putty (the composition includes a specialized plasticizer). These substances give the surface additional water resistance, and the products themselves after repair can be used at different temperatures. And thanks to the plasticizer, the period of application of the finished mass can be extended over time.

For metal

The main thing when working with metal surfaces is to completely degrease the working surfaces. Epoxy is actively used by modern motorists. The adhesive helps with quick repairs and allows the driver to easily reach the nearest service workshop. Epoxy compounds are also used as a putty in the repair of body parts.

For plastic

If the working surface of the plastic parts is smooth, it is pretreated with sandpaper to obtain a roughness. In this case, the gluing will be especially strong and reliable. After applying the adhesive composition, the parts are firmly connected and for better adhesion they are grabbed with clamps.

Adhesive can work with plastic, wood and other materials

Adhesive can work with plastic, wood and other materials