Views

The most common solutions now are:

-

heat-wall;

-

expanded polystyrene;

-

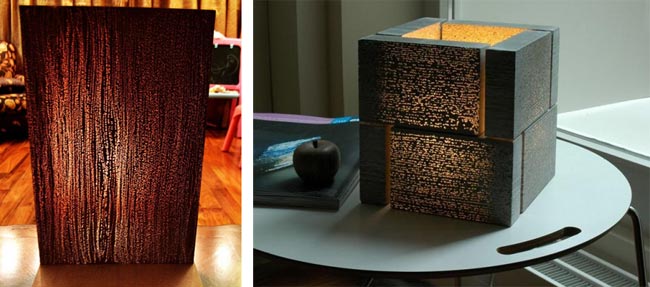

liquid wood (it is also composite boards);

-

hyper-pressed Lego bricks.

The name "teplofosten" speaks for itself. These are multilayer thermoblocks, which, along with simple concrete, include:

-

expanded polystyrene;

-

carbon fiber rods;

-

expanded clay concrete with a large number of pores.

As for the expanded polystyrene itself, it is officially allowed only as an inner wall layer. However, some consumers use it as a permanent formwork. The prospect of such a decision will be shown in the near future. But the composite board is wood fibers mixed with polymer resin. This material is mainly used to decorate walls and floors.

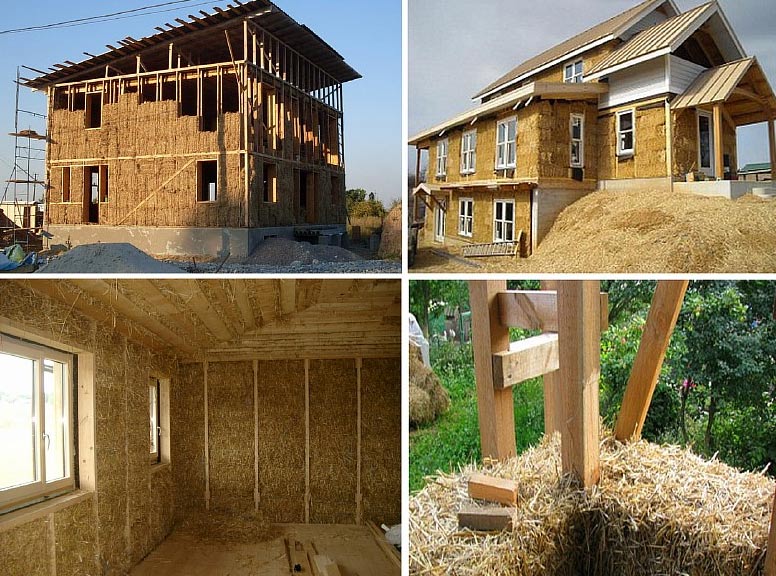

Also sometimes found:

-

bags filled with earth;

-

pressed straw;

-

shell rock tyrsa.

But these three types of solutions will still rather be exotic for domestic developers, even those interested in non-standard methods. More often you can find buildings from cargo (for example, sea) containers. Competent decoration gives a good look and solves the problem of uniformity. But in addition, you will have to do some serious warming in order to exclude the stifling heat in summer and the intolerable cold in February. A serious drawback of such a solution can also be considered insurmountable restrictions on the size of rooms in width and height.

Adobe houses are also considered experimental. During their construction, clay is mixed with straw and other plant fibers. Despite its antiquity, this approach is now experiencing a rebirth, since such a material is undoubtedly environmentally friendly. Old-type adobe huts are still found in Ukrainian, Moldovan and South Russian villages.

Semisamanny buildings, erected in the 1970s-1980s, are found in the vicinity of Belgorod and Voronezh. The frame itself was built from oak planks. It was covered with clay and covered with bricks. The reason for this method of construction is obvious: at that time, full-fledged brick structures would be prohibitively expensive. Another option for "radical savings" is the use of slate.

Strictly speaking, its classification as an experimental material is conditional. For roofing and finishing wall work, it has already been used in large quantities, moreover, for a long time. However, we are talking about a somewhat non-standard application:

-

a metal frame is being built, similar to that intended for gypsum board;

-

the wall inside the house is covered with chipboard;

-

the outer edge of the wall is covered with slate;

-

additionally, plastering is carried out, completely hiding this material.

In terms of external and consumer characteristics, this solution is relatively good. It is almost impossible to determine what is under the plaster. However, using a wall for support (for example, attaching a ladder to it) is undesirable. Such houses are more designed for summer use. They are being actively built in the Crimea.

The fox hole construction is another ancient achievement that has been tried in many regions of the world. But it is quite obvious that it will never leave the experimental stage. The formation of walls and ceilings involves the use of planks. Roofing material or birch bark is used for waterproofing.

Brick: pros and cons

Yes, the brick is strong

frost-resistant, not afraid of fungus and does not rot. He is not afraid

precipitation and does not burn, solar ultraviolet light does not have any

influence. The brick is durable and also meets all environmental and

aesthetic standards. The strength of the house is due to both the quality of the material and

masonry method - each next laid row of bricks knits the previous one, then

yes, there are no vertical seams passing through at least two rows.

This masonry requires

certain qualifications, especially when linking corners and laying walls with a thickness

more than one brick. Thus, the complexity of building a house from

brick requires highly skilled labor. Another significant disadvantage

is the weight of the brick: you need a reinforced, solid foundation. Due to the high

the thermal conductivity of the brick, the house cools down quickly, and it warms up, so as not

it seemed that the house was damp, it would take several days. It's pretty simple

explains: when laying, the thickness of the mortar is about 1 cm, and at small sizes

brick, such a thickness of mortar is no longer a "bridge", but a real

"Bridge" of cold. The deadlines for the delivery of brick houses are usually delayed, so

how they cannot be plastered at once for two reasons: the shrinkage of the house (and the house

will surely settle due to the significant weight) and moisture in

solution, which takes several months to completely evaporate. In addition to

to all these disadvantages, the brick can collapse if it absorbs moisture before winter.

And this is possible even if all production technologies are followed.

bricks, if clays with salts dissolved in it are caught: water will wash the salt out of

bricks, and itself will occupy the voids. This is the beginning of a destructive process.

And one moment. Brick production cost not less than

than one and a half times, more expensive than the production of other materials, of which

erecting walls. Considering that a brick is several times smaller than any other

building block, the labor intensity of construction increases significantly. Together

the same price and labor intensity make a brick house quite expensive.

Pros and cons of foam concrete as a material for building houses

Foam concrete is similar to aerated concrete in its porous structure, but has closed pores. The blocks are made from cement and sand by adding water and a foaming agent to the mixture.

For the production of foam concrete, neither complex technology nor expensive equipment is required. This allows you to get a fairly budgetary material, but also carries certain risks, making production attractive for small non-professional firms. The blocks made in artisanal conditions are of low quality.

Advantages of foam concrete:

- light weight;

- low thermal conductivity;

- ease of cutting;

- low hygroscopicity due to the closed pore system.

Cons of foam concrete:

- insufficient gas exchange (steam passes poorly, therefore a forced ventilation system is needed);

- does not lend itself to bending stress;

- subject to significant shrinkage, which leads to the formation of cracks.

Despite the existing drawbacks, this rather cheap material is often chosen for building a house. Also, with its help, they perform sound and thermal insulation of walls, roofs, floors, etc.

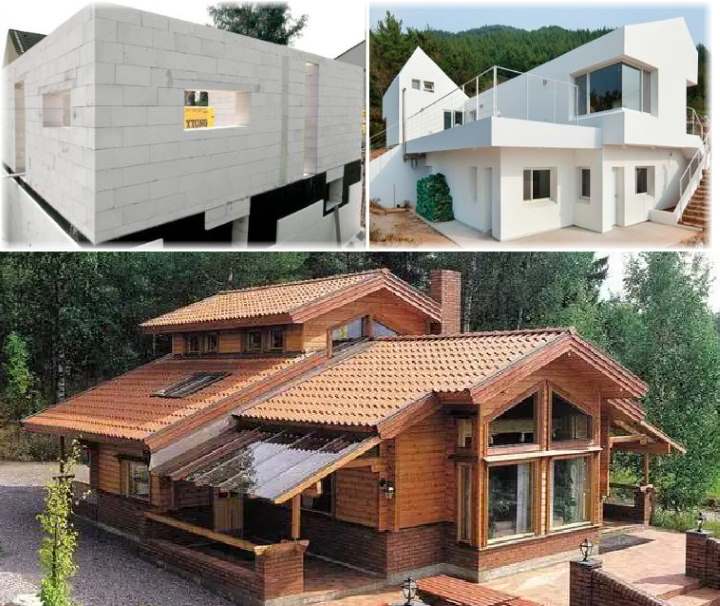

Types of materials for walls

The building materials market offers a wide variety of different options for building the walls of your home. There are several types of bricks alone: silicate, clinker, ceramic, fireclay. And wood has been one of the most popular and demanded building materials for many years. The cost of such raw materials depends on the type of wood (pine, oak, birch, cedar), the type of material (logs, boards, beams). A very popular and more economical option is various types of blocks: foam blocks, ceramic blocks, thermoblocks, lightweight concrete blocks, etc. In Europe, for example, houses are most often erected using the frame method, which is very fast and inexpensive. About 70% of the private housing stock in Europe is occupied by frame technology for the construction of buildings. Builders also note the cost-effectiveness and energy efficiency of SIP panels.

Consider the main types of materials:

Log cabins and log houses

A log house is an object made from cut trunks of a solid tree. Work such as cutting corners, adjusting joints and grooves is always done manually.

Log house

Such houses look presentable, soundly and have a lot of advantages:

Architectural version of a log house

The disadvantages of log buildings include:

Log house

Glued or profiled timber is a cheaper building material for the walls of a house, which is in great demand today.

Glued laminated timber house

Pros of a bar:

In addition, such material is relatively inexpensive.

However the cant:

Frame house

They say that such a structure can be built alone, with certain knowledge and skills. But the scheme of its construction is more complex and ornate than, for example, a brick one.

Frame house under construction

All the advantages of frame houses:

Completed frame house

The disadvantages of frame structures include:

SIP panels

Canada and America have been actively using frame-panel technologies in construction for more than half a century. In our country, this method is not yet so popular. SIP-panel is a three-layer building material, which is made of two layers of OSB and internal insulation of expanded polystyrene.

This is what the SIP panel looks like

Advantages of SIP panels:

In addition, SIP panels are an environmentally friendly building material.

This is how a house built from SIP-Panels looks like without facade decoration

Its disadvantages include the following aspects (of which, by the way, there are many):

Brick walls

Brick is the most common and most affordable material for building the walls of a house from the outside. It is usually made from clay and is enhanced with various impurities. All the advantages of bricks:

Brick house

The disadvantages of building materials include:

Expanded clay blocks

Ceramic blocks are made of red clay, just like bricks. But the blocks differ from them in more overall dimensions. This option for building walls from ceramic blocks is very similar to the technology for building brick houses.

Expanded clay block

Pros of ceramic blocks:

House of expanded clay blocks without external finishing

The disadvantages of ceramic blocks include:

Foam blocks

Foam blocks are a versatile type of building materials for walls. They consist of aerated concrete, which has good performance characteristics.

Foam block

Advantages of foam blocks:

House of foam blocks without facade decoration

The disadvantages of foam blocks are:

Ceramic blocks

Ceramic block is a material made from a mixture of clay and sawdust, after which the element is fired in a kiln

Ceramic block is a material made from a mixture of clay and sawdust, after which the element is fired in a kiln

A ceramic block is a material made from a mixture of clay and sawdust, after which the element is fired in a kiln. This is a fairly durable product that allows you to quickly build walls at home. The strength of the ceramic block is so high that it can be used to make a multi-storey building. Inside, the material has a porous structure, and the outer surface is corrugated. For a tight connection, the ends of the material have grooves and ridges.

The height of the ceramic block is a multiple of the rows of brickwork, and other dimensions may be different. Thus, it is possible to build from a ceramic block according to projects that are designed for brick. But the construction speed is much higher, since one ceramic block measuring 238x248x500 mm, which weighs 25 kg, is equal to 15 bricks, each of which weighs 3.3 kg. In addition to increasing the speed of construction, the cost of mortar is reduced, because it will be needed less.

Walls with a thickness of 380 mm or more made of this material do not need insulation, since the thermal conductivity of the product is only 0.14-0.29 W / m²x ° C. Marking of wide blocks M 100. If you need to make thin but strong walls, then you can take elements with marking 150. Frost resistance of ceramic blocks is at least 50 cycles.

Pros and cons of ceramic blocks

Since the block has pores, the material has high heat and sound insulation characteristics.

Since the block has pores, the material has high heat and sound insulation characteristics.

The advantages include:

- Low specific gravity and high strength significantly expand the scope of this material.

- Installation of large-sized products is carried out quickly and without unnecessary labor costs.

- Saving mortar due to the size of the elements and the absence of the need to make vertical seams.

- Frost resistance of a conventional ceramic block is higher than that of an ordinary brick.

- Good fire resistance. The product is able to resist burning for 4 hours.

- Since the block has pores, the material has high heat and sound insulation characteristics.

- An optimal microclimate is created in a room made of ceramic blocks, since the walls can "breathe" and regulate the air humidity.

- The house can last a century and a half without losing its thermal insulation characteristics.

This has material and disadvantages, among which the following are worth mentioning:

The price of ceramic blocks is quite high.

Since these products are relatively new in our market, it is difficult to find a good bricklayer for masonry.

This fragile material must be stored and transported very carefully.

Brick

A house built of bricks can last a century, or even one and a half

A house built of bricks can last a century, or even one and a half

A house built of bricks can last a century or even a century and a half.There are many types of bricks that differ in important operational and technical characteristics.

So, for the construction of walls, silicate and ceramic types of bricks are used. Let's consider their features:

- Ceramic bricks are made from fired red clay. It is a durable, moisture resistant, environmentally friendly material. There are solid and hollow bricks on sale. The more voids in the brick, the higher its thermal insulation performance.

- Silicate brick is made on the basis of lime, sand and some additives. It also comes in corpulent and hollow forms. The latter option is lightweight and has improved thermal insulation properties. Silicate solid products are distinguished by good sound insulation properties, but high thermal conductivity.

Also, this wall material is divided into front and ordinary:

- It is better to build the walls of the house from ordinary bricks. Products may have small defects in the form of cracks and chips, but due to this, their price is more acceptable. In addition, the appearance of the product is not as important for the internal masonry of the walls as for the front masonry.

- Facing brick (front) is a wall material used to decorate the facade. All products must have the correct geometric shape, smooth or embossed surface, be free from flaws and defects. The price of a facing brick is higher than that of its ordinary counterpart.

The strength of this wall material is directly related to its brand, which can be from M 75 to M 300. The number indicates the load that one square centimeter of the product can withstand. The higher the brand, the greater the specific gravity of the product. To build a 2 or 3-storey house, a brick of grade 100-125 is enough. To complete the foundation and basement, products with the brand 150-175 are used.

Also, when choosing a brick, it is important to take into account its frost resistance, that is, the number of freezing and thawing cycles that the product can withstand without damage and reducing strength by no more than 20%. This indicator is marked with the letter F and a number from 15 and above

For warm regions, products with frost resistance grade 15 can be used; in colder latitudes, bricks of the F25 grade are used. For facing work, a brick with a frost resistance of at least 50 is suitable.

Advantages and disadvantages of bricks

Among the advantages of this wall material, it is worth noting the unlimited possibilities in terms of design and implementation of the most complex projects.

Among the advantages of this wall material, it is worth noting the unlimited possibilities in terms of design and implementation of the most complex projects.

Among the advantages of this wall material, it is worth listing the following:

- Impressive service life.

- Aesthetic appeal.

- Unlimited possibilities in terms of design and implementation of the most complex projects.

- The material is not susceptible to corrosion, damage by fungi and microorganisms.

- The product does not burn.

- High sound and heat insulation characteristics.

The disadvantages include the following:

- Due to the small size and high specific gravity, laying brick walls takes a long time and costs a lot.

- Under the brick walls, it is necessary to equip a solid buried foundation, and this entails increased costs for materials and earthworks.

- In most cases, brick walls need to be additionally insulated.

What to look for when choosing a material for building a house

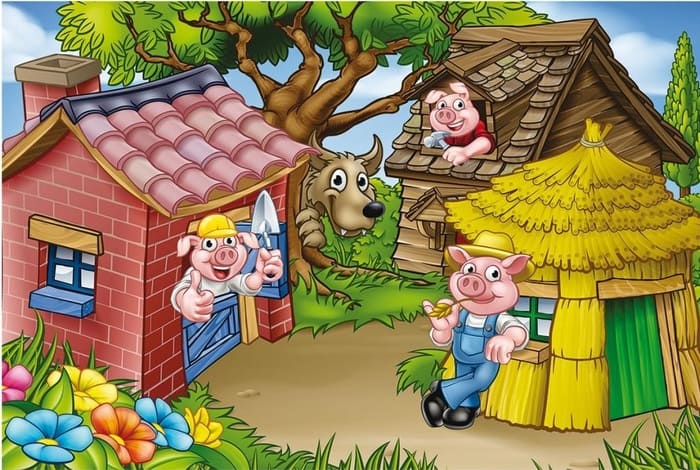

Probably, there is no such person who, from childhood, using the example of the tale of three piglets, has not mastered the truth about the importance of material in building a house. But for some reason, already being adults, when it comes to real construction, people completely forget these obvious things and begin to economize on materials with might and main, convincing themselves that the quality of construction will not suffer at all.

Of course, modern technologies have made great strides forward, and the industry offers us quite decent materials for little money. But for an ordinary person who first encountered the construction of a house, it is very difficult to understand the abundance of proposals and find adequate material that meets all needs and capabilities. In fact, which would be better - brick, aerated concrete, wood, sandwich panels?

This is a serious question, because walls consume about a quarter of the total construction budget.

How to choose the right material so that you don't have to redo almost everything in the future, what parameters should be taken into account?

- Price. Lightweight material will allow you to save money without compromising on quality. In this case, a strong foundation is not needed either.

- Thermal insulation. If the walls begin to transmit heat intensively, then it will be very expensive to heat such a house in winter. Therefore, before choosing a material for construction, calculations should be made based on the desired temperature parameters and climatic characteristics. It is possible to reduce the thermal conductivity of the walls due to the insulation. In addition, there are materials for the construction of buildings that do not need thermal insulation due to low thermal conductivity.

- Labor costs. This parameter can be reduced if you use large blocks, and not, for example, bricks. The building will be erected several times faster. The easiest way is to build a frame house with panel walls.

- Finishing work. Modern wall materials are made with attractive designs, so they do not need additional finishing. Hence, this is another opportunity to save money.

Next, we will tell you in detail about popular building materials, their main qualities, pros and cons. This information will help you decide what exactly should be used to build a house.

Wood

Many people who decide to build a house opt for a tree.

Many people who decide to build a house opt for a tree.

Many people who decide to build a house opt for a tree. This natural material is environmentally friendly. It creates a favorable microclimate in the house, maintains optimal humidity and saturates the air with healing phytoncides. A wooden house is warm in winter and not hot in summer, since wood has good thermal insulation characteristics.

A wooden house can be built from the following items:

- The log can be natural or rounded. In the latter case, the material has the correct shape and smooth surface, but it needs additional protective treatment, since the natural protective resin layer, which is under the bark, is removed during the cylindering process.

- You can use glued (profiled) and sawn or planed timber. Better houses are obtained from laminated veneer lumber, which has special grooves and ridges for a snug fit of the elements.Sawn timber is more often used for frame houses.

- Frame-panel houses are made of OSB, chipboard, moisture-resistant plywood, which are attached to the frame. Insulation is laid inside the wall.

The main advantages of wooden houses are their environmental friendliness, comfort and reasonable price. A lightweight foundation can be made for such a house. Disadvantages - fire hazard, shrinkage.

Aerated concrete properties

The duration of the construction of experimental facilities should be determined by the construction organization project in accordance with the norms for the duration of construction of enterprises, buildings and structures approved by the USSR State Construction Committee.

In cases where, according to the conditions of experimental construction, longer than those established by the specified norms are necessary, the terms, ministries and departments must agree on the duration of construction of the experimental facility with the USSR State Construction Committee and the USSR State Planning Committee.

2.6. Research and design organizations - leading performers - developers of projects for the construction of experimental facilities draw up work programs for experimental construction, participate in the implementation of these programs, develop guidelines for drawing up consolidated scientific and technical reports on the results of experimental construction.

Experimental construction work programs provide for:

the purpose of the experimental construction;

the order and scope of scientific research before the start, and in necessary cases and during the construction of experimental facilities;

the procedure and scope of observations during the construction of experimental facilities, and, if necessary, the state of these facilities during the period of operation;

technical and methodological assistance to construction and installation organizations in the implementation of construction under the project, as well as in the organization of accounting for material and technical resources and labor costs;

supervision over the construction of experimental facilities and the development of new developments and technological processes in the construction industry;

measures to monitor the implementation of the experimental construction work programs;

guidelines for the preparation of consolidated scientific and technical reports on the results of experimental construction in accordance with GOST 19600-74;

recommendations developed where necessary and related to the peculiarities of the application of scientific and technical achievements in the construction of experimental facilities, as well as testing of elements, materials, products, structures and equipment of experimental facilities.

The experimental construction work programs specify the organizations:

4. It is a big risk to choose a completely new building material or a new technology.

It is more correct to pay attention to the technologies that have been worked out over the years, to look at the constructed objects that have stood for several seasons, to communicate with the owners. As a result, you will have a better understanding of how the house will behave in two or three years, and you will not face unpleasant surprises.

Irina Galitskaya, Commercial Director of Greenside:

1.Our company is engaged in the production of laminated veneer lumber. This popular material allows you to quickly build quality, modern and beautiful wooden houses. Since this is a relatively new material for building houses, the latest advances in science, technology, research and development in the field of building materials are used in its production throughout the entire technological cycle.

If you carefully study the full production cycle of this material, if you delve into all stages of timber harvesting and processing, then there will be no doubts about the reliability, strength, durability and suitability of laminated veneer lumber for the construction of a modern wooden house. Therefore, we are not inclined to experiment with an already debugged technological process.

There is an opinion that for a wooden house it is necessary to provide heating power at the rate of 1 kW of energy per 10 m2 of area, that is, we may need up to 7 thousand kW of electricity per month to heat a 200-meter house, and this is not counting home appliances. Agree this is a lot. Moreover, when there are many modern materials that allow you to minimize these costs, but about them a little later.

The photo shows that the logs are very hot, in fact, the interface of the logs is a zone of high heat loss.

Aerated concrete properties

Aerated concrete includes aerated concrete and aerated concrete

blocks. Inside the concrete, in the first case, there are cells with air, in the second - with

hydrogen. In the first case, bubbles are formed as a result of foaming,

concrete hardens under normal conditions. In the second, aluminum is added to the solution

powder or paste, which, when interacting with water, release gas (hydrogen).

The solution "grows", it is sent to an autoclave, where it solidifies when

certain temperature and pressure. Let's see the pros and cons of these materials

separately.

Foam concrete we knew in the middle

last century, but they began to build from it recently, when they started talking about

heat saving. Still, air is an excellent heat insulator. At the same time through

foam concrete almost does not pass sounds. Since the foam blocks are lightweight and in size

more bricks, then laying does not become a time-consuming process. Yes, and shtrobut

walls under the communication system are easy. How easy it is to give the block different

forms, which means that you can create bay windows, make an oval wall, etc. In addition

foam concrete does not burn and is easy to transport.

The disadvantages include a rather high

moisture absorption (albeit at a shallow depth). The walls require annual rainfall

moreover, they must stand on stable foundations-slabs, otherwise on blocks in

as a result of deformations, significant cracks appear.

Aerated concrete even lighter than foam concrete, great

processed (it can be cut with an ordinary hacksaw,

drill with ordinary drills, etc.). Heat insulating and soundproofing

functions are also at their best. Lightness requires less labor, and good

heat-shielding properties reduce the amount of material required. With all

this should not be forgotten about the high strength at a relatively low price.

Disadvantages can

manifest itself in two cases. The wall breathes and therefore gradually accumulates moisture.

To eliminate this phenomenon, you need a wall finish with good waterproofing.

The second minus is the fragility of aerated concrete, that is, the wall should not experience any

movements to avoid cracks. A this requires a durable tape foundation.

Appointment

One of the newest solutions is the development of the Japanese company Kengo Kuma. A double layer of leather membrane is used for finishing. This material provides excellent heat dissipation. The walls are built from Japanese larch. For outdoor insulation, fluorocarbon tarpaulins and bamboo stems are used.

For the construction of a house, the following can be used:

-

salt blocks;

-

plates "Isoplat";

-

glass facades with light blocking properties;

-

conductive concrete.

For roofs used:

-

modified roofing material;

-

polymer-based membranes;

-

shinglas;

-

katepal.

You can learn about what a building heat block is from the video below.

House of foam blocks

Foam concrete is the most common material for the construction of private houses today. It is a mixture of sand, cement, water and foam. Lightweight and warm, the material is easy to use, it can be given any size, it does not require a massive foundation, and even a non-professional can handle the construction of walls from such material.

Foam blocks are produced in large rectangular slabs of a grayish-white color, and a large amount is not required to build a wall, unlike, for example, brick, which is laid out in several layers. Time costs, accordingly, are also reduced.

The obvious advantages of foam concrete include its low thermal conductivity, which reduces the cost of heating the house. In the event of a fire, a lightweight foam block does not explode, like ordinary concrete, and does not emit toxic substances, since there are no slags and crushed stone in its composition.

Foam concrete is environmentally friendly, it maintains an optimal microclimate in the house, it is well ventilated and does not rot, unlike wood. Finally, thanks to its porous structure containing tiny air chambers, foam concrete has high noise absorption properties and saves on additional sound insulation. The main disadvantage of foam concrete is its hygroscopicity, i.e., the ability to absorb moisture. Excessive moisture in the walls leads to the fact that the house becomes damp, its thermal conductivity increases, and this is fraught with the appearance of mold. If the concrete absorbs a lot of moisture over the summer, it can cause the walls to crack in the winter. In order to prevent this from happening, it is necessary to lay a vapor barrier: priming the walls and filling their inner surfaces.

The main disadvantage of foam concrete is its hygroscopicity, i.e., the ability to absorb moisture. Excessive moisture in the walls leads to the fact that the house becomes damp, its thermal conductivity increases, and this is fraught with the appearance of mold. If the concrete absorbs a lot of moisture over the summer, it can cause the walls to crack in the winter. In order to prevent this from happening, it is necessary to lay a vapor barrier: priming the walls and filling their inner surfaces.

When buying foam concrete as the main building material, it is necessary to document how long it was exposed to aging. The fact is that foam concrete is slowly gaining strength, and over time, the process of its hardening does not stop.If the manufacturer does not have the appropriate premises in which the foam blocks must be kept, there is a risk of buying a fragile material that will quickly deteriorate over time.

In the process of interior decoration of such houses, it is necessary to take into account all the characteristics of foam concrete, and select the appropriate materials. For better ventilation of the walls, you need to use hinged plasterboard structures, under which vapor barrier membranes are placed.

Depending on your preferences, you can finish the inner surfaces with wood, MDF, acrylic paints on plaster and wallpaper, but it should be remembered that all these materials must be treated with moisture-proof compounds.

What it is?

The story about building experimental materials should start with their definition. This category includes mainly the latest developments, which are supplied in very modest batches. The industry usually simply does not have time to master the production of sufficiently large volumes at first. Some time ago, experiments were carried out with gas silicate blocks and non-removable foam formwork. However, the situation is changing rapidly, and in 2020 professional builders will no longer be surprised by this.

The experiment period is generally considered to end after formal certification based on performance tests. It is unreasonable to think that all such decisions are unambiguously bad. Often, many of them, after certification, begin to be used very massively. It should be understood that new technological developments are not always sold under the brand of “experimental materials”. Some firms under this name sell something obscure - very old solutions, half-forgotten now, or bizarre combinations that are more likely to cause bewilderment.

Moreover, the fate of each specific experimental material is unpredictable. Until recently, gas silicate and foam concrete blocks that were part of this group quickly gained popularity and became a familiar component of modern construction. But the clay, as it was in the experimental category, remains in it, despite its stable use. One way or another, all such materials are significantly more profitable than those used in large quantities.