Installation rules

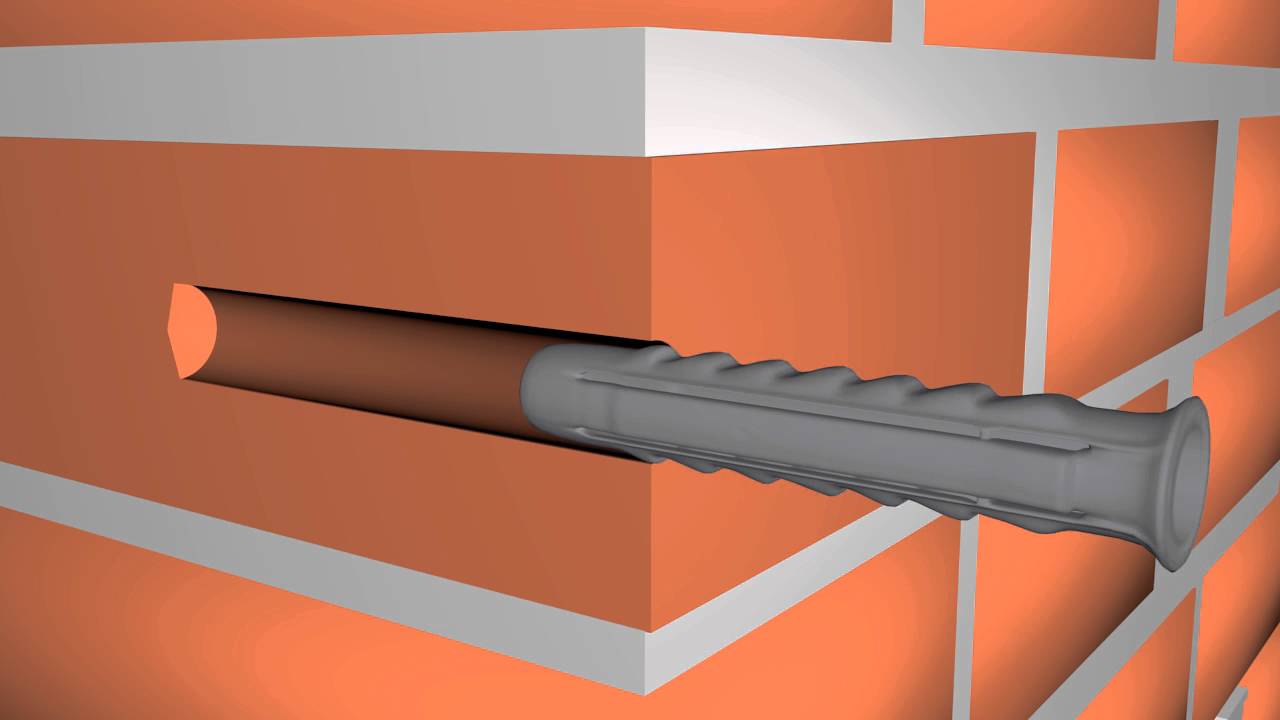

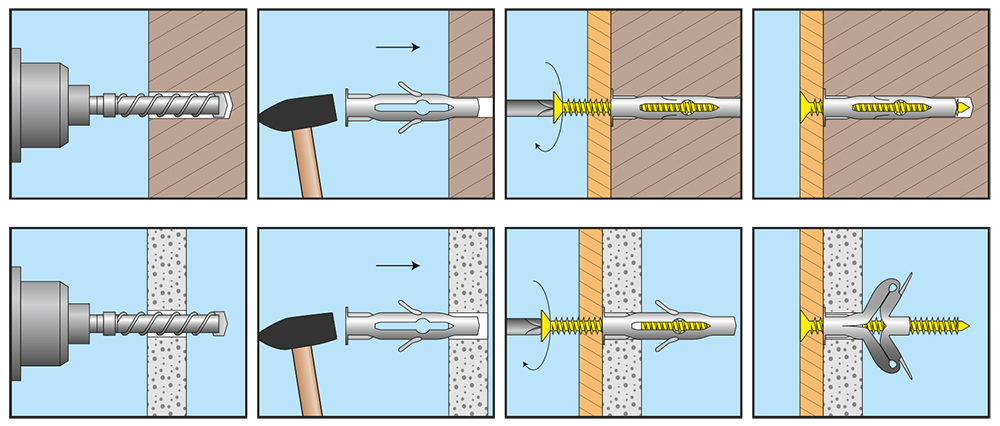

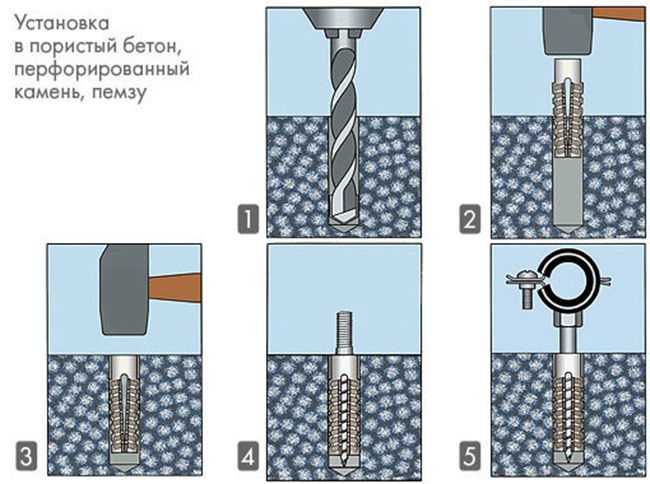

The main installation methods are twisting and hammering into a prepared hole.

- Using a hammer drill (you cannot use a perforator, it can crush the material), a hole is drilled in the gas silicate block. For plastic dowels, it is recommended to use a drill with a diameter of 1 mm less, for metal dowels - 2 mm.

- The cavity is blown out of dust.

- The fasteners are carefully, without distortions, screwed in with the installation tool (the KBT dowels are mounted using a hexagon, with other models a screwdriver works) or hammered in with a hammer (metal dowels), a rubber mallet.

- The final stage is tightening a self-tapping screw or mounting screw. It is better to do this operation without an electric tool, manually, or start the screwdriver at low speed.

Special dowels for gas silicate blocks appeared not so long ago, as, indeed, this attractive building material itself. Most likely, in the future, various installation designs will be developed and the existing ones will be improved.

For information on how to choose the right dowels for gas silicate blocks, see the next video.

What fasteners to choose for brick walls?

When choosing a suitable dowel, they are guided by 5 main parameters, namely:

- size and load on the dowel;

- type of structure to be mounted and base material (wall, floor, ceiling);

- the method chosen to secure the elements.

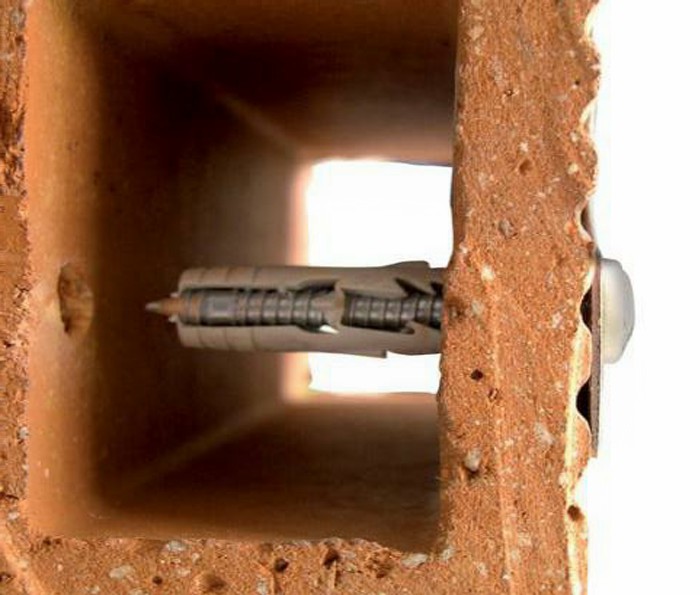

It is worth noting that if it is not possible to independently determine the load, then it is better to take dowels designed for the maximum permissible load for fastening. Hollow brick, although it is a common building material, is not reliable for fixing dimensional elements on the wall, therefore, strong fasteners are used. During installation, the plastic on the nail is rolled up and does not allow the entire structure to fall out of the hole. In addition, it is the most budgetary option.

Application features

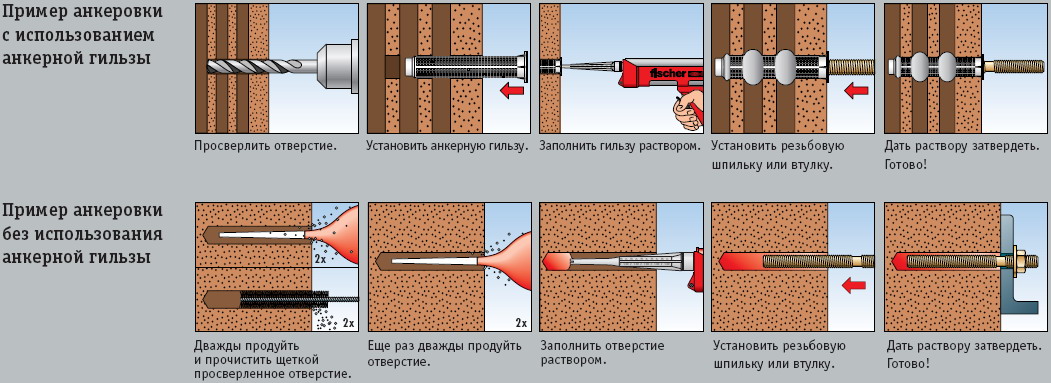

The installation process is carried out in several stages. The main ones are:

- Hole preparation.

- Composition room.

- Installation of the anchor into the uncured polymer mass.

- Tightening the nut.

Each of these stages is associated with its own characteristics.

To install you will need:

- chemical anchor;

- injection gun;

- threaded stud or fittings;

- hammer drill or drill;

- Boer;

- torque wrench;

- metal brush;

- handheld or industrial vacuum cleaner;

- Remedies.

With the tools in hand, you can start installing the chemical anchor.

Cooking the hole

When working with brickwork, it is important to avoid splits and cracks in the brick. This requires refraining from using the hammer function on the equipment and drilling perpendicular to the plane.

To successfully install a hollow brick chemical anchor, a hole 2 millimeters larger than the diameter of the stud is required. It is necessary to mark in advance on the drill corresponding to the length of the anchor, or use the depth gauge.

To improve adhesion, it is required to thoroughly clean the hole from dust and crumbs. This is done using a metal brush and a hand pump, with which the hole is blown several times until there are no visible dust residues.

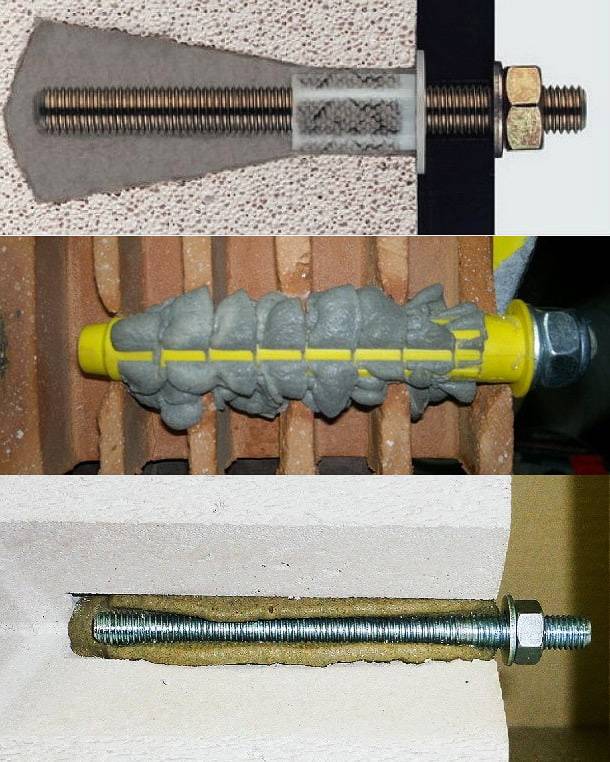

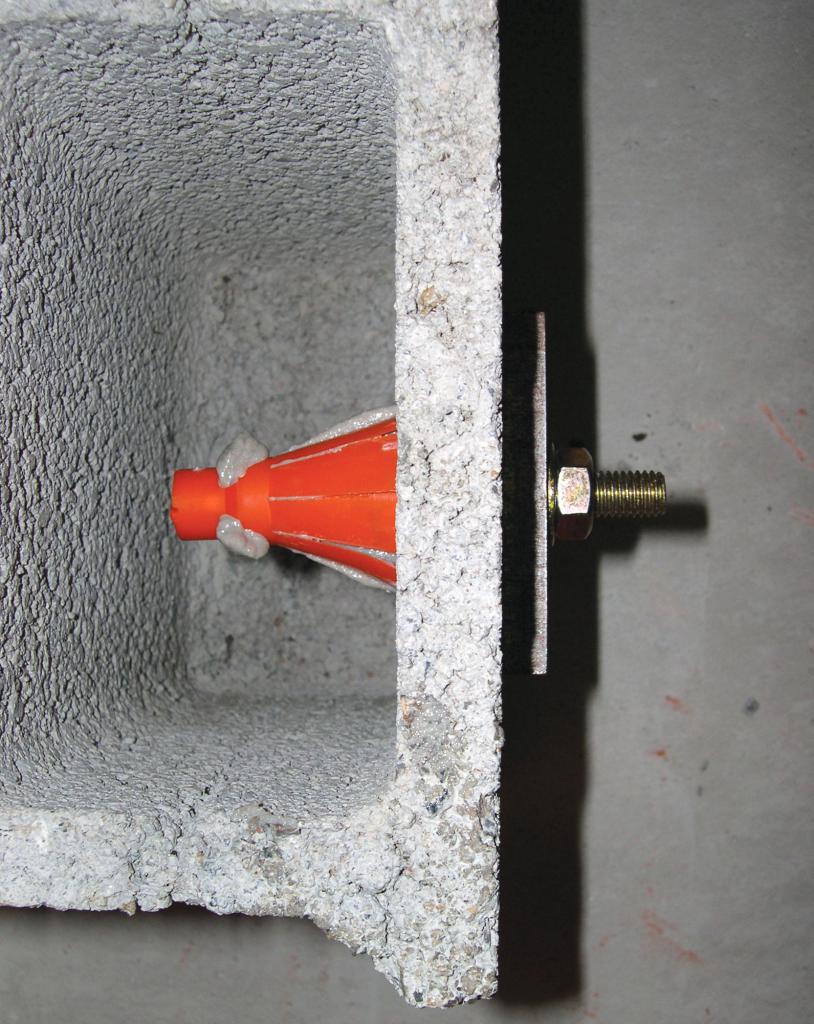

Introducing the composition

The polymer mass is introduced into the hole using an injection gun. If the mixture has a uniform gray color, then it can be applied.It often happens that initially it is not possible to achieve good mixing - such a mixture should not be used. To use the gun, you need to place the nozzle in the drilled cavity and fill it with the compound. After each dose of glue is placed in the hole, it is required to remove the instrument slightly until more than 65% of the cavity volume is filled.

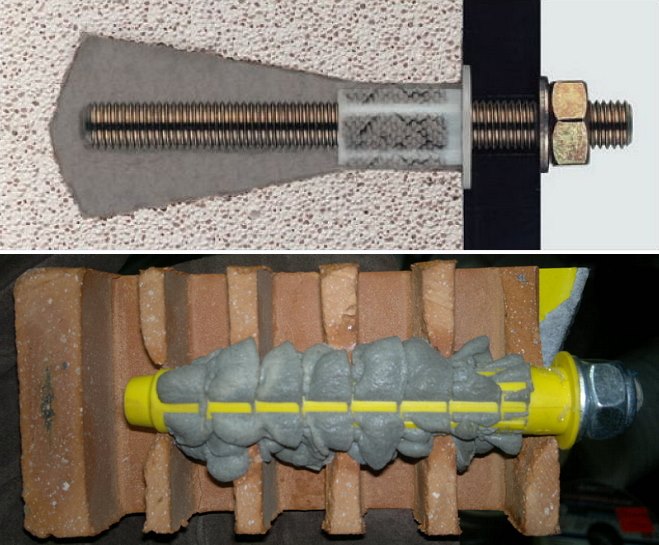

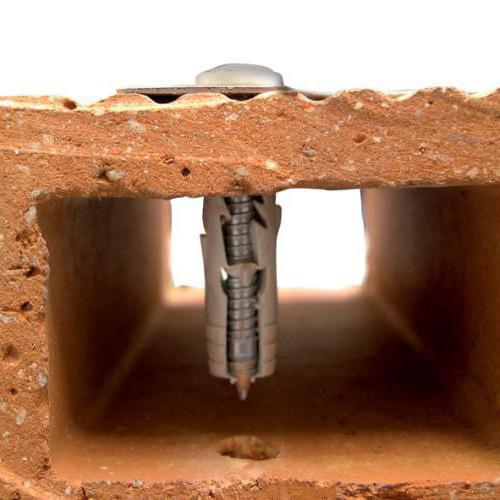

The procedure for placing a chemical dowel in a hollow brick is characterized by a number of features. They are related to the fact that the presence of a large number of voids does not allow the formation of a natural hole. To achieve the goal, a special plastic sleeve is inserted, which is filled with glue. When the pin is immersed in a hollow brick, part of the chemical composition comes out through the mesh walls of the sleeve into the cavity. This promotes more grip.

There are also special ampoules. They are placed in the hole, the composition is mixed with a hairpin. The second option is more suitable for piece work, when there is no need to buy cartridges with a chemical composition.

Installing a metal anchor

We place the metal structure in the hole using rotational movements

It is important to distribute the solution evenly. To do this, it is recommended to periodically pull the fasteners towards you and only then tighten it

While the glue dries, you can correct the position of the anchor.

Tighten the nut

After waiting for the complete solidification of the polymer mass, you can proceed to the installation of equipment and structures. The manufacturer's instructions indicate the maximum force applied to tighten the nut. It is recommended to use a torque wrench in order to control the applied forces.

Chemical anchors are suitable for fasteners made of steel. Due to its positive properties, the anchor can be installed in high humidity or even under water. When used correctly, it is possible to avoid the destruction of the brick, which allows installation at the very edge of the surface.

Chemical anchor is a new direction in construction, thanks to which complex work is simplified. The offer market is becoming more extensive, there are more anchors with various new fastener characteristics.

Hollow brick

What is this material? In modern construction, two types of bricks are used - hollow and solid. The main function of the first materials is the construction of buildings, which must be as strong and durable as possible.

This brick is good in all respects. The material is lightweight, strong, easy to install. However, it has a significant drawback. It retains heat poorly in rooms. Although hollow brick practically does not differ in strength from solid brick, it is more often used in finishing work. The internal void in such a building material can be, depending on the type and manufacturer, from 30% to 50%. Low-melting types of clay are used as raw materials for such blocks. It is from it that red brick is made. There is also another option. It is a silicate hollow white appearance. Let's take a look at the features and properties of mounting blocks.

Types and features

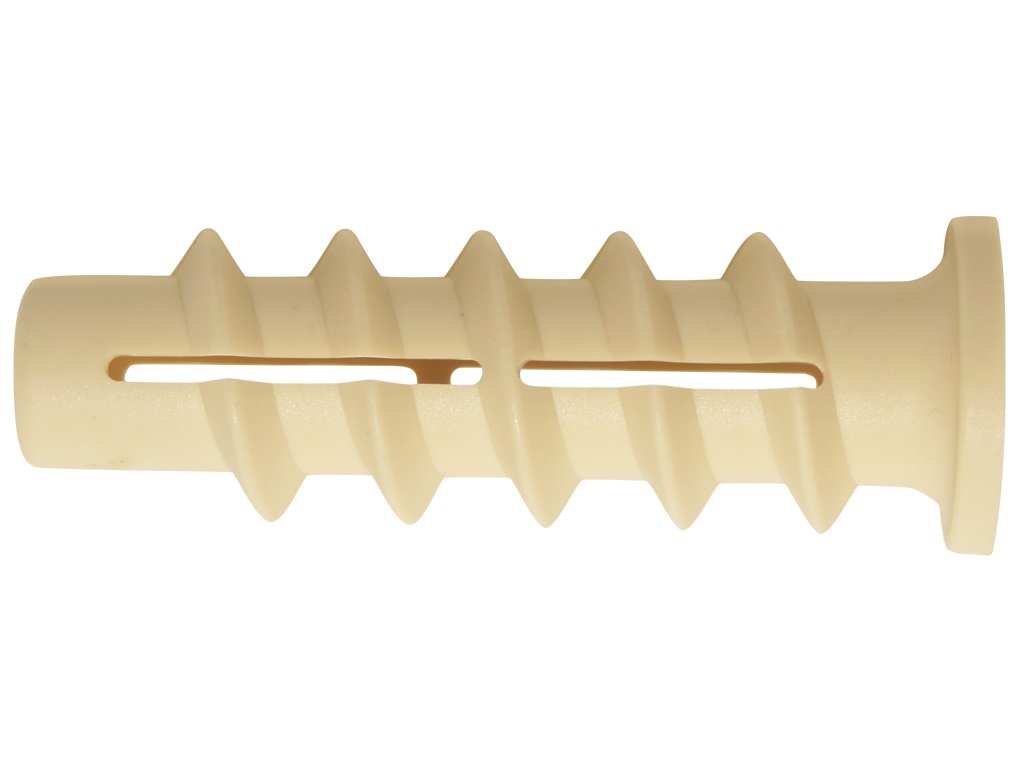

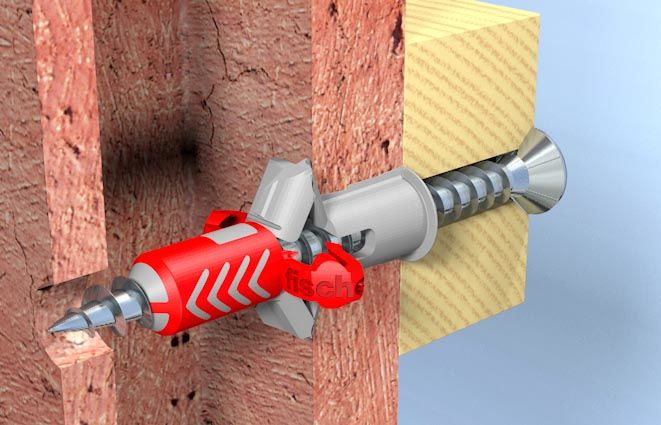

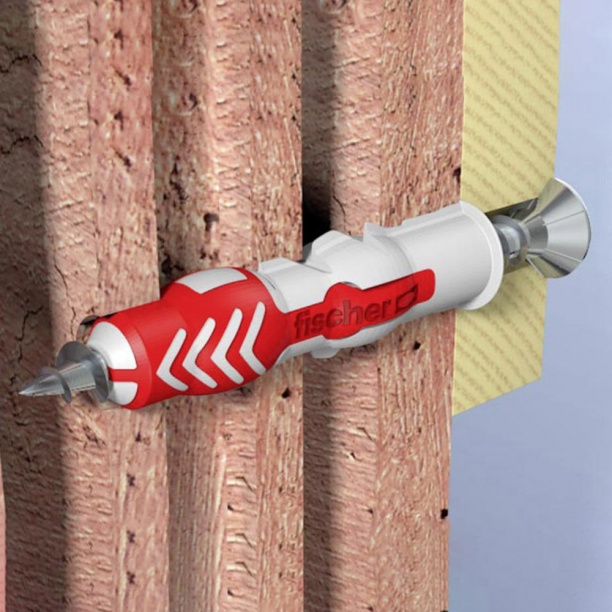

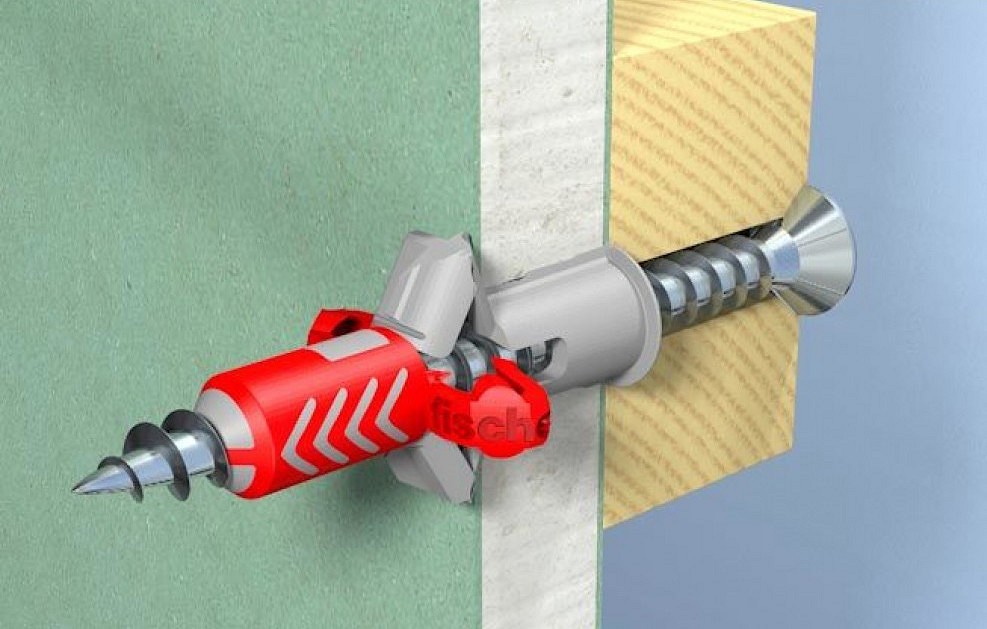

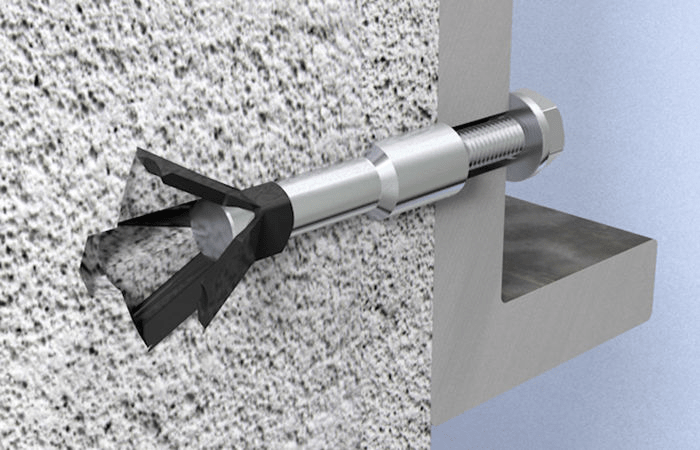

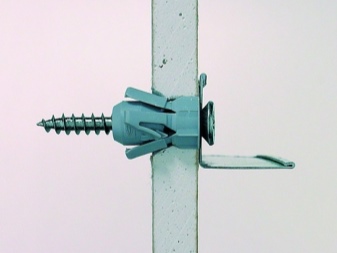

The dowel fastening device is a bushing with four petals and a rough surface. When twisted or clogged, they begin to expand in the porous structure of aerated concrete. The teeth and incisors in such a device contribute to a secure fixation. They can be especially secured when the teeth move in a spiral and the tip of the screw does not protrude beyond the dowel.

Fasteners, depending on the material used, can be:

- metal - stainless steel, galvanized, brass, aluminum, with the addition of an anti-corrosion compound;

- plastic (polyethylene, polypropylene, nylon).

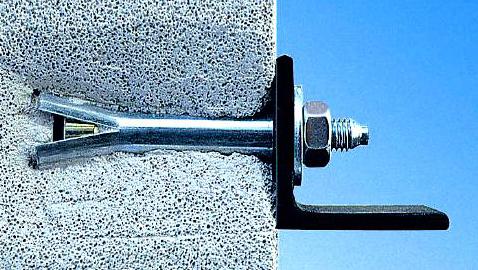

The first type is considered the most reliable in operation.They are perfect for push-through and complex installations. However, such fasteners have a significant drawback - they begin to oxidize under prolonged exposure to moisture. Equip them with supporting elements in order to minimize the risk of twisting, falling through heavy hardware inside aerated concrete blocks.

Fasteners made of plastic are appreciated for their lightness, versatility and resistance to corrosion processes. Of all the varieties, nylon dowels are considered the best.

All these fasteners are divided into hammered and screwed in, depending on the installation method. They are suitable for installation without pre-drilling the blocks and are also threaded into a pre-drilled hole.

By the type of thread and fixation of the elements, the bushings can be standard with the same section length and helical spiral. There are cone-shaped hardware, which diverge to the sides with blades when twisted. Some begin to expand when the structure is pulled apart.

A separate group includes chemical anchors. Their fixation occurs due to the polymerization of a special composition. They are very convenient to use, since it is enough just to put the capsule in the prepared place.

Metal dowels

These fasteners are fire resistant and are therefore often used in installations where there is a risk of fire. Metal dowels have a locking collar, which is also called a "collar". At the moment of twisting, it prevents the sleeve from turning around its axis and prevents it from falling into the wall. Most often they are made from galvanized steel.

The metal dowel for aerated concrete is used when performing the following works:

- for the installation of equipment and furniture with an impressive weight;

- fixation of pipelines, including the most complex ones;

- fastening guides designed for the installation of sheets of gypsum board.

Plastic and nylon retainers

Such fasteners are good because they are not affected by corrosion processes. The plastic dowel for aerated concrete has special spiral ribs. This part of the part is responsible for maximum adhesion to the cellular structure of the material. The main advantage of plastic mounts is environmental friendliness. The advantages also include resistance to aggressive environmental influences.

They are distinguished by their low cost, which makes them irreplaceable and always in demand when working with aerated concrete. Despite all the positive characteristics, they are not suitable for use on the facade surface. Their significant disadvantage is poor resistance to subzero temperatures. In winter, during frosts, such a fastener can easily burst.

The nylon versions are also non-corrosive. However, they are more durable than plastic counterparts. They are often used when doing outdoor work. A nylon dowel for aerated concrete is considered much stronger and more durable. They are much more expensive in cost, so they are rarely bought by consumers.

The high price is fully justified, since the characteristics of the clips allow them to be used for many jobs. For example, with their help, they make the installation of window and door openings. This is a great option for mounting mirrors and installing lighting fixtures, if you use fasteners with a diameter of less than 12 mm.

Chemical anchor

Often, massive objects have to be fixed on the aerated concrete surface. In this case, chemical anchors are used. Metal dowels, in comparison with anchor bolts, will not be able to withstand very large weight. They are sent to a prepared place using a special adhesive.

What is a dowel?

The fastener consists of the following elements:

- Tapered collar at the end of the product. It adjusts the depth of penetration into the brick. Galvanized in yellow or white.

- Retaining wings. They provide anti-scrolling protection for the element.

- A tip that, when the screw is tightened, changes shape into a knot.

The dowel is cylindrical with a cavity inside, which looks like 2 uniform thickenings. The fastening part for concrete, as a rule, is made of both metal and various types of plastic. Pulling out this fastener from the wall is impossible due to tendrils that prevent rotation in the structure. And for a concrete surface of a porous type, glue is mainly used as a base.

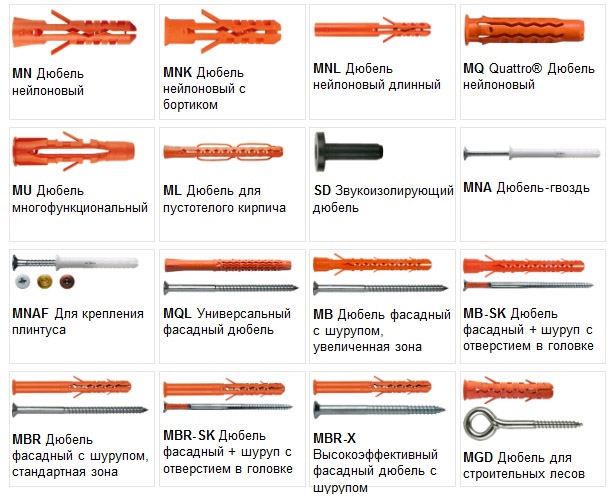

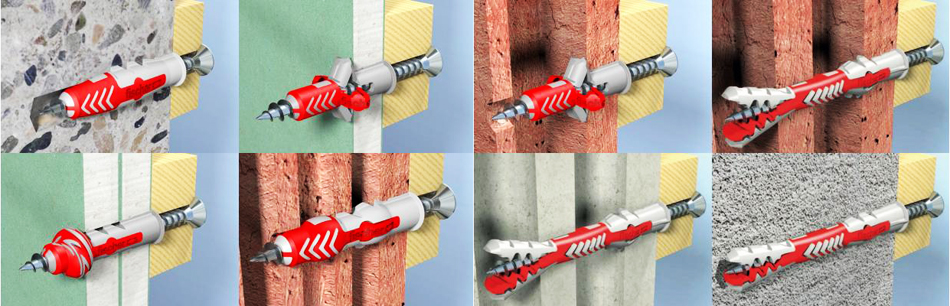

As for brick walls, it is allowed to use dowels for concrete for solid bricks (for silicate and ceramic), but builders do not recommend using this mount for hollow bricks (slotted). For it, dowel nails are specially made of a slightly larger size, so that when it gets inside, the end of the screw reaches the volumetric part, and not the voids. The spacer sleeve expands when the correct thread diameter is screwed in. The firm "Fischer UX - Fischer" is widely known on the market, which produces a universal fastener product and other varieties.

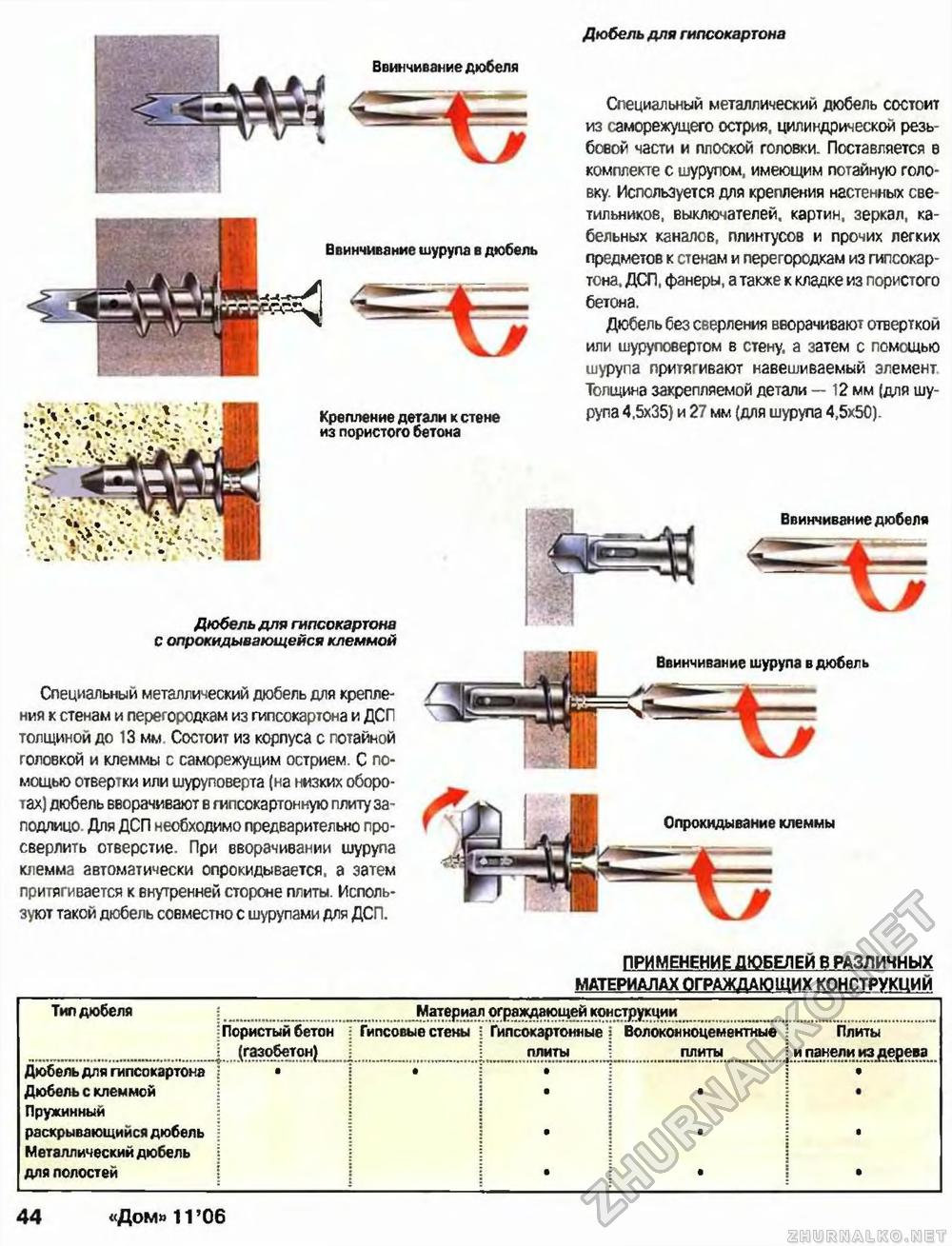

Dowel Fischer HMH for drywall, metal "MOLLY" with hook

Appointment. The dowel is used to create tear-resistant fastening points on drywall.

Design features. The dowel consists of a bushing with a split middle part and a set screw with a rectangular hook head. On the flange adjacent to the front surface of the drywall, there are pointed locking spikes that prevent the dowel from turning during installation.

Principle of operation. When the set screw is screwed in, the threaded part of the sleeve is attracted to the base, the middle part folds in the form of "petals" and creates a reliable supporting surface on the back of the drywall.

Fastener material. The dowel is completely made of galvanized steel.

How to use?

The principle of installation of dowels is the same as for other types of fasteners. You need to act in the following order:

- first you need to prepare holes for the dowel, which should be smaller than the diameter of the attachment; for example, for fasteners of 8 mm, you will need to use a 7 mm drill;

- if you take a tool such as a perforator, then you need to turn off the impact mode in it, of course, it is advisable to use a drill in this case, since it is more effective;

- plastic fasteners must be carefully screwed in using a screwdriver; if metal parts are used, then they should be driven into the bore hole with a hammer;

- when doing work, it is imperative to make sure that the products do not touch or are crooked;

- when the cuff is installed all the way, you can proceed to screwing a self-tapping screw or a universal-type bolt;

- it is necessary to screw in the self-tapping screw with a screwdriver, adhering to the required depth.

Materials (edit)

What material is preferable? It would seem that what could be more reliable than metal? The advantages of this material are obvious: strength, durability, ability to withstand heavy loads. However, there are also disadvantages to metal spacer fasteners. First of all, their high price and, oddly enough, non-versatility of use. As a rule, such dowels are used to mount any structures to brick walls. It is perfect for hanging various overall equipment: a gas boiler, a water heater, heating system elements, sports simulators, grilles, awnings, etc. A special type of metal consumables are frame fasteners designed for fastening window and door frames to brick walls.

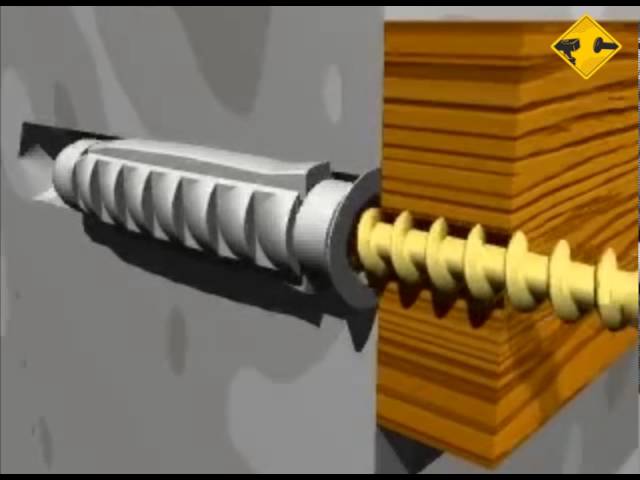

During installation, the dowel is inserted into a prepared hole of the corresponding diameter, and then a stud with an external thread is screwed into it. The hairpin expands the dowel tabs, and they are securely fixed in the hole.

Manufacturing of plastic dowels is much cheaper. This has led to a huge variety of plastic expansion plugs.The simplest of them have the same principle as described above for their metal counterparts.

A screw or self-tapping screw is screwed into the plastic sleeve, a special nail with a threaded notch can also be driven in. The introduction of a metal rod leads to the expansion of the structure petals, which securely fix the dowel in the material. Plastic plugs for hollow bricks have a special design.

During the installation process, their petals are twisted into tight "knots", this helps to fix them in the voids. Reinforced plastic dowels may well compete with some models of metal dowels in terms of fastening reliability. The use of plastic consumables is very wide. From mounting paintings and mirrors to fixing heavy equipment.

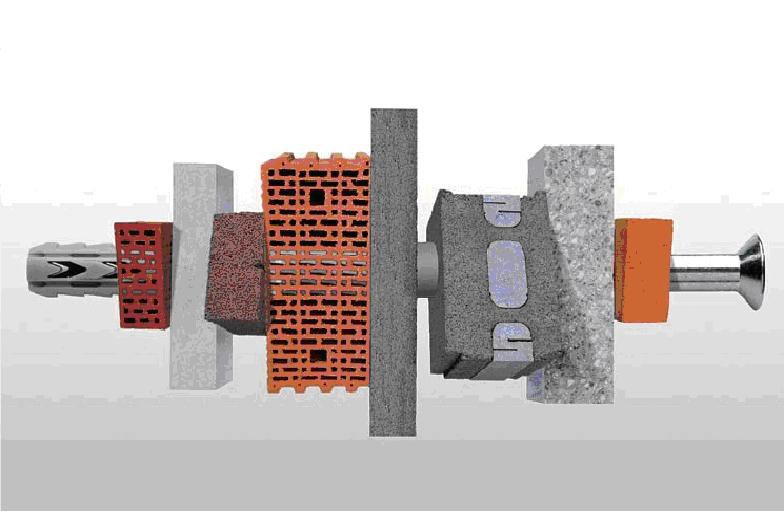

Types of dowels

The selection of the most relevant dowel depends on the type of surface to which the fastener will be performed, as well as on the type of structure to be attached (weight, size, operating conditions).

Depending on the material, they are divided into metal (stainless steel or coated with anti-corrosion compounds, made of brass or zinc and aluminum alloys) and plastic

Depending on the material, they are divided into metal (stainless steel or coated with anti-corrosion compounds, made of brass or zinc and aluminum alloys) and plastic

There are such variations of dowels:

- Expansion dowel. Ideal for brick wall, stone or concrete. Relevant for relatively light structures. Strength characteristics are due to the presence of special spacers - antennae.

- Butterfly fasteners. Dowels of this type are used for foam blocks and other hollow surfaces. The special shape of the fasteners allows you to hold structures of significant weight.

- Universal dowel. A special type of fastener designed for work on concrete, stone, hollow and porous surfaces. Depending on the narrowly focused targets, scaly and spring-spiral ones are distinguished.

- Dowel nail. A type of fastener that allows the fastest possible attachment of drywall, wooden parts to a brick surface, concrete.

- Facade or otherwise - frame fasteners. A variation of this type implies the presence of two types of fasteners designed for working with hard and soft materials. Most relevant for the installation of window and door frames, as well as other facade structures (insulation cladding).

- Dowel clamp. Plastic type of fastener designed for work with electrical wiring.

- Chemical anchor. The strength characteristics of chemical anchors and capsules are several times higher than those of other metal anchors. The use of chemical anchors and capsules is important for working with structures, the operation of which occurs in the future under excessive vibration, dynamic and static loads.

- Dowel umbrella. A specific form of fasteners is provided for the implementation of measures with thermal insulation, hinged gypsum plasterboard structures.

- KBT nylon dowel. It is widely used for working with aerated concrete, hollow materials. A dowel for foam concrete is the best option for indoor and outdoor work. Provides reliable and fast fastening.

- Adjustment. Implementation of works related to the fastening of the lathing, preceding the fastening of the sheathing.

- GB. Dowel variation used when working with aerated concrete. Provides a secure attachment point, designed for heavy loads. It is used for fastening pipelines, suspended ceilings, awnings, metal and wooden roof structures. A dowel is used for fastening facade structures.

- Metal anchor. One of the most durable types of fasteners used to work with massive structures.

Depending on the method of installation, all mechanical dowels for aerated concrete walls are divided into blocks that can be driven in and screwed in without preliminary drilling.

Depending on the method of installation, all mechanical dowels for aerated concrete walls are divided into blocks that can be driven in and screwed in without preliminary drilling.

Self-installation of aerated concrete dowels

Before installing the fasteners, you will need to prepare the following tools:

- drill or hammer drill and drill bits for concrete;

- Phillips screwdriver

- hammer;

- pencil and tape measure.

After that, you need to follow a few simple steps.

Drill a hole

In order for the dowels for gas silicate blocks to "sit down" reliably, you need to properly drill holes for them. To do this, it is better to use a drill with a smaller diameter (1 mm) than the dowel itself. Accordingly, if you have 8 mm fasteners in your hands, then a drill will be required for 7 mm.

The only exception is a metal dowel, for which it will be necessary to reduce the hole not by 1, but by 2 mm.

If you are using a puncher for work, be sure to turn off the "blow". But, it is better to take a regular electric drill, which is much better at this task.

Install the dowel into the wall

At this stage, it is necessary to thoroughly clean the prepared hole from concrete dust and other particles. Depending on the material from which the fastener is made, the installation process will differ:

If you are using a plastic dowel, then carefully screw it into place with a screwdriver (this type of fastener usually has slots for both Phillips and slotted tools)

You need to tighten the fasteners all the way.

If you prefer metal dowels, then you must first install them in the seat, and then use a hammer to carefully hammer the products into the wall until they stop. Make sure that the dowel is not distorted.

Tighten the self-tapping screw

At the final stage, when the fasteners are already firmly "sitting" in the wall, it remains only to tighten the self-tapping screw or a standard mounting bolt with a screwdriver. At the same time, there is no need to be afraid that the product will skew.

When tightening the self-tapping screw, do not use an electric tool, as you can accidentally rotate the fastener around its axis, which will damage it. In addition, working with a screwdriver, you can overtighten the bolt and it will completely "go" into the wall.

Thanks to special dowels, you can not be afraid to mount even the heaviest objects on the aerated concrete wall. However, if you need to hang a small picture or a paper wall calendar, there is no need to philosophize, in this case a regular nail will suffice.

We do the installation of foam concrete fasteners correctly

In order for the fixing in the foam block to last for many years and withstand the expected loads, it is necessary to perform the installation correctly. It all depends on the chosen dowel, design features and tasks.

Screw-in dowels are made with a special thread, so they are very easy to install. Drop-in anchors are made with large teeth that expand in the drilled hole. The fasteners are driven in exclusively with a rubber hammer so as not to damage the foam block wall.

The chemical anchor is attached in a different way. A hole in the format of a cylinder with a tapered cut is drilled under it, then the hole is cleaned, a cylindrical sleeve is installed and the cavity is filled with a solution (or a capsule with glue is inserted, which releases the substance outward at the moment of crushing), a threaded pin is mounted.

Fastening dowels into a foam concrete wall

- First you need to prepare the necessary tools for performing the work - the fasteners themselves, a screwdriver with drills (exactly matching the diameter of the fastener or slightly less), a hexagon, a building level.

- Then the wall is carefully marked out, planning the fasteners and using a level.

- Holes are made according to the marks - in length equal to the length of the dowel + 2 of its diameter.

- They clean the holes with a construction vacuum cleaner or any tool that allows you to clean out the remains of foam concrete and dust.

- The dowel is screwed in with a hexagon.

- Next, you need to mount the mount.

With the right choice of the dowel in exact accordance with the loads and the tasks set, it will not be difficult to perform durable and reliable fastening. In Moscow and the region, other regions, a large selection of various products is presented by design, type, load, material

In the process of work, it is important to observe the technology and sequence of actions, to do everything carefully and efficiently

How to choose the right fastener

There are many different options for dowels. Each type of mechanism is designed for a certain weight, material and mounting method. The reliability of the installation of the mounted interior parts depends on the correct choice and fastening.

For dense walls, spacer, frame and nail fasteners are used; a dowel-clamp is used to fasten the cable. In hollow or loose walls, which are constantly crumbling, fasten fasteners with a spacer end and external thread. For sheets of drywall, chipboard or other materials - molly and butterfly. An expansion dowel is also mounted in the plastic panel for fastening.

Features and purpose

The uniqueness of such a dowel is that it has a multi-section sleeve structure. The fastener initially has a metric-type screw with a Phillips head, ring, and the like.

The hollow core dowel is easy to install. This can be done with a screwdriver or assembly pliers. Due to the use in hollow materials, the fastener has a large openable thrust wing area, which ensures the reliability of fixation. Provision is made for re-using the screw after removing it from the dowel. The remaining dowel does not lose its fastening properties.

The range of hollow wall plugs includes more than a dozen types. It can be difficult for a layman to make a choice if he does not know what exactly is right for him in a particular case.

For hollow walls

Such a dowel is made of nylon, zinc-aluminum alloy, galvanized steel. Fastening technology is:

- programmable deformation;

- thread and programmable deformation;

- thread plus swivel.

Some are reusable, but most are single use.

For tongue-and-groove plate

This type of fastener is also made of metal or nylon, has a two-piece design - spacer and non-spacer. The spacer part changes its configuration during installation. A dowel of this kind can have a restriction in the form of a cylindrical or round cuff, which will not allow it to fall into the hole. According to the method of installation, fasteners are divided into driven and screwed. Dowels for GWP through-type have an elongated non-expansion part. The spacer type is installed in the wall for its entire length.

Types of fasteners for gas silicate block, foam concrete and aerated concrete:

- frame;

- nylon;

- plastic;

- metal.

This choice allows the use of dowels in accordance with the forthcoming load. For lightweight structures, nylon or plastic are ideal. Heavy equipment and furniture are attached to metal dowels. This is the most durable and fireproof type of fastening.

Varieties of dowels

Depending on what exactly you need to fix in the aerated concrete surface, you need to choose the appropriate dowel.

Metal

The metal dowel is usually made of galvanized steel. Such products are fire-resistant, therefore they are often used in fire-hazardous premises. It is also suitable for complex installation:

- drywall guides;

- heavy furniture and equipment;

- any pipelines: gas, water supply, sewer.

High-quality metal fasteners should be equipped with a special stopping flange or collar, thanks to which the dowel will not turn or fall through (which quite often happens when working with porous surfaces).

The only drawback of such fasteners is their susceptibility to corrosion.

Galvanized steel products are the most expensive, but this is due to their reliability and reusability.

Plastic

Dowels of this type are made of polypropylene or polyethylene, so that the fasteners do not corrode.The plastic retainer is equipped with spiral ribs that provide the best grip on the porous surface.

In addition, plastic products are environmentally friendly, resistant to aggressive environments and are quite cheap. It is recommended to use them for installation work in rooms with high humidity, for fastening plumbing pipes and metal profiles.

However, for outdoor work, such dowels are not suitable due to their low resistance to subzero temperatures (with the onset of winter, the plastic will burst).

Nylon

Nylon products can also be classified as plastic fasteners. They are also highly resistant to corrosion, however, unlike previous fixings, the nylon plug can also be used for outdoor use. In addition, this type of product is much more reliable than polypropylene and polyethylene analogues.

Most often, such fasteners are used:

- when installing window and door openings;

- for mounting mirrors and lamps (for this it is best to use fasteners with a diameter of no more than 12 mm);

The only drawback of nylon foam concrete dowels is their high cost.

For more information on different types of dowels, see the video:

Frame

Such a dowel for aerated concrete is made from both nylon and plastic or metal. The product is distinguished by a "pan-shaped" design, due to which the device can significantly reduce the load on the foam block, therefore, the reliability of such an attachment increases.

Frame fasteners are also used in the installation of doorways, window frames and guides.

Having picked up the fasteners for the foam concrete, it remains only to fix it correctly in the wall.

Conclusion

Hollow brick is a building material that helps trap heat in a room. It is inexpensive and effective to build from it, especially since there are so many different fasteners for it.

Fashion for Naked: the best images of the stars. We select a Naked cosmetic bag for your make-up It's nice when fashion pushes us not only to experiment, but also to accept ourselves and our beauty. Fashionable positive attitude to your own body.

Toxicosis: causes, consequences, treatment The assumption that nausea worries a woman only in the morning is incorrect. It can last all day, but is most pronounced in the morning. It comes from.

What does the shape of your nose say about your personality? Many experts believe that looking at the nose can tell a lot about a person's personality.

Therefore, when you first meet, pay attention to the nose of the unfamiliar

15 Cancer Symptoms Women Mostly Ignore Many of the signs of cancer are similar to those of other diseases or conditions and are often ignored.

Pay attention to your body. If you notice

Why are some babies born with the "kiss of an angel"? Angels, as we all know, are kind to people and their health. If your child has the so-called kiss of an angel, then you have nothing to do.

13 Signs You Have The Best Husband Husbands are truly great people. What a pity that good spouses don't grow on trees. If your significant other does these 13 things, then you can.