Scope of application

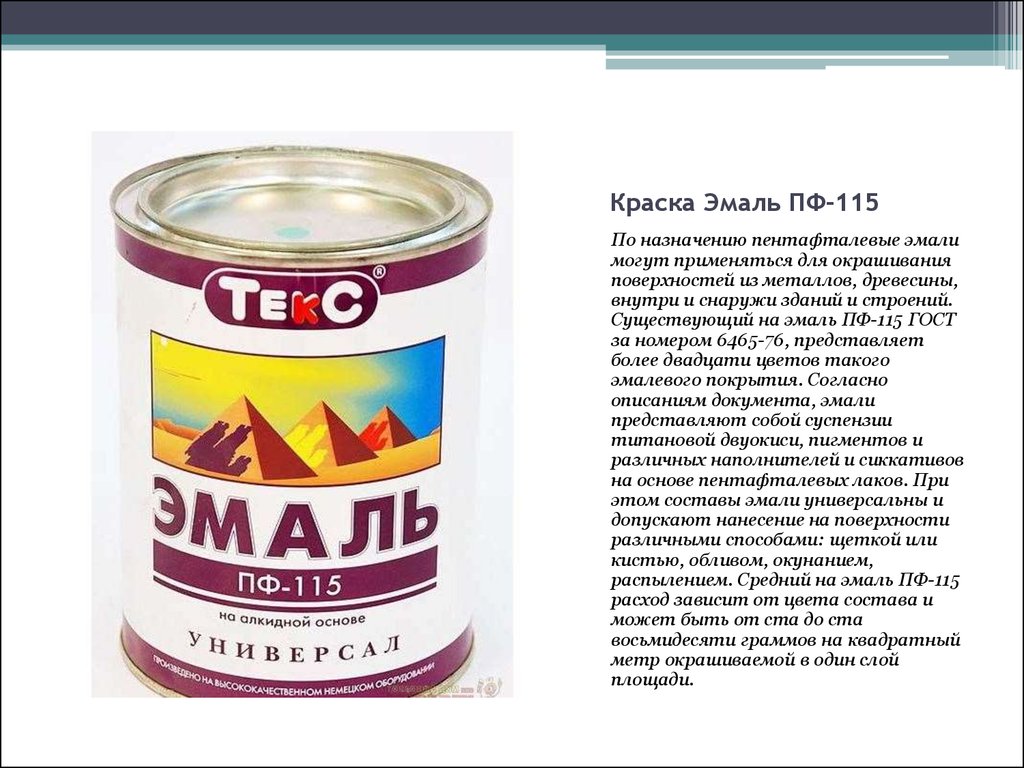

PF-115 refers to alkyd enamels, as evidenced by the letter designation "PF", indicating a pentaphthalic binder base. Studying the numbers 115 gives us the following: by the first number we find out where the paintwork is applied. So, the number 1 informs us that we have before us an atmosphere-resistant paint, which is recommended for use in outdoor work. The subsequent number 15 is the catalog serial number of the product, so these numbers do not contain any practical information.

Although this alkyd paint boasts the widest range of applications, it was developed primarily for anti-corrosion protection of metal structures used in natural areas with temperate, cold or tropical climates.

It is used in the following industries:

- engineering;

- construction of highways;

- railway transport;

- machine tool;

- aircraft building;

- military-industrial;

- production of metal structures.

Due to the intensive drying rate (about a day) and the rapid weathering of the odor, this paintwork is often used for internal work. LKM is also suitable for processing wood, concrete, brick and other surfaces that are negatively affected by atmospheric influences, provided that the surface preparation technology for painting is followed.

PF-115 is rightfully considered a "national" product. This paint is used with might and main by various utilities when there is a need to put in order "irresponsible" objects such as various benches, elements of fences next to entrances, basement doors, and protective gratings. It is indispensable for coloring those products that need not only to provide anti-corrosion protection, but also to give certain decorative qualities. In addition, wooden frames on windows or facades are often painted with PF-115 enamel, so buildings quickly acquire a well-groomed appearance, and utilities avoid unnecessary costs.

Most of the industrial premises and warehouses are equipped with full-fledged heating systems. Since aesthetics in such facilities plays a secondary role, it is practiced here to install a large number of practical heating registers that maintain the optimal temperature in the room. They, along with cast-iron radiators, are often painted with pentaphthalic paint, again for reasons of economy.

Peculiarities

Our compatriots at all times preferred to deal with inexpensive, affordable, easy-to-use, and most importantly, reliable products and things. And if we talk about paintwork materials, then the list of attractive consumer qualities must be supplemented with such a property as versatility. All these criteria are met by PF-115 enamel paint - a paint and varnish material widely used in various industrial sectors and in everyday life.

Its main purpose is to provide anti-corrosion protection of metal structures, railway transport, urban vehicles, agricultural machinery, military equipment, surface parts of self-propelled / non-self-propelled floating structures and other objects, the operation of which involves constant atmospheric influences. At the same time, the scope of this enamel is much wider. It is allowed to be used as paint on wood, concrete, foam concrete and reinforced concrete, stone or brick.

Despite the fact that in a number of technical characteristics, many modern analogues are significantly superior to PF-115, it still does not give up its positions in the paint and varnish market.Sustained long-term demand for it is due to the optimal combination of price and quality, as well as the fact that over the decades of its existence, this enamel has repeatedly proved its worth in solving a variety of problems, thereby gaining the trust of a wide range of users.

Consumption and application

Pentaphthalic enamel is intended for painting surfaces made of wood, metal, brick, cement and concrete, which are exposed to atmospheric influences. It is also widely applicable for interior decoration of residential and public buildings.

The work of PF-115 on metal involves preliminary priming. This will ensure the tightness of the coating, reducing the impact of water and oxygen on the metal, and as a result, the absence of rust formation.

Consumption rate PF-115 paint per 1m2 is about 80-100 g. This figure largely depends on the structure and material of the surface, and the method of application. The minimum flow rate is achieved using a roller or brush, the maximum flow rate is achieved with pneumatic spraying.

The density of PF-115 paint varies within 0.9-1.3 g / cm3. The lower this indicator, the thicker the paint, the better the hiding power and the stronger the formed film. But thick paint is more difficult to apply to the surface, so it can be slightly diluted with a solvent or white spirit until it works.

To correctly determine how long does PF-115 paint dry, it is worth considering the grade of the finishing material color. All enamels (made according to GOST 6465-76) first and highest grade dry to degree 3 * at t 20 ° C within 24 hours, except for red and cherry first grade (48 hours).

* According to laboratory tests, "grade 3" is when a sheet of paper does not adhere to the painted surface under the influence of a weight of 200 g for 60 seconds.

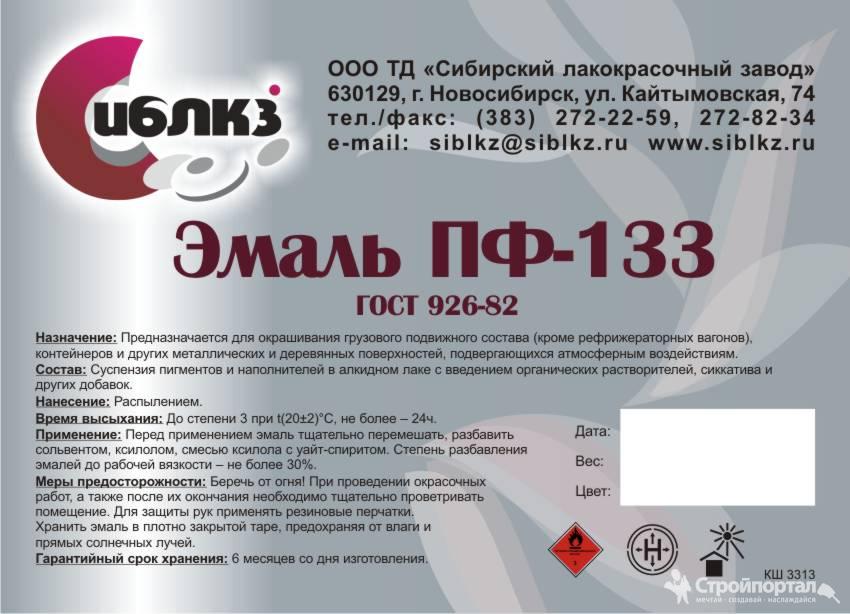

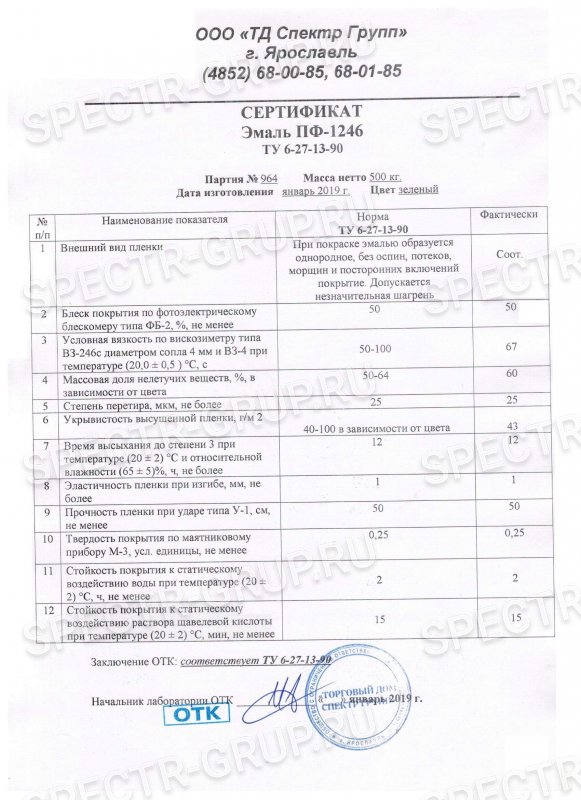

Features and application of PF-133 enamel

Modern paints and varnishes are quite diverse. To obtain a high-quality result, you should strictly take into account the specifics of each option.

Enamel PF-133 is an excellent product, but it should also be used strictly according to the technology provided by the manufacturer.

Peculiarities

GOST 926 82 stipulates that this enamel, regardless of color, must be a suspension of dyes and fillers in an alkyd-based varnish. Organic solvents, driers, and sometimes other components are added to the mixture.

The product specifications are quite decent. Two coats of enamel (if they cover the previously primed surface) will provide reliable protection for 36 months in temperate climates.

Application of the composition is possible:

- pneumatic spraying;

- spraying in an electromagnetic field;

- by spraying in an airless space;

- bathing the product in the mixture;

- pouring jets;

- with a brush.

Preparation for work

When using enamel PF-133 in any area, it is necessary to stir it and bring it to the target viscosity using:

- solvent;

- xylene;

- nefras;

- special thinners (for subsequent painting in electromagnetic fields).

According to the standards for PF-133 enamel, its density is 1100 - 1200 g per 1 sq. m. The established requirements provide for a dilution of up to a maximum of 30%.

The difference is determined by the unequal chemical composition of the enamel of different colors.

It is important to remember that the product is toxic and poses a significant fire hazard.

Safety regulations

PF-133, as well as the thinners and solvents used with it, can provoke skin irritation and the appearance of eczema. It is worth fearing the destructive effect of the composition on the blood, mucous membranes and respiratory tract, as well as on the nervous system. Experienced painters prepare individual respiratory protection for work and wear rubber gloves. In case of contact of the enamel with the skin, it is immediately washed off with warm soapy water.

Pentaphthalic enamel, regardless of dilution and ambient temperature, is highly flammable.

At industrial facilities and construction sites, it is necessary to conduct continuous monitoring of air quality.

Practical properties and use

The composition adheres well to metal, the coating shines and turns out to be very hard. The product perfectly tolerates negative weather conditions, temperatures of -40 and +60 degrees. PF-133, in contrast to the more familiar PF-115, can “survive” chamber drying. No effort during air drying can give a film comparable in strength and stability.

The composition does not form streaks and wrinkles, it is immediately applied with a perfectly smooth layer. Drying time ranges from 24 to 48 hours, this is determined by the number of layers and the temperature. Contact with water for 10 hours (at room temperature and immobility of the liquid) does not lead to negative consequences.

Preliminary preparation involves priming with mixtures of PF, EF and GF. The use of their complete chemical analogs is also allowed. The tree must be thoroughly cleaned of any dust and dirt. The best option is sanding. It is not allowed to paint PF-133 over a damaged or poorly adhered previous coating.

It is allowed to dilute the enamel itself with a combination of xylene with white spirit up to 70%. In this case, the proportion of white spirit in the diluting composition cannot exceed 50%. Recommended operating air temperatures - from +5 to + 30 degrees, relative humidity - maximum 80%.

1 liter of PF-133 can cover 19.5 - 26 sq. m. surface. This indicator is influenced by the smoothness or roughness of the substrate, operating temperature, dilution, professionalism in application, the geometry of the product to be coated. If chalk or lime paint is located below, the composition must be removed completely, regardless of its safety and stability. With chamber drying, the air temperature can reach 82 degrees, which reduces the processing time to 120 minutes.

PF-133 should be stored in a dark, dry room, excluding exposure to wind and direct sunlight. The minimum allowable temperature is -20 degrees. Under standard conditions, the enamel can be stored for 12 months. When the warranty period expires, only special laboratory tests make it possible to recognize it as fit for use.

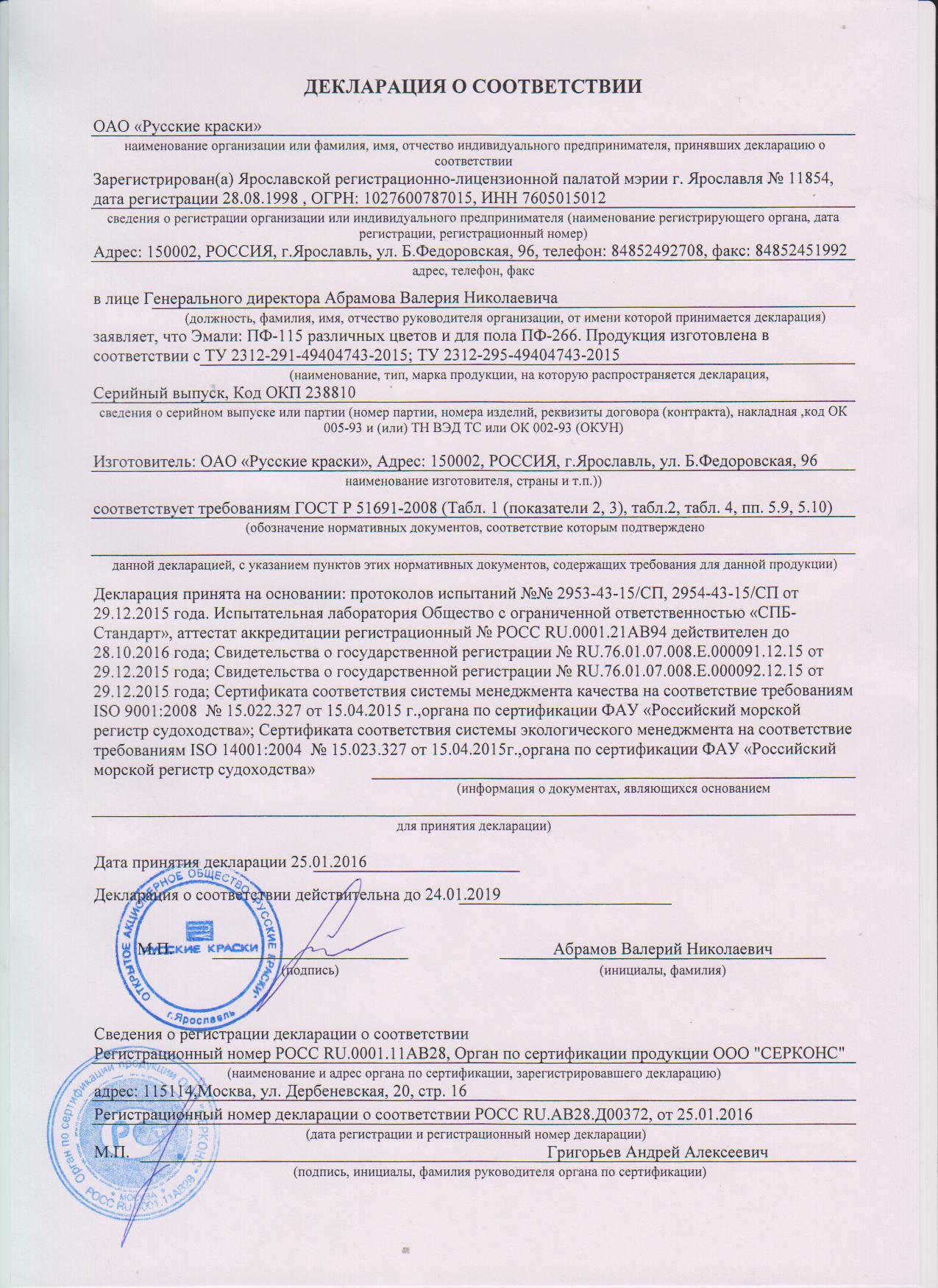

When buying paintwork materials, it is important to study the certificates of conformity for the practical characteristics and hygienic properties of the goods. For an overview of PF-133 enamel, see the following video

For an overview of PF-133 enamel, see the next video.

Enamel PF-133: characteristics, consumption and application rules

Painting is not an easy process

Much attention should be paid to what the surface will be covered with. The building materials market offers a wide range of paints and varnishes

This article will focus on PF-133 enamel.

Main characteristics and scope

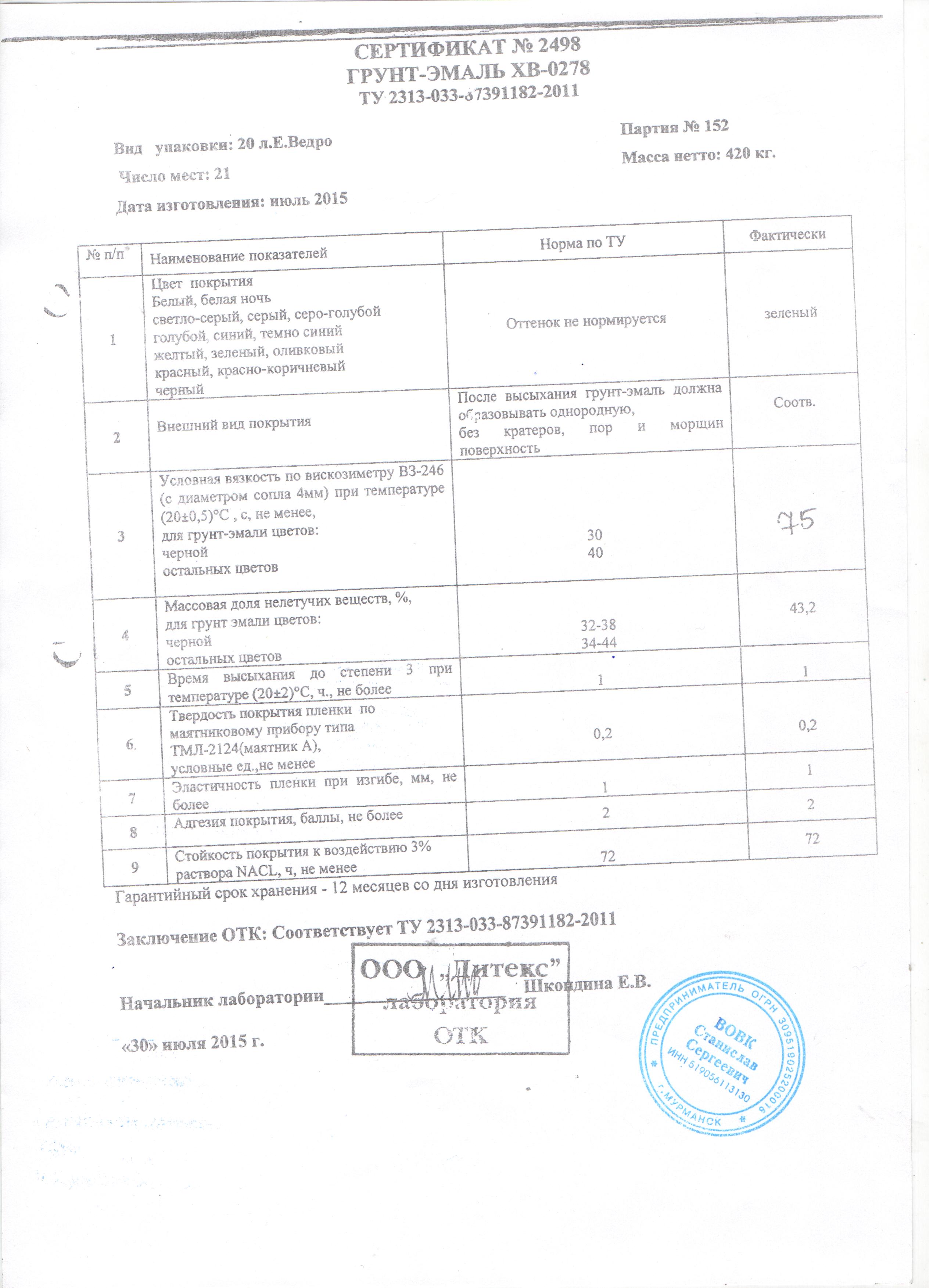

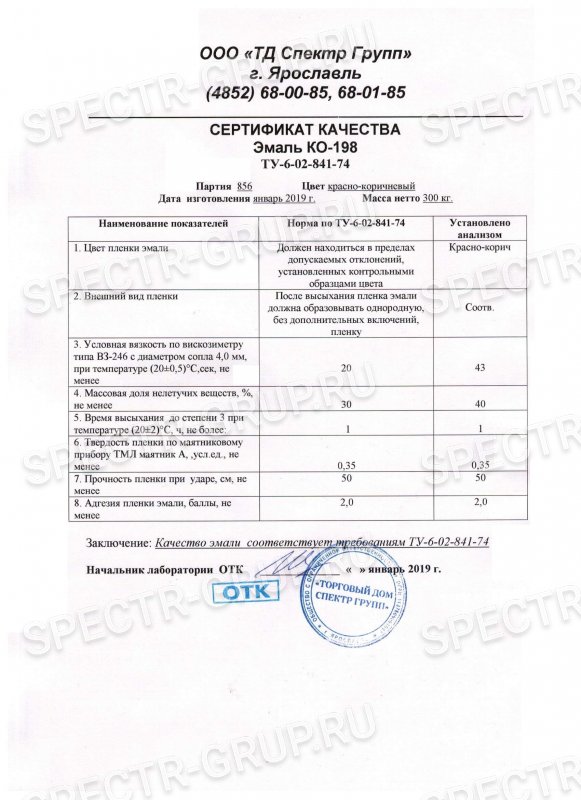

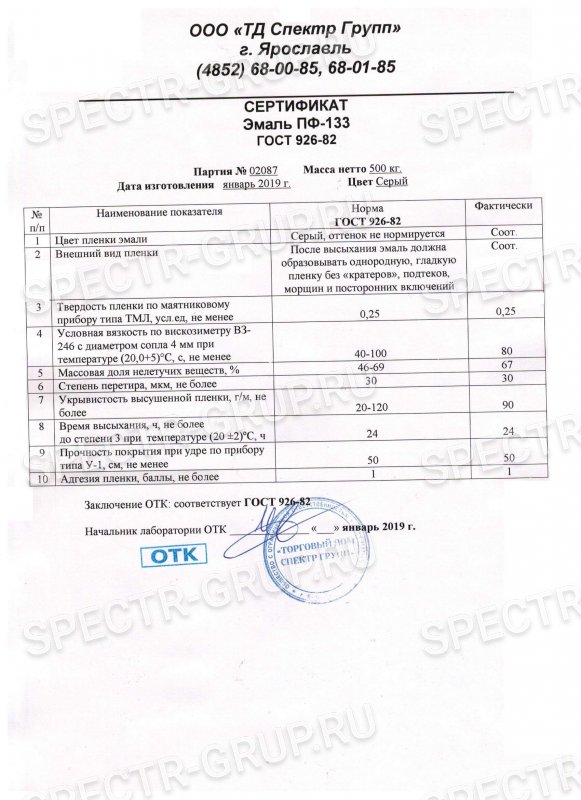

Any paint and varnish material must have a certificate of conformity. PF-133 enamel paint corresponds to GOST 926-82.

This will give you confidence that you are purchasing quality and reliable products. Otherwise, you risk not getting what you wanted. This will not only ruin the result of the work, but can also be hazardous to health.

Enamel of this class is a mixture of colorants and fillers in an alkyd varnish. Additionally, organic solvents are added to the composition. Other additives are allowed.

Specifications:

- appearance after complete drying - a homogeneous even film;

- the presence of gloss - 50%;

- the presence of non-volatile substances - from 45 to 70%;

- drying time at a temperature of 22-25 degrees is at least 24 hours.

Considering the above characteristics, we can say that the material is not suitable for all types of surfaces. Most often this paint is used for covering metal and wood products. The enamel is perfect for painting wagons, containers for cargo transportation.

It is worth highlighting such a feature of enamel as resistance to variable climates.Also, the paint is not afraid of exposure to oil solutions and detergents. The enamel applied according to the rules has an average life of 3 years. This is a fairly long period, considering that the paint can withstand temperature changes, and is also not afraid of rain and snow.

Surface preparation

The surface to be coated with enamel must be carefully prepared. This will maximize the life of the paint.

Preparation of metal surfaces:

- the metal must be free from rust, impurities and have a homogeneous structure to shine;

- to level the surface, use a primer. It can be a primer for metal of the PF or GF class;

- if the metal coating has a perfectly flat surface, then the paint can be applied immediately.

Preparing wood flooring:

- The first thing to do is determine if the wood has been previously painted. If yes, then it is better to remove the old paint completely, and clean the surface of grease and dirt.

- Carry out processing with sandpaper, and then thoroughly vacuum from dust.

- If the tree is new, then it is better to use drying oil. This will help the paint to lie smoother and also provide extra adhesion to the materials.

Application process

Applying paint to a surface is not a difficult process, but it is important to take it seriously. Stir the paint thoroughly before starting work.

It should be uniform. If the composition is very thick, then before use, the paint is diluted, but not more than 20% of the total mass of the composition.

Layers must be applied at intervals of at least 24 hours at an air temperature of +25 degrees... But surface drying is also possible at 28 degrees. In this case, the waiting time is reduced to two hours.

Surface painting can be done in several ways:

- brush;

- using a spray gun - airless and pneumatic;

- jet pouring of the surface;

- using electrostatic spraying.

Consumption

Enamel consumption depends on what surface is processed, what is used to apply paint, temperature conditions. Also important is how diluted the composition is.

For spraying, the paint must be thinned with white spirit. The mass of the solvent should not exceed 10% of the total mass of the paint.

If painting is done with a roller or a brush, then the amount of solvent is halved, and the composition itself will be denser and smoother on the surface.

The recommended thickness of one layer is 20-45 microns, the number of layers is 2-3. Average paint consumption per 1 m2 is from 50 to 120 grams.

Security measures

Do not forget about security measures. Enamel PF-133 refers to combustible materials, so do not perform any actions near sources of fire.

Work must be performed in a well-ventilated area with rubber gloves and a respirator

It is important to avoid contact with the skin and respiratory system. Store the paint in a cool, dark place, away from children.

An overview of the enamel lining PF-133 can be seen in the video below.

Physical state and chemical composition

The paint itself is viscous, with small solid particles.

PF-115 enamel differs in color, brightness, tone and density, which is created by pigments (colored powders), which are responsible for the formation of shades and give transparency to some materials.

Pentaphthalic varnish is composed of vegetable oils, resin, rosin and glycerin.

In addition to pentaphthalic material, various oils and a desiccant are added to the solvent - a substance that helps to dry faster on the surface.

An organic solvent (white spirit) is added precisely to oil solutions.

The transparent substance is extracted from oil, it has an oily consistency, it liquefies the paint if it is too thick and does not affect the composition itself.

The paint contains titanium white (titanium dioxide), a non-toxic substance that creates a white pigment in paint materials, holds the oil on the surface and scatters light.

Alkyd enamel differs not only in a variety of colors, but also in moisture resistance, tolerates long-term exposure to UV radiation, and does not crack after drying due to its strength and elasticity.

PF-115 is already sold in a certain color, but you can change it if you add another paint to the solution. At the same time, the volume will increase.

The most common shades:

- Blue.

- White.

- Gray.

- Beige.

- Pink.

- Orange.

- Cherry.

- Citric.

- Terracotta.

- Khaki.

- Red.

- Salad.

- Ivory.

- Black.

- Blue.

- Turquoise.

Plastic, bendable structural parts after staining retain their original appearance - the enamel does not break off and does not wear off with frequent interaction.

Colors

Enamel PF-115 is presented in a fairly wide range of colors. However, it is not at all limitless. As a rule, basic colors and a small number of shades are offered. If there is no suitable tone in the palette, you can always get it yourself by mixing several colors.

By color, the enamel of the species in question is:

- white (and white matte);

- beige;

- cream;

- yellow;

- orange;

- green;

- red;

- blue;

- gray;

- lilac;

- pistachio;

- turquoise;

- cherry;

- brown;

- black etc.

Enamels of different shades mix and tint perfectly. For this, tinting pastes are used. As a rule, they are packed in small-volume plastic bottles with a narrow neck, which allows you to measure the required amount of color by drops. The asterisks on the packaging of the composition indicate its resistance to sunlight.

Getting the desired shade of enamel at home is quite simple - you just need to strictly follow the tinting technology.

- First, you need to tint a small amount of enamel for the test, paint a small area of the surface and let it dry.

- Color is added to the paint drip. First, a small amount of enamel is painted, then it is added to the main jar and mixed thoroughly.

- If you need a large amount of material, then you need to tint not separately in cans, but all the paint at once.

When creating a paint of a new shade, you must remember the following nuances:

- for mixing, it is necessary to use a color scheme and paint and varnish material from the same manufacturer;

- the intensity of the shade may change slightly after the coating has completely dried - this must always be remembered;

- if the shade is selected using a computer program, then the monitor must be correctly adjusted to avoid distortion of the future paint color.

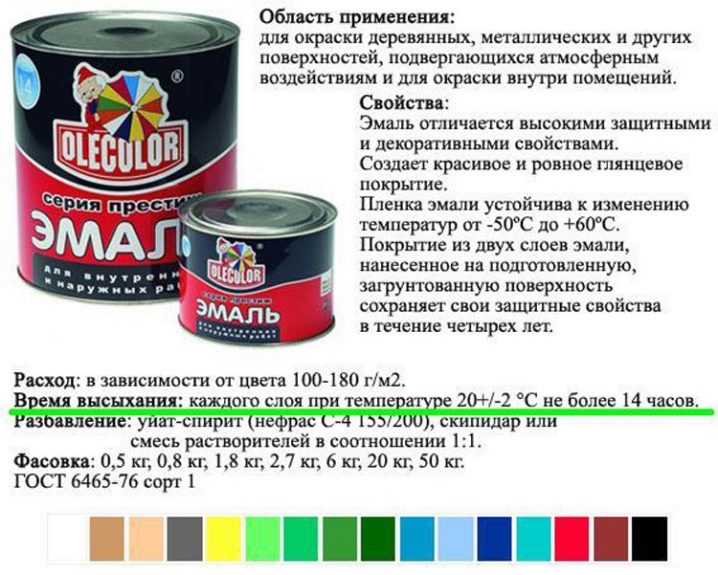

Consumption

There is no clear regulation of enamel consumption. The amount of paint required to cover 1 m2 of surface depends on the color of the enamel, the number of layers, the type of application tool used (brush, roller, pneumatic spray), the characteristics of the material to be painted. Average consumption is from 100 to 180 g of enamel per 1 m2.

As for the colors, the least economical options in terms of consumption are white and red enamels. An intermediate option is colored paints. Least of all, black enamel is required for processing the same surface area.

Let's consider what surface area can be covered with 1 kg of enamel of different colors:

- white - 7-10 m2;

- black - 17–20 m2;

- blue, light blue - 11-14 m2;

- brown - 13-16 m2;

- red - 5-10 m2.

The number of layers depends on the color of the selected enamel (as a rule, white or light paint is applied several times), the type and condition of the surface to be treated. For example, concrete or brick must be painted in at least 2 layers.

We will talk in more detail about the technology of working with different types of surfaces below.

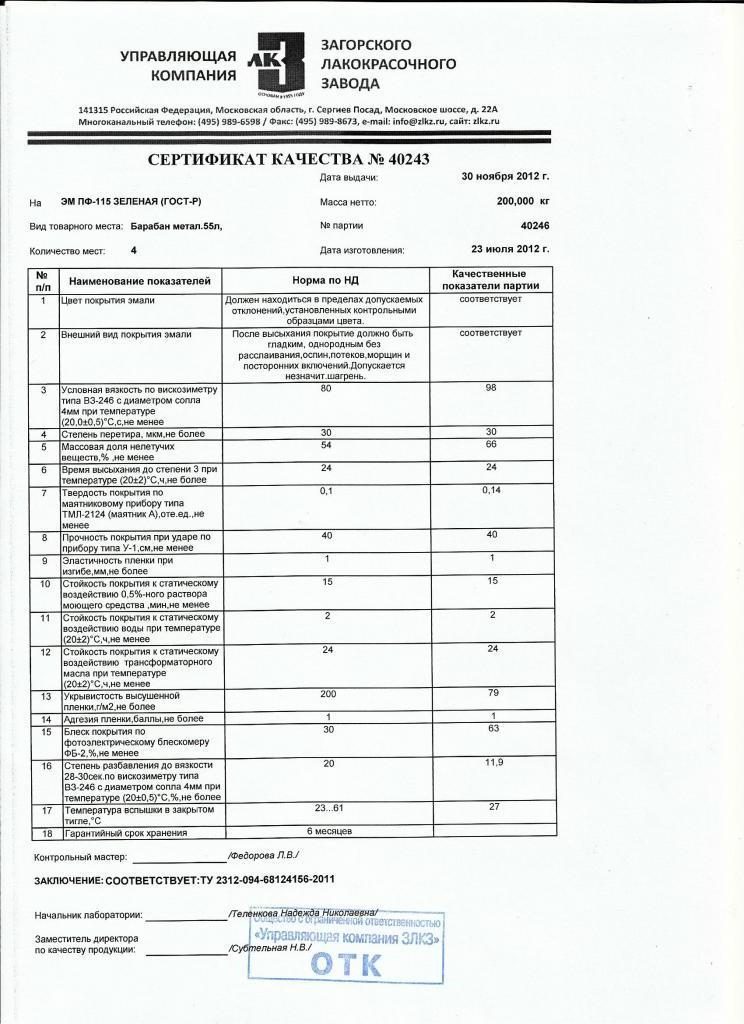

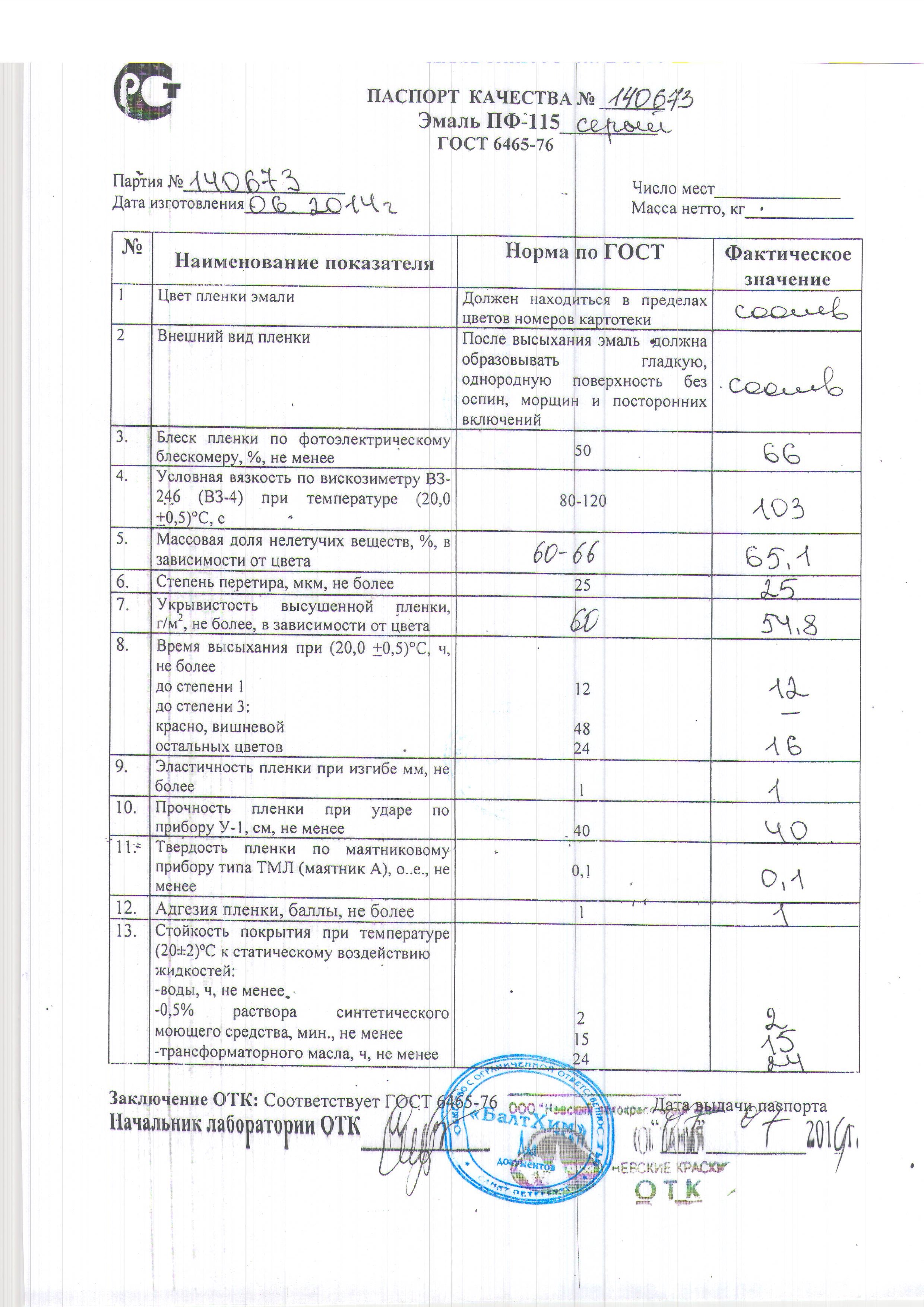

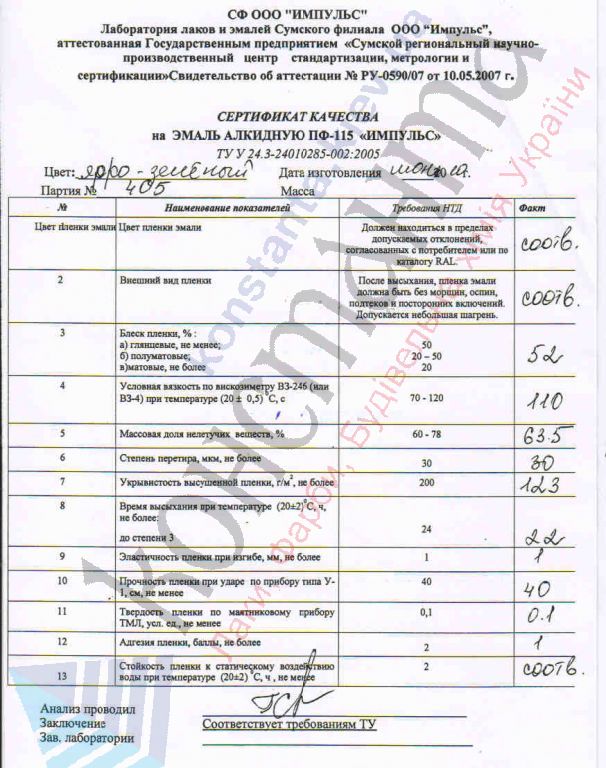

Technical characteristics of PF-115 paint

The technical characteristics of the PF-115 may change not only from color changes.Due to the slightest difference between oil or other components, the proportions in the paint may change, and therefore the properties of the entire composition (everything is compared according to GOST 6465 76).

Due to these differences, the period during which the paint can be used can be reduced or increased, that is, the service life depends on changes in the slightest proportions.

In the first place in terms of stability - enamel PF-115 white (varnish is contained in a large ratio, not less than 27-28%). Enamel PF-115 gray contains the least substances - about 20%, in blue up to 25-26%.

But this does not mean that all colors except white are unstable - the solutions contain many other impurities that improve the quality.

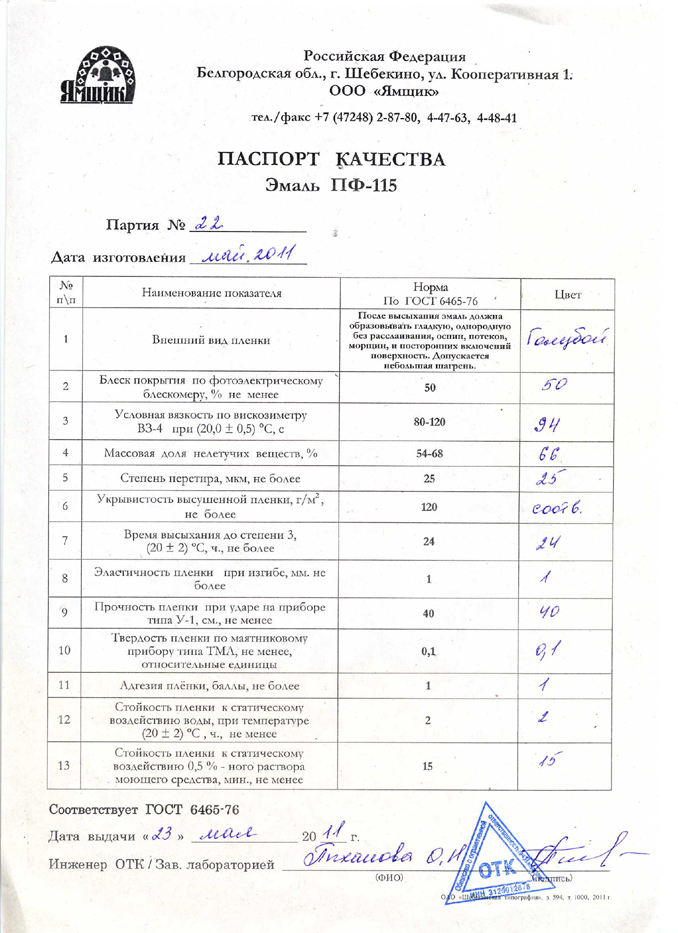

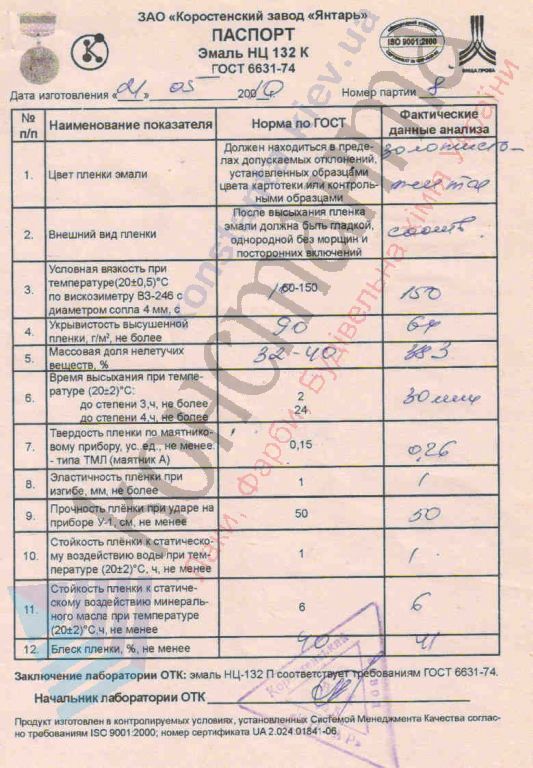

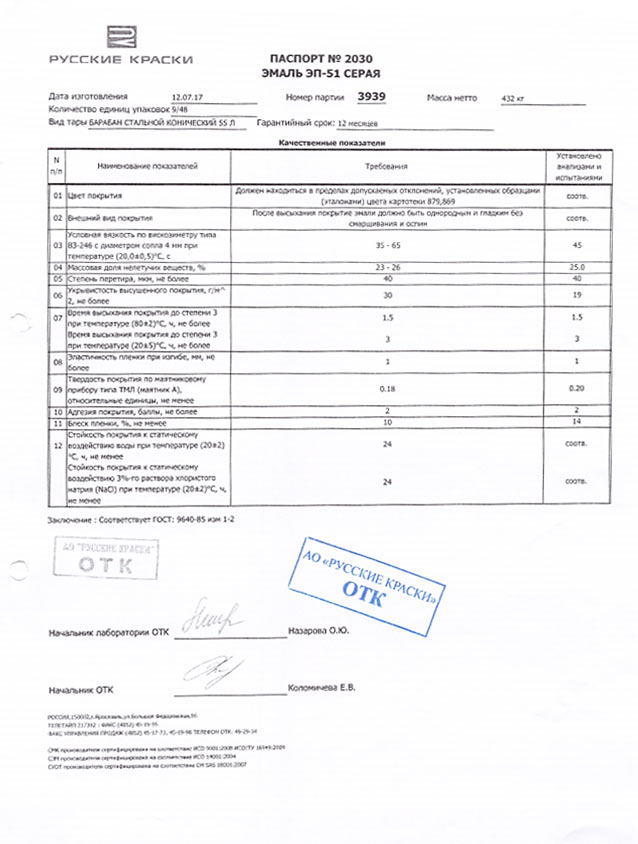

Enamel PF-115 specifications GOST 6465 76

table

| Shine | From 50% |

| Weight loss after complete drying | Up to 71% |

| Dilution with water (viscosity) at 20 ° C | Up to 123% |

| Drying at 19-22 ° С | Throughout the ducks |

| Shockproof | Up to 40 |

| The ability of the pigment to overlap the surface color | Up to 115 g / m2 |

| The cost of enamel for 1 layer depends on the selected color | Up to 180 g / m2 (maximum 0.18) |

| Maximum use temperature | Up to -50 ... + 60 ° С |

| Toxic substances | Moderate discharge, not above average |

| Flammability | Flammable |

| Smell | Harsh, poisonous |

| Hardness | Up to 0.25 |

| Cohesion of surfaces of dissimilar liquids or solids | 1 point |

| Permeability (dielectric) | Up to 11 |

Always wear protective clothing, gloves and a respirator mask.

After completing the work, ventilate the room - the smell of paint should completely disappear.

Painting scheme with enamel PF-115

Primer for metal: use "GF-0119", "VL-05", "GF-021", "VL-023" (always with the number 0 at the beginning).

It can be painted without primer, but then the enamel must be diluted with a solvent (sometimes up to 50%).

A rusty surface can be treated not only with PF-115 (in two layers), but also with Unicor K - a water-dispersion ground paint, with the addition of auxiliary substances and a synthetic polymer (one layer is enough).

PF-115 paint is suitable for processing pro-lined wood - apply no more than three coats. Wood treated with linseed oil will be covered with a protective film and will save enamel consumption.

Plaster, brickwork, concrete coating, old, worn or surfaces requiring restoration are processed in three layers.

After applying the solution, you need to wait at least a day; in some cases, removable parts can be dried at a temperature of no more than 110 ° C (within one hour).

Tips & Tricks

- The presence of a pungent, pungent odor. White spirit is found in many types of enamels, but an overly intense odor is a sign of a poor quality product.

- After opening the can and storing it in the open air, the original enamel is covered with a film.

- If the coating does not dry even after 48 hours, then this is a very poor quality product.

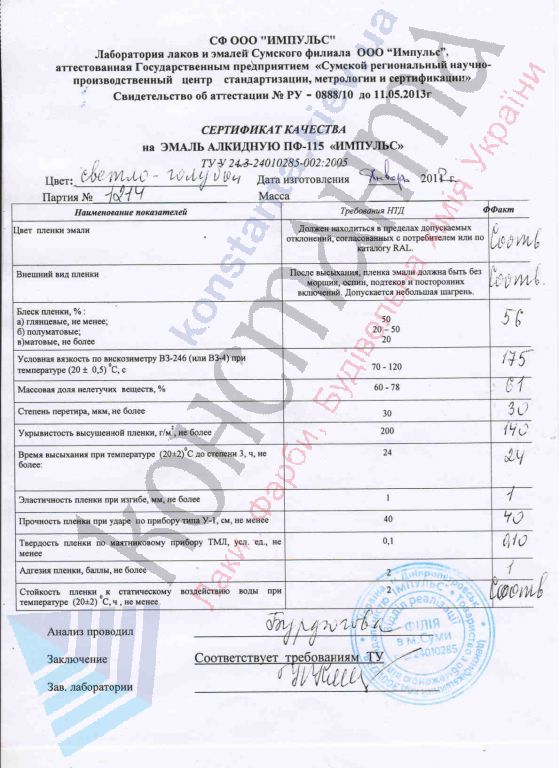

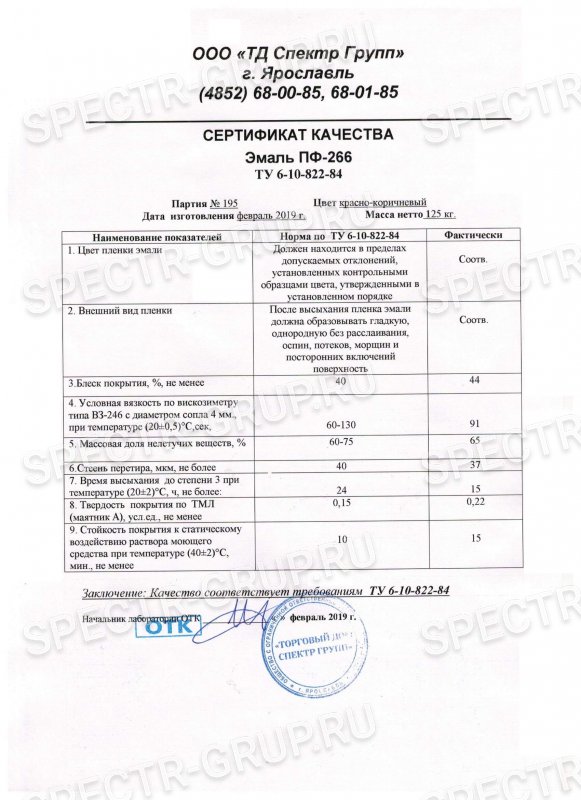

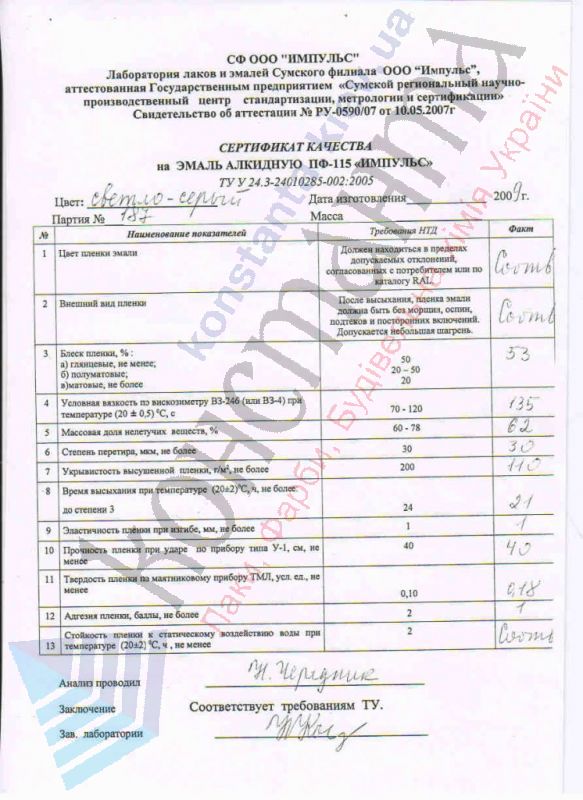

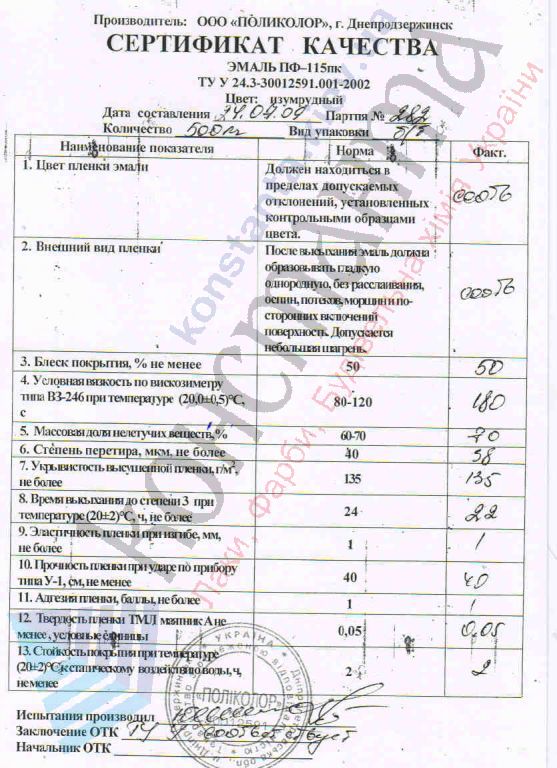

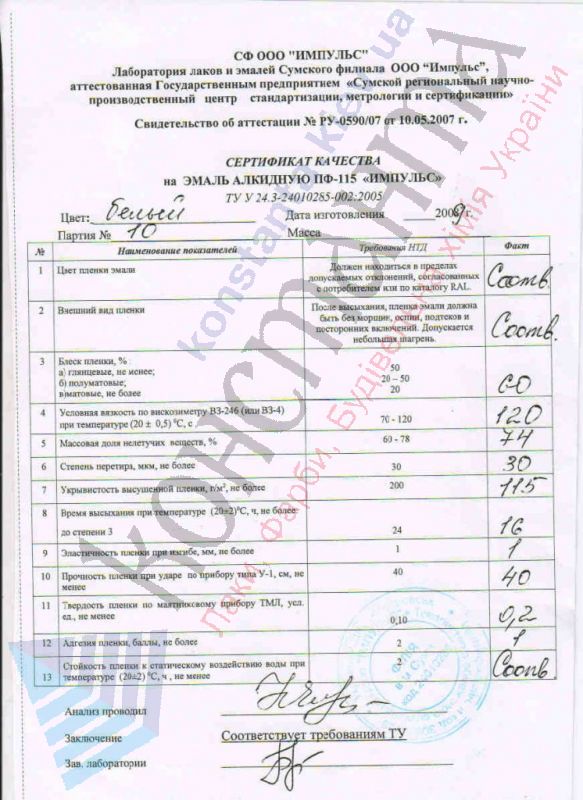

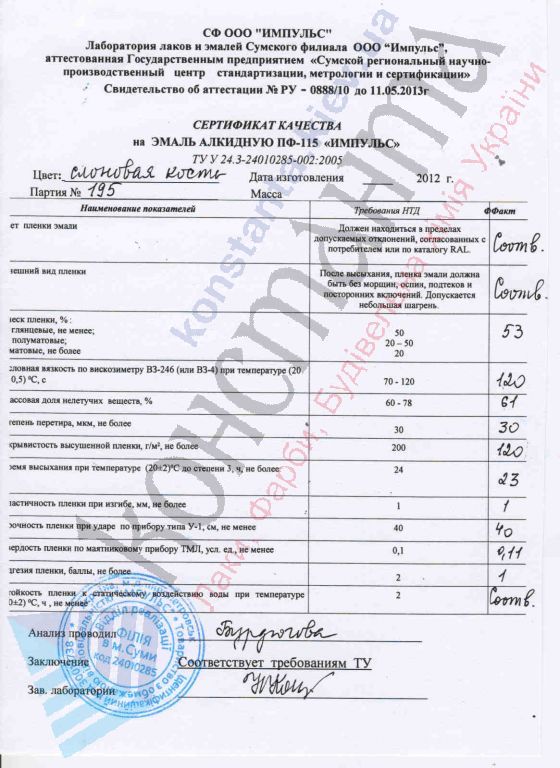

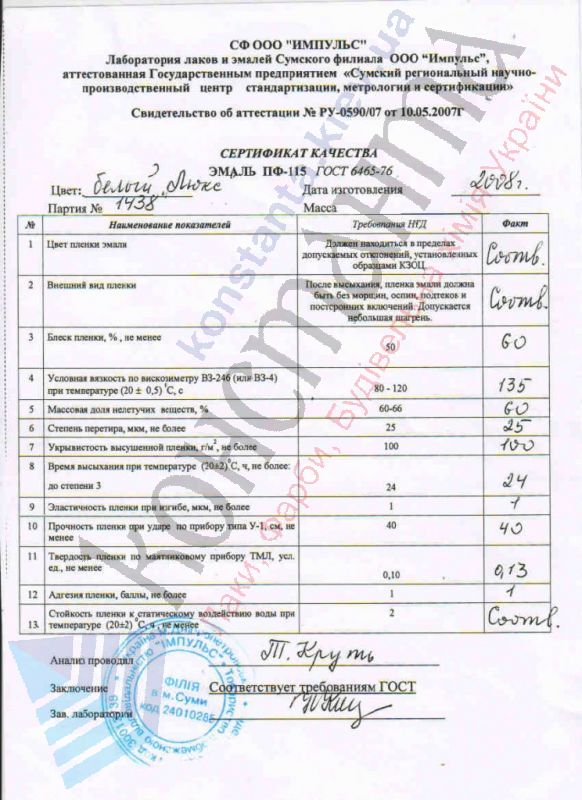

- Certificates of conformity, which must be present with the seller, will help to ensure the quality of the products.

Most often, customer claims related to the long drying time of the coating appear precisely after the purchase of the material in questionable retail outlets.

Painting

The universal qualities of PF-115 allow you to paint the surface at an air temperature of 5 to 35 degrees Celsius. To apply paint, use brushes, brushes, rollers or spray guns. Immersion staining is also used.

Metal structures are painted with at least two layers of enamel after preliminary priming. For high-quality painting of wood, brick, concrete or plaster, you will need two or three layers, each 18-23 microns thick. The spread in thickness is due to differences in the structure of the painted material and the color of the paint.

After applying a layer of enamel, the surface must dry. Drying at 20 ° C takes up to 24 hours. When faster drying is needed, high temperatures (100-110 degrees) are allowed.

After the enamel dries, the surface becomes glossy, uniform, smooth.It is resistant to abrasion, weather and chemical influences. PF-115 is compatible with almost any type of paintwork.

Surface preparation

Before applying the enamel, it is necessary to carry out preparatory measures so that the paint and varnish layer lays down qualitatively.

The work is done in this order:

- Remove traces of grease, dirt, old paint coat from the surface. To do this, you can use washing powder, soap or soda solution. Sand the wood materials. Remove traces of rust from metal structures.

- Dry the surface thoroughly (especially when it comes to plaster or concrete).

- If metal is to be painted, treat it with a degreasing agent and apply an anti-corrosion primer.

- If wood will be covered with enamel, apply drying oil, Biotex primer or universal varnish.

- For porous surfaces, an alkyd primer is preferable.

Primer application rules:

- Dilute the composition with a solvent (if necessary according to the conditions of the instructions).

- Stir the composition with a wooden stick.

- Apply the primer in a thin layer using a brush or roller.

- Let the surface dry.

Note! Pentaphthalic primers can be applied over old paint. However, then you need to sand its layer

Security measures

Painting should only be carried out using personal protective equipment (goggles, gloves, respirator). If paint and varnish material gets on the skin, wash the affected area with warm soapy water. When carrying out work, it is necessary to provide good natural or artificial ventilation. There should be no sources of ignition near the area to be painted.

Enamel consumption

One of the advantages of PF-115 is economical consumption. Specific indicators depend on many circumstances:

- Application method. When working with a spray gun, paint and varnish material is consumed less economically compared to using a brush.

- Manufacturing technology. PF-115 is produced not only according to GOST, but also according to TU. In the latter case, the flow rate is approximately 50% higher.

- Substrate preparation degree. A well-primed surface reduces the consumption of paints and varnishes.

- Consumption per 1m2 even depends on the color of the enamel. The most economical option is black paint, and the most wasteful option is white. Other colors are intermediate.

- The type of material to be painted. Consumption per 1 m2 for metal will be less than when painting wood, which absorbs part of the paintwork.

Enamel consumption - from 100 to 180 grams per square meter of one layer.

Application and recommended paint schemes

Waterproof alkyd enamel PF 115 can be applied with any type of painting tool - brush, roller, spray

When calculating the amount of paint required, it is imperative to take into account the peculiarity of the surface to be painted and the color of the paint.

Concrete, brick, unpolished wood absorb paint quite intensively and its consumption will be higher than when covering planed wood, metal or previously painted surfaces.

Selection of the amount of paint by color

Depending on the color, the consumption of a standard paint is quite large. At room temperature, to paint 1 m2 of the same type of unprimed surface, you will need:

0.1-0.14 kg - white paints

0.05 - 0.06 kg - black paints

0.07 - 0.1kg - blue paints

0.07 - 0.08 kg - brown paint

0.1 - 0.2 kg - red colors

The calculation is given for a single coat. When determining the real, the number of layers is multiplied by the given figures and again multiplied by a factor of 0.9 - for each subsequent layer there is less paint than the first. The second coat can be applied no earlier than 24 hours after the completion of the previous coat.

Only ideally dry surfaces are painted, heated to a temperature of at least +5 C. It is optimal to carry out painting work using PF 115 in dry, calm weather at an outside air temperature in the range of +15 ... + 22 C.In this case, the paint will maintain optimal viscosity, the solvent will not evaporate too quickly from the surface, and the risk of sagging will be minimized.

The method of application also affects the paint consumption. When using a roller, it will be larger than a brush, and a spray may lead to some overrun. Also, the average consumption directly depends on the quality of surface preparation for painting and compliance with standard paint application schemes.

Painting schemes with enamel PF-115

1. Coloring of metal.

Metals of all types are painted with enamel only after priming with compositions GF 0119, VL 05, GF 021 or their analogs compatible with pentaphthalic paints. In the index of primers, the number 0 must be first. If there are no primers, and the surfaces are not very critical, then for the primer you can use the PF 115 enamel itself, diluted with white spirit to 50% of the original density.

Surfaces bearing traces of corrosion are treated with Unicor rust inhibitors (converters) before priming. These compounds are applied after mechanical cleaning of metal from rust and grease. They transform the products of corrosion into strong and tight joints, which do not differ in hardness from the solid metal. Metals are painted with PF 115 enamel in two layers.

2. Coloring the tree.

On wood, the enamel is applied without a primer in 2 - 3 layers. If necessary (recommended), treat the wood surface with fire retardants, antiseptics and fungicides compatible with pentaphthalic paints. Manufacturers of paintwork materials offer a wide selection of such compositions, but when using them, you must carefully study the instructions - some of them are designed for acrylic paints, some act as an independent coating.

3. Plaster, concrete, brick.

These materials are painted with enamel in 2 - 3 layers without a primer. But it is advisable to use anti-mold preparations - the enamel forms a dense surface with low vapor permeability and residual moisture can cause favorable conditions for the development of mold and mildew in the bulk of the material if pest spores remain there.

When painting any of the materials, the surface must be thoroughly cleaned of dust and dried. Residual moisture should not exceed 10 - 15%. Fresh concrete walls and foundations, as well as brick structures, can be painted no earlier than six months after the end of the installation. The interval between applying the next coat of paint is at least one day.

In most cases, the paint is sold ready-to-use in its original container. But after opening the can, the solvent begins to evaporate intensively and the density of the enamel increases. To bring the paint to a working consistency, white spirit or solvent is used, as well as their mixtures. It is not recommended to use gasoline and kerosene - although they dissolve the enamel, they significantly change its shade and shine.

When preparing the paint for work, it must be thoroughly mixed by adding the solvent in small portions. In the process of work, the paint also needs to be mixed periodically.