Specifications

Epoxy adhesive mixture is a synthetic mass in which an irreversible chemical reaction takes place to form a durable material. The resin-based adhesive can include a modifier, hardener, solvent, fillers, plasticizers.

The main component in the adhesive is epoxy resin. It also consists of epichlorohydrin with phenol or bisphenol. The resin can be modified. An epoxy resin modified with rubber improves the toughness characteristics. Organophoric modifiers reduce the flammability of the product. The addition of the modifier laproxiv increases the elasticity.

Compounds of aminoamides, polyamines, organic acid anhydrides can act as a hardener. Mixing epoxy with a hardener will initiate a thermosetting reaction. The proportion of hardeners is 5-15% of the resin.

Solvents can be xylene, alcohols, acetone. The solvent does not exceed 3% of the total solution volume. Plasticizers are added to increase the reliability of the fastened parts. For this, ester compounds of phthalic and phosphoric acid are used.

Fillers are used to impart bulk and additional physical characteristics to the finished product. Dust of various metals, mineral powders, fibers, cement, sawdust, micropolymers are used as fillers. The amount of additional fillers can vary from 1 to 300% of the total weight of the epoxy resin.

Operating temperature range - from -20 to +120 degrees. The extra strong adhesive can withstand temperatures up to +250 degrees.

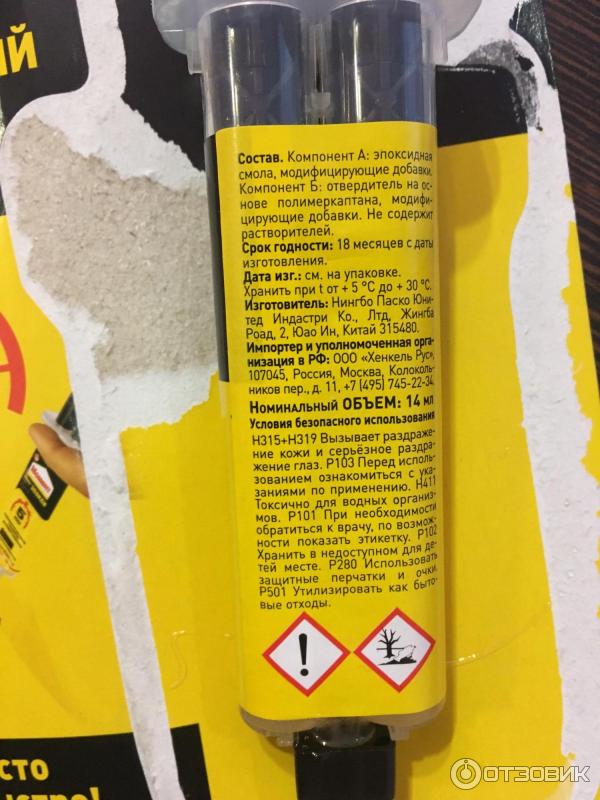

Epoxy glue has a 3 hazard class according to the classification of GOST 12.1.007-76 and is a low-hazard irritant substance, but it can cause an allergic reaction on the skin. For the environment, it is environmentally hazardous and toxic if released into water bodies.

The pot life of the prepared mixture ranges from 5 minutes to two hours, depending on different manufacturers. The different composition of the glue shows strength from 100 to 400 kgf per 1 cm2. The average density per m3 is 1.37 tons. Elasticity upon impact and displacement of the seam - within 1000-2000 MPa. The cured epoxy layer shows resistance to gasoline, alkalis, acids, salts, oils, kerosene. Degradable in toluene and acetone.

"Super Epoxy"

It is recommended to use glue for the following purposes:

- work with glass and similar materials: crystal, glass, porcelain, faience, ceramics, it is possible to use it on fiberglass;

- sealing cracks, gaps and other flaws on the surface;

- filling gaps between glass surfaces;

- connection of materials with different texture and density: textile material, wood, metals (regardless of alloy and type), polystyrene, plastic, polycarbonate, polyvinyl chloride.

Not strongly recommended for use on food contact items. If you need to carry out minor repairs, it is advisable to purchase one or two small packages so that the glue does not deteriorate during long-term storage. The standard volume is 6 ml.

How to wash?

When working with epoxy, protective agents should be used to avoid contact of the mixture on the skin. If it was not possible to prevent contamination, then the uncured mixture is thoroughly washed off with soapy water. When it was not possible to completely wash off the remnants of the components, you will have to use acetone, wiping the stubborn stain.

There are several ways to remove cured epoxy from various materials.

Freezing the stain.Since the epoxy mixture is able to withstand temperatures down to -20 degrees, freezing in the freezer does not seem to be effective. A special aerosol refrigerant is used for freezing. The epoxy becomes brittle when sprayed with refrigerant. The resin can now be cleaned with a spatula or blunt knife.

For heating, you can use a household hairdryer or iron. A hairdryer at the maximum temperature level is used to heat solid heat-resistant surfaces. You can direct a stream of hot air to the dirt for a few minutes. The softened area is removed with a spatula. Heating is carried out until the surface is completely cleaned. If the epoxy glue gets on the fabric, then heating is carried out with an iron, placing a cotton rag on the front side.

Scraping. Power tool cleaning is suitable for scratch-resistant hard surfaces. The scraping can be done with any sharp metal instrument.

Use of chemical solvents. This method is suitable for wear-resistant materials that will not degrade with thinners. Acetone, ethyl alcohol, toluene, butyl acetate, aniline are used as dissolving agents. The contaminated area is moistened with any solvent, allowed to act, then proceed to mechanical cleaning.

You can wash epoxy from glass or mirrors with solvents or acetic acid. The method of heating the surface and the contaminated area will also be effective. A spatula and a soft cloth will help to remove the remnants of glue.

You can use a solvent-soaked cloth to wipe off the epoxy from the glue application tool. Cleaning should be started immediately after completion of work, without allowing the composition to harden. The sooner you start wiping off the contaminated area, the easier the glue will be washed off. The following methods for getting rid of epoxy mixture on various surfaces will help clean up the dirt and preserve the appearance of the product.

"Moment Super Epoxy Formula 5"

The composition is suitable for use in normal conditions, indoors with normal humidity. The mixing of the components of the adhesive solution is carried out at the moment they are squeezed out of the syringe, so users do not have to deal with this separately. It is highly recommended to glue the surfaces 1-2 minutes after the mortar components have been mixed.

Once cured, the adhesive will not shrink or expand, so there will be no deformation of the glued surfaces. If necessary, the hardened adhesive mixture can be polished, painted, drilled. The process of complete curing begins 4-5 minutes after mixing the components. After 7-9 hours, the glue mixture gains maximum strength.

"Moment Super Epoxy Formula 1"

Glue "Epoxy Formula 1" is a universal adhesive that is produced in a syringe. With its help, you can accurately, quickly and efficiently glue together dissimilar materials.

Due to the presence of a syringe and a mixer nozzle, it is convenient for the user to choose the desired dosage of glue, evenly process the glued surfaces, saving the glue solution.

The two components are mixed during the process of squeezing out of the syringe, so users do not have to mix them themselves before starting work.

The features of the composition "Moment Epoxy Formula 1" include:

- It does not react in any way to water, chemical solvents, oil compositions during operation.

- Suitable for indoor and outdoor use.

- The curing process begins to occur within 60-120 seconds after application to the surface.

- During the curing process, Moment Epoxy will not expand or contract.

- After about 7-9 hours, the highest level of adhesion is achieved.

"Moment Epoxy Formula 1" is available in the form of a 14 ml syringe on a blister card.It is recommended to store it only in its original packaging, in a dark place out of the reach of children, at room temperature. If the package is closed, then it can be stored for 1.5 years from the date of release.

Types and characteristics of glue

According to the number of bottles included in the package, the glue is of the following types:

- One-component. It is a ready-to-use mixture of epoxy with solvents and plasticizers. It begins to harden after opening the sealed package. Usually, such adhesives perform a small amount of work, they can glue minor defects, seal seams, close up gaps. The funds are widely used in everyday life, needlework.

- Two-component. It is sold in a package in the form of two containers. One contains epoxy in the form of a paste, plasticine, and the other contains a hardener. They need to be mixed in a certain proportion, quickly used for their intended purpose. Most epoxy adhesives are two-part adhesives and can glue almost any object.

By consistency, adhesives are liquid and in the form of a plastic, thick mass. Liquid materials are sold in tubes and do not require dilution. It is recommended to repair chips, pits, and other defects with a plastic-like mass. Before using it, you need to knead it in your hands, mix it.

According to the method of curing, materials are classified as requiring heat treatment and not requiring it. The former are heated before the introduction of the hardener, the latter must be kept at room temperature.

Views

Two-component glue of the Moment brand is currently produced in several varieties. So, often in hardware stores you can see a sample of "Super Epoxy Transparent". This epoxy is versatile and does not expand as it cures. In addition, the model is durable and unaffected by various oils and water.

You can often find a sample of Super Epoxy Metal epoxy glue in stores. This glue is capable of firmly gluing together products from different metals and alloys. It can be used for both external and internal work. Often this composition is also used to bond other materials (wood, marble, stone).

The next model is "Super Epoxy Formula 1". This adhesive mass provides ultra-fast gluing of products consisting of any materials. This composition is sold in a package that comes in the form of a syringe with a special mixer attachment. This allows the substance to be dispensed correctly and evenly covered the material.

The sample "Super Epoxy Formula 5" today is also often used in construction work. Like the previous model, this glue is produced in a special syringe with a mixer attachment that allows you to easily mix the components of the composition. This substance cures completely within 5 minutes. And after 8 hours, you can even drill and grind it if necessary.

Glue "Super Epoxylin" can be called a universal mass for gluing various materials to each other.

This model is represented by a putty having a cylindrical shape, in which, under the element visible from the outside, there is another element required for hardening.

Currently, many consumers use Epoxilin Mini glue for construction work. This product is available in a compact package (6 ml). It is often used for the restoration of various products. This composition is a special putty in a batch package and hardens within just 10 minutes after being applied to the material.

Many people prefer Epoxylin 2 in 1 glue. It looks like a putty in a cylindrical package, each of them contains 48 g of the composition. In each sample, there is another component under the first outer component that is required for curing. Both of these substances should be thoroughly kneaded with your hands and mixed, then they will react.This composition is often used to seal defects.

Model "Epoxylin Metal" is designed for strong, reliable bonding of various metals and alloys. It is also represented by putty in a cylindrical package. Often, such glue is used to add missing elements. After all, it can be given almost any shape.

Epoxylin Duo glue is a special gray plasticine. It is used both for gluing different materials, and in order to add the necessary parts (table corners). Such a substance dries after 5 minutes after application, and after 15 minutes it acquires excellent strength. Typically, it is sold in a 2 x 25.2 x 50mm package.

You will learn more about the properties of Moment epoxy glue from the video below.

Where can I get it?

Given the popularity of the above brand, it will not be difficult to find this product. It is offered by both large construction hypermarkets and small shops. You can also purchase the product remotely via the Internet. In order not to become a victim of fraudsters and not to spend money on a fake, contact only the official representatives of the brand.

When choosing a product, be sure to read the description for it, study the technical characteristics, scope of use and other data. It is also advisable to calculate the required amount of the composition. If this is your first time doing the job or you have little experience, it is recommended that you purchase a margin of safety in case of unexpected costs or errors during repairs.

Properties and scope

The popularity of epoxy is determined by its positive qualities.

The epoxy adhesive mixture exhibits the following properties:

- forms a non-shrinkable seam without cracks;

- high adhesion to various materials;

- resistance to chemical solvents, alkalis and oils;

- heat resistance up to +250 gadus;

- frost resistance up to -20 degrees;

- resistance to mechanical stress;

- elasticity allows you to drill and grind the seam without chips;

- hardened glue lends itself to staining and varnishing;

- does not conduct electric current;

- the cure rate does not depend on the thickness of the adhesive layer;

- the ability to add additional components to the composition;

- moisture resistance;

- weather resistance;

- wear resistance.

The addition of asbestos increases heat resistance and hardness. Titanium dioxide imparts a white color to the entire solution. Iron oxide will help to achieve red color and fire resistance. Iron powder will increase the coefficient of thermal conductivity and heat resistance. Reduces the viscosity and hardens the epoxy mixture with silicon dioxide. The soot will give the glue a black color. The aluminum oxide will increase the strength and dielectric properties. Glass fibers and sawdust will add significant volume when filling large voids.

The downside when using epoxy adhesive is the setting speed. In a short period of time, you need to apply and fix the glue line, remove excess glue and clean the work area and hands. After the adhesive has hardened, removal is carried out only with strong mechanical stress. The quicker you start cleaning up sticky epoxy, the easier it is to clean up the dirt with minimal effort.

Do not glue objects that come into contact with food with epoxy. Nickel, tin, Teflon, chromium, zinc, polyethylene, silicone are not sticky. Soft materials break on contact with the resin-based composition.

Due to the large number of unique properties, the adhesive epoxy mixture is widely used in various sectors of the national economy. Epoxy grout is used in various fields.

- In the construction industry. The adhesive is used to fill cracks in concrete, cement screeds, reinforced concrete beams and slabs, further strengthening the entire structure.They are used to connect iron and concrete elements in bridge construction. Sections of building panels are glued with epoxy. It gives waterproofing properties to insulation and chipboard, reduces heat losses, creating tightness in the sandwich panel. During finishing works with tiles and mosaics, an epoxy mixture is used as an adhesive solution, which quickly hardens and has moisture-repellent properties.

- In the automotive industry. In production, brake pads are attached with epoxy glue, plastic and metal surfaces are bonded, used in automotive repair work for metal and plastic. It helps to repair defects in the body and gas tank, to restore the trim.

General recommendations for use

Epoxy glue of the Moment trademark is often used and widely used in the market of construction and repair materials, but few buyers know how to properly handle the product during use.

Work must be carried out in protective clothing. Be sure to use gloves. Once on exposed skin, the glue dries immediately and it will be very problematic to remove it. Aggressive ingredients can cause wounds and burns. It is strongly recommended to use protective masks respirators to prevent harmful vapors from entering the respiratory tract.

Use work clothes that you don't mind getting dirty. It is almost impossible to remove a caked glue stain from a fabric. Be as careful and attentive as possible.

The main thing is to clearly follow the instructions and listen to advice from the masters.

- the elements or surfaces to be glued should be thoroughly cleaned with sandpaper;

- remove dust and other foreign particles;

- the hardener and the main component, which are in different compartments, are mixed in the same proportions. The set comes with a container and a spatula designed specifically for this;

- mix the two components thoroughly;

- the solution must be used within 5 minutes, then it hardens and becomes completely unusable;

- after applying glue to the required surfaces, it is necessary to firmly press the elements together and fix them in this position for 1-2 minutes. At this time, you can not move it, otherwise the seam will lose its uniformity and shape.

Instructions for use

All gluing manipulations are carried out only with gloves. Glue that gets on your hands is difficult to remove, it instantly hardens, and it can also cause a burn. Special knowledge and skills are not required when using the product, the instructions for use are simple:

- Clean bonding surfaces. For this purpose, water, degreasers, paper, sandpaper and other convenient devices are used. Ultimately, there should be no dirt, dust, grease on the base.

- Cut off the tip of the nozzle at the syringe, mix the hardener and resin in equal proportions. The kit usually comes with an attached bowl and a stirring paddle.

- Apply the mixture to both surfaces within 3-5 minutes. After 5 minutes, the epoxy will be unusable. Press the parts down, fix for 2 minutes.

- Leave the product for a day before active use. To improve the quality of the seam, do not move the parts during the specified time, otherwise the seam may turn out to be uneven. The joint can be sanded and polished after 8 hours.

- Excess glue that has come out must be removed immediately. Fresh glue spots are removed with acetone, dried ones will have to be removed with difficulty mechanically.

Composition

The glue is based on epoxy resin. Additional elements are added to it, giving special technical characteristics. In order for the product to retain its liquid form for a short time, manufacturers add a solvent. As soon as this component evaporates, the resin begins to harden. The result is a tight and secure seam.External environmental factors are practically unable to destroy its density.

Optimal use of glue - for attaching small-sized parts to each other and to the base. This is possible due to the quick adhesion of the composition. If you apply the adhesive to a large surface area, it will dry before being used.

Pros and cons of epoxy glue

Adhesives based on epoxy resins are diverse, but they all have common advantages:

- Resistant to aggressive chemicals, including oils, gasoline, non-concentrated acids and alkalis. Detergents and other household chemicals do not destroy the seam.

- Heat resistance. It tolerates an increase in temperature up to +250 C.

- Elasticity. Small displacements of the glued fragments, drilling and grinding of the seam are possible.

- Complete waterproofing.

- Good adhesion to a variety of materials including plastics, wood, cement, drywall, etc.

- Shrinkage and crack resistance.

Epoxies also have some disadvantages that must be considered before using them. The mix should not be selected to work with nickel, polyethylene, zinc, silicone, chromium and Teflon. It is forbidden to glue objects that come into contact with food with such compounds. Another disadvantage is the high speed of hardening, so work should be done very quickly and accurately. Otherwise, it will be impossible to correct possible flaws.

Areas of use

Strong adhesion is guaranteed with a combination of ceramic, wood, porcelain and natural stone surfaces. It is also suitable for glass, leather, metal structures. They are restoring marble structures. In this case, the parts themselves may not be of the same type, for example, a leather decorative item and a mirror. After drying, the seam does not shrink or stretch, therefore it is not recommended to use on rubber objects. The adhesive composition is resistant to atmospheric factors and does not allow moisture to pass through.

Henkel brand glue is indispensable when working with plastic surfaces. It is not relevant when working with polyethylene and polypropylene parts. Contraindicated when working with Teflon, utensils in which food is prepared / served.

Advantages and disadvantages

Epoxy has a number of positive characteristics, due to which it continues to lead among analogues. Here are the advantages of the glue:

- elastic seam - the presence of a small mobility of the adhesive joint will prevent the appearance of cracks and prevent destruction;

- the ability to withstand temperature fluctuations - the product is heat-resistant, you can use the finished product at temperatures up to +250 degrees (some adhesives are even more high-temperature);

- no harm from low temperatures - the glue seam is frost-resistant, does not lose strength characteristics even at -30 degrees, this allows the material to be used for outdoor work;

- moisture resistance - glue with epoxy is waterproof, does not react to the action of water, water vapor during operation;

- suitability for gluing most known materials - the glue is really universal, suitable for almost any surface;

- short drying time - after application, the parts quickly become a single whole, and after the final polymerization, it is almost impossible to peel them off.

Despite the high quality, heavy-duty composition of the product, it has a number of disadvantages. Here they are:

Composition and properties

Epoxy adhesives from different manufacturers may contain different components, but the basic composition is always the same, it corresponds to GOST, attached certificates. Two main substances are strictly required in the composition:

- the actual epoxy resin;

- liquid or pasty hardener.

Polyamines, carboxylic acids, aminoamides are used as a curing compound.One-component adhesives always contain solvents (acetone, xylene, alcohols), which prevent the mass from solidifying before contact with air and evaporation. As modifying additives and fillers for glue can act:

- synthetic rubber;

- formaldehyde resin;

- fiberglass;

- clay, chalk;

- aluminium oxide;

- powders of vanadium, nickel, zinc;

- silicone resins.

Also, the glue includes plasticizers that give it plasticity. Thanks to them, the mixture hardens and does not crumble, remains elastic. The percentage of the bulk and different fillers varies widely - from 5 to 50%.

All of the above binders provide the epoxy adhesive with the desired properties:

- optimal density;

- seam strength;

- high speed of curing;

- resistance to oils, gasoline, water, atmospheric factors;

- resistance to cracks, shrinkage.