APPLICATION

Surface preparation

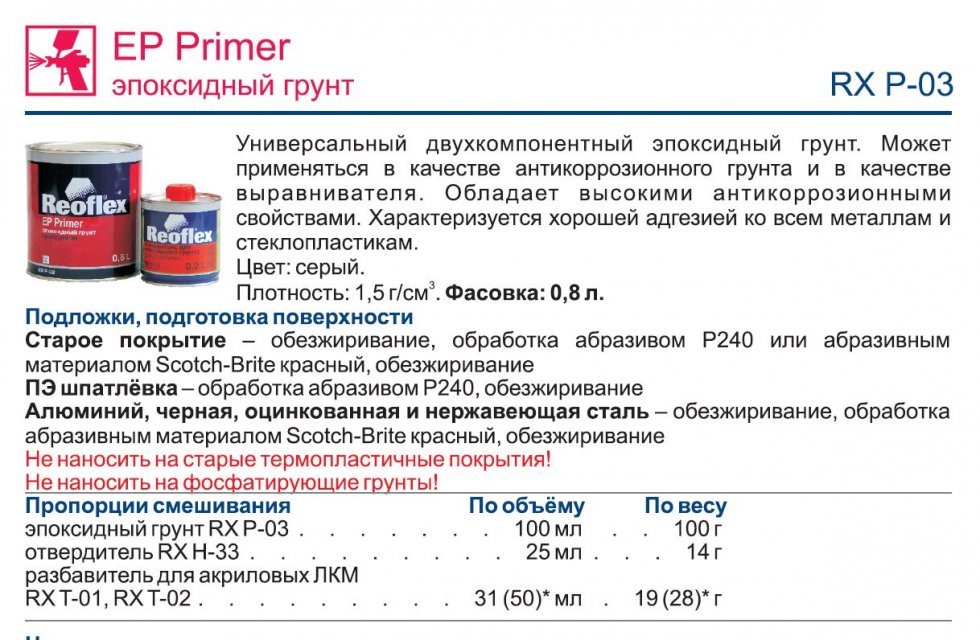

EP-140 is applied with a primed metal surface. Primers such as VL, AK, EP

Application methods

Pneumatic spraying, brush, bulk.

Application conditions

Before use, make sure that EP-140 enamel is well mixed and homogeneous throughout the container. To prepare the composition, mix the hardener with the base in the ratio specified in the quality document for each batch of material, and mix thoroughly for at least 10 minutes. The resulting mixture is kept for at least 30 minutes at the application temperature. The prepared enamel is applied to the surface of the metal to be protected by airless spray, brush or roller at an ambient temperature of 10 ° C to 30 ° C and relative humidity not higher than 80%. To prevent moisture condensation, the surface temperature must be at least 3 ° C above the dew point.

Dilution of the enamel prior to application is generally not required

After one layer has dried (6 hours at 20 ° C), subsequent layers of enamel are applied in the same way.

Precautionary measures

The material is flammable! Do not work near open sources of fire. Keep out of the reach of children

During and after painting work, the room should be thoroughly ventilated; rubber gloves should be used to protect hands.

This information is based on our laboratory test results and practical experience. As we update it and improve the materials, we reserve the right to change the above information without further notice.

Application of EP-1236

Epoxy enamel EP-1236 is widely used in machine building, shipbuilding, machine tool building and other industrial sectors, providing protection against corrosion of aluminum and steel surfaces of structures. This paint (EP-1236 enamel) is also used for painting sea containers.

Primers VL-023, EP-076, VL-02, EP-0199, EP-0263S can act as the previous layer.

Before painting with EP-1236 metal surface, you need:

- clean it to a shine from scale and rust

- the cleaned surface must be cleaned of dust and degreased with a cloth moistened with white spirit by wiping

- for better adhesion, it is advisable to prime the surface with EP-class primers (for example, EP-0199)

- the composition must be prepared by mixing the hardener with the base in the ratio shown in the material quality certificate, and mix well for 10 minutes to get a homogeneous mixture

- prepared EP-1236 enamel is applied to the metal surface with a roller, brush, or by spraying at an ambient temperature of 5 to 30 ºС.

If the need arises, the enamel can be diluted with solvents of the class R-5, R-4, R-5A, or toluene. After the initial coating has dried, another coat of paint is applied.

You can buy EP-1236 enamel, both at retail and wholesale, by contacting the feedback address.

This enamel is stored in a dry building, excluding direct sunlight exposure to the storage site. Enamel is a flammable material, therefore, paint should not be used near sources of fire.

Areas in which the use of this enamel is justified

Shipbuilding

The low cost of the material and good anti-corrosion characteristics allow the use of enamel for painting small boats, yachts, boats. This material is often used to cover the elements and assemblies of the engine room of ships. It can act as a protective coating applied to the outer surfaces of the ship's hull and its superstructures.EP-140 is also chosen as a protective and decorative coating for non-self-propelled craft and port equipment.

Aviation industry

This product is in great demand among aircraft manufacturers and private air clubs, where it is used to paint internal elements, propellers and other components.

Equipment and metal structures

In addition, EP-140 has proven itself well as a coating used in the manufacture of machine tools, tank equipment and agricultural machinery. Silver colored enamel is widely used for painting various pipelines, casings, and casings that are exposed to periodic or constant heating.

Railway transport

The EP-140 chemical-resistant enamel is often used to paint the outer surfaces of diesel locomotives, carriages and auxiliary equipment. A wide range of colors allows you to easily choose the desired color, and resistance to aggressive gases provides reliable protection of the metal from the effects of exhaust gases.

"AntikorKhim" and "AntikorBEP-M" - own development of specialists of JSC "PKF-SPEKTR"

At the end of the article, we would like to present you our own developments - the chemical-resistant enamel "AnticorChem" and a specialized protective coating for the inner surfaces of fuel tanks - "AnticorBEP-M".

AntikorChem is a modern universal coating based on modified epoxy resins that withstands prolonged exposure to acids and alkalis. The maximum service life is 15-20 years!

AntikorBEP-M is a specialized product used for anti-corrosion protection of metal surfaces of fuel tanks. Withstands temperatures up to 160 degrees. The service life of the coating is 12 years!

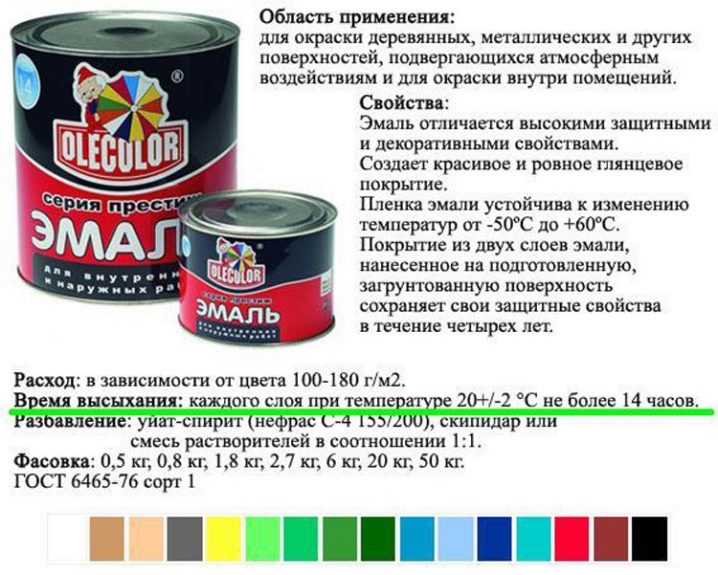

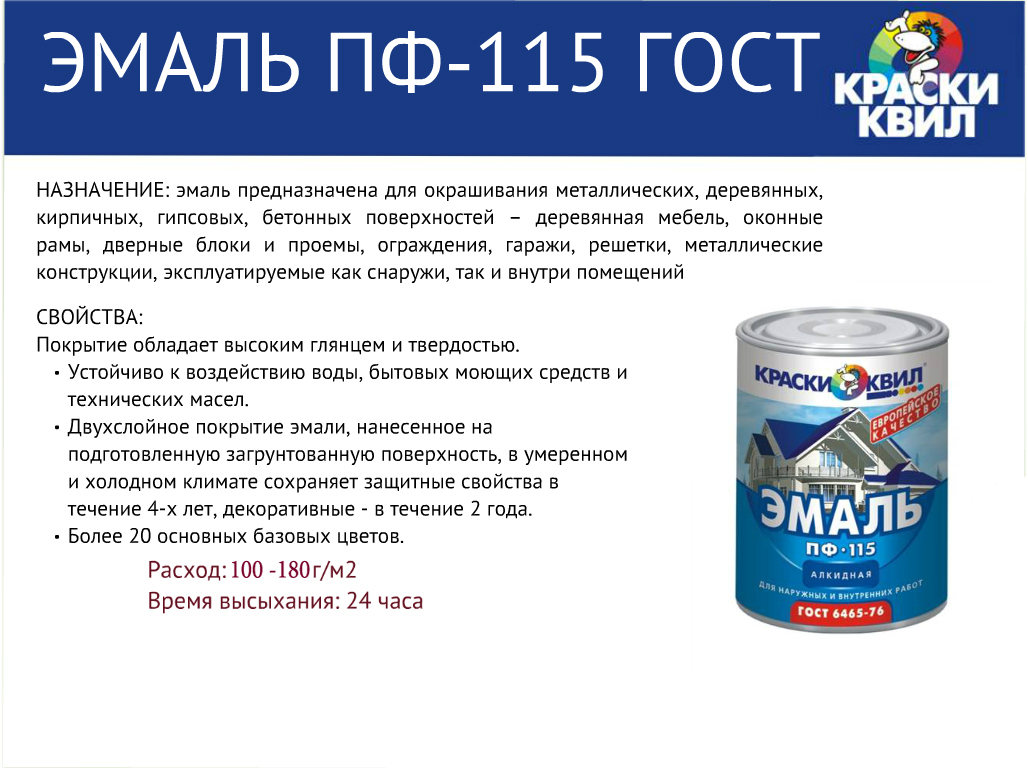

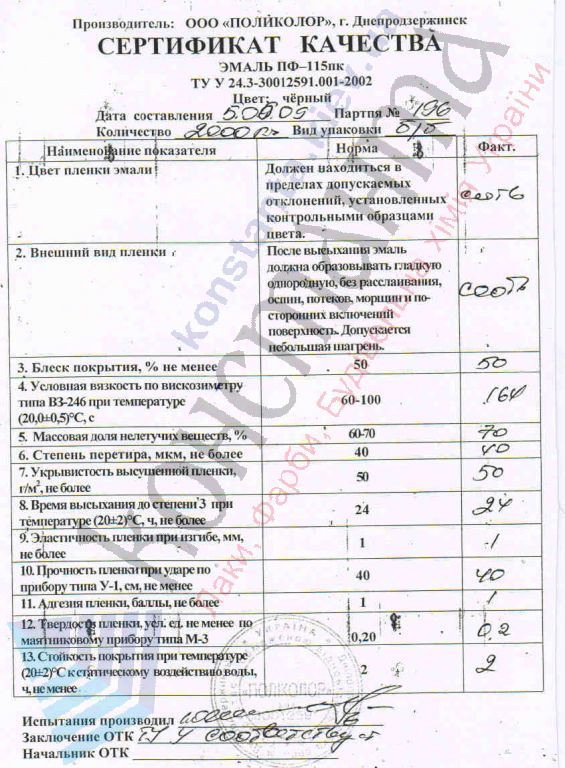

Popular brands of enamel PF-115

"Lacra"

Weatherproof alkyd enamel PF from the manufacturer "Lakra" is one of the most popular paints. You can choose a volume from 0.8 to 20 kg.

Good gloss, especially in greens, reds and blues. The yellow is a little dull. In general, saturation depends on the choice of hue and the number of layers applied.

The quality largely depends on the batch: if you painted part of the fence, and left the second part for the next season, it is not a fact that the new paint can will be of the same quality as the previous one (from the buyer's review).

The solution dries quickly, adheres well, and is very durable. Minus: pungent smell.

"Optimum" PF-115

Enamel dries faster than other solutions (maximum 7 hours). More suitable for covering decorative details inside the house. It paints well, one layer is enough (thick).

Reviews are different, someone thinks that the paint dries for a long time or is watery. This is possible if the operating conditions have been violated.

"Fazenda" PF-115

The paint will not fade, and the matte, pleasant shine will not disappear even after a year. The enamel is so strong that it is difficult to erase it even with a solvent.

The price for a jar is low, you can paint decorative surfaces both outside and inside the building (dries up in 8 hours). The paint spreads well through the pipes, no drips remain. The solution is not thick, so there is no need to dilute it.

The smell is pungent, but this is a minus of all paints and varnishes.

There is a waterproof paint PF-115 with the addition of antiseptic additives (BIO). This is a new class of coating, in which there is a protective antifungal, fungicidal, sporicidal, bactericidal agent. During storage, a film does not form on the surface.

You can paint walls, windows, doors, ceilings. The beige paint is popular in hospitals, schools, kindergartens and is suitable for painting concrete, metal and wood surfaces.

Service life - a year, drying speed - 24 hours.

Scope of application and technical characteristics

The scope of application of this type of paint and varnish material is wide. EP enamels cover surfaces of different materials:

- plastic;

- concrete;

- metal, copper, aluminum alloy;

As for the technical characteristics, they are spelled out in GOST 24709-81.Structures and any other surfaces coated with EP paints are resistant to the destructive effects of the environment. Before application, the surface must be prepared in advance. Clean off the old paint layer, degrease, remove dirt, dust, signs of corrosion, moisture. Before starting work, the paint must be thoroughly mixed. To have a uniform consistency and color. The color palette is very rich.

Note that the high degree of protection of EP paints prevents the constant processing of surfaces from different materials.

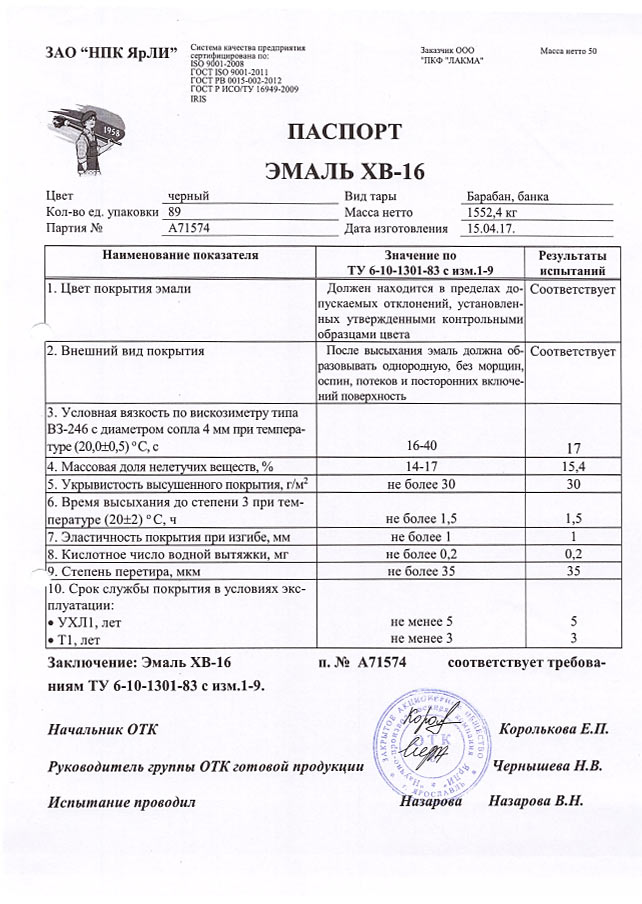

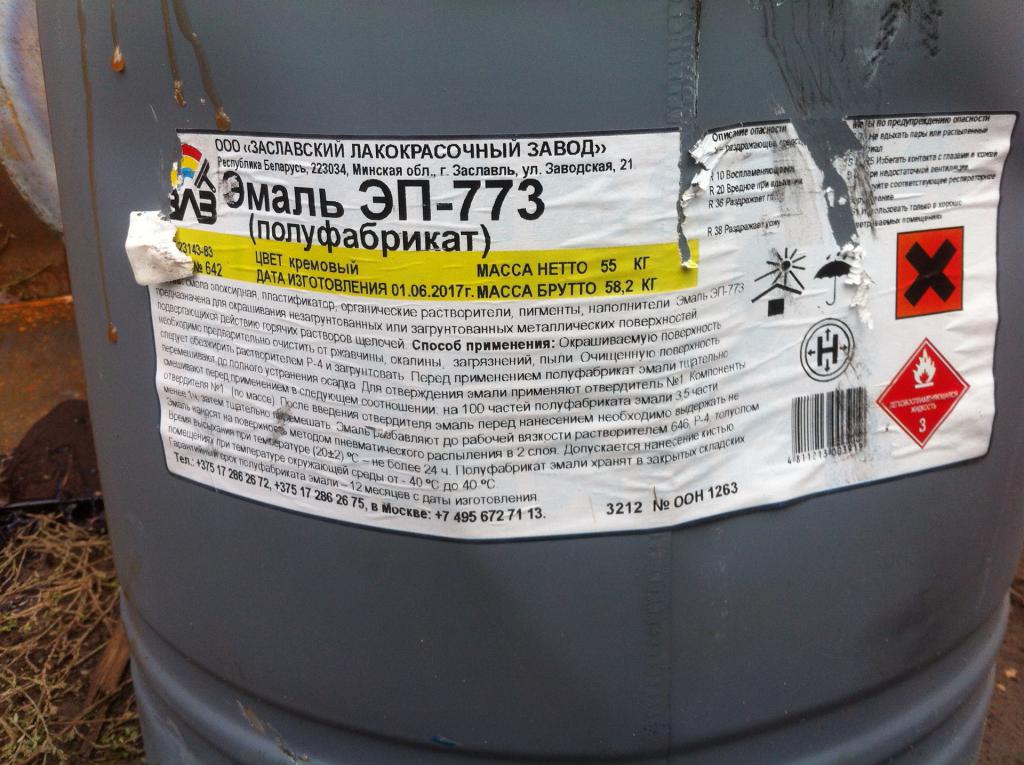

EP-773

This enamel protects the surface from the aggressive effects of an alkaline environment. Application requires compliance with all safety conditions. LKM EP-773 meets the requirements of GOST 23143-83.

It is used for painting metal structures indoors. You can dry the surface after painting in a cold or hot way. Two-component enamel. Therefore, it is not necessary to prime the surface in advance. The paint can be matte, glossy or semi-matt. Enamel consumption per square meter is 80-120 grams. The time of complete drying is a day at a temperature of + 20C. At a temperature of 120 ° C, the drying time is 2 hours. Thinner - solvent Р4, 646 or toluene

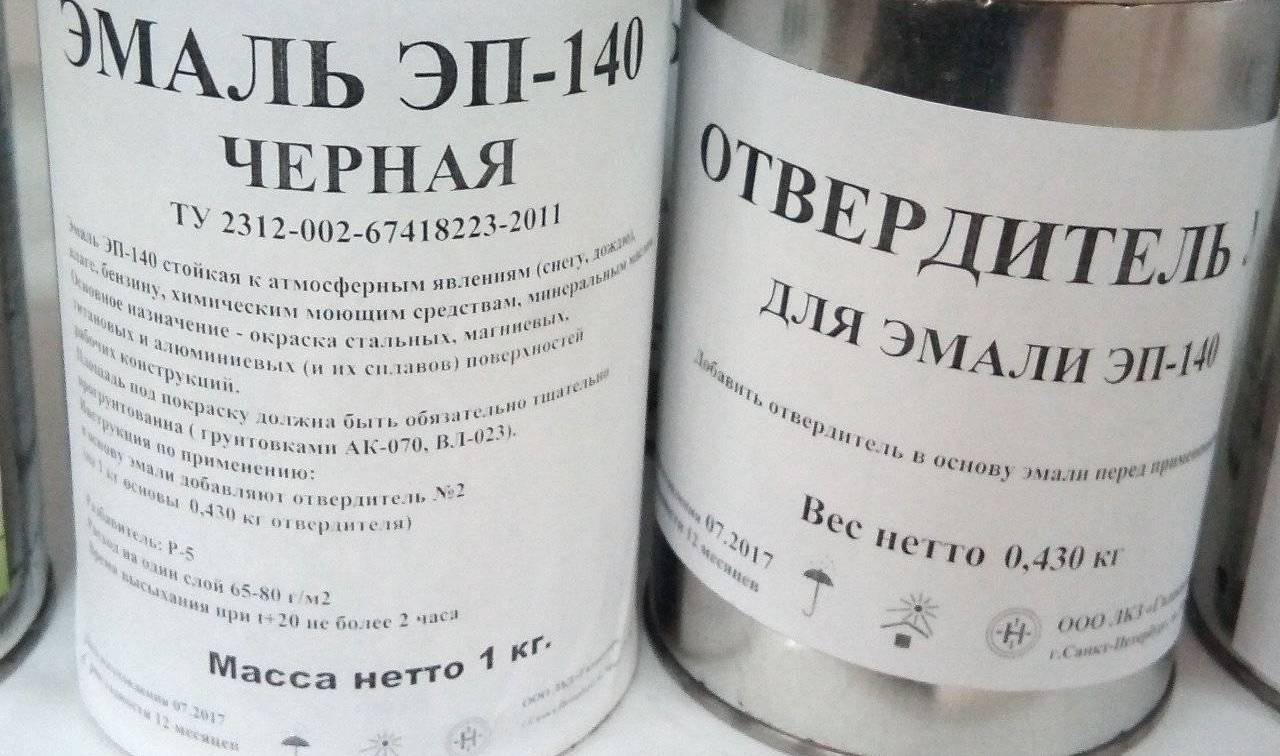

EP-140

Scope of application aircraft industry, railway transport, metal structures, shipbuilding. The composition contains various fillers, pigments. Hardener No. 2 is added during painting. It is sold together with paint. It is added to the enamel during the preparatory stage. The coated surface is protected from moisture, gasoline and oils.

This composition is used for indoor and outdoor work. Cover constructions in urban and rural areas. Thinner - solvent R-5 or a mixture of acetone, ethyl cellosolve and xylene. Drying time - 6 hours at 20C, 2 hours - at 90C. Consumption for one layer is 70-130 g / m2.

EP-1236

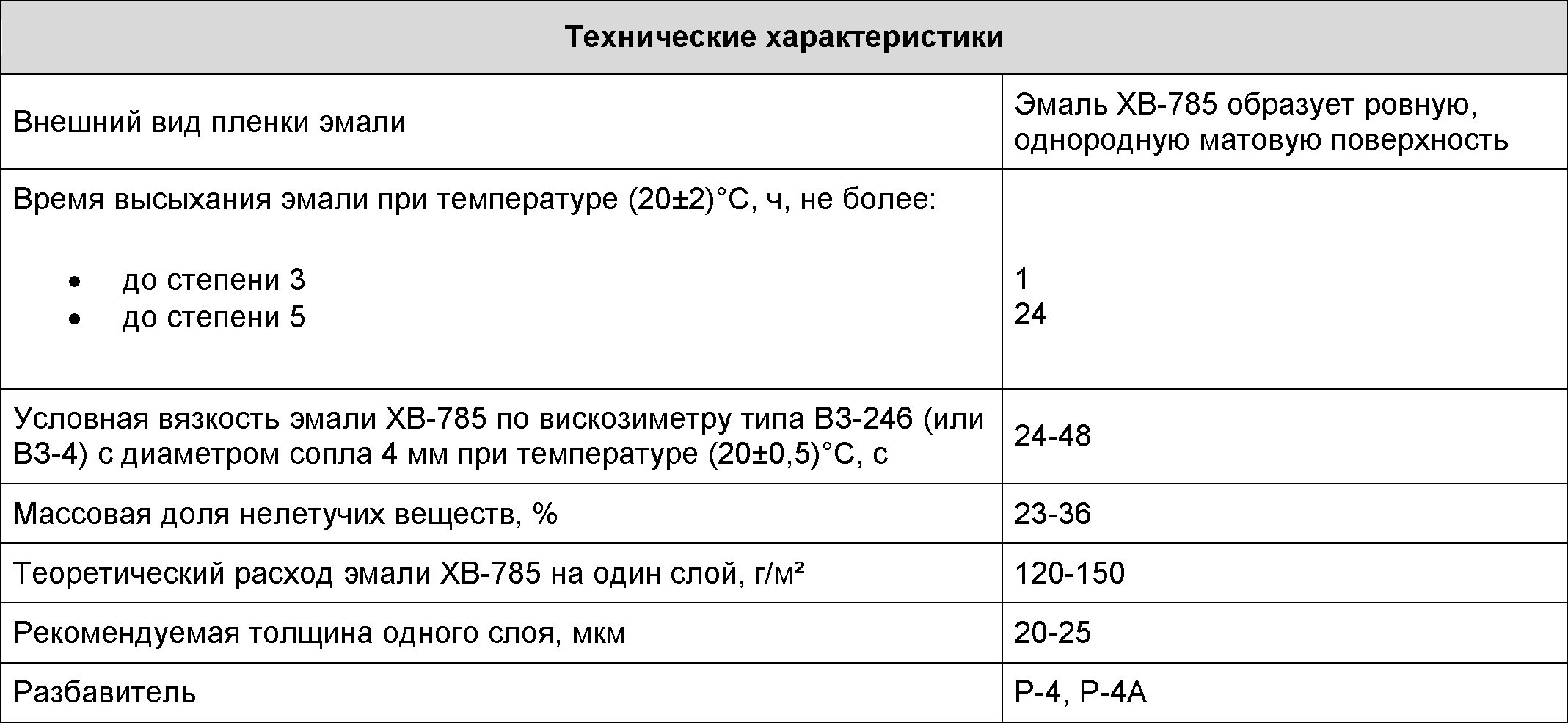

It is based on two epoxy and perchlorovinyl resins. Like all of the above paints, it protects the metal surface from corrosion. The film formed after drying is matte. The range of colors is varied. Some manufacturers are ready to produce at the request of the consumer.

The formed film retains its protective functions for up to six years of operation. It is recommended to apply 2-3 coats at a thickness of 40-50 microns. The mixture should be thoroughly mixed in a container until smooth. It is operated with R-4, R-5, R-5A solvent. Drying time - 3 hours at a temperature of 20C. Consumption for 1 layer - 20-400 g / m2.

EP-5116

Two-component suspension. It is considered universal. It is applied over the old paint layer. There is no need to prime it in advance. It is applied in two ways air and airless. Clean the tool with a solvent that does not include alcohol. The shelf life is six months, subject to the manufacturer's requirements.

Designed for corrosion protection in water and soil of steel structures, cooling towers, pipelines. Diluted with xylene or ethyl cellosolve.

Drying time: 1.5 hours at 80C.

Consumption per layer: 300-350 g / m².

Precautionary measures

When working with alkyd enamels, in particular with PF 115, the following precautions must be observed:

- You need to store the paint in an airtight package;

- Take measures to ensure fire safety;

- To carry out painting works in protective rubber gloves;

- Avoid breathing enamel fumes;

- After completing the work, ensure thorough ventilation of the room for 2-3 days.

Considering the above facts, we can conclude that the alkyd enamel PF-115, developed in the USSR back in the 70s of the twentieth century, has not yet lost its relevance. The ability to use when painting any surfaces, the high quality and appearance of the obtained protective and decorative coatings ensured the wide popularity of the paint among the ordinary consumer.

Video demonstration of the removal of PF-115 enamel using the "RIPAG" remover

In addition, the favorable price / quality ratio allows domestic alkyd enamels to successfully compete with leading foreign manufacturers.

Composition and properties

This enamel is used for painting surfaces and products from a wide variety of metals: steel, aluminum, titanium, copper, magnesium, as well as their alloys. Before applying the enamel, the surface must be thoroughly primed.

EP-140 has a complex composition. It consists of two components, which are sold and used as a complete set. Usually it is a semi-finished enamel and hardener.

This composition withstands the peculiarities of the climate of the tundra and taiga, it is also adapted to the hot and dry conditions of the steppes, deserts and semi-deserts. However, enamel works best in a temperate climatic zone. Coatings treated with EP-140 enamel can be used both at home and at work. Enamel is used for both external and internal finishing works.

The coating is durable, it is distinguished by high hardness and excellent moisture resistance. The treated coating is unaffected by oil and gasoline.

We should also highlight the silvery enamel: the surfaces treated with it are capable of withstanding temperatures up to 200-250 degrees. Also, paint is released for processing rough metal without prior priming. Surfaces painted with such enamel are resistant to aggressive chemical environments.

All EP-140 enamels have a long service life. They can be applied in a variety of ways. They have a high drying rate, do not change their properties when hot dried.

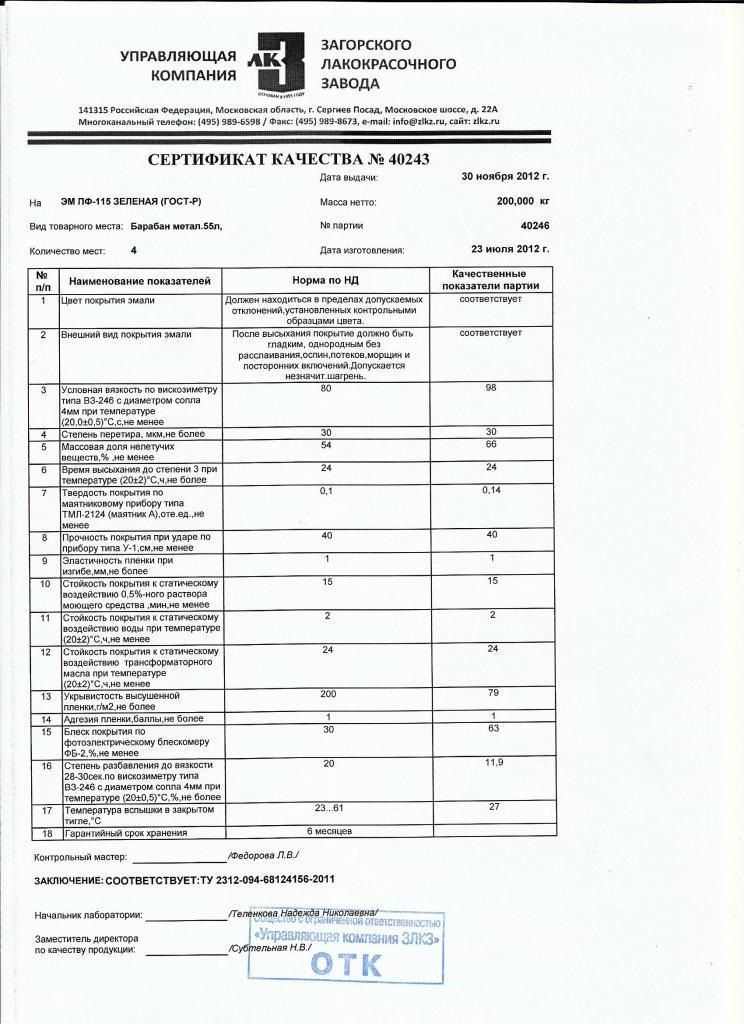

GOST

GOST is a state standard that regulates the correct manufacture of products that meet all requirements, norms and technical characteristics. In 1976, GOST 6465-76 was created for PF-115 by the Ministry of the Chemical Industry, which sets out all the conditions for production, transportation, storage, guarantees, and quality.

There are other GOSTs, which mention the name of the enamel:

- 9980.1 - the rules of acceptance work are spelled out;

- 9980.2 - the procedure is spelled out in accordance with which samples are taken for analysis;

- 9980.3 - the rules for packaging, labeling are spelled out;

Purpose and areas of application

Due to its high viscosity and excellent adhesion, the use of PF 115 paint is very wide.

The composition can be painted:

- wood;

- concrete;

- plaster;

- putty;

- brick;

- metal.

It is not suitable except for roofing work - with strong heating of sheets of slate or tin, cracks may appear and the color changes greatly.

Enamel is used mainly for external work for structures in the open air. It is used both as a monolayer coating and as part of multilayer ones, in combination with primers, anticorrosive and antiseptic impregnations, insulating layers. Enamel does not possess its own antiseptic and bactericidal properties, therefore, when processing wood and walls made of brick or concrete in humid conditions, such additives are necessary.

Enamel PF-115 possesses and very high decorative properties - according to GOST 6465-76 it is produced in 22 colors and shades. In recent decades, manufacturers have offered modernized paint, which is available in almost all RAL colors. In this case, the color number from the catalog is indicated on the paint cans or barrels. This is one of the few cases when it is preferable to buy a paint made not according to GOST rather than a standard one. But it must be taken into account that this type of enamel costs more than usual due to the use of expensive dyes.

The high elasticity of the film, which can be obtained by painting surfaces in two or more layers (a single-layer coating is used only when renewing a previously completed finish with the same paint, provided that there are no cracks and blisters on it) allows PF 115 to be used in completely different climatic conditions.The temperature range at which the finished coating retains its properties is incredible - 50 ... + 60 C. But the paint fully complies with the declared characteristics only if all technological rules for applying the coating layer are observed. We will tell you how to use enamel correctly further.

What does marking PF-115 mean?

Well-known to professional builders and owners of private houses, PF-115 enamel appeared on the market in the distant 60s of the last century. Until now, it remains one of the most practical paints for various types of repair and construction work. Such durability of the paint is due not only to the low price, but also to a number of unique consumer qualities.

The paint is produced practically unchanged from the day it first entered the market. Its composition is regulated by GOST 6465-76. If you want to use the classic PF 115, then buy paint made in accordance with GOST. Many manufacturers make changes to the chemical composition and produce paint according to TU. It is very difficult to guess whether its properties are improved or worsened; it can only be verified experimentally. But there is not always time to do this, and not everyone can afford to buy paint, albeit inexpensive, for experiments.

The name of PF 115 encodes the chemical composition and the main areas of application. The index is understandable to a specialist, but does not mean anything to an ordinary buyer. However, the information is very important.

The letter PF symbol means that pentaphthalic varnish (a type of alkyd resin) acts as a binder for the paint. The scope of application of pentaphthalic paints is exterior and interior work on a wide range of materials.

Numbers 115 show the scope of application:

- 1 - for outdoor work in various climatic conditions;

- 15 - the number of the chemical composition, determined by GOST and deciphered by the manufacturer.

According to its physical state, paint PF-115 is a suspension, a suspension of solid and liquid particles of various kinds in a liquid medium. The particles are represented by solvents, dyes, pigments, desiccants, titanium dioxide and other fillers. The base is a rather viscous pentaphthalic varnish, which dissolves white spirit or other organic liquids.

Physical state and chemical composition

The paint itself is viscous, with small solid particles.

PF-115 enamel differs in color, brightness, tone and density, which is created by pigments (colored powders), which are responsible for the formation of shades and give transparency to some materials.

Pentaphthalic varnish is composed of vegetable oils, resin, rosin and glycerin.

In addition to pentaphthalic material, various oils and a desiccant are added to the solvent - a substance that helps to dry faster on the surface.

An organic solvent (white spirit) is added precisely to oil solutions.

The transparent substance is extracted from oil, it has an oily consistency, it liquefies the paint if it is too thick and does not affect the composition itself.

The paint contains titanium white (titanium dioxide), a non-toxic substance that creates a white pigment in paintwork materials, holds the oil on the surface and scatters light.

Alkyd enamel differs not only in a variety of colors, but also in moisture resistance, well tolerates prolonged exposure to UV radiation, and does not crack after drying due to its strength and elasticity.

PF-115 is already selling a certain color, but you can change it if you add another paint to the solution. At the same time, the volume will increase.

The most common shades:

- Blue.

- White.

- Gray.

- Beige.

- Pink.

- Orange.

- Cherry.

- Citric.

- Terracotta.

- Khaki.

- Red.

- Salad.

- Ivory.

- Black.

- Blue.

- Turquoise.

After staining, plastic, bendable structural parts retain their original appearance - the enamel does not break off and does not wear off with frequent interaction.

Chemical composition of PF-115 paint

In the classic form, the composition of the PF 115 paint includes various components, in depending on color... Different types of enamel differ, both in the number of components and in their percentage. But the peculiarity of this paint is that, regardless of the composition, the basic performance properties remain unchanged.

The paint is produced in ready-made colors; you can change the shade only by mixing different modifications of PF 115 in a certain proportion. Moreover, by mixing a precisely dosed test amount of different paints and having obtained the desired color, it is possible to proportionally increase the volume of components and prepare the required supply of paint of the desired selected shade.

For example, consider the composition of the most common types of PF 115 paint, the technical characteristics of which are largely the same.

White:

1.pentaphthalic varnish - 28%;

2. titanium dioxide - 62%;

3. white spirit - 10%.

Blue:

1. varnish - 26%;

2. TiO2 - 60%;

3. zinc white - 6%;

4. azure - 4%;

5. solvent - 4%.

Gray:

1. Varnish - 20%;

2. TiO2 - 75%;

3. carbon black - 0.5%;

4. solvent - 4.5%.

The paint produced in accordance with GOST exactly corresponds to this chemical composition and the coating will have the qualities that are indicated in the paint passport.

Scope of application

Due to its protective properties under adverse weather conditions, fire resistance, moisture resistance, frost resistance and anticorrosive properties, the XB 124 enamel can be used in different areas of production:

- for repair and construction in the construction of private buildings, to maintain the strength of wooden facades;

- in the engineering industry;

- in instrument making for various purposes;

- for the processing of reinforced concrete, steel structures, bridges and production workshops;

- in the military industry to protect the surface of equipment and other objects from corrosion, sunlight, cold.

Enamel "XB 124" is extremely in demand in the construction of residential and industrial complexes in the Far North, where its frost-resistant qualities are highly appreciated, which make it possible to strengthen the outer walls in low temperatures.

Also, the paint is used for decorative painting of any metal structures. For wood, the dye can be used additionally as an antiseptic for the prevention of fungus and mold.

The official document on the quality of building material is GOST No. 10144-89. It sets out the main characteristics of the product, rules of application and maximum permissible ratios of components.

How to apply enamel "XB 124", see the next video.