Safety regulations

- if staining is carried out indoors, it is imperative to organize high-quality ventilation. The enamel contains harmful, toxic substances that in a closed room will adversely affect the respiratory organs and human well-being;

- it is forbidden to apply paint near heating devices, sparks and open flames, since XB-124 is a highly flammable, fire hazardous solution;

- during the application of the composition, it is imperative to protect the skin with a special protective suit and rubber gloves;

- to protect the eyes, it is recommended to use glasses, as if the mixture gets into the eyes, vision may deteriorate;

- to avoid the ingress of toxic fumes into the respiratory tract and respiratory organs, you must wear a respirator or gas mask.

Basic practical properties

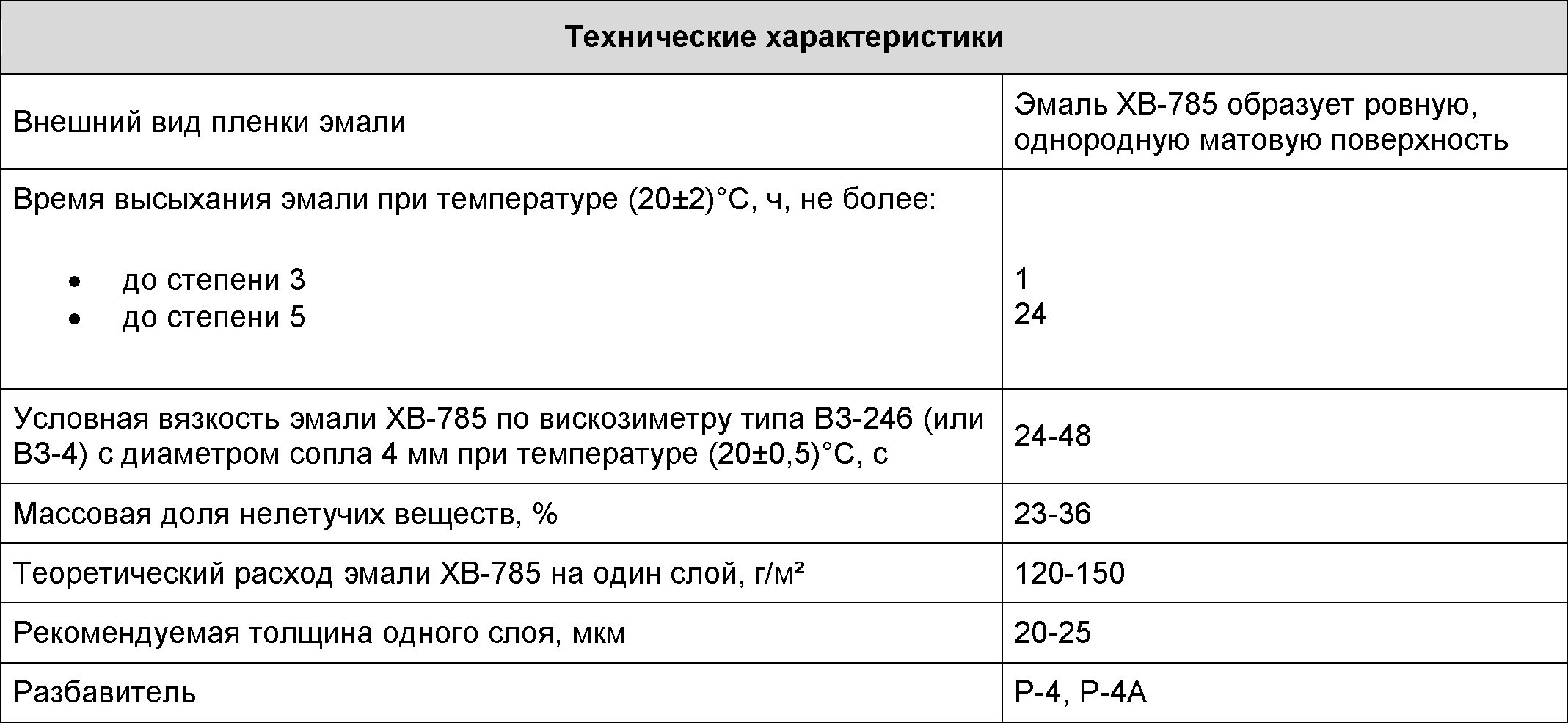

XB-785 reaches the third degree of drying at room temperature in 60 minutes, and the fifth degree - at most after 24 hours. The concentration of non-volatile substances is determined by the color of the mixture, and depending on it, it can be from 24 to 36%. The created film layer is elastic (it is allowed to change its size during thermal expansion or contraction by 1 mm).

Consumption per 1 m² is on average 0.114-0.146 kg of the mixture (if the work is carried out in one layer under normal conditions stipulated by the instructions). The layer has a thickness of 17 to 24 microns.

Drying time before applying each subsequent coat is approximately 60 minutes (at room temperature). Black enamel is consumed in the amount of 0.06 kg per 1 sq. m. If white paint is used, its costs will be 0.09, and if yellow, then 0.15 kg per 1 sq. m. m. The surface to be trimmed should not show the slightest signs of corrosion.

It should be borne in mind that XB-785 can easily catch fire, since it includes:

- butyl acetate;

- acetone;

- sovol.

Since the solvents used in enamel production contain various lead compounds, they can be hazardous to humans. This makes general and local ventilation of the premises absolutely necessary. And even in such conditions it is impossible to work without personal protection.

How to apply correctly?

The admissible relative humidity is 80%. If the mixture is applied to the originally primed surface, it retains its qualities for 5-6 years.

It is advisable to degrease before applying this brand of enamel with white spirit.

For priming the original surface, soils of the categories are used:

- XC-010;

- XC-059;

- XC-068.

Painting is done with rollers and brushes, if you are not limited to manual methods of work, you can use pneumatic and vacuum sprayers. Regardless of the method of use, paints and varnishes are thoroughly mixed until a homogeneous solution is obtained. Solvents are used to bring the mixture to a working viscosity; it is also permissible to clean contaminated tools and other surfaces with them.

Before starting work with perchlorovinyl enamel, it is required to find out what the surface temperature is. Normally, it should be at least 3 degrees higher than the dew point.

The manufacturer's instructions indicate that the composition must be applied in a minimum of a couple of layers, the thickness of each of them is from 60 to 100 microns. Storage of enamel should be carried out in a hermetically sealed container, away from open fire and heat. Direct sunlight and paint moistening are not allowed.

Long-term storage can lead to:

- increasing the viscosity of the composition;

- sediment formation;

- cleavage of complex dyes.

When this period passes, the manufacturer is automatically released from any responsibility for the consequences of its use and further storage. Standard packing is 25 and 50 kg, which allows using one package to cover an entire apartment or an overall wall.

It is recommended to apply the enamel in three or four coats. If a varnish of the same brand is used, it is applied in a maximum of two layers. The durability and beauty of the outer coating (subject to technological regulations) are guaranteed.

Enamel XB-785 is used in painting:

- industrial baths;

- large capacity tanks;

- facilities under construction;

- machines and mechanisms that transfer the action of water and steam;

- equipment and technology designed for high or low air temperatures;

- electroplating industrial equipment;

- other technological machines and mechanisms;

- vehicles.

When working with the XB-785, it is necessary to wear a respirator, have a loaded and tested fire extinguisher and a box of sand ready nearby.

According to the operating data, the enamel easily tolerates contact with hydrogen sulfide. Static exposure to a solution of sodium chloride (at a concentration of 3%) does not lead to a deterioration in the quality of the coating in 48 hours; for mineral oil this figure is 72 hours.

You will learn how to enamel a bath in the following video.

Safe handling of enamel

It is necessary to work with KO-811 enamel wearing rubber gloves and a gas and dust respirator. If it gets on your face or hands, wash them immediately with warm water and soap. Ventilate the work area thoroughly.

Enamel is one of the flammable substances, therefore, when working with it, it is forbidden to smoke and keep an open flame nearby. The work site must be equipped with the necessary fire extinguishing equipment.

Organosilicon enamels occupy a leading position among protective paints and varnishes. They are able to withstand elevated temperatures and can be successfully used for painting heating and hot water supply systems, various boilers, pipes and heating batteries, as well as other equipment operating in conditions of high temperatures and high humidity.

You can learn more about how to properly paint home batteries with enamel.

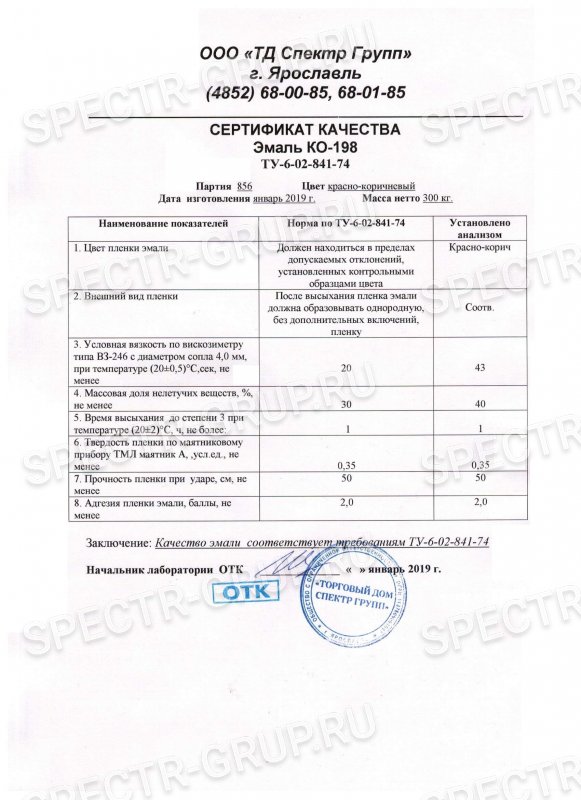

Differences between enamels of the KO series

Several enamels are produced in the KO series, which have much in common, but also have a number of differences in description and characteristics.

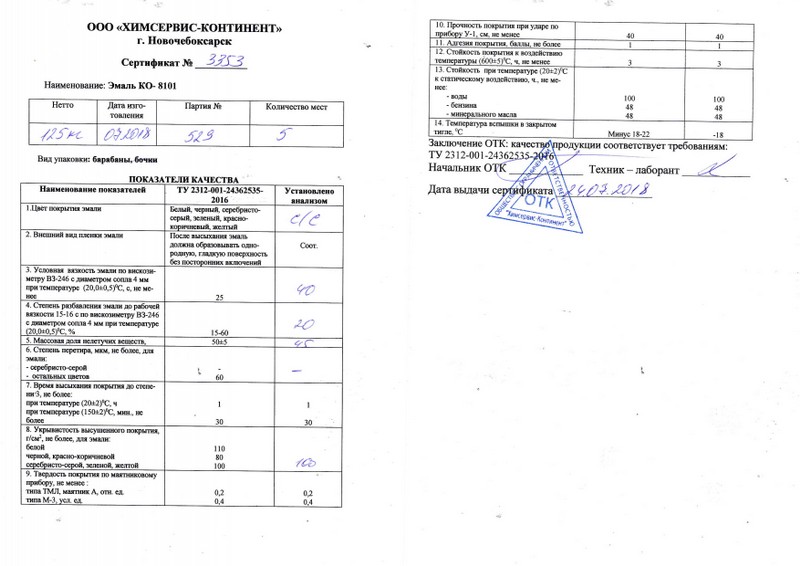

KO-8101

Anticorrosive enamel KO-8101 is used at temperatures of -60 ... + 600 degrees, mainly for painting exhaust systems of cars, for application to pipelines, furnaces, heating systems. The aim is to protect against rust and give the products an attractive appearance.

Enamel colors:

- black;

- Gray;

- blue;

- green;

- White;

- Red;

- beige, etc.

The product is one-component, does not require special preparation before application. Priming before using the enamel is also optional.

KO-8104

The scope of application of this tool is similar - it is used to protect metal products from corrosion, withstands temperatures up to +600 degreesbut for a shorter time. Therefore, paint is most often used in mechanical engineering, for application to pipelines. Also, the product can be used to process products made of concrete, stone, brick, and other mineral materials. Product colors - green, gray, blue, red-brown, blue, yellow and others.

KO-8111

This product can be used to protect steam, gas turbines, generators, heat pipelines. KO-8111 stands out favorably from other organosilicon enamels by its ability to not react for a long time to the action of various chemicals, not to lose its properties in an aggressive environment. Also, this material can be applied to surfaces at subzero temperatures.

KO-870

In terms of properties, this enamel practically does not differ from the previous ones, but it has higher indicators of resistance to the action of water.Therefore, it can be used where there is contact of products with moisture, there is an increased humidity of the air. The tool has proven itself perfectly in outdoor use, where surfaces are exposed to the direct action of precipitation. Scope of application - concrete and brick fences and other products, appliances, gas and steam turbines, generators. Like its counterparts, the material is available in a variety of colors.

KO-868

It is used where the surface is affected not only by high temperature, but also by high humidity. It is permissible to apply the agent on concrete, artificial stone, brick, but the main material for protection is metal. Most often, enamel is used for application to:

- pipelines;

- construction equipment;

- reservoirs;

- tanks;

- hydraulic structures;

- agricultural machinery.

Also, the material can be applied to asbestos-cement surfaces. It fits well even at negative temperatures, withstands up to +600 degrees.

As with all paint and varnish derivatives, you should protect your hands with rubber gloves and, if possible, use respirators. If accidentally splashed into the mouth, consult a doctor immediately.

Specifications

|

Heat resistance of enamel film ko-8101 at t ° (600 ± 5) ° С, h, not less |

|

|

Film strength upon impact on the U-1 device, cm, not less |

|

|

Mass fraction of non-volatile substances,% |

40±5 |

|

Film adhesion, points, no more |

|

|

The degree of dilution of enamel to a working viscosity of 15 s according to a VZ-246 viscometer with a nozzle diameter of 4.0 mm at t ° (20 ± 2) ° С,% |

30-80 |

|

Film hardness according to the pendulum device M-3, conventional units, not less |

0,4 |

Service life and storage of KO-8101

The guaranteed service life is more than 15 years, storage and serviceability after the container is damaged - 12 months.

CERTIFICATES AND REGULATORY DOCUMENTATION

PRICES ARE CURRENT ON 23 september 2019 G.

The offer posted on the site is not a public offer. All information contained on the Site is for informational purposes only and is not exhaustive. The prices indicated on the Site are for informational purposes only, may differ from the actual prices at the time the Visitor was familiar with them on the Site. The information presented on the Site regarding configurations, technical characteristics, appearance, cost, conditions of purchase of Products, service, etc. may differ from the actual characteristics and conditions of purchase of Products, and may also be changed at any time. The information on the Products presented on the Site does not mean that the latter is available for sale.

All the colors

2007-2019LLC "ALL PAINTS". ALL RIGHTS RESERVED, WHEN COPYING THE MATERIAL, THE LINK TO THE SITE IS OBLIGATORY. 0.186 s.

Dyeing process

Work should take place at a humidity of less than 80%, in a temperature range of -30 to +40 degrees. The spray gun will provide high-quality spraying, the minimum number of layers is two.

It is necessary to take into account some of the subtleties when painting:

- On areas with low accessibility, joints and edges, it is better to apply the compound with a brush by hand.

- When using pneumatics, the distance from the tool nozzle to the surface should be 200-300 mm, depending on the device.

- The metal is painted in two or three layers at intervals of up to two hours, if the temperature is below zero, the break time is doubled.

- Initial drying takes two hours, after which polymerization occurs and final drying, which is completed in a day.

The consumption of the dye can vary from 90 to 110 grams per square meter, depending on the texture of the base, the degree of its porosity and the experience of the master.

When working, follow the safety regulations. Since the enamels contain solvents, this determines the III class of hazard to human health.Therefore, for quiet operation and harmlessness of the process, you should take care of the maximum ventilation of the room, personal protective equipment, always have on hand materials at hand - sand, asbestos fire blanket, foam or carbon dioxide fire extinguisher.

For information on safety when working with such materials, see the video below.

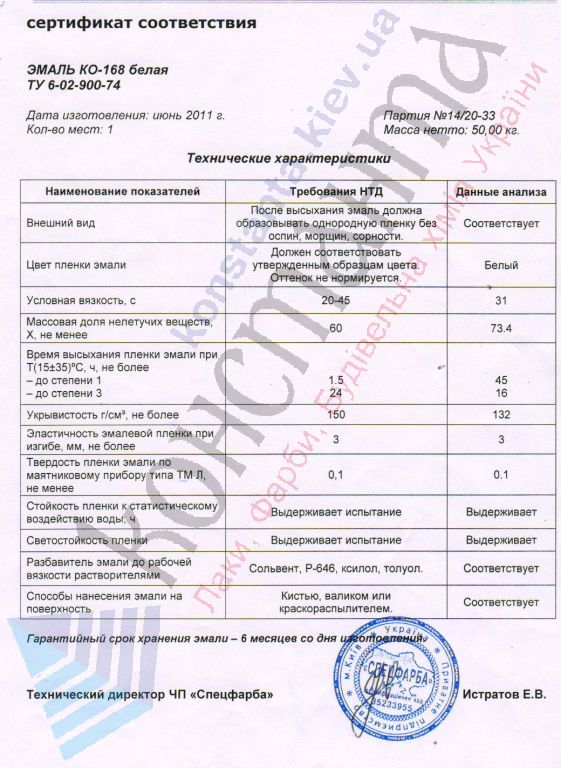

Specifications

This paintwork is a suspension of various color pigments dissolved in an organosilicon varnish. This type of dye is produced in two versions: KO-811 and KO-811K. Both types of paint and varnish coatings are used to protect against corrosion of products made of steel, titanium and aluminum, the heating of which during their operation can reach up to + 400 ° C.

Heat-resistant enamel KO-118 throughout the entire period of operation retains its appearance unchanged. It is weather and moisture resistant. This paint is recommended for use in rooms with high levels of humidity and in open spaces. Due to its increased resistance to the action of various oils and gasoline, this paint can be recommended for surfaces in contact with these compounds.

After drying, KO-118 forms a uniform film on the painted surface that does not have wrinkles and foreign inclusions. At an air temperature of 20 ° C, the relative viscosity of this enamel is about 12–20 cu. That is, that makes it possible to apply this coating by spraying.

The content of non-volatile compounds in the mass ratio in red enamel is about 30–35%. For black and green enamels, this figure is 39–45%, and for white and steel dyes, this value ranges from 48–55%. For other colors, the content of non-volatile components is about 46–54%.

The elasticity of the film formed by this paint, when bending the product after drying the coating, does not exceed 3 mm, so that it is possible to paint small-diameter pipes without fear of violating the integrity of the coating.

The hardness index of this enamel is not less than 0.5 cu. e. It has sufficient strength to be resistant to damage from shock and other mechanical influences, and its heat resistance at temperatures of the order of 400 ± 10 ° C - not less than 5 hours.

The consumption of the dye per 1 m2 when applied in two layers is about 100 g. The recommended layer thickness when the surface is coated with KO-811 or KO-811K enamel is about 40-50 microns.

Properties and order of operation of enamels of the KO-811 brand and other varieties

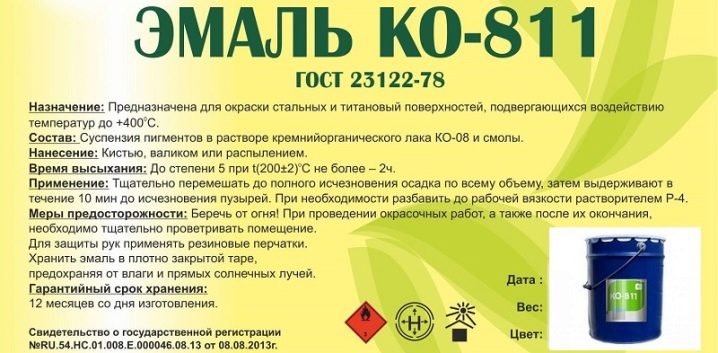

Appointment

Enamel KO-811 and KO-811K are intended for protective anticorrosive painting of steel, titanium and aluminum surfaces exposed to temperatures up to + 400 ° C during operation.

Specifications

This paintwork is a suspension of various color pigments dissolved in an organosilicon varnish. This type of dye is produced in two versions: KO-811 and KO-811K. Both types of paint and varnish coatings are used to protect against corrosion of steel, titanium and aluminum products, the heating of which during their operation can reach + 400 ° C.

Heat-resistant enamel KO-118 throughout the entire period of operation retains its appearance unchanged. It is weather and moisture resistant. This paint is recommended for use in rooms with high levels of humidity and in open spaces. Due to its increased resistance to the action of various oils and gasoline, this paint can be recommended for surfaces in contact with these compounds.

After drying, KO-118 forms a homogeneous film on the painted surface that does not have wrinkles and foreign inclusions. At an air temperature of 20 ° C, the relative viscosity of this enamel is about 12–20 cu. That is, that makes it possible to apply this coating by spraying.

The content of non-volatile compounds in the mass ratio in red enamel is about 30–35%. For black and green enamels, this figure is 39–45%, and for white and steel dyes, this value ranges from 48–55%. For other colors, the content of non-volatile components is about 46–54%.

The elasticity of the film formed by this paint, when bending the product after drying the coating, does not exceed 3 mm, so that it is possible to paint small-diameter pipes without fear of violating the integrity of the coating.

The hardness index of this enamel is not less than 0.5 cu. e. It has sufficient strength to be resistant to damage from shock and other mechanical influences, and its heat resistance at temperatures of the order of 400 ± 10 ° C - not less than 5 hours.

The consumption of the dye per 1 m2 when applied in two layers is about 100 g. The recommended layer thickness when the surface is coated with KO-811 or KO-811K enamel is about 40-50 microns.

Application

You can apply paint to a metal surface brush or rollerbut it is preferable to work with a pneumatic device. Airless spraying is better suited for large areas to be treated. The electrical equipment provides a better design. For such a supply of paint, it must be diluted as much as possible with the solvent "RFG" or "R-4A".

The preparatory phase includes several main points:

- Thorough cleaning of metal from dirt, dust, oils, scale and rust is required. The indicator is the characteristic gloss of the surface, the evenly distributed roughness of the material, in places with scale the color of the base may be darker.

- After cleaning, completely dust and degrease the coating. To do this, wipe it with a rag dipped in white spirit.

- Check for greasy stains by wiping with special filter paper based on cellulose, fibrous substances and asbestos (it must not be left with traces of oil).

- It is permissible to use abrasive, sandblasting for cleaning. In this way, even the smallest particles of rust can be removed from the metal.

- In the presence of individual contaminants, they are removed and degreased locally.

- Then you should carry out the primer with the compositions "VL", "AK" or "FL". The surface should dry completely.

Immediately before painting, the solution is stirred until a homogeneous mass is formed and the first layer is applied to a dry primer. Initial drying lasts no more than 3 hours, after which the next layer can be applied.

The three-layer coating is mainly made for temperate climates, four layers are for the tropical zone. If it is necessary to protect the metal in cold conditions, it will be necessary to paint three layers of paint on the primer "AK-70" or "VL-02". The time interval between coats is at least 30 minutes.

Enamel KO-811, KO-811K

REFINE PRICE

Section: for metal surface

| Standard | GOST 23122-78 |

| By type of material | Enamel |

| By type of protected surface | Stainless steel, Primed metal, Titanium |

| By area of application | Mechanical engineering / Machine tool building, Steel structures / Steel structures, Buildings and structures / Construction industry |

| By type of binder | KO (organosilicon) |

| By special properties | Wear-resistant coating, Heat-resistant paints and varnishes, For outdoor use, Glossy / Semi-gloss, For indoor use |

| By resistance to impact | Moisture resistance, Wear resistance, Corrosion protection, Heat resistance |

GOST 23122-78

Enamel composition: is a suspension of pigments in a solution of organosilicon varnish (for KO-811 enamel) with the addition of a stabilizer for KO-811 K enamel.

Application of enamel: intended for protective anticorrosive painting of steel, titanium and aluminum surfaces exposed to temperatures up to + 400 ° C during operation.

Color: enamels are produced in the following colors: - KO-811 - red, black, green; KO-811K - white, red, yellow, blue, blue, steel, brown, light brown, olive.

Enamel properties: have heat resistance up to + 400 ° C, as well as increased atmosphere and moisture. oil and petrol resistance.

Preparation for application: the surface is cleaned of dirt, rust, scale, loose old coating and degreased.

Enamel application: mix the enamel thoroughly, apply to the previously cleaned surface with a brush, roller or spray gun in 1-2 layers with intermediate drying between layers for 15 minutes, at a temperature of (20 + 2) o С

Thinner to working viscosity: solvent or thinner 646, xylene, toluene.

Shelf life: 12 months from the date of manufacture.

Technical specifications

|

Indicator name |

KO-811 |

KO-811K |

|

Appearance |

After drying, the enamel film should be uniform, without wrinkles, pockmarks and foreign inclusions |

|

|

Enamel film color |

The shade is not standardized |

|

|

Conditional viscosity at t (20 ± 0.5) ° C, sec, according to a VZ-246 type viscometer with a nozzle diameter of 4.0 mm: - enamel - semi-finished enamel |

15-20 |

13-20 |

|

Mass fraction of non-volatile substances,%, in enamel: - red - green and black in semi-finished enamel: - white - steel - other colors |

30-3539-45 |

49-5548-5446-54 |

|

Drying time of enamel, h, no more: - to degree 3 at t (20 ± 2) ° C - to degree 5 at t (120 ± 2) ° C at t (200 ± 2) ° C |

2,0 |

2,0 2,0 |

|

Elasticity of the enamel film when bending, mm, no more |

3 |

3 |

|

The hardness of the enamel film according to the pendulum device M-3, cu, not less |

0,5 |

0,5 |

|

Heat resistance of enamel film at t (400+ 10) ° C, h, not less |

5 |

5 |

|

Resistance of the enamel film to static impact at t (20 + 2) ° С, h, not less - water - gasoline |

242 |

242 |

|

Consumption for two-layer coating, g / m2 |

250-300 |

120-150 |

Distinctive properties

The basis of the material is polyvinyl chloride chlorinated resin, which is supplemented with alkyd compounds, organic solvents, fillers and plasticizers. When added to the mixture of coloring pigments, a suspension of a certain shade is obtained, the technical characteristics of which correspond to world quality standards.

The main important properties of the paint:

- the ability to withstand large amplitudes of critical temperatures;

- resistance to any kind of metal corrosion (chemical, physical and electrochemical interaction with the environment);

- fire resistance and moisture resistance, immunity to the aggressive effects of oils, detergents, household cleaning products, gasoline;

- plastic, moderately viscous structure, providing good adhesion;

- preventing the emergence and spread of rust;

- durability and the ability to optimally fulfill the decorating task.

The enamel dries completely in about 24 hours. For strong thickening, different types of solvents are used.

To protect coatings from temperature extremes and corrosion, enamel is applied to wood and reinforced concrete. Metal works are carried out after the necessary priming. The painted surfaces are kept in cold conditions for at least 4 years. When exposed to high temperatures and intense ultraviolet radiation - up to 3 years. Before use, the tree does not need to be primed, the enamel is applied to it immediately. Three layers are enough for 6 years of successful operation.

Application method

Before painting the surface with this type of dye, it must be thoroughly cleaned by removing dust, mechanical particles, fats, salts and other fragments and compounds from it. Such surfaces are degreased with a rag moistened with a solvent such as acetone, solvent or xylene. If there is scale or rust, they can be removed manually or mechanically, or with using the sandblasting method.

If it is not possible to use a sandblaster and when the products to be painted will be used at temperatures below 100 ° C, it is permissible to use a rust converter. Remains of the old ink layer are also removed. As a result, the surface prepared for painting should be sufficiently clean and dry.

Then the enamel is diluted to the state of working viscosity by means of toluene or xylene for KO-811 in a ratio of 30–40%, for white - in a proportion of 70–80%, and for other colors - 40–50%. After thorough mixing, the enamel is left for 10 minutes so that air bubbles come out of it.

If we are talking about KO-811K, then its semi-finished product is mixed with a stabilizer in a ratio of 100: 6 for white paint and in a ratio of 100: 7 for other colors. So that the prepared composition does not dry out, it should be used no more than 24 hours in advance.

On the surface to be painted, the enamel should be applied with a spray gun with a nozzle diameter of 1.8–2.5 mm from a distance of about 20–30 cm. Work can be carried out at temperatures from -30 ° C to + 40 ° C.

Enamel is applied to metal products in two or crown layers. Each layer should dry for 0.5 to 2 hours, depending on the ambient temperature. During operation, the full hardening of the enamel layer is carried out when the painted products and equipment are heated.

Application and recommended paint schemes

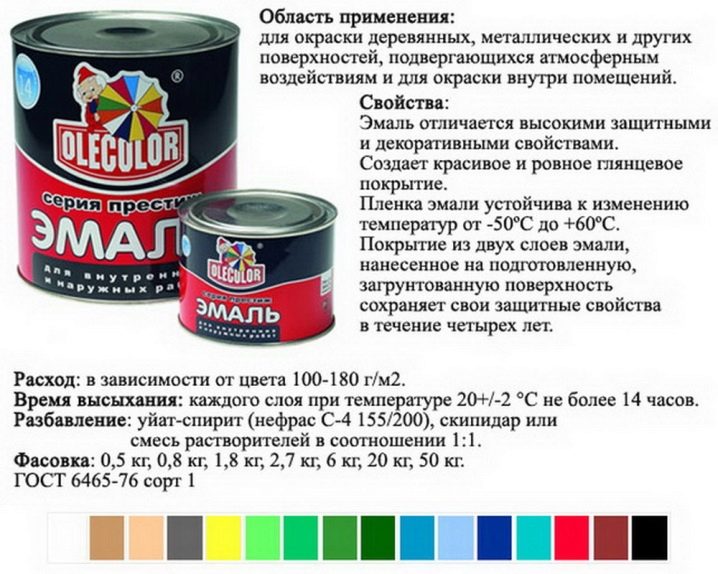

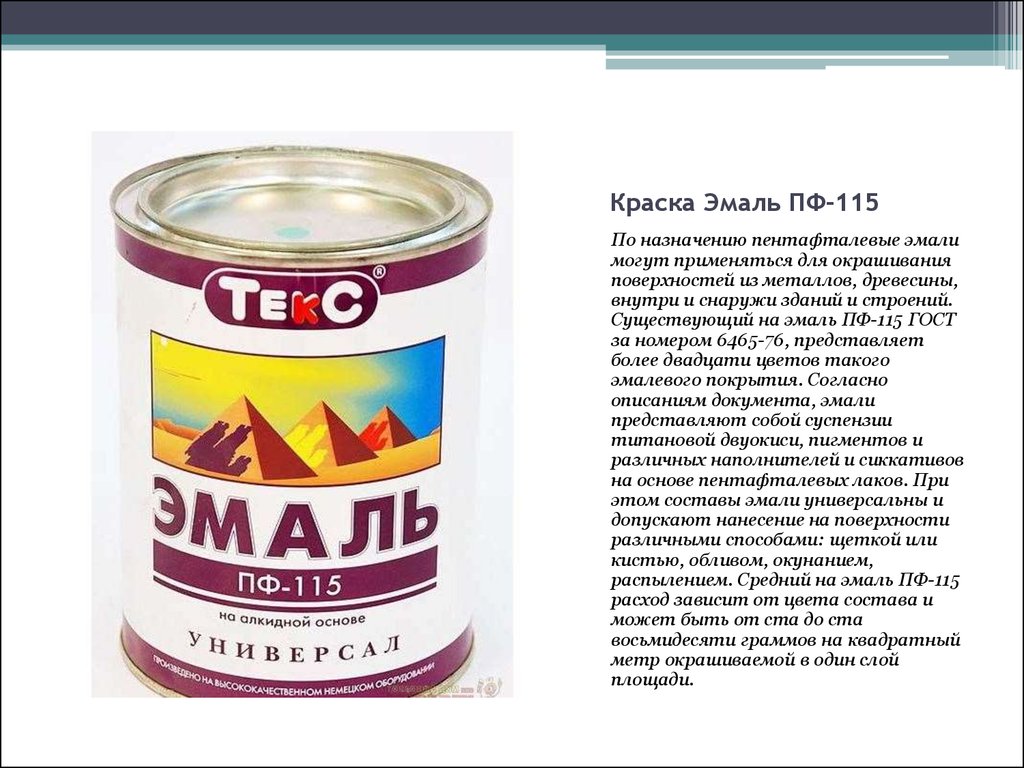

Waterproof alkyd enamel PF 115 can be applied with any type of painting tool - brush, roller, spray

When calculating the amount of paint required, it is imperative to take into account the peculiarity of the surface to be painted and the color of the paint.

Concrete, brick, unpolished wood absorb paint quite intensively and its consumption will be higher than when covering planed wood, metal or previously painted surfaces.

Selection of the amount of paint by color

Depending on the color, the consumption of a standard paint is quite large. At room temperature, to paint 1 m2 of the same type of unprimed surface, you will need:

0,1-0,14 kg - white paints

0.05 - 0.06 kg - black paints

0.07 - 0.1kg - blue paints

0.07 - 0.08 kg - brown paint

0.1 - 0.2 kg - red colors

The calculation is given for a single coat. When determining the real, the number of layers is multiplied by the given figures and again multiplied by a factor of 0.9 - for each subsequent layer there is less paint than the first. The second coat can be applied no earlier than 24 hours after the completion of the previous coat.

Only ideally dry surfaces are painted, heated to a temperature of at least +5 C. It is optimal to carry out painting work using PF 115 in dry, windless weather at an outside air temperature in the range of +15 ... + 22 C. In this case, the paint will maintain optimal viscosity, solvent - do not evaporate too quickly from the surface, and the risk of sagging is minimized.

The method of application also affects the paint consumption. When using a roller, it will be larger than a brush, and a spray may lead to some overrun. Also, the average consumption directly depends on the quality of surface preparation for painting and compliance with standard paint application schemes.

Painting schemes with enamel PF-115

1. Coloring of metal.

Metals of all types are painted with enamel only after priming with compositions GF 0119, VL 05, GF 021 or their analogues compatible with pentaphthalic paints. In the index of primers, the number 0 must be first. If there are no primers, and the surfaces are not very critical, then for the primer you can use the PF 115 enamel itself, diluted with white spirit to 50% of the original density.

Surfaces bearing traces of corrosion are treated with Unicor rust inhibitors (converters) before priming. These compounds are applied after mechanical cleaning of metal from rust and grease. They transform the products of corrosion into strong and tight joints, which do not differ in hardness from the solid metal. Metals are painted with PF 115 enamel in two layers.

2. Coloring the tree.

On wood, the enamel is applied without a primer in 2 - 3 layers. If necessary (recommended), treat the wood surface with fire retardants, antiseptics and fungicides compatible with pentaphthalic paints.Manufacturers of paintwork materials offer a wide selection of such compositions, but when using them, you must carefully study the instructions - some of them are designed for acrylic paints, some act as an independent coating.

3. Plaster, concrete, brick.

These materials are painted with enamel in 2 - 3 layers without a primer. But it is advisable to use anti-mold preparations - the enamel forms a dense surface with low vapor permeability and residual moisture can cause favorable conditions for the development of mold and mildew in the bulk of the material if pest spores remain there.

When painting any of the materials, the surface must be thoroughly cleaned of dust and dried. Residual moisture should not exceed 10 - 15%. Fresh concrete walls and foundations, as well as brick structures, can be painted no earlier than six months after the end of the installation. The interval between applying the next coat of paint is at least one day.

In most cases, the paint is sold ready-to-use in its original container. But after opening the can, the solvent begins to evaporate intensively and the density of the enamel increases. To bring the paint to a working consistency, white spirit or solvent is used, as well as their mixtures. It is not recommended to use gasoline and kerosene - although they dissolve the enamel, they significantly change its shade and shine.

When preparing the paint for work, it must be thoroughly mixed by adding the solvent in small portions. In the process of work, the paint also needs to be mixed periodically.

EP-5116 waterproof, anticorrosive enamel

EP-5116 enamel is produced as a set, the set of two-component material includes a base (pigments, fillers, inactive thinners, plasticizers, epoxy resins) and a hardener.

Immediately before use, the components (I and II) are mixed in a 1: 2 ratio until homogeneous, while their temperature should be above +16 ° C. The base, if necessary, can be heated in a specially equipped room to +50 ° C to reduce the viscosity. After drying, the enamel forms a smooth, even surface, reliably protecting the metal from corrosion (see also ep-5287 and xc-717).

| Technical characteristics of ep-5116 waterproof enamel | |

|---|---|

| Appearance and color of the coating | After drying, EP-5116 enamel should form a flat, smooth black surface, the shade is not standardized |

| Drying time of EP-5116 enamel to degree 3 at a temperature of (80 ± 2) ° С, h, no more | 1,5 |

| Mass fraction of non-volatile substances of EP-5116 enamel,%, not less | 94 |

| Theoretical consumption of EP-5116 enamel per layer, g / m2 | 300÷330 |

| Recommended thickness of one layer, microns | 50÷60 |

| Recommended number of layers | 2 |

| Viability of EP-5116 enamel at a temperature of (20 ± 2) ° С after mixing the components, h, not less: | |

|

5

24 |

| Diluent | Xylene, Ethyl cellosolve |

| To prepare the composition of Enamel EP-5116, it is necessary to mix components I and I I in the ratio indicated in the quality certificate for each batch of material and mix thoroughly, while the temperature of the components should not be lower than + 16 ° С. Component I, if necessary, can be heated to reduce the viscosity to a temperature of 30 ÷ 50 ° C. |

| Stir components I and I I thoroughly before use until the settled pigment is evenly distributed. |

| The resulting EP-5116 enamel, if necessary, is diluted to a working viscosity (18-25 s according to a VZ-246 viscometer with a nozzle diameter of 4 mm) with xylene or ethyl cellosolve. |

| EP-5116 enamel is applied to the surface of the metal to be protected with a roller, brush with a paint sprayer or with a device for spraying high-viscosity two-component materials. Large-sized items are painted with enamel in atmospheric conditions at a temperature not lower than + 5 ° С. It is allowed to carry out painting works at negative temperatures (up to -18 ° C), in this case, so that the anticorrosive enamel on metal dries to degree 3, the drying time may increase up to 30 hours. |

| EP-5116 enamel is flammable! Do not work near open sources of fire.Perform work with good ventilation using personal protective equipment. Do not allow anticorrosive metal enamel to enter the respiratory and digestive organs. If the material comes into contact with the skin, wash it off with warm water and soap. |

|

It is recommended to store EP-5116 enamel indoors at a temperature not lower than -30 ° C to + 30 ° C, excluding direct sunlight and moisture. Manufacturer's warranty:JSC "PKF Spectr" guarantees the compliance of Enamel EP-5116 with the requirements of GOST 25366-82, provided that the consumer observes the conditions of transportation and storage. The guaranteed shelf life of the enamel components is 6 months from the date of manufacture. During storage, the enamel components should not form a dense, difficult-to-mix sediment. After the expiration of the warranty period, the enamel is subject to verification for compliance with the requirements of GOST 25366-82 and, upon establishing compliance, can be used by the consumer for its intended purpose. |

Articles about the material:

EP-5116 anticorrosive enamel is a reliable means of protecting structures from the effects of the aquatic environment.

Universal anti-corrosion enamels are able to very effectively protect metal from moisture, industrial atmosphere and even mechanical stress. However, this statement will be true only on condition that the action of each of these factors will not go beyond the "reasonable framework."

Read more →