How to apply enamel

It is necessary to carry out priming after preliminary preparation of the surface, which may be rusty. Loose rust should be rubbed thoroughly to peel off. It is necessary to remove the remnant of the previous coating, scale, dust, dirt, using solvents.

Proper storage

In order for the coating to be of high quality, the storage conditions of the product must be observed. It can be transported by any transport, but the air temperature should not exceed 30 - 35 degrees Celsius.

During transportation and storage, strict observance of the conditions for protecting the enamel from atmospheric precipitation is required. Storage does not allow exposure to sunlight, moisture. The container is tightly closed during storage. Permissible storage temperature: from -25 to +30 degrees. Compliance with the conditions guarantees excellent properties of the product up to six months from the date of production.

Breeding procedure

How to dilute the enamel? For dilution, use solvents R-4, R-4A. The same means can be used for preliminary preparation and cleaning of the surface from contaminants. It is permissible to use thinners R-670A, R-670.

Specific dilution rates are not indicated, the viscosity of the finished product is determined by the application method. Direct application with a roller or brush may make the mixture thicker than with a spray gun.

The solvent is added in small portions, each time the mass is thoroughly mixed. After the primer is applied to the surface, the solvent evaporates quickly and the coating remains strong. It is necessary to work with solvents, wearing a pair of gloves, protecting the respiratory system with a respirator, and protecting the skin with thick clothing.

Enamel application

It is possible to apply the primer-enamel XB-0278 in different ways:

- airless spray;

- pneumatic spraying;

- roller;

- brush;

- by dipping into the product.

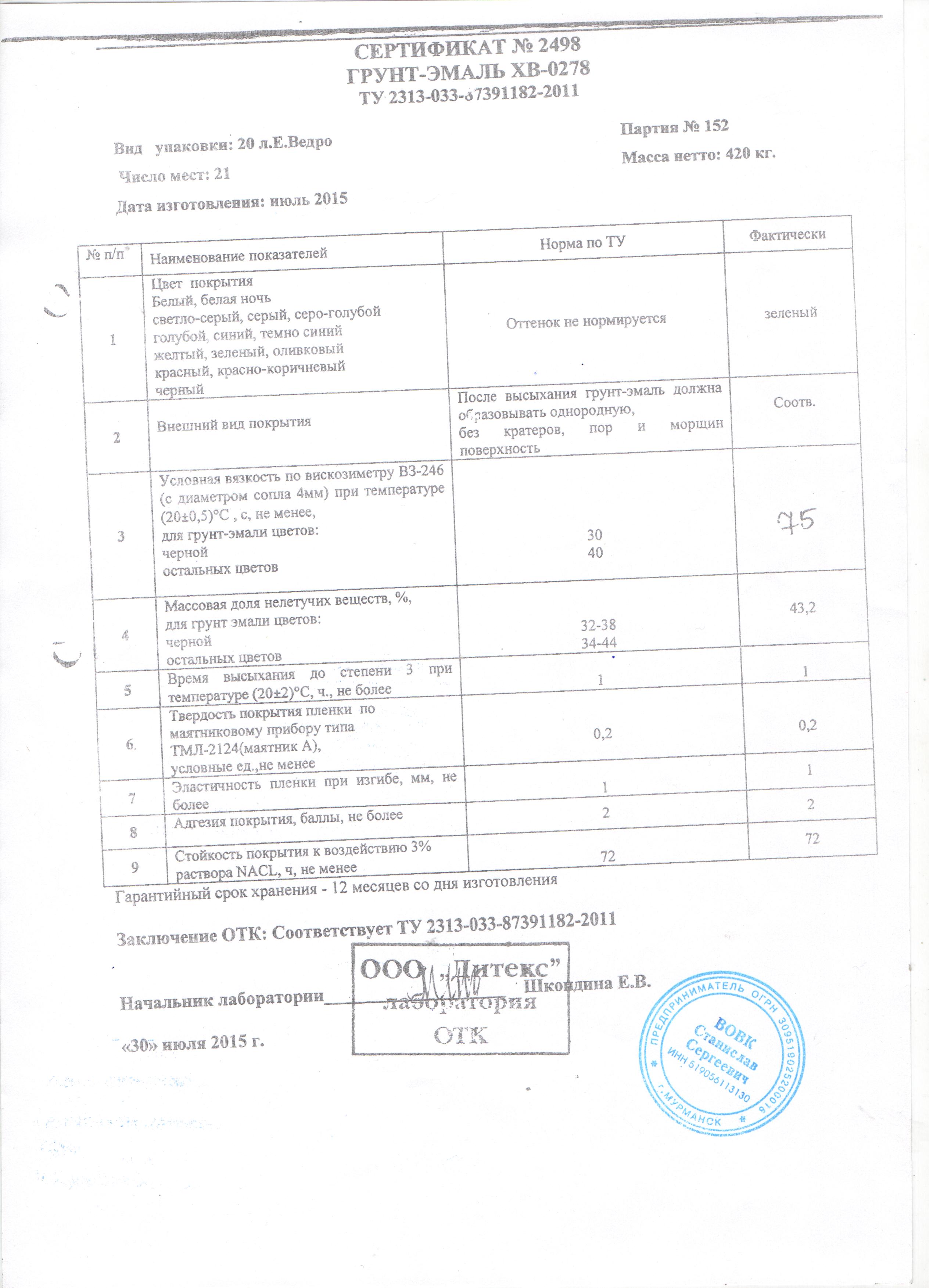

Air temperature during work: from -10 to +30 degrees, humidity - 80%. The first layer should be dried for 1 - 2 hours (temperature - twenty degrees). The remaining layers are applied every hour. Two or three layers are enough to provide a stable coating, with the first serving as a rust converter, the second as an anti-corrosion primer, and the third as a decorative coating.

Consumption according to standards

Typically, the consumption is not higher than 100 - 150 g / square meter of the surface (the figure is indicated for the first layer of the primer). Subsequent layers will require slightly less enamel - up to 100 - 120 g.

Scope of application

Due to its protective properties under adverse weather conditions, fire resistance, moisture resistance, frost resistance and anticorrosive properties, the XB 124 enamel can be used in different areas of production:

- for repair and construction in the construction of private buildings, to maintain the strength of wooden facades;

- in the engineering industry;

- in instrument making for various purposes;

- for the processing of reinforced concrete, steel structures, bridges and production workshops;

- in the military industry to protect the surface of equipment and other objects from corrosion, sunlight, cold.

Enamel "XB 124" is extremely in demand in the construction of residential and industrial complexes in the Far North, where its frost-resistant qualities are highly appreciated, which make it possible to strengthen the outer walls in low temperatures.

Also, the paint is used for decorative painting of any metal structures. For wood, the dye can be used additionally as an antiseptic for the prevention of fungus and mold.

The official document on the quality of building material is GOST No. 10144-89. It sets out the main characteristics of the product, rules of application and maximum permissible ratios of components.

How to apply enamel "XB 124", see the next video.

Enamel XB-518 protective

Enamel XB-518 is used for painting pre-primed steel and aluminum surfaces operated in atmospheric conditions.

Appointment

Enamel XB-518 protective refers to enamels with special properties. It is intended for painting pre-primed surfaces made of steel, aluminum and its alloys. It is also used independently, without priming, for a short term, for wooden surfaces in special-purpose products. It is used for application on plastic, plastics (on EP-0010 putty).

APPLICATION:

Enamel is used to protect metal products exposed to the static effect of water and industrial oils, including cannon grease, in the atmospheric conditions of zones with cold, temperate and tropical climates. Enamel is applied in 2-3 layers on primers: GF-0119, GF-0163, GF-032, GF-031, GF-021, PF-0142, PF-020, PF-033, FL-03K, FL-03Zh, FL-086, V-KF-093, XV-050, XC-010, XC-068, XC-059, AK-070, AK-069, KF-030, VL-02 (with overlapping primer AK-070) or similar. The choice of the primer on which the enamel is applied depends on the surface to be painted and the climatic conditions of use of the coating.

PROPERTIES:

Enamel XB-518 is applied both to primed and non-primed surfaces by spraying or brushing. It is easy to use, it is produced with a low viscosity, therefore it does not require a large amount of solvent, it is easy to apply, it dries quickly enough under natural conditions, it is compatible with most paintwork materials. With initial viscosity, it can be applied with a brush; when applied by spraying, it is diluted with a solvent P-4A or P-4. The coating formed by the enamel is elastic, at the same time it has high strength and hardness, it is resistant in the atmosphere of various climatic zones, to the static effect of water, industrial oils (gun grease). You can buy hv-518 from us. After drying, the enamel XB-518 forms a flat, smooth surface without wrinkles, pockmarks and foreign inclusions, of a protective color (the color must be within the permissible deviations established by the control color samples).

Specifications XB-518

Nominal viscosity of KhV-518 according to the VZ-246 viscometer with a nozzle diameter of 4 mm at a temperature of (20.0 + 0.5) oC, s

Mass fraction of non-volatile substances,%

Drying time to degree 3 at a temperature of (20 + 2) оС, h, no more

Hiding power of the dried film, g / m2, no more

Flexural elasticity, mm, no more

Film strength upon impact on the U-1 device, cm, not less

Pendulum hardness of the film: TML, pendulum A, rel. units, not less

М-3, conv. units, not less

Adhesion, points, no more

Film resistance to static impact of water at a temperature of (20 + 2) oC, h, not less

Film resistance to the static effect of gun grease at a temperature of (20 + 2) оС, h, not less

at a temperature (60 + 5) оС, h, not less

Recommended paint schemes

steel - primer GF-0119, GF-0163, GF-032, GF-031, GF-021, PF-0142, PF-020, PF-033, FL-03K, FL-03Zh, FL-086, V-KF -093, XB-050, XC-010, XC-068, XC-059, AK-070, AK-069, KF-030, VL-02 (with overlapping primer AK-070) or similar, on a rusty surface "Unicor "Or rust converter - 1 layer + HV-518 enamel - 2-3 layers;

aluminum and its alloys - primer AK-070 (or VL-02 with overlapping AK-070) or similar, on a rusty surface "Unicor" or rust converter - 1 layer + HV-518 enamel - 2-3 layers.

Without priming: wooden surfaces, plastic (or with EP-0010 putty) - 2-3 layers of XB-518 enamel.

The enamel is stored in a tightly closed container, protected from moisture, heat and direct sunlight at temperatures from -40C to + 40C.

Enamel XB-785 is chemically resistant. Technical characteristics and recommendations for use

Before starting work, it is necessary to clean the surface to be treated from rust or other contaminants (the plane of the metals must have the same roughness and metallic luster). For this, shot blasting or sandblasting can be used.If it is impossible to use the above methods, the use of cord brushes is allowed. It should also be noted that the surface must be cleaned to the degree of degreasing in accordance with GOST 9.402-2004 (it is recommended to use white spirit). After that, you will need to prime the metal surfaces with soils of the following grades: XC-068, XC-010 and XC-059. After completing all the preparatory work, you can proceed directly to staining.

How to apply XB-785 enamel? The technical characteristics allow the following methods:

- roller;

- brush;

- pneumatic spraying;

- by airless method;

The paint and varnish material must be mixed well to obtain a homogeneous mass. In some cases, solvents will be required to obtain working viscosity (they can also be used to clean tools). A prerequisite is the elimination of moisture condensation. To do this, make sure that the temperature of the treated surface is at least 3 ° C above the dew point. The paint must be applied in layers. The first one dries up for about 1 hour (at an air temperature of the working zone + 20 ° C). The next layer is applied only if the previous one is completely dry.

This enamel can be used together with the XB-784 varnish.

Colors

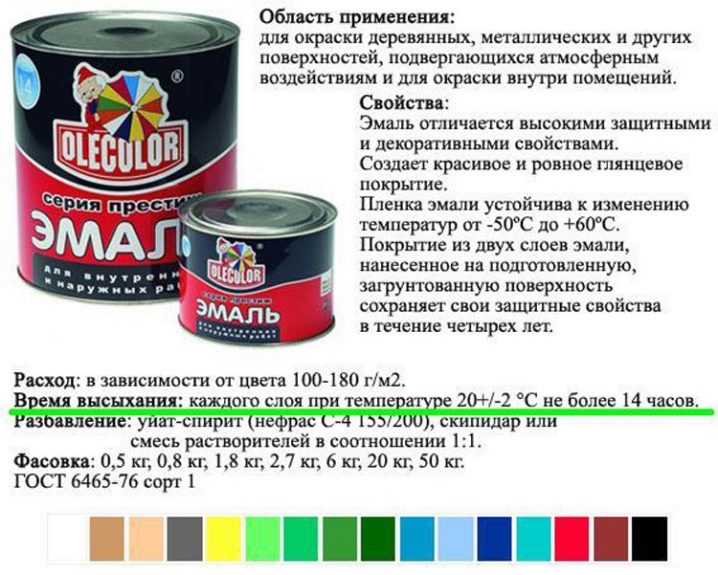

Store shelves are flooded with enamels of completely unpredictable colors in the struggle for consumer choice. Since childhood, we are all familiar mainly with white enamel for the bathroom, but we should not be limited to this. One shade or another is obtained by mixing different coloring metals.

Blue enamel can be obtained by adding cobalt oxide or copper to the composition. She is often covered with pipes or even walls in outbuildings outside the city.

For a summer cottage fence or shutters, green enamel is often used, created from a mixture of chromium or copper oxides, as well as nickel.

Pink enamel is also popular now - it is used in the interiors of art spaces or beauty salons, for painting a girl's bicycle. This delicate shade is obtained from a mixture of chromium and tin oxides.

The most popular enamel color is black. It is often used in the interiors of living quarters, even for the same plumbing. This color is formed from a mixture of nickel oxides in a combination of iron and manganese, sometimes with the addition of cobalt and chromium compounds.

Pearlescent VGT - know-how of recent years, designed to work with different surfaces such as wood molding, plaster or metal. In addition to the already colored decorative plaster or clear colorless wallpaper, mother-of-pearl enamel can also be applied.

It contains such elements as pearlescent pigment, water-based dispersion acrylic polymer and modifying additives. Thanks to this, it was possible to obtain unusual shades such as gold, bronze, pearl, garnet, silvery white and even the color "chameleon".

Mother-of-pearl VGT enamel is used not so much to protect the surface from an aggressive environment, but to give an even greater decorative effect, characteristic shine and interesting texture to the element of the design decoration of the room. Nevertheless, such a coating is used both for application to objects that are permanently indoors, and for objects that are outdoors for most of the year, having a high resistance to atmospheric changes and resistance to water and light.

If necessary, such enamel can be diluted with water as a solvent, but the proportion of water should not exceed 5%, otherwise the enamel will lose most of its protective properties.

Enamel ХВ-785

Enamel XB-785 characteristics and application:

Enamel is a suspension of pigments in a solution of resins, in a mixture of organic solvents with the addition of plasticizers and belongs to the group of chemically resistant paints and is indispensable for the renovation of any room. Advantages of paint: easy to apply to the surface and does not rub off for a long time. The coating is easy to clean.

Paint XB-785, possessing high protective properties from external chemical factors (water, detergent, various natural factors) retains its color for a long time, does not fade in the sun, unlike analogues. Acid-resistant enamel xv 785, applied to metal, will withstand dousing with hydrochloric or sulfuric acid.

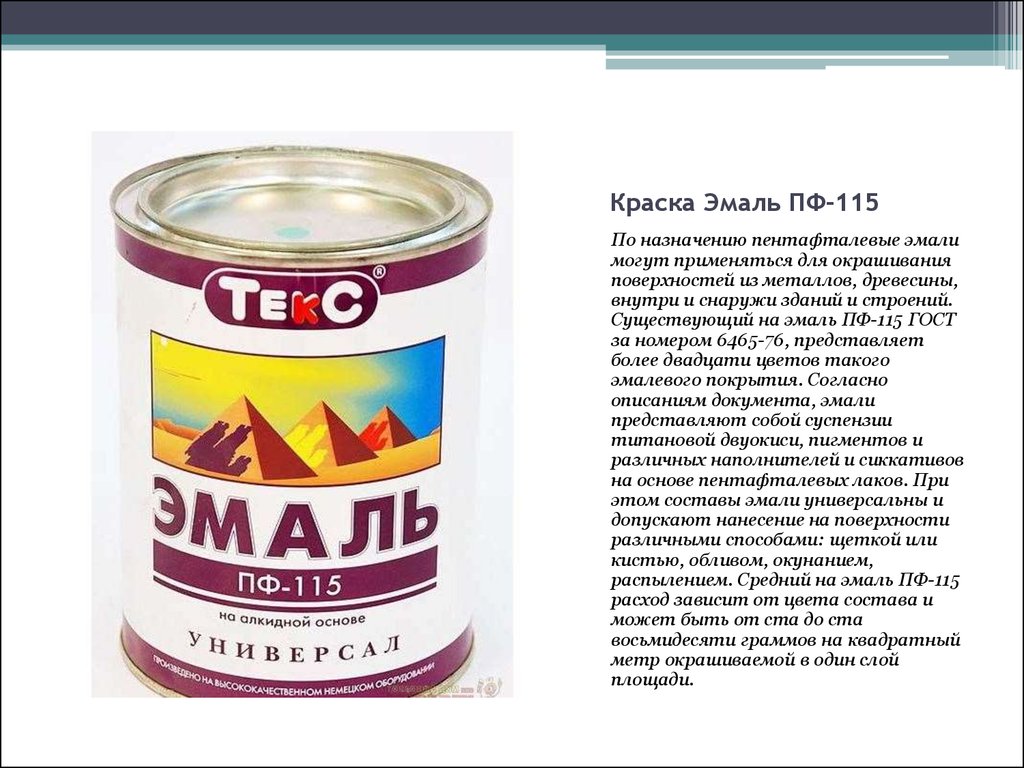

GOST 7313-75 regulates the production of paint in six colors: yellow, ivory, gray, red-brown, white and black.

Paint ХВ-785 (enamel ХВ-785) is intended for obtaining a durable coating of various types of surfaces. This type of enamel protects the surface from the effects of alkaline and acidic environments, as well as from other natural and chemical reagents. The enamel is applied to the primed surface. The enamel coating will withstand heating up to plus 60 ° C.

Paint XB-785 instructions for application:

Before using, the paint must be thoroughly mixed, inside the container, to the very bottom. If there is a film on the enamel surface, it must be removed. Enamel thinner to working viscosity is a special organic solvent depending on the surface to be painted. The enamel is applied to a clean and dry surface, pre-primed, for a longer service life of the applied enamel. The primer XB-785 can be used as a primer FL-03 K, GF-0119 or XC-059. The thickness of the two-layer coating is 35-45 microns.

The enamel is applied to the surface by spraying in 2-3 layers, reciprocating from top to bottom. The thickness of one layer is 18-23 microns.

After applying the enamel, it is worth waiting for it to dry completely, which is achieved a day after staining. When bending a soft material on which enamel has been applied (for example, fiberboard), it is necessary to take into account its fragility, the possibility of bending up to 1 mm. Thinner for ХВ-785 for diluting and washing equipment Р-4 and Р-4А.

XB-785 consumption depends on the color and is in the range of 80-120 g / m². Enamel hv 785 white has an average consumption of 90 g / sq. Maximum flow rate for yellow. Enamel xv 785 yellow 150 g / sq.

The recommended number of layers is 2-3 for a longer service life.

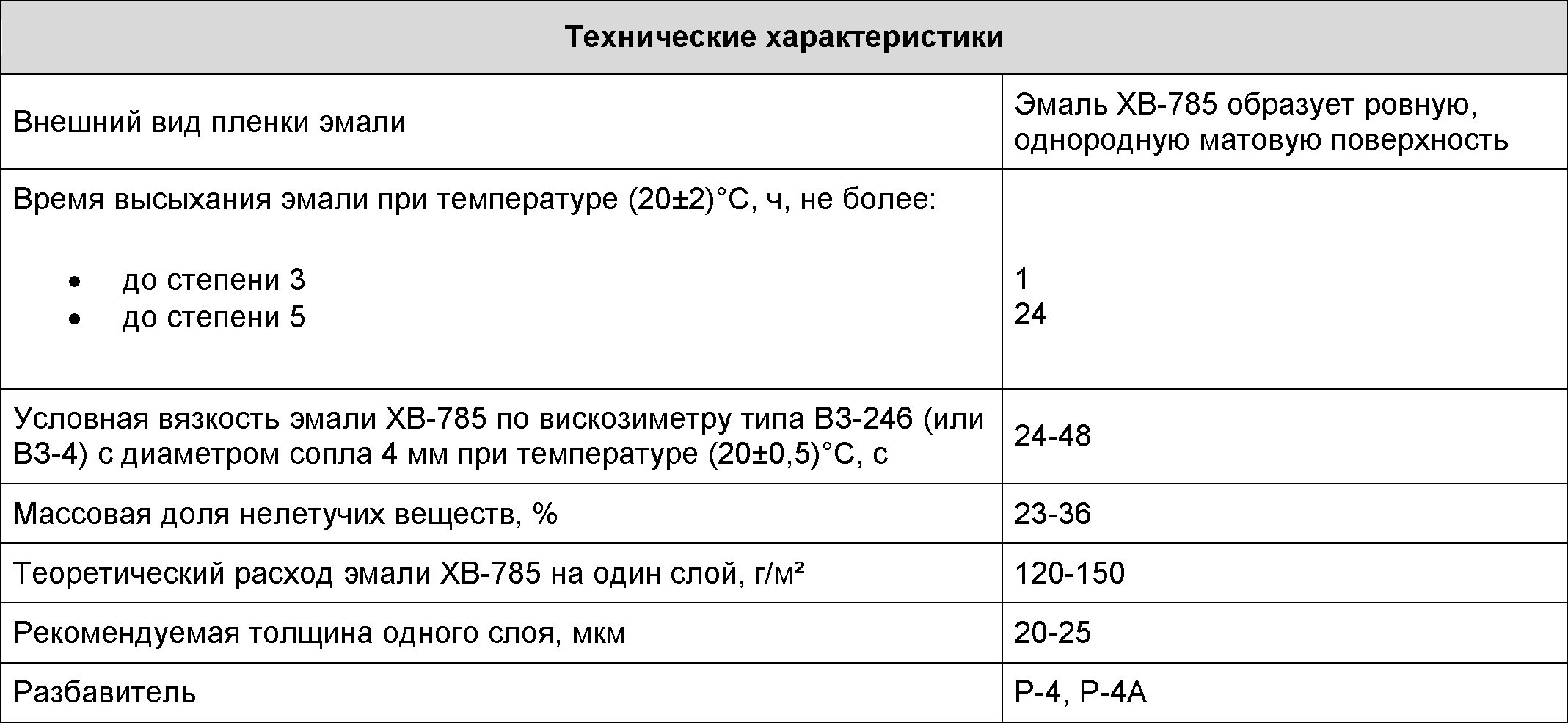

XB-785 specifications

The name of the indicators is indicated for xv 785 in the certificate of conformity. Requirements of GOST 7313-75:

1.The color of the enamel film must be within the tolerance limits established by the samples of the color reference card or approved color samples

2. The appearance of the film after drying, the film is homogeneous, even, without wrinkles, streaks and foreign inclusions

3. Nominal viscosity according to the viscometer type VZ-246 (or VZ-4) at a temperature of (20 ± 0.5) ° С for 30-60 s;

4. Mass fraction of non-volatile substances 26-40%

5. The degree of grinding is not more than 50 microns

6. Covering the dried film, no more than 150 g / m²;

7. Drying time at a temperature of (20 ± 2) ° С: up to degree 3 no more than 1 hour; before grade 5 no more than 24 hours;

8. Flexural elasticity of the film, no more than 1 mm;

9. Film hardness according to the pendulum device of the TML type (pendulum A), not less than 0.15 units;

10. Film adhesion, no more than 2 points;

11. Resistance of the coating to static action of acid and alkali: after the test, the coating should be unchanged and the metal underneath should be free from corrosion. Film color change is allowed.

Store in a dry, dark place. Do not expose to moisture, fire, direct sunlight. Keep out of the reach of children. Expiration date - 12 months from the date of production.

When buying HV paint in bulk, a discount is provided. Passport for xv 785 is a mandatory document issued upon shipment.

Wholesale price for XB-785 enamel is negotiable. You can buy enamel from 1 kg by contacting the sales department: (4852) 59-99-09 or by sending a request from the website.

Application

You can apply paint to a metal surface with a brush or roller, but it is preferable to work with a pneumatic device. Airless spraying is better suited for large areas to be treated. The electrical equipment provides a better design. For such a supply of paint, it must be diluted as much as possible with the solvent "RFG" or "R-4A".

The preparatory phase includes several main points:

- Thorough cleaning of metal from dirt, dust, oils, scale and rust is required. The indicator is the characteristic gloss of the surface, the evenly distributed roughness of the material, in places with scale the color of the base may be darker.

- After cleaning, completely dust and degrease the coating. To do this, wipe it with a rag dipped in white spirit.

- Check for greasy stains by wiping with special filter paper based on cellulose, fibrous substances and asbestos (it must not be left with traces of oil).

- It is permissible to use abrasive, sandblasting for cleaning. In this way, even the smallest particles of rust can be removed from the metal.

- In the presence of individual contaminants, they are removed and degreased locally.

- Then you should carry out the primer with the compositions "VL", "AK" or "FL". The surface should dry completely.

Immediately before painting, the solution is stirred until a homogeneous mass is formed and the first layer is applied to a dry primer. Initial drying lasts no more than 3 hours, after which the next layer can be applied.

The three-layer coating is mainly made for temperate climates, four layers are for the tropical zone. If it is necessary to protect the metal in cold conditions, it will be necessary to paint three layers of paint on the primer "AK-70" or "VL-02". The time interval between coats is at least 30 minutes.