Enamel properties

Wooden and metal products, which will be covered with a layer of XB-124 enamel, are reliably protected from the influence of unfavorable damaging factors. The product is especially suitable for wood - in this case, no additional application of a primer is required, it is enough to apply three coats of paint. This will make it possible to create a protective film on the surface for up to 6 years or more (if we are talking about operation in a temperate climate).

In cold (arctic) climates, surfaces must be primed using AK-070 primer, which contains aluminum particles. Three layers of enamel on top of such a primer allows the product to be used for up to 5 years. In tropical climates, preliminary priming is carried out with the FL-03K agent for 2 layers, then four layers of enamel are performed. This will help the products to serve for at least 3 years.

Positive properties of the paint that distinguish it favorably from analogues:

- high anti-corrosion qualities;

- preventing the spread of rust, if present, before applying the enamel;

- providing a beautiful appearance;

- ability to withstand temperature fluctuations;

- resistance to fire, moisture, detergents, household chemicals, oils, gasoline;

- elasticity;

- durability.

How to apply correctly?

The admissible relative humidity is 80%. If the mixture is applied to the originally primed surface, it retains its qualities for 5-6 years.

It is advisable to degrease before applying this brand of enamel with white spirit.

For priming the original surface, soils of the categories are used:

- XC-010;

- XC-059;

- XC-068.

Painting is done with rollers and brushes, if you are not limited to manual methods of work, you can use pneumatic and vacuum sprayers. Regardless of the method of use, paints and varnishes are thoroughly mixed until a homogeneous solution is obtained. Solvents are used to bring the mixture to a working viscosity; it is also permissible to clean contaminated tools and other surfaces with them.

Before starting work with perchlorovinyl enamel, it is required to find out what the surface temperature is. Normally, it should be at least 3 degrees higher than the dew point.

The manufacturer's instructions indicate that the composition must be applied in a minimum of a couple of layers, the thickness of each of them is from 60 to 100 microns. Storage of enamel should be carried out in a hermetically sealed container, away from open fire and heat. Direct sunlight and paint moistening are not allowed.

Long-term storage can lead to:

- increasing the viscosity of the composition;

- sediment formation;

- cleavage of complex dyes.

When this period passes, the manufacturer is automatically released from any responsibility for the consequences of its use and further storage. Standard packing is 25 and 50 kg, which allows using one package to cover an entire apartment or an overall wall.

It is recommended to apply the enamel in three or four coats. If a varnish of the same brand is used, it is applied in a maximum of two layers. The durability and beauty of the outer coating (subject to technological regulations) are guaranteed.

Enamel XB-785 is used in painting:

- industrial baths;

- large capacity tanks;

- facilities under construction;

- machines and mechanisms that transfer the action of water and steam;

- equipment and technology designed for high or low air temperatures;

- electroplating industrial equipment;

- other technological machines and mechanisms;

- vehicles.

When working with the XB-785, it is necessary to wear a respirator, have a loaded and tested fire extinguisher and a box of sand ready nearby.

According to the operating data, the enamel easily tolerates contact with hydrogen sulfide. Static exposure to a solution of sodium chloride (at a concentration of 3%) does not lead to a deterioration in the quality of the coating in 48 hours; for mineral oil this figure is 72 hours.

You will learn how to enamel a bath in the following video.

Features of the use of paint enamel XB-124

Most often, this remedy used for processing metal and wooden structures. Therefore, it is in great demand in the fields of industry, industry, instrument making, automobile production and others.

It is used for food freezers, gas and electric stoves, household technicians, chimney and piping systems. It is also applicable at home; it can be used to process various metal objects that require protection from corrosive damage. Private houses made of wood, treated with this paint, become more resistant to various weather conditions, receive protection from mold, fungi and dampness.

Private houses made of wood, treated with this paint, become more resistant to various weather conditions.

Private houses made of wood, treated with this paint, become more resistant to various weather conditions.

Subtleties of application

Work begins with the stage of surface cleaning. Traces of corrosion are removed from the metal, dust is wiped off. The formation of fungi, mold, moss, dirt, etc. is eliminated from wooden products. Dispose of, if necessary from greasy and oil stains using white-spirit, or another solvent. Rust is removed mechanically. Before proceeding to the next stage, the surface must be thoroughly cleaned.

Further it is recommended to carry out priming work. Cover the entire surface with a primer. Wait until the primer is completely dry before proceeding to painting.

Work begins with the stage of surface cleaning.

Work begins with the stage of surface cleaning.

First, the solution is brought to the desired density with the help of a special solvent, after which you can proceed directly to applying the enamel, for this you can choose one of the tools: brush, roller, spray gun. If several layers are applied, then the subsequent ones can be applied only after the previous one has dried, you should wait at least 60 minutes.

When working, do not forget about the precautions, the observance of which will prevent the occurrence of health problems:

- When carrying out work inside the building, it is necessary to provide air access, organize a ventilation system;

- Do not work close to heating devices, open fire and sparking objects (the material is flammable);

- Be sure to wear a protective suit and gloves to protect your skin from direct contact with paint;

- It is also necessary to protect the organs of vision, the ingress of funds may lead to its violation;

- To prevent toxic elements from entering the respiratory system, use a respirator and gas mask;

- When buying, it is worth checking the presence of a certificate of conformity, because it must be manufactured, according to GOST, only certified products can meet all properties, the use of a fake can lead to unpredictable consequences.

Be sure to wear a protective suit and gloves to protect your skin from direct contact with the paint.

Product consumption per square meter

To reduce consumption and increase the service life of the coating, it is necessary to monitor the temperature indicators and air humidity when performing painting work. Consumption directly depends on the density of the mixture and the number of layers applied. Provided that the rules for using enamel prescribed on the packaging are observed, it will be consumed approximately 120-170 grams per square meter. (when applied with a brush or roller). When using a spray gun, XB-124 will be consumed in smaller quantities - 110-130 grams per square meter.

The cost of this enamel is quite low. With a small expense and a low price, this is a very budgetary tool, this is due to its choice both for domestic needs and in industrial institutions.

Consumption directly depends on the density of the mixture and the number of layers applied.

Consumption directly depends on the density of the mixture and the number of layers applied.

Enamel ХВ-124

Enamel ХВ-124 has high protective properties, shows resistance to gasoline, detergents and low temperatures.

Before applying the enamel to the surface, it is necessary to prime it with AK, FL, VL materials.

If there is a need to dilute the enamel, then you can use the R-4A solvent.

- applied by brush, airless and pneumatic spraying, electrostatic spraying

- in the case of application by electrostatic spraying, a special substance is used for dilution

- the material can be either protective or gray

Enamel XB-124 is applied to wood and metal surfaces. Before applying, the surface must be well cleaned of dust and dirt, and the enamel must be mixed.

GOSTU

GOST 10144-89

TYPE OF

One-packing material based on polyvinyl chloride and alkyd resins.

RECOMMENDED USE

For painting primed metal surfaces, as well as wooden surfaces, used in atmospheric conditions.

DESCRIPTION

A coating consisting of three layers of XB-124 enamel applied to a primed surface should retain protective properties in a temperate climate for 6 years. A coating consisting of four layers of XB-124 enamel applied on a phosphated and primed surface FL-03K surface must retain protective properties in tropical climates for 3 years. A coating consisting of three layers of XV-124 enamel applied to a surface primed with AK-070 primer or VL-02 primer with aluminum properties in cold climates for 4 years. The film of XB-124 enamel is resistant to detergents, industrial oil, gasoline, low ambient temperatures.

CERTIFICATION

Hygienic conclusion of the Office of the Federal Service of Rospotrebnadzor in St. Petersburg, valid throughout Russia.

SPECIFICATIONS

1) the practical consumption depends on the layer thickness, application method and conditions, surface roughness and shape of the product 2) the thickness of one layer on the vertical surface depends on the degree of dilution of the material, temperature, application method, surface roughness and shape of the product Color - protective, gray; at the request of the customer can be produced in other colors; Drying time at a temperature of (20 + 2) 0С: up to degree 3 - no more than 2 hours; up to degree 5 - no more than 24 hours;The proportion of non-volatile substances: by mass - 27 ÷ 33%; by volume - 15 ÷ 19%. Theoretical consumption per layer - 115 ÷ 145 g / m2; 9.3 ÷ 7.3 m2 / l; Recommended thickness of one layer - 18 ÷ 23 microns; Recommended number of coats - 2 ÷ 4

MIX RATIO

DILUENT

Thinner R-4A. When applied by electrostatic spraying, the enamel is diluted to working viscosity with a special thinner.

CLEANING TOOLS

Solvents: R-4A, R-4, a mixture of acetone and toluene

CONDITIONS OF VALIDITY

WARRANTY PERIOD OF STORAGE

In its unopened original packaging: 12 months from the date of production.

SURFACE PREPARATION

Preliminary priming with materials such as AK, FL, VL.

APPLICATION METHODS

Pneumatic, airless spray, electrostatic spray application possible, and brushing of selected areas.

CONDITIONS OF APPLICATION

Before use, it is necessary to make sure that the enamel is well mixed and homogeneous throughout the container.pneumatic or airless spraying at an ambient temperature from minus 100C to 300C and a relative humidity of not more than 80%. After drying the enamel layer (2 hours at a temperature of 200C), apply subsequent layers. When applied by electrostatic spraying, the enamel is diluted to working viscosity with Thinner 1 or 2 in accordance with GOST 10144-89.

PRECAUTIONARY MEASURES

The material is flammable! Do not work near open sources of fire. Perform work with good ventilation, wearing rubber gloves, using personal protective equipment

Avoid inhalation and digestion. If the material comes into contact with the skin, wash it with warm water and soap. Store the enamel indoors in a tightly closed container, excluding direct sunlight and moisture at temperatures from minus 300C to plus 300C.

Properties and application of HV-785 enamel

Enamel XB-785 is an anti-corrosion agent that can be used to cover various surfaces to protect them from negative environmental factors. The properties of the paint are such that the protective layer created by it prolongs the service life of the products, therefore the enamel is used in everyday life and in industry.

The composition and purpose of the enamel

Enamel ХВ-785 - varnish (paint and varnish material), which contains chlorinated polyvinyl chloride resin, the base of the product. The composition contains organic solvents, plasticizers, and other fillers. The composition also includes various pigments - for example, black paint is made with the addition of pencil graphite. The enamel is produced by PKF Spectr, created in accordance with GOST 7313-75, has all the necessary state certificates and certificates.

The product creates a beautiful and durable coating, and its applications are varied:

- building construction;

- technological baths, tanks;

- equipment for electroplating shops;

- containers for chemical solutions;

- equipment in contact with water, steam, air with high or low temperatures;

- Automotive industry;

- production equipment.

Enamel has a number of positive properties:

- profitability, low price;

- resistance to wear and stress;

- durability.

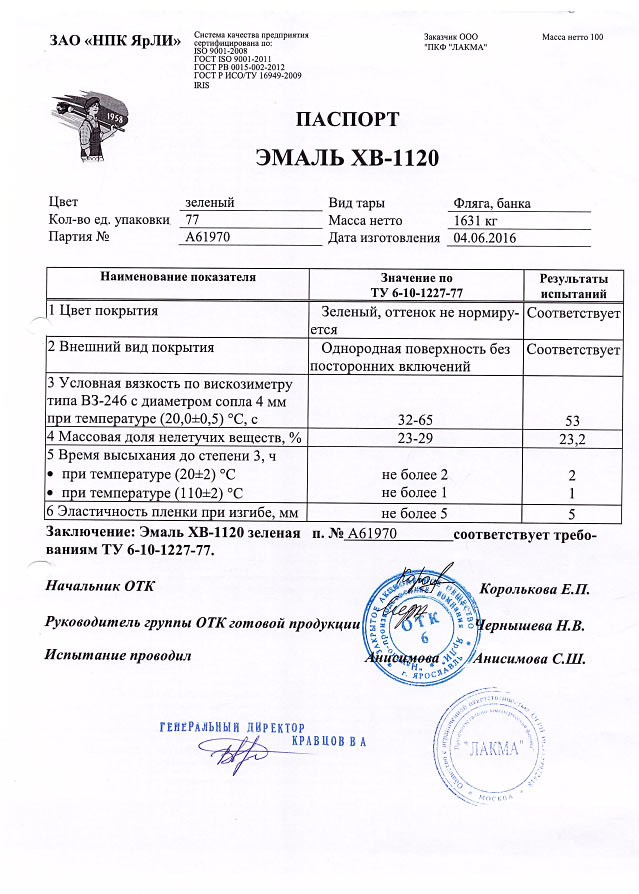

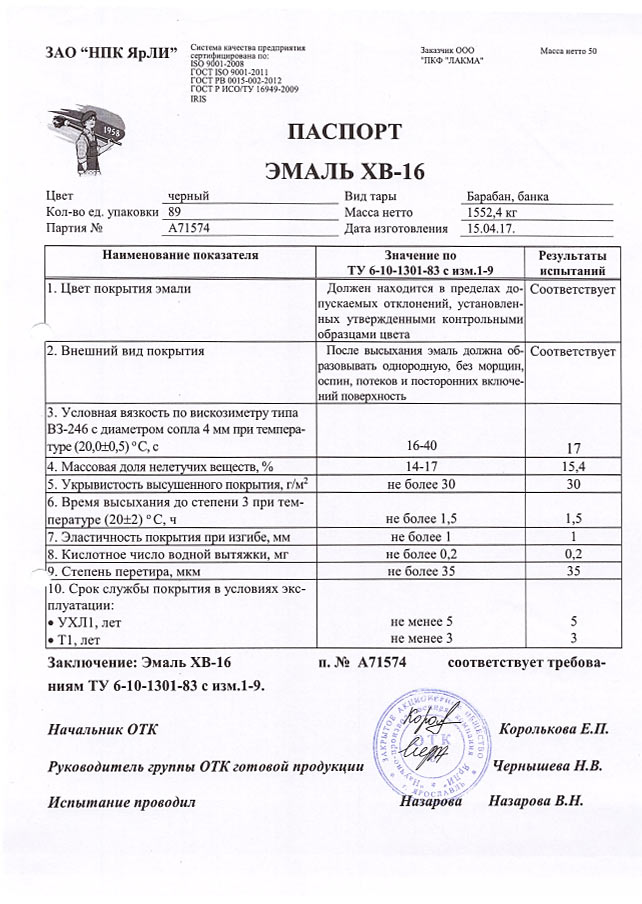

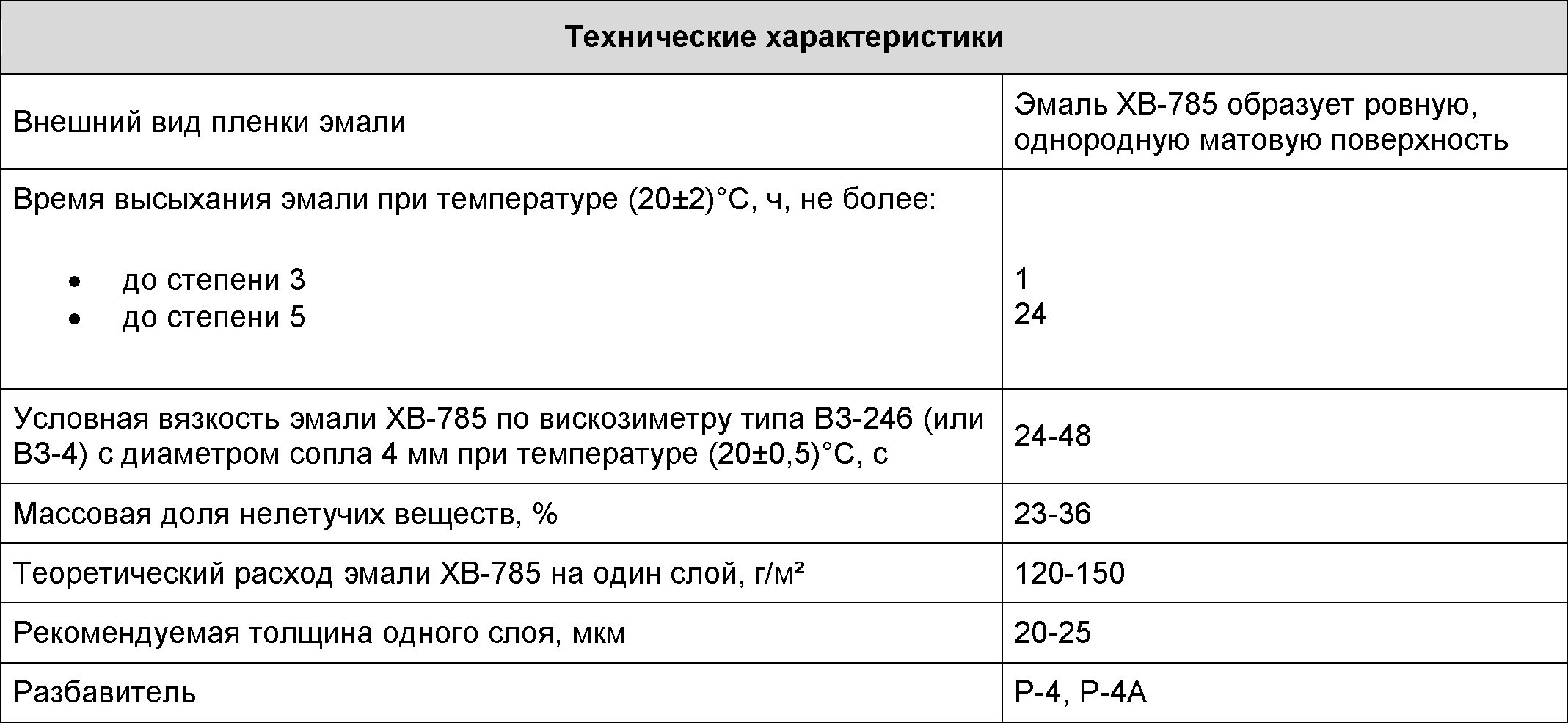

Specifications

The relative viscosity of the paint is measured with a B3-246 viscometer and is 24-48 s. Technical characteristics of the tool:

- the share of non-volatile compounds - up to 36%;

- adhesion - 2 points;

- coating elasticity - 1 mm;

- layer hardness - 0.15 (coefficient).

Colors

The product is available in different colors - beige, gray, black, white, red-brown, yellow shades are presented on the market.

You can choose the color of the enamel depending on the requirements and desires, but you should take into account the peculiarities. So, the darkest paints are used for use in aggressive and outdoor conditions, the lighter ones are used for indoor use of products.

Storage conditions

The paint is stored only with a tightly sealed lid, away from sources of fire, heat, in a dry, dark place. Storage temperature - from plus 30 to minus 30.

Consumption

Observing all the conditions for applying the product, the rate of its consumption per 1 m2 will be 125 - 150 grams. This figure is indicated for one layer of paint with an air humidity of up to 80% during application. The required layer thickness is 60 - 100 microns.

Drying time

At a temperature of 20 degrees Celsius, the paint will dry in an hour (up to degree 3), complete drying (degree 5) will occur in a day.

Features of applying enamel

To dilute the enamel, you can use the solvents declared in the instructions - P4, P4A. Before painting, a comprehensive surface cleaning should be done - remove dirt, dust, clean rust, degrease with White Spirit. It is permissible to use sandblasting machines or cord brushes. Further, the surfaces must be primed 1 - 2 times, depending on the degree of wear (use primers XC-068, 010, 059).

Painting is done with a brush, spray, roller.Pre-enamel is thoroughly kneaded. The ingress of moisture should be excluded, work is carried out only in a dry room or above the dew point. Layers are applied every hour, usually 2-3 coats are enough.

Safety requirements

The paint is highly flammable, contains toxic compounds (lead and others), so it is important to be careful when working. The room must be ventilated and the worker must wear a suit and respirator. To avoid a fire, have sand, fire extinguishers nearby

In a domestic environment, you should not neglect such rules - then harm to the body and dangerous consequences will not happen

To avoid a fire, you should have sand and fire extinguishers nearby. In a domestic environment, you should not neglect such rules - then harm to the body and dangerous consequences will not happen.

Application and recommended paint schemes

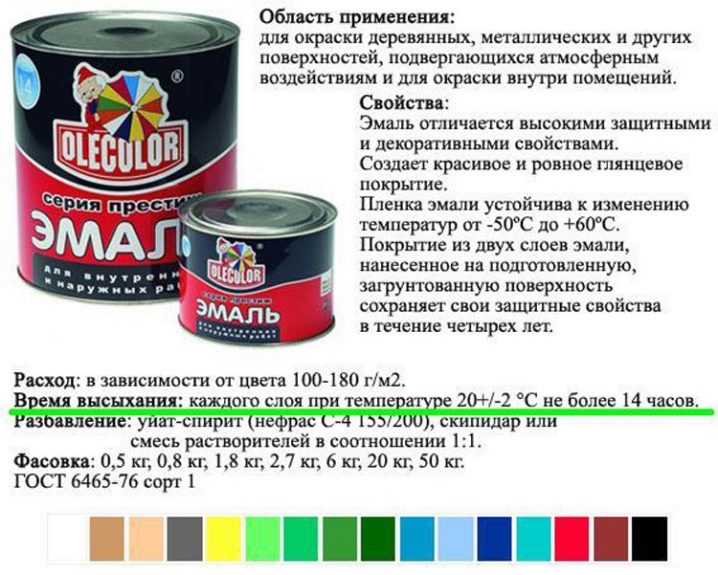

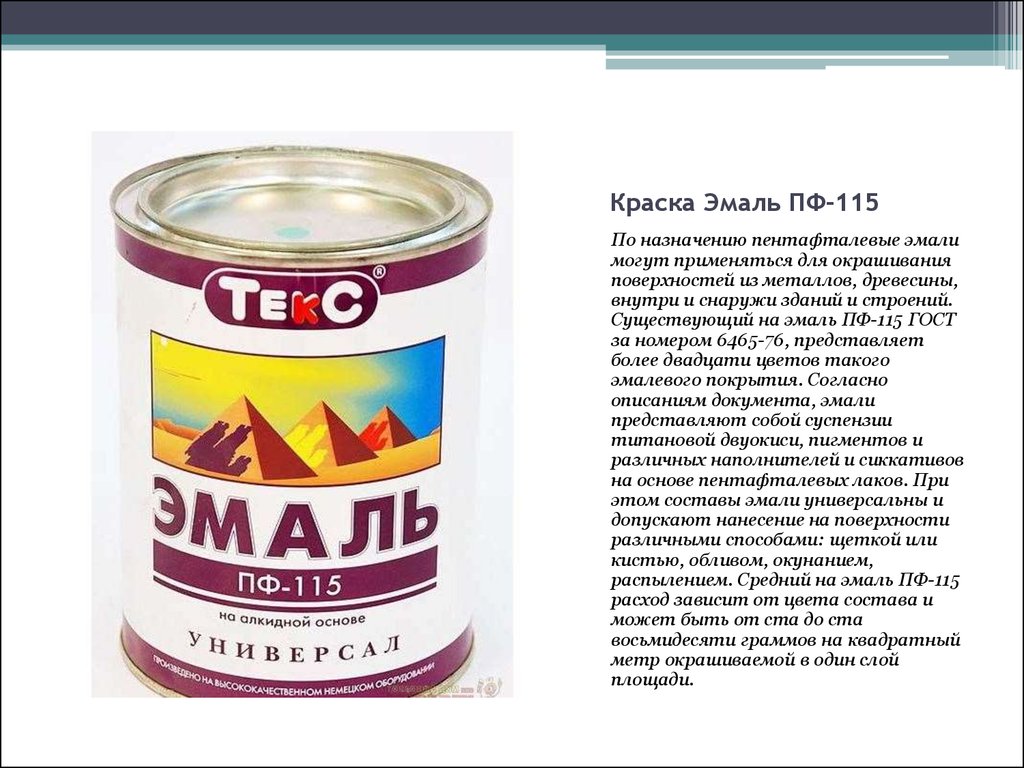

Waterproof alkyd enamel PF 115 can be applied with any type of painting tool - brush, roller, spray

When calculating the amount of paint required, it is imperative to take into account the peculiarity of the surface to be painted and the color of the paint.

Concrete, brick, unpolished wood absorb paint quite intensively and its consumption will be higher than when covering planed wood, metal or previously painted surfaces.

Selection of the amount of paint by color

Depending on the color, the consumption of a standard paint is quite large. At room temperature, to paint 1 m2 of the same type of unprimed surface, you will need:

0.1-0.14 kg - white paints

0.05 - 0.06 kg - black paints

0.07 - 0.1kg - blue paints

0.07 - 0.08 kg - brown paint

0.1 - 0.2 kg - red colors

The calculation is given for a single coat. When determining the real, the number of layers is multiplied by the given figures and again multiplied by a factor of 0.9 - for each subsequent layer there is less paint than the first. The second coat can be applied no earlier than 24 hours after the completion of the previous coat.

Only ideally dry surfaces are painted, heated to a temperature of at least +5 C. It is optimal to carry out painting work using PF 115 in dry, windless weather at an outside air temperature in the range of +15 ... + 22 C. In this case, the paint will maintain optimal viscosity, solvent - do not evaporate too quickly from the surface, and the risk of sagging is minimized.

The method of application also affects the paint consumption. When using a roller, it will be larger than a brush, and a spray may lead to some overrun. Also, the average consumption directly depends on the quality of surface preparation for painting and compliance with standard paint application schemes.

Painting schemes with enamel PF-115

1. Coloring of metal.

Metals of all types are painted with enamel only after priming with compositions GF 0119, VL 05, GF 021 or their analogues compatible with pentaphthalic paints. In the index of primers, the number 0 must be first. If there are no primers, and the surfaces are not very critical, then for the primer you can use the PF 115 enamel itself, diluted with white spirit to 50% of the original density.

Surfaces bearing traces of corrosion are treated with Unicor rust inhibitors (converters) before priming. These compounds are applied after mechanical cleaning of metal from rust and grease. They transform the products of corrosion into strong and tight joints, which do not differ in hardness from the solid metal. Metals are painted with PF 115 enamel in two layers.

2. Coloring the tree.

On wood, the enamel is applied without a primer in 2 - 3 layers. If necessary (recommended), treat the wood surface with fire retardants, antiseptics and fungicides compatible with pentaphthalic paints.Manufacturers of paintwork materials offer a wide selection of such compositions, but when using them, you must carefully study the instructions - some of them are designed for acrylic paints, some act as an independent coating.

3. Plaster, concrete, brick.

These materials are painted with enamel in 2 - 3 layers without a primer. But it is advisable to use anti-mold preparations - the enamel forms a dense surface with low vapor permeability and residual moisture can cause favorable conditions for the development of mold and mildew in the bulk of the material if pest spores remain there.

When painting any of the materials, the surface must be thoroughly cleaned of dust and dried. Residual moisture should not exceed 10 - 15%. Fresh concrete walls and foundations, as well as brick structures, can be painted no earlier than six months after the end of the installation. The interval between applying the next coat of paint is at least one day.

In most cases, the paint is sold ready-to-use in its original container. But after opening the can, the solvent begins to evaporate intensively and the density of the enamel increases. To bring the paint to a working consistency, white spirit or solvent is used, as well as their mixtures. It is not recommended to use gasoline and kerosene - although they dissolve the enamel, they significantly change its shade and shine.

When preparing the paint for work, it must be thoroughly mixed by adding the solvent in small portions. In the process of work, the paint also needs to be mixed periodically.

Storage conditions

The enamel is flammable. When storing indoors, all conditions must be ensured. One of the first and most important conditions is the absence of exposure to direct sunlight. The paint can should be tightly closed.

A source of fire, heat should not be located nearby. The storage area should be dark and cool. The air temperature in the room should not be lower than - 30 degrees, but also not higher than +30 degrees. According to the manufacturer, the shelf life from the date of manufacture is one year. Not completely used paint can be stored for no more than six months. Long-term storage increases the viscosity of the enamel.

Application area

LKM is designed to protect concrete, reinforced concrete, brick, asbestos-cement and other mineral surfaces. Black and red-brown varnish is used as part of a complex coating, which is selected individually for each type of aggressive environment in accordance with the normative documentation for painting. XB-784 is used in multi-layer compositions that are applied to both previously primed and unprepared surfaces.

A distinctive feature of PVC coatings is their high resistance to mechanical stress. In addition, they are excellently resistant to atmospheric phenomena. They can be operated from -30 to +40 ° C. Perchlorovinyl coverings:

- are resistant to ultraviolet light;

- without loss of characteristics withstand prolonged exposure to water;

- have high wear resistance.

Important! Vinyl-coated surfaces can be cleaned with synthetic detergents. XB-784 is used together with XB-785 enamel

At the same time, the protection of such a coating from acids, alkalis, salts, harmful corrosive gases, such as CO2 and SO2, will be guaranteed. Working temperature +60 ° C

XB-784 is used together with XB-785 enamel. At the same time, the protection of such a coating from acids, alkalis, salts, harmful corrosive gases, such as CO2 and SO2, will be guaranteed. Working temperature +60 ° C.

Acids that can compromise the integrity of the coating:

- sulfuric;

- salt;

- phosphoric.

Another purpose of the varnish XB-784 is toning and wood protection. If you want to get a lighter shade, the product is combined with a simple colorless varnish.

Among the clear advantages of using XB-784 for wood processing, the following can be distinguished:

- resistance to water, weak solutions of acids, salts, alkalis;

- ease of use - the varnish dries quickly, so the next layer can be applied after a short time;

- beauty of the processed products - toning emphasizes the natural color of the wood.

The colors used can be of the widest range, selected at the request of the customer. In addition to the common black and dark brown colors, gray, yellow, ivory and others are used. White is used on request.

Material KO-814

This paint is recommended for use on metal equipment, oil and gas pipelines, waste furnaces, car exhaust systems and other equipment. Its properties make it possible to protect surfaces from high temperatures - up to +500 degrees.

Description

In addition to protection from high temperatures, the material KO-814 will protect against the effects of cold (up to -50 degrees). It is a heat-resistant organosilicon enamel, which is also characterized by high moisture, salt, petrol, oil resistance. The tool is two-component. According to certificate of conformity and GOST, it is sold as PAP-2 powder (aluminum) and semi-finished varnish KO-85. The components are connected in a ratio of 5: 100.

Specifications

In the description of the parameters of the material, the following should be noted:

- the appearance of the film is silvery, smooth, homogeneous;

- viscosity according to the VZ-4 viscometer at a temperature of +20 degrees - 12-18 s;

- drying time at a temperature of +20 degrees - 2 hours, final polymerization - after 72 hours;

- coating strength according to the U-1 device - 50 cm;

- resistance to water at +20 degrees - 24 hours;

- resistance to the action of gasoline at +20 degrees - 24 hours;

- consumption - 100-120 g / sq. m;

- number of layers - 1-2;

- layer thickness - 20-40 microns.

Preliminary work with the surface and the product

After cleaning from any contaminants (rust, salt, grease, dirt), as well as from the remnants of the old coating, degrease with xylene, toluene. For the manufacture of enamel, combine 100 parts of varnish and 5 parts of aluminum powder. Stir until homogeneous, incubate for 10 minutes, until the exit of air stops. Use the product within 8 hours.

Painting works

Surfaces are painted at a temperature of -30 ... + 40 degrees, air humidity - no higher than 80%. The metal base is painted for 2-3 layers, each is dried for at least an hour at room temperature (it is better to keep it for 2 hours). If the temperature is negative indoors or outdoors, the drying time will be 2-3 times longer. Full curing occurs when used in a hot environment. For application, a direct method of spraying using pneumatic units is used.

Outdoor enamels

The leader in durability and strength, perhaps, are organosilicon enamels. The brands of enamels KO-42, KO-855, KO-174 are produced in a wide variety of shades and provide good protection against external influences.

Alkyd enamel (PF and GF brands) is used for painting wooden and metal surfaces. It provides a hard, durable glossy film after drying. Most alkyd enamels have drying time 24 hours, but quick-drying paints are also available, which dry in 1 hour.

A very strong and durable semi-matte coating is provided by XB enamel, which in its basis contains perchlorovinyl and glyphthalic resins. For painting the plastered concrete or brick surface of the facade of the building, it is recommended to use the enamel XV-161. This paint is highly resistant to atmospheric precipitation.

Enamel XB-0278 is used for painting prepared metal and wood surfaces for outdoor use. It is applied to the surface by airless or pneumatic spraying.

For the same purposes, as well as for painting concrete and reinforced concrete building structures, KhV-16 enamel is used. In addition, this enamel can be used to decorate fabrics.This type of enamel is applied by spraying.

Due to its unique durability, KhV-785 enamel is used in a complex coating to protect equipment, metal products and reinforced concrete building structures from the aggressive effects of concentrated inorganic acids, alkalis, salts and gases, as well as from prolonged contact with water at temperatures no higher than 60-65 оС. Also applied by spraying. In addition, polyurethane enamel is used for the same purposes. Metal enamel is applied to galvanized iron, aluminum and ferrous metals.

Enamel NTs-132 dries very quickly, perfectly protects against the damaging effects of dampness and direct sunlight. The basis of NTs-132 enamel is nitrocellulose. It is used for painting wooden and pre-primed metal products, as well as for any outdoor work. NC enamel is applied to the surface by spraying technology. Before starting work, it is recommended to clean the surface well of dirt, dust, grease, technical lubricants. Clean metal products from rust and be sure to prime them.

Interior materials

I must say that this division into materials for external and internal decoration is rather arbitrary, since almost all enamels for external work can be used indoors as well. But it is better and cheaper to use special enamels for this purpose. Alkyd enamels and some others are perfect for this. We will talk about them.

EP enamel is prepared on the basis of epoxy resin. EP-140 enamel coating is used for painting pre-primed surfaces made of steel, magnesium, copper and its alloys, as well as titanium and aluminum amalgams. All paint components are mixed immediately before use. It should be remembered that epoxy enamel requires special storage conditions - it should be stored in an airtight container, out of direct sunlight.

GF-92 enamel based on glyphthal varnish is used for windings of electrical machines. There are two types of GF enamel. For the processing of stationary parts of the windings, GF 92 HS enamel is used - cold drying enamel, and GF 92 GS hot drying enamel is used for both fixed and rotating parts of the winding.

Enameled wire (enameled wire) is used directly in the coils of electrical appliances. It is coated with an electrical insulating varnish based on modified polyester resins, due to which the wire has high thermal properties and great flexibility.

Rust enamel will help to paint a metal surface covered with corrosion products. For these purposes, a unique product has been created - a primer-enamel. This is a triple action agent - enamel rust primer. It is designed to protect metal units exposed to aggressive gases and vapors of an industrial atmosphere.

Heat-resistant enamel is used for painting surfaces used at high temperatures. Such enamels are used for painting pipelines, boilers, heating systems, railway tanks, etc. Heat-resistant enamels form coatings of increased hardness and durability.

Safety regulations

When working with this paint and varnish composition, it is important to observe the following rules to maintain health:

- if staining is carried out indoors, it is imperative to organize high-quality ventilation. The enamel contains harmful, toxic substances that in a closed room will adversely affect the respiratory organs and human well-being;

- it is forbidden to apply paint near heating devices, sparks and open flames, since ХВ-124 is a highly flammable, fire hazardous solution;

- during the application of the composition, it is imperative to protect the skin with a special protective suit and rubber gloves;

- to protect the eyes, it is recommended to use glasses, as if the mixture gets into the eyes, vision may deteriorate;

- to avoid the ingress of toxic fumes into the respiratory tract and respiratory organs, you must wear a respirator or gas mask.

Enamel XB-124 - the main properties and scope of the composition

This paint coating covers the product with a film that protects it from harmful effects, improves the decorative appearance of the premises, and improves durability. Additionally, enamel perfectly protects products from rust. All thanks to the unique composition.

The main element is polyvinyl chloride chlorinated resin, it also includes: alkyd resin; various fillers; plasticizers.

To acquire the required enamel color, pigments are added to it. It is produced in certain colors (green or gray). If required, production in other colors is possible (the color requested by the buyer is created).

The area of application is wide because the enamel has good indicators of protective properties: against meteorological conditions; fire resistance; moisture resistance; frost resistance.

The area of application is wide because the enamel has good indicators of protective properties: against meteorological conditions.

The area of application is wide because the enamel has good indicators of protective properties: against meteorological conditions.

It is used by:

- In the construction of individual wooden houses, in order to strengthen the material, also during repair work;

- In the engineering industry;

- In the production of various types of devices;

- For covering buildings made of reinforced concrete, steel, bridges and production halls;

- In military affairs, they are used to cover equipment and other equipment, and to protect them, thus, from the appearance of rust, ultraviolet radiation, frost.

In addition to its excellent stability indicators, it has aesthetic properties; it is more often used to paint metal products. But it is also used for painting wood, here it is used as an antiseptic against fungal microorganisms and mold.

Enamel XB 124 has the technical characteristics prescribed in GOST 10144-89, the shelf life of the product is six years.

It proved to be excellent in severe frosts, increasing the strength of structures in difficult weather conditions.

It proved to be excellent in severe frosts, increasing the strength of structures in difficult weather conditions.

What are the technical characteristics

Before adopting this enamel, it will be logical to understand its characteristics. It has the following technical characteristics:

- It is permissible to use at a humidity of 50-80%, temperature indicators from -10 to +30;

- Complete drying occurs in a day;

- Viscosity level 35-60 s;

- Grinding is equal to 30 micrometers;

- Grip indicator 2 points;

- The level of non-volatile particles is 30-33%.

Complete drying occurs in a day.

Advantages and disadvantages

Choosing which tool is best suited for the task at hand, they begin to study the positive and negative qualities of the product

Therefore, now attention will be paid to these particular features.

So, XB 124 paint stands out with the following advantages:

- Protective properties against corrosive formations;

- Does not let the previously existing rust layer on the surface further;

- Forms a pleasant-looking coating;

- Shows reliability in case of sudden changes in temperature indicators;

- Even withstands such external influences as high humidity, fire, household chemicals, aggressive chemicals;

- When completely dry, it covers the surface with an elastic protective layer;

- The performance data is long term.

The disadvantages include:

- Strong smell;

- Poor adhesion. It is required to pre-treat with a primer;

- Painting indoors is not recommended.

It even tolerates such external influences as high humidity, fire, household chemicals, aggressive chemicals.

It even tolerates such external influences as high humidity, fire, household chemicals, aggressive chemicals.