Novbytkhim: safety

Work with Novbytchim paint is carried out at fairly comfortable temperatures - + 5- + 30 ° C. Novbytchim enamel is intended for painting floors inside residential buildings. It contains no volatile particles harmful to health. Polyurethane base, mineral additives give the paint high mechanical properties. The concrete floor, painted with Novbytkhim enamel, is able to withstand mechanical loads, the effect of fuels and lubricants, salt solutions. The paint is available in five colors - from burgundy to blue. The composition does not tolerate temperature jumps. Therefore, it is better to use the more expensive Texil paint for the floors of a permanently opened garage.

Work with Novbytkhim paint is carried out at fairly comfortable temperatures - + 5- + 30 ° С. The concrete floor must be dry and cleaned prior to painting. Before use, the paint must be diluted with xylene. The manufacturer recommends using solvents released by Novbytchim specifically for this paint. Work is performed using rollers, brushes, sprayers. The composition is applied in two or three layers, the interval between stains should be 3 hours - this time is enough for the film to stop sticking. Complete polymerization occurs after 100 hours.

The price of paint fluctuates depending on the packaging: 1 liter in a three-liter container costs about 3.5 conventional units, and in a 20-liter can - up to 3.

Analogs for grade PF-115

| Enamel PF-133 |

Enamels PF-133 are intended for painting freight rolling stock (except for refrigerated cars), containers and other metal and wooden surfaces

| Varnish PF-170 |

Varnish PF-170 is a solution of pentaphthalic resin in organic solvents, modified with semi-drying vegetable oil with the addition of a desiccant.

| Varnish PF-283 |

Varnish PF-283 is intended for application on wood and metal surfaces to obtain a high-gloss decorative coating

| Enamel PF-218 |

Enamel PF-218 is a suspension of pigments, fillers and fire retardant in pentaphthalic varnish with the addition of solvents.

| Enamel PF-266 |

Enamel PF-266 is intended for covering painted and unpainted floors.

| Enamel PF-1217 |

Enamel PF-1217 is a suspension of pigments in a solution of alkyd varnish with the addition of additives that give the coating specific properties (fillers, driers, etc.).

Material consumption:

0.08-0.13 kg / m²

Solvent:

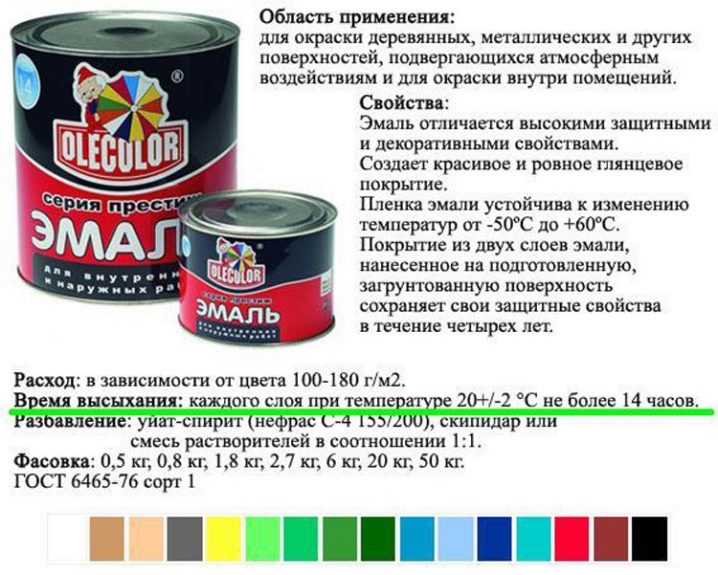

solvent, white spirit, turpentine or their mixture in a 1: 1 ratio

Colour:

Purpose of paint, how to use it correctly

Oil paint PF-115 is suitable for painting stone and brick surfaces, metal structures, wood, concrete, plaster (cement).

Despite the fact that the maximum operating temperature of the enamel reaches + 60 ° C, you should not paint the roof (slate or tin covering).

Severe overheating of the roof will destroy the paint, it will quickly crack and burn out.

A layer of paint on a hot battery dries out too quickly, volatiles evaporate, and the enamel falls off in pieces. To prevent this from happening, apply the solution to a disconnected, completely cooled radiator.

The optimum temperature for enamel application is + 5 ° С.

For outdoor decoration, it will be better if all structures are in shaded areas. To protect parts from rust, mold or other damage, it is recommended to add special antifungal additives to the paint.

The peculiarity of PF-115 paint is that you can apply several layers of the same color to the structure and get a shade that will differ from the original sample, but the solution will remain the same elastic if one layer were applied.

After drying, the parts painted according to all the rules will easily withstand the temperature.

This does not apply to the roof, because a constant temperature pressure will be exerted on the roof.

Ways to use enamel

For painting, use a roller of medium hairiness or a paintbrush. Spraying of enamel with a spray gun is allowed.

After preliminary preparation of PF-266 and the base to be treated, you can start painting. To apply the composition, use a paint brush or medium-bristled roller. The spray method can be used. Basically two layers are applied. To obtain a more reliable coating in the required places, it is advisable to process the surface three times. In this case, the drying period may exceed one day.

After completing the work, you need to put the tools in order. The roller or brush must be cleaned of enamel residues. To do this, use a solvent, vegetable oil, dry cloth. The container with the unused composition should be tightly covered with a lid so that it retains its qualities. The ingress of moisture or the penetration of sunlight is inadmissible.

Paint for your home, utility room or garage?

Floor painting

First of all, you should decide what kind of floor will be painted: in the house, utility room, garage, cellar. Therefore, at least three main types of paint should be distinguished:

- Acrylic;

- Polyurethane;

- Epoxy primer enamels.

If the coating is wooden, then paint containing acrylic and alkyds will be required, since it is these substances that can increase the wear resistance of wooden surfaces.

If painting is required in a utility room or on the floor surface where there are metal floors, it is best to use polyurethane paint. It will not form bubbles and cracks, such a coating will be quite durable.

Enamels for finishing concrete floors

Paints can be applied to the surface with a roller or spray gun All exterior paints offered by the industry allow you to give the concrete surface the necessary aesthetic, physical and hygienic properties. They are divided according to the method of use - for indoor and outdoor work. Depending on the chemical base, they are divided into four classes of paints: epoxy, polyurethane, acrylic (Quil, Prestige), rubber. Among the polymers offered by the domestic industry, the most famous are Teksil, Prestige, Aquapol, Quil. Foreign companies are also well represented in the market.

- Epoxy paint is a proven material that is traditionally used in industrial production. The two-component base gained popularity half a century ago, during the spread of concrete as a building material.

- Rubber paint is a polymer composition that is actively used today for painting walls, roofs, floors. Most often it is used for finishing swimming pools: the rubber surface has good water resistance and excellent decorative effect.

- Acrylic paints are a relatively new product based on the polymer resin of the same name using organic solvents. For the concrete floor of the garage, TD Kvil paint is suitable. It can be used to cover the concrete floor indoors, on the site under a canopy, the entrance in front of the gate. The film can withstand temperature changes within all climatic zones - from northern to equatorial.

- Polyurethane concrete floor paint - usually one component. The well-known manufacturer Krasko offers a Polymerstone composition made on the basis of a highly elastic and durable polymer. The same company produces Texil paint, which is widely used by finishers.

Peculiarities

Enamel PF-266 is made on the basis of alkyd varnish. Its manufacture in our country is regulated by GOST 6465-76.

According to the standard, the composition also includes a coloring pigment, solvent, mineral fillers. Thanks to this content, a kind of suspension is obtained, which, when applied to a tree, not only provides a decorative function, but also protects the surface from negative environmental influences, for example, moisture. In addition, the surface treated with this product acquires a glossy shine.

Enamel PF-266 is specially designed for wooden surfaces. It is intended for indoor use only. Outdoors, the coating will have a short lifespan.

Due to the availability of these products, they are often used for painting floors in public premises such as gyms, dormitories, industrial warehouses. Individuals rarely buy this paint, mainly for painting floors in old wooden houses or in a dwelling in the country.

Before using enamel PF-266, you should familiarize yourself with its technical characteristics:

- This coating forms an even glossy coating on the surface. Film gloss is at least 50%.

- The enamel gives the surface moisture resistance.

- Good abrasion resistance. Here, the strength index is 0.25 kg / μm.

- It perfectly tolerates temperature drops from -40 to +60 degrees. Do not be afraid of the destruction of the coating in conditions when the building is not used or heated during the winter period. Also, the paint can be stored and transported at low temperatures. This will not affect the quality of the product and subsequent operational properties.

- At a temperature of +20 degrees, its viscosity is 70-100 s.

- The degree of paint grinding is maximum 40%.

- Consumption of the composition for one layer is 80 g / sq. m. The number of layers depends on the color of the enamel.

- The paint dries in 24 hours at an ambient temperature of at least 20 degrees. But the floor will become completely ready for the load only after three days. The surface will gain final strength only after 2 weeks. A completely dry layer of the film has an impact strength of at least 30 cm.

- The bending elasticity of the layer is 1 mm.

- The adhesion of the paint composition to the covered surface corresponds to 1 point.

- Diluted with white spirit.

- The volume of containers into which the composition is poured in production can be found different. It ranges from 0.9 l to 50 l.

Purpose of the composition

Designed for painting surfaces made of metal or wood. Used in household and industrial premises. An important point is that the composition is approved for use only inside buildings. It is not suitable for outdoor work.

Enamel PF-266 is suitable for painting a previously prepared floor surface. Moreover, the base can be both previously painted and unpainted. Most often, the composition is used in those rooms where people are periodically, and not constantly. In such situations, the paint is a protective compound for the floor, and not its finish. That is why enamel is usually packed in large metal cans (30 or 50 liters). Individuals use this tool extremely rarely. Usually it is purchased by construction organizations that repair public premises (dormitories, locker rooms, and so on).

FLOOR ENAMEL alkyd-urethane quick-drying

Home \ \ PRESTIGE \ Enamels \ FLOOR ENAMEL alkyd-urethane quick-drying "PRESTIGE"

INCREASED STRENGTH AND FAST DRYING

Scope: Designed to cover new and previously painted wooden floors used inside residential, domestic and industrial premises. Composition: Suspension of a mixture of pigments and fillers in a modified alkyd-urethane resin, with the addition of a desiccant, solvents and various additives for targeted purposes. Properties and features: Fast drying. Glossy. After drying, it forms a durable, abrasion-resistant coating. Forms a surface resistant to oils, water, household detergents and disinfectants. Surface preparation: The work surface must be dry and free from contamination. Remove peeling old coating and sand the surface of cracks and grooves must be filled. Sand the filled surface, remove sanding dust with a soft cloth and prime.Clean metal surfaces from rust and scale, degrease with a white spirit solvent and prime with an alkyd primer (GF-021, GF-0163, etc.). When applied to old pentaphthalic coatings, it is necessary to pre-grind the surface to a matt state with sandpaper. Application and Consumption: Available ready-to-use. Stir well before use. If necessary, it is possible to dilute with white spirit or solvent, as well as their mixture in a 1: 1 ratio. Thinning depends on the method of application (brush, roller, spray gun). The approximate consumption for a single layer coating is 150 g / m2. Consumption may vary depending on the type, condition and structure of the surface. Enamels can be applied in 1-2 layers. Drying time and processing temperature: It is recommended to paint work at a temperature of + 5C - + 35C and a relative humidity of 655%. Avoid drafts and direct sunlight; it is not recommended to apply enamel in high humidity. Drying time at temperature (202) С and relative air humidity no more than 65%: 6 hours. The second coat can be applied after the previous coat is completely dry. Under other conditions, the drying time of the enamel may vary. Cleaning of tools and hands: Rinse hands and tools immediately after work with white spirit or nefras C4-150 / 200, wipe dry with a dry cloth. Data characterizing the hazard of the cargo: Danger label according to GOST 19433 drawing 3; class number, subclass - 3.3; classification code - 3313; UN serial number - 1263; emergency card number (for transportation by rail) - 305. Storage and transportation: Store in a tightly closed container, in a cool, well-ventilated place away from heating devices, protecting from moisture and direct sunlight, at a temperature not lower than + 5 ° C. Frost-resistant products! Transportation at temperatures up to minus 40 ° C is possible. 5 times freezing is allowed, followed by mandatory thawing and thorough stirring before use. In case of freezing, keep for 24 hours at room temperature

Precautions: Contains volatile organic solvents, therefore personal protective equipment must be used when working. Carry out painting work with the supply and exhaust ventilation operating

Use rubber gloves to protect your hands. In case of contact with eyes, rinse immediately with plenty of water and consult a doctor if necessary. Keep out of the reach of children! Disposal: Do not pour paint and varnish products into the sewage system, water bodies, or onto the soil. Dispose of dry containers as household waste. Transfer liquid residues to collection points for hazardous substances. Reminder: Do not mix with other paints and varnishes. Expiration date: 24 months from the date of production.

Safety criteria:

The enamel does not contain: - desiccants, including metals of chemical substances of the 1st hazard class, the amount of which in terms of the dry residue exceeds 0.5% - lead crown. Supporting documentation:

PROPERTIES

- quick dry

- increased hardness and gloss

- elastic properties in case of micro fractures

- excellent impact resistance

- highest abrasion resistance

- economical solution

Preparatory operations and features of using PF-115 paint

In order to ensure an even high-quality paint and varnish coating, the surface must be carefully prepared before applying PF-115 enamel. The work is carried out in the following sequence:

- Mechanical cleaning. With the help of special tools and cleaning agents, dirt, a layer of peeling paint and other contaminants are removed.

- Degreasing is in progress.

- The surface is leveled and completely dried.

Metal structures are treated with fine-grained emery paper, a rust converter and covered with a primer compatible with pentaphthalic paint (in the marking, the first number is 0).As a primer, you can use PF-115 enamel diluted with white spirit. When renewing a decorative coating, it is enough to apply one layer of enamel of the same color, provided that there are no cracks or bulges. For strength, after the first layer has dried, a second is applied.

Concrete and plastered surfaces must be completely dry. They are painted without prior application of a primer. Due to the low vapor permeability, it is required to apply anti-mold preparations under the paintwork. To obtain a durable elastic coating on concrete structures, 2-3 paint coats are required.

Wooden products are sanded. The enamel is applied in two layers. The wood is pre-impregnated with an antiseptic. Porous surfaces are treated with a special alkyd compound. The interval for applying the second layer can be 24 hours. In the process of work, it is necessary to add a solvent to the paint and stir periodically to obtain a homogeneous mass.

What should be in the paint?

In addition to those listed above, there is a third type that may require painting - this is a concrete floor. Special compositions are best suited for it, they can be acrylic, water-based, and polyurethane.

The main thing is that the manufacturer indicated on the can that they are suitable for the porous concrete surface. Epoxy primer enamels are also suitable for this case.

Painting the floor with a roller

The correct choice depends on the characteristics of the room where the floor is being painted. Where crowds of people are often formed, temperature changes are observed, polyurethane enamel is best suited.

When the room is used as a storage room and the movement in it is minimal, for example, a pantry, then it is best to use water-based paint. If applied to a freshly poured floor, it will acquire a uniform, even color.

In addition, you should pay attention to the composition of the paint. Enamels containing antifungal and antimicrobial components are suitable for a wooden floor.

For iron, it will be promising to see anti-corrosion substances in the paint composition. Of course, any floor must be protected from moisture. Abrasive substances, which are also provided in a can of paint, can easily cope with this.

Enamel and surface preparation

Before using the emulsion for wood floors, preliminary work is carried out. They are needed not only by the paint itself, but also by the material on which the composition will be applied. Enamel preparation procedure:

- After opening the lid, remove the film formed on the surface. This must be done carefully, without leaving hard pieces in the container, otherwise the appearance of the surface will be damaged.

- Mix the composition well, making it homogeneous. This operation is recommended to be performed using a drill with a special attachment.

- Add solvent (if necessary and not more than 10%). This means can be PC-2, turpentine, White spirit.

- Filter the product with regular gauze.

Preparation of the base includes work on its cleaning:

Wash the floor with detergents

Pay special attention to traces of old paint and rust - they must be removed using special products.

Wash the floor again with clean water.

Sand the surface, then remove the dust.

Rinse the floor with water and dry. Paint can now be applied.

Precautionary measures

Paints and varnishes emit vapors that are hazardous to human health. Taking this fact into account, when working with them, you must remember to observe safety rules. You should take care of personal protection - gloves and a respirator.

Floor paint is highly flammable and must not be used near open flames. It should not be applied in the immediate vicinity of food storage areas and in rooms where fresh air does not penetrate.

As a result of the use of PF-266, the processed materials will not only last much longer, but also please the eye, therefore enamel is quite popular among consumers.