Views

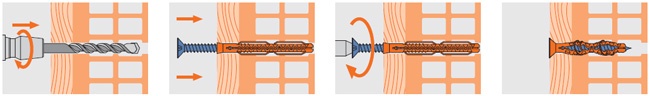

Dowel-nails are classified depending on the characteristics of the bearing surface. In particular, for solid porous concrete, hardware of the M150 brand will be required - it is characterized by a special relief and includes a pair of spacers, additionally they provide a self-tapping screw or a threaded stud. Aerated concrete hardware is equipped with wide-pitch spiral ribs. They are optimal in the case of a large area of contact between the hardware and the hole. For drywall, concrete and many other porous materials, the choice is best made in favor of products equipped with spiral threads. They usually have a twist drill at the end, which allows fixation to be carried out without preliminary hole preparation.

There are the following types of nails for hollow bases:

Molly - the distinctive feature is the release, which provides a strong fixation of the drywall; the maximum load on each hardware reaches 30–35 kg;

There are also self-tapping and wedge hardware. According to the installation technique, the hardware is divided into those installed with a construction pistol, as well as driven ones. To fix the anchor-type hardware, you need to place the pistol in the area of the intended attachment and "drown" the trigger. At the same time, there is no need for drilling holes and this greatly reduces the total time of repair and installation work, and in addition, eliminates the formation of construction dust in the room, which usually appears when using a drill and screwdriver. At the end of such hardware, a thickened rod is provided; a lock washer is attached to it. The inner nail provides for a large hat, it does not allow the hardware to sink into the building material

It is important to keep in mind that such fasteners cannot be reused.

From the point of view of functional purpose, the brass dowel-nail can also be attributed to this category. Its fixation is carried out by screwing it into the drilled holes. A distinctive feature of such products is their anti-corrosion characteristics, which determines a wide scope of their operation. The functionality of the driven dowel-nails varies depending on their dimensions. Most often, their length ranges from 25–70 mm. Such a choice of dimensions allows hardware to maintain the versatility of fastening not only for loose bases, but also for harder surfaces. The lack of strength of loose bases is compensated by a smaller pitch between fasteners.

Application features

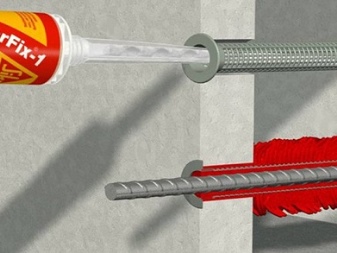

The installation process is carried out in several stages. The main ones are:

- Hole preparation.

- Composition room.

- Installation of the anchor into the uncured polymer mass.

- Tightening the nut.

Each of these stages is associated with its own characteristics.

To install you will need:

- chemical anchor;

- injection gun;

- threaded stud or fittings;

- hammer drill or drill;

- Boer;

- torque wrench;

- metal brush;

- handheld or industrial vacuum cleaner;

- Remedies.

With the tools in hand, you can start installing the chemical anchor.

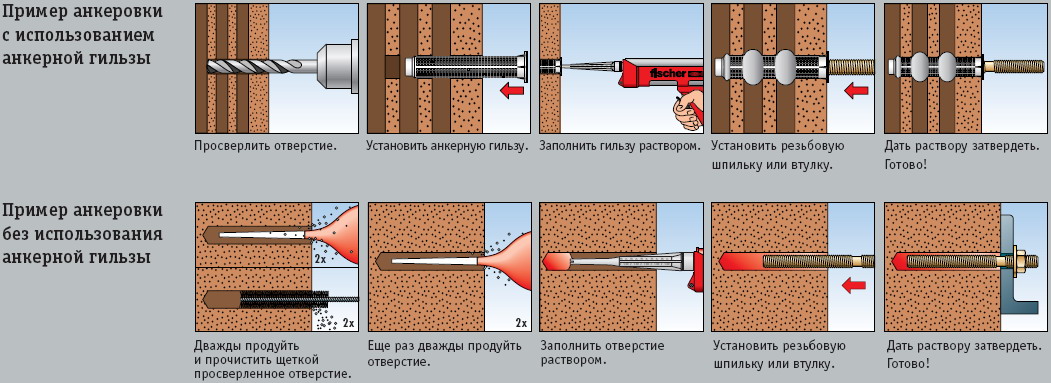

Cooking the hole

When working with brickwork, it is important to avoid splits and cracks in the brick. This requires refraining from using the hammer function on the equipment and drilling perpendicular to the plane.

For a successful installation of a chemical hollow brick anchor a hole 2 millimeters larger than the diameter of the stud is required. It is necessary to mark in advance on the drill corresponding to the length of the anchor, or use the depth gauge.

To improve adhesion, it is required to thoroughly clean the hole from dust and crumbs.This is done using a metal brush and a hand pump, with which the hole is blown several times until there are no visible dust residues.

Introducing the composition

The polymer mass is introduced into the hole using an injection gun. If the mixture has a uniform gray color, then it can be applied. It often happens that initially it is not possible to achieve good mixing - such a mixture should not be used. To use the gun, you need to place the nozzle in the drilled cavity and fill it with the compound. After each dose of glue is placed in the hole, it is required to remove the instrument slightly until more than 65% of the cavity volume is filled.

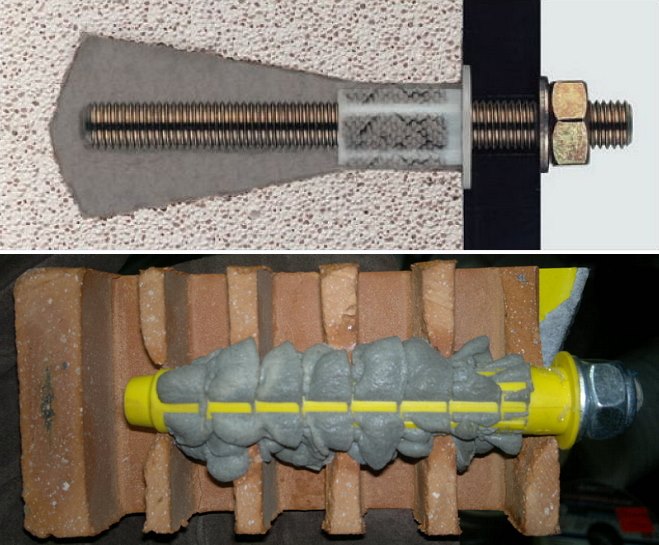

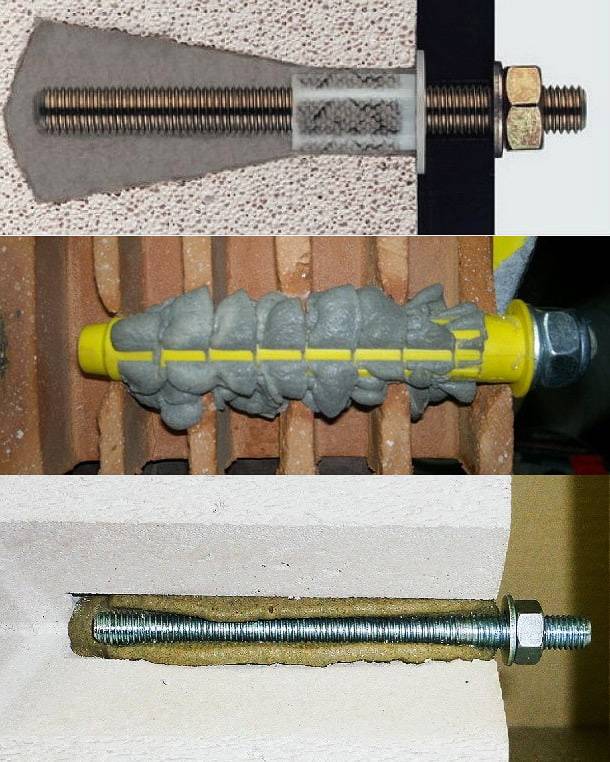

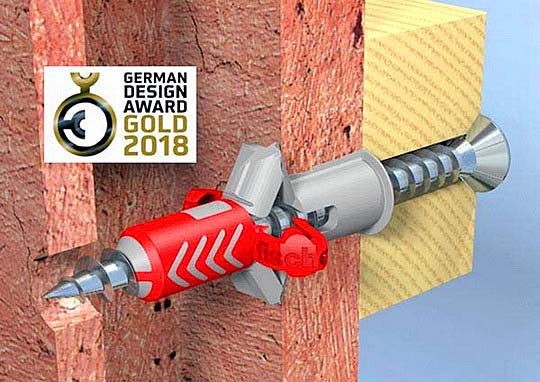

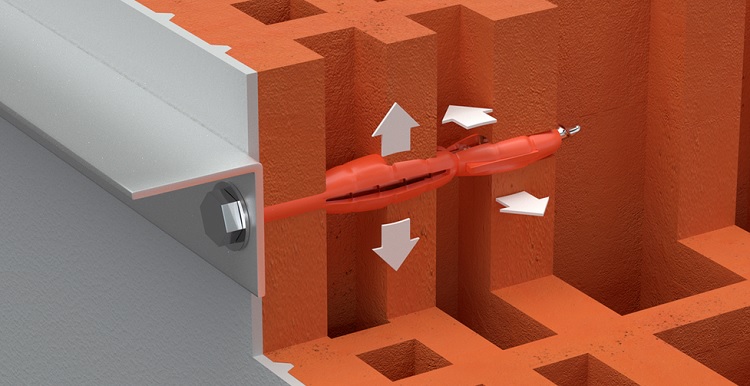

The procedure for placing a chemical dowel in a hollow brick is characterized by a number of features. They are related to the fact that the presence of a large number of voids does not allow the formation of a natural hole. To achieve the goal, a special plastic sleeve is inserted, which is filled with glue. When the pin is immersed in a hollow brick, part of the chemical composition comes out through the mesh walls of the sleeve into the cavity. This promotes more grip.

There are also special ampoules. They are placed in the hole, the composition is mixed with a hairpin. The second option is more suitable for piece work, when there is no need to buy cartridges with a chemical composition.

Installing a metal anchor

We place the metal structure in the hole using rotational movements

It is important to distribute the solution evenly. To do this, it is recommended to periodically pull the fasteners towards you and only then tighten it

While the glue dries, you can correct the position of the anchor.

Tighten the nut

After waiting for the complete solidification of the polymer mass, you can proceed to the installation of equipment and structures. The manufacturer's instructions indicate the maximum force applied to tighten the nut. It is recommended to use a torque wrench in order to control the applied forces.

Chemical anchors are suitable for fasteners made of steel. Due to its positive properties, the anchor can be installed in high humidity or even under water. When used correctly, it is possible to avoid the destruction of the brick, which allows installation at the very edge of the surface.

Chemical anchor is a new direction in construction, thanks to which complex work is simplified. The offer market is becoming more extensive, there are more anchors with various new fastener characteristics.

Selection of suitable self-tapping screws for drilling

Self-tapping screws refer to fasteners in the form of a rod, having a screw-in thread, a pointed end and a head. The thread holds the shank of the screw in the wall, thereby providing fixation and immobility. According to the classification, self-tapping screws for drilling are divided into the following types.

- Universal, suitable for any mounts - the most common.

- Self-tapping screws that strengthen metal sheets without a dowel. Before screwing in the self-tapping screw, drilling is mandatory.

- Self-tapping screws without dowels for fastening soft metal and wood, plastic.

- Self-tapping screws in the form of a Christmas tree, capable of strengthening a concrete or brick wall, going along with the dowels, by driving inward.

- Nagels - self-tapping screws without a dowel, are needed to strengthen a brick wall or a wall of concrete.

In order to choose the right self-tapping screws for drilling, it is important to consider what kind of metal or alloy they are made of. The scope of application of these products depends on the material of manufacture.

- Stainless steel. A huge plus is moisture protection. The presence of metals such as chrome and nickel prevents these screws from rusting.

- Carbon steel. Compared to the previous type, this metal is not protected from moisture, but it is more durable.

- Brass self-tapping screws for drilling are a relatively expensive, but high-quality material.You can work with them in both salty and acidic environments. Brass is resistant to corrosion, but this alloy is soft and deforms under heavy load.

If you choose self-tapping screws for drilling in concrete with a dowel, you need to take into account that the capsule is previously hammered into it, and the screw itself is already screwed into it. The mechanism is made in such a way that the sharp ends of the capsule stick into the wall as the self-tapping screw is screwed into the hole, expanding the area of the fastener for a more durable fastening.

Such a fastening system, where a plastic sleeve expands the fastening area, is used in the following cases:

- increased load on self-tapping screws;

- more rigid fixation for aerated concrete;

- the need to eliminate vibrations to prevent the screws from loosening.

In the absence of a dowel, for self-tapping screws you will also need to drill a small hole, it is also better to calculate in advance the length of the screw to be passed through. Otherwise, the self-tapping screw will either not reach the required depth, or drown in the wall. Reinstallation can only damage the fragile hole in the concrete.

There are also so-called turbo screws. The advantage of such a screw is the variable thread that has notches. It is noted for good adhesion to a concrete wall. Such self-tapping screws can be screwed in with an ordinary drill, they do not require excessive efforts. The turbo screw is applicable for cellular and hollow concrete blocks.

The color of the screws is also important. In relation to color, self-drilling screws are as follows.

- Silver - these screws are suitable for any climatic conditions. Resists the onset of corrosion. Suitable for work both indoors and outdoors.

- Yellow - covered with a protective zinc coating with an admixture of copper. Applicable only for interior work.

- Black - contain an oxide film. Such self-tapping screws are not suitable in rooms with a high percentage of humidity, for example, in saunas and greenhouses, it is undesirable to use such fasteners.

When tightening self-tapping screws with a conventional drill, it is important to choose a drill, taking into account the following recommendations:

- the drill should be a couple of millimeters smaller than the self-tapping screw;

- when using a hammer tool, it is better to purchase a drill that has grooves on the clamping part of the drill;

- when drilling, you can use a universal brick drill bit for a drill.

You will learn more about concrete drills in the video.

Dowel for aerated concrete - scope

New settlers who buy an apartment in a modern new building have bare walls at their disposal, which require finishing. But, on the one hand, this is even good, because by carrying out finishing work on your own, you will know almost every corner of your apartment, accordingly, you will get acquainted with the materials from which it is made. Today, due to the fact that foam concrete is quite cheap, plus everything, it has a low weight, in new buildings it is used for the construction of partitions, and this is where the new settler gets on the underwater rock.

If you do not know this, then when installing, for example, a TV on the wall, you will face difficulties when you start mounting the bracket. Well, if you know what material you will be installing in, in our case it is a porous base, it is enough to have a dowel for foam concrete, and the installation will take place, as they say, without a hitch. The same problems may arise in your kitchen, as a rule, the bathroom and kitchen partition have a common wall, and this wall is made of soft porous material. In this case, you also need to use such a universal mount.

During repairs, builders use such a fastener almost everywhere they encounter porous substrates. With this dowel, suspended plasterboard ceiling frames, door frames, metal frames on the walls are mounted, the list goes on and on.But I also want to note that, according to its technical data, such a mount can withstand a load weighing 40 kilograms, and this is not the limit.

Information! Technical documentation on the use of such a mount recommends, if you have a fairly heavy structure, to increase the number of fasteners and reduce the distance between them to 10 millimeters.

Expert advice

Before deciding how to drill concrete walls and getting started, you should pay attention to the following recommendations:

- if the hole diameter exceeds 12 mm and the depth is 10-11 cm, it is better to use a hammer drill or a hybrid device (drill-hammer drill);

- if holes are made for plastic dowels, the depth should be 7-10 mm greater than the size of the fastening element, since concrete dust and small particles of stone remain inside;

- it is recommended to start work at low speeds so that the nozzle does not move due to the increased torque, and the impact mode is turned on when the drill passes 2-4 mm in depth;

- the dust generated during the drilling process can be removed with a vacuum cleaner, it is advisable to do this in the process, periodically stopping the drill and cleaning the hole from concrete particles;

- it is imperative to observe safety precautions during work: it is required to wear gloves to eliminate the risk of sliding of the handle and safety glasses so that the crumb does not get into the eyes and does not damage the mucous membrane.

Dowel Drill Size Chart

In most cases, a concrete wall is drilled with a perforator, dispensing with a drill. If, as part of the repair, you need to make no more than 15-20 holes or the wall is made of foam concrete, using a drill is the best choice that will save time and money.

Before punching a hole, you need to make sure that there is no wiring in this place, and check whether the nozzle is suitable for such work (the duration and efficiency of work depends on which drill the drill is equipped with)

When deciding how to drill the wall, you should pay attention to the victorious crowns: with such a drill using a drill, you can easily punch a hole up to 10-12 cm deep

Which one is better to use?

Which type of dowel fasteners is best suited for certain works, it can be difficult to determine, first of all, due to the enormous variety. When purchasing a dowel, of course, it is always advisable to consult the store so that you do not have to go to the store again. Let's try to give general recommendations. For solid bricks, almost the same dowels are suitable as recommended for concrete. If the walls are made of this kind of material, you might say you're in luck. Most universal anchors will work fine. Even heavy and bulky items can be securely fixed, not to mention shelves and cabinets.

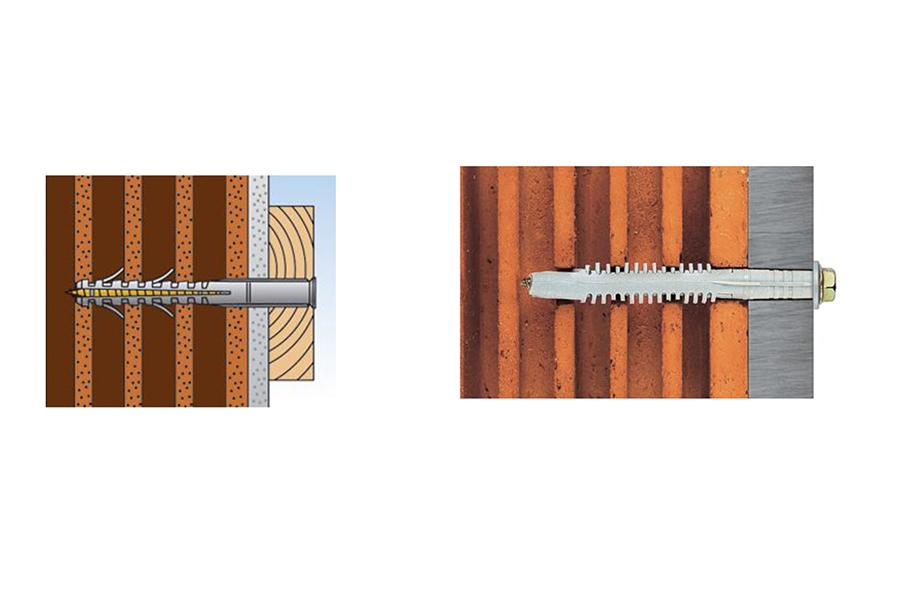

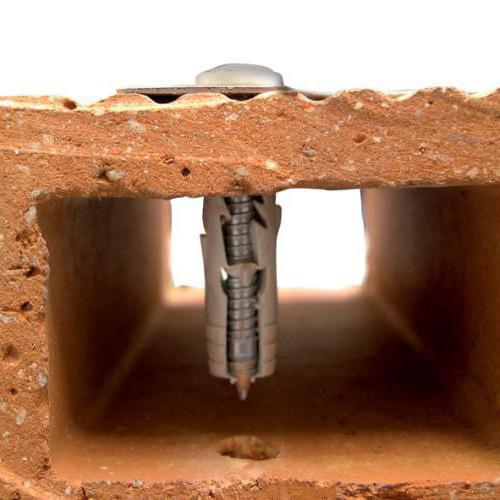

It is quite another matter if the brick is hollow. For hollow bricks, most universal dowels are completely unsuitable. It is dangerous to hammer a nail dowel into such a wall, as this can cause the formation of cracks not only on the surface, but also in the partitions inside the brick, in this case it will be simply impossible to fix anything in the same place, and the hole in the wall will have to be repaired.

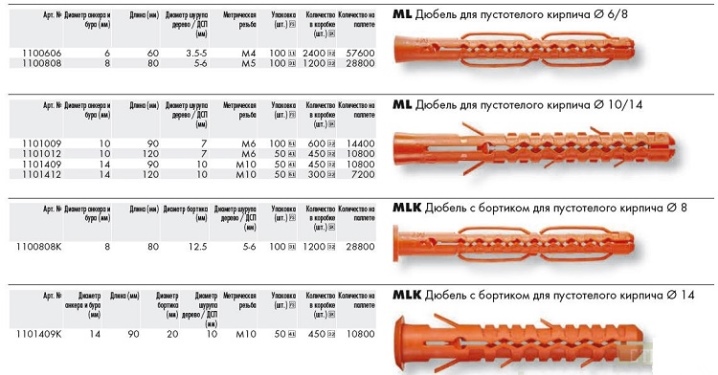

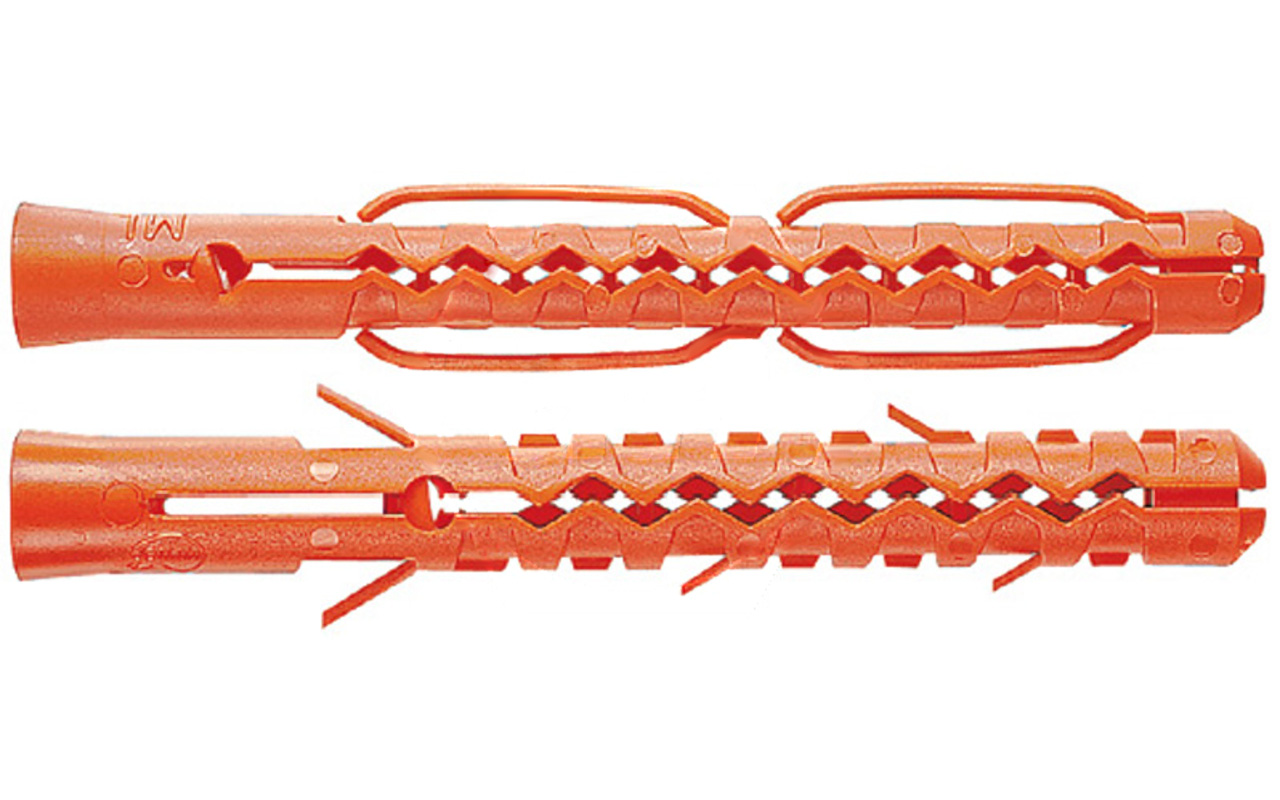

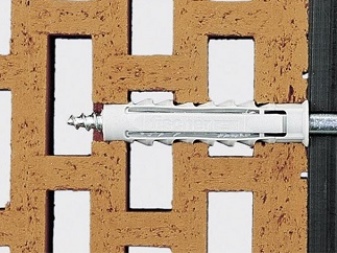

For slotted and hollow bricks, special plastic dowels are required, which roll up into a knot, or metal anchors with petals resting against the partition from the inside

Work with such consumables should be very careful, since, unlike a solid brick, which has voids, as a rule, it is more fragile. A facing brick, combining strength with some decorativeness, requires special care.

The appearance of chips and cracks in this case is simply unacceptable.

It is also important to remember that such a brick usually has voids to reduce its weight, which greatly limits the use of some anchors and dowel-nails.

For facing porous bricks, elongated plastic dowels are most preferable, during the installation process they form complex nodes that can reliably fix them in the voids of such structures. Fasteners for red and silicate bricks are somewhat different. Red is usually softer, and there is a danger of twisting the dowel in the hole if the diameter of the drill is incorrect or during the drilling process the master could not withstand the perpendicular and the hole turned out a little larger.

About dowels

The dowel is a fastening element designed for fastening various building structures, insulation, cladding materials to the surface of various types of walls. Dowels are used when the free end of the rod (screw, anchor) is not accessible for the installation tool. The dowel is driven into the wall or the main part, a screw is screwed into it, while the dowel expands and it is impossible to remove it. Today the dowel is a versatile and popular fastener.

Dowels come in various designs and are made from different materials.

All dowels can be conditionally divided into two groups:

1. Dowels for monolithic (without voids) bases - have a spacer principle of operation.

2. Dowels for hollow bases - have an anchor principle of operation.

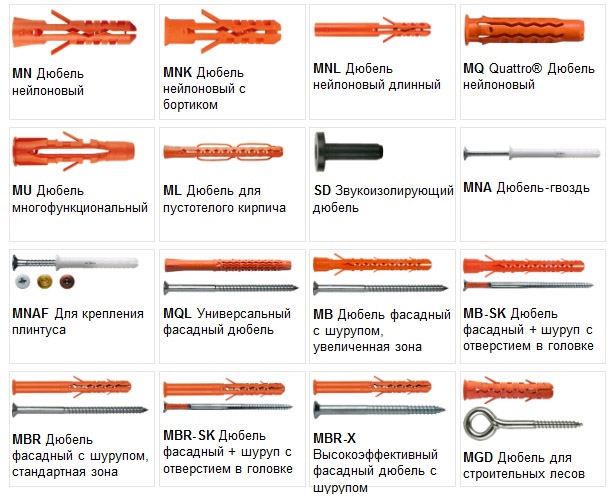

Dowel classification:

Standard nylon plugs: The plugs fit any wall and can be used with screws from 2 to 16 mm in diameter.

A hole is drilled in the wall, corresponding to the diameter of the dowel, in which it is held by the antennae directed backwards, and when wedged with a screw, it is "firmly" pressed into the walls of the hole with its large teeth.

Dowels for aerated concrete: A hole is drilled for such a dowel, corresponding to the diameter of its core. It is driven into the hole with hammer blows, and at the base it is held by spiral ribs and wedging under the action of a screw.

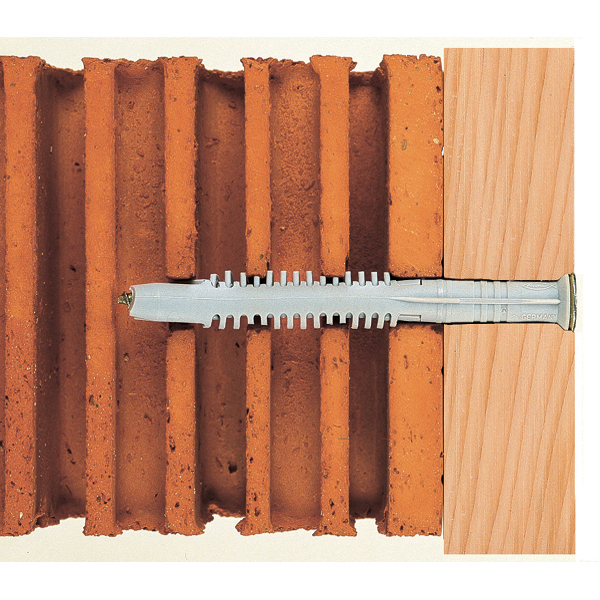

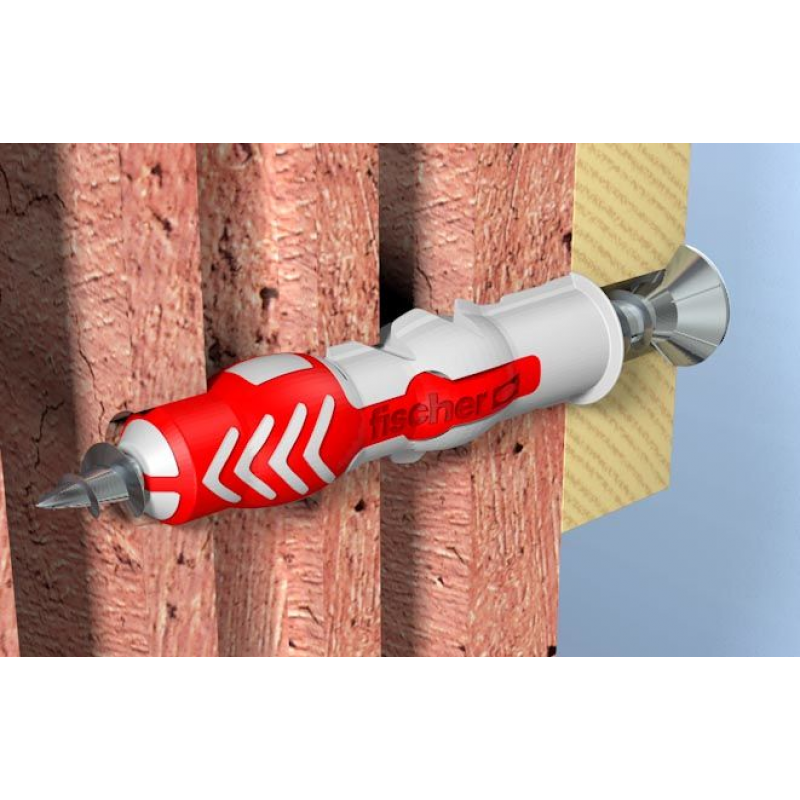

Frame dowels: 60 to 360 mm long. There are two main types - for solid solid substrates and for soft and hollow (slotted) materials. The elongated spacer part ensures that the dowel engages several lintels in the base with voids at once. They are used for fastening window and door frames, as well as cladding elements through a layer of plaster, thermal insulation.

Distance dowels (adjustment): fix the battens under the sheathing at some distance from the wall. They allow you to adjust the position of the battens of the lathing relative to the base in the range from 0 to 30 mm during their installation due to a dowel and a screw of a special design divided into two parts (one for the base, the other for the rail).

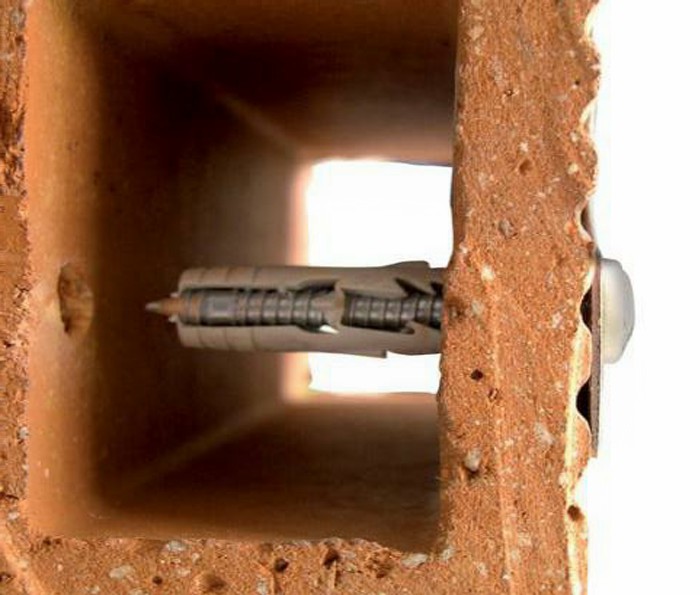

Universal: when fixing objects to a hollow base, they "determine" the presence of a hollow space. In the cavity, the dowel bulges out and is thus fixed in it. When attached to a solid brick or concrete base, it, unclenching, comes into close contact with the walls of the hole. Dowels with spring-loaded flap bars: for attaching objects to hollow partitions and false ceilings, for example, for hanging chandeliers. The dowel strips, passing through the hole into the cavity behind the casing, open under the action of the spring and abut against the inner surface of the casing.

Metal: for thin-walled hollow structures, they are able to withstand rather heavy loads.

When the screw is screwed in, the dowel plates bulge in all directions and press against the inner supporting surface.

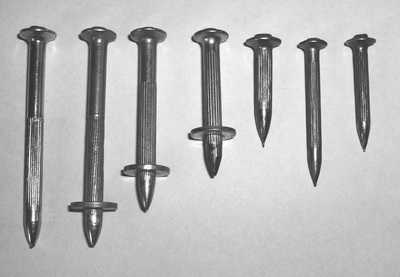

Nail dowels: designed for quick fixing of skirting boards, battens under the sheathing, when you need to install a large number of them. They are completed with a nail with a "finish" (knurling in the form of inverse cones). The dowel with a nail is inserted into the hole in the wall through the fastened rail. The nail is driven in with a hammer.

Insulation holders: for attaching mineral wool or hard foam insulation.A hole in a concrete or brick wall is hammered into a hole without a nail or screw.

Dowels for concrete and solid bricks: designed for large (up to several tons) loads, made of metal and completed with threaded rods or bolts. Suitable for attaching sunshades, garage doors or hoists. Plastic and metal: for soft materials (drywall and aerated concrete).

How is the timber fastened to the brick wall?

The set of tools is determined by the type of fastening and the functionality of the wooden elements. When attaching a bar you need:

- drill or hammer drill;

- drills and drills;

- hammer;

- roulette;

- pencil;

- dowels;

- corners;

- staples;

- nails;

- screws;

- screws, etc.

Soft method

This method is easy and quick to work with, but unreliable - it will not work for heavy loads. But for decoration and lathing it is used. This method can be used without the help of outsiders, as it does not require building skills. If you follow the instructions, the result will be satisfactory.

U-shaped metal brackets are needed to complete the fasteners. They are fixed on a brick with a distance of 40 cm. At a level of half a meter from the floor, an indent of 60 cm is made between them. The more fasteners, the more firmly the board holds. This will avoid deformation of the cladding. Under mechanical stress, the timber looses, and the structure is broken

Therefore, be careful when working.

When building a house or carrying out repair work, there is often a need in it, in which it is necessary to fasten the timber to a brick wall. In most situations, it carries a rather heavy load, in the rest it serves only as a frame element on which you can attach the cladding material.

Fastening the timber to the wall

During the construction of a house or its repair, a situation often arises when it is necessary to fasten the timber to a brick wall. In one case, it must carry a fairly serious load, in the other, it must serve only as a frame, where some kind of facing material is attached, for example, siding outside the building or drywall inside. For those who know the technology of installation, attaching a timber beam to brickwork will not be a big problem.

The brick should be drilled carefully, strictly at right angles, without "loosening" the drill, so as not to split the brick. Splitting can cause brick to shatter

if a brick enters the cavity, you will have to use an anchor-type dowel, which, when screwed into the wall, forms a knot, or an expansion dowel.

For concrete, you need a drill with a perforator function and strong plastic dowels for self-tapping screws, sometimes it is additionally lubricated with glue before driving the plastic dowel into the wall.

In the process of performing various construction works, there is often a need to fix the timber on a brick wall. For inexperienced craftsmen, this task often raises a number of questions. Therefore, in this article, we will look at how to fix a wooden block to a brick wall, as well as some other wooden parts.

How to twist

Screws for lightweight and heavyweight concrete are no different. Self-tapping screws are used without a dowel. The dowel is fastened after pre-drilling the hole. Retention in the base takes place according to the principle of an anchor screw. Then, through the part, it is screwed into the prepared hole. With notches for countersinking, the self-tapping screw firmly adheres to the part, due to the frictional force it additionally holds it and dampens vibrations.

It is important to use the self-tapping screw correctly, as you can easily break it off. It is required to screw in a screw with a non-countersunk head with a certain effort, since due to high loads during tightening it can be broken by simply overtightening

The risk of head breakage is also associated with the high heating temperature of the self-tapping screw body when screwing into concrete.

The order of twisting the dowel:

- Fastening of window and frame structures is carried out by at least two people.

- Level the structure to be reinforced and fix it.

- Transfer the installation dimensions to the hole drilling plane.

- Remove the structure and drill holes.

- Re-install the structure and screw the screw through the structure into the prepared hole.

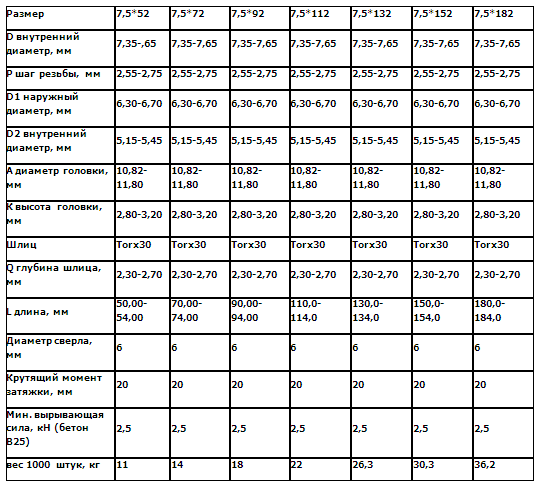

Table 1. Standard dimensions for pre-drilled concrete screws.

Pricing

The price of screws for concrete is almost the same everywhere. The product is valuable: a pack of self-tapping screws for 100 pcs costs from 250 to 550 rubles, the price is influenced by the size of the screw in length. Many suppliers offer to buy self-tapping screws for concrete: the popularity of the dowel among "windows" and "door doors" has not passed for the last 10 years. Installation organizations (electricians, plumbers) and construction firms also do not hesitate to use this product. Turboscrews for monolithic construction projects are being purchased in large quantities. The main sold-out sizes are 7.5 * 112, 7.5 * 132, 7.5 * 152.7.5 * 202.

Due to its popularity, it is produced both in the Russian Federation (according to GOST 9012-59) and imported in large quantities from Europe and China.

Types of chemical dowels and installation methods

Compositions-adhesives are usually two-component. They are prepared immediately before installation work. Often, this composition can be bought either in ampoules for a certain diameter and length of the hole, or in special cartridges and other packages. This package consists of two compartments. One contains the glue itself, the other contains a hardener. In the process of installation work, an ampoule is inserted into the prepared holes, and then a mounting metal rod - it will crush the package with glue. Then polymerization will begin, which will provide the connection with the necessary strength. Installation using cartridges is performed by squeezing out the glue and hardener composition in the required proportions, mixing the substances. Then the resulting mixture is pumped into the hole. Construction professionals speak very positively about these products. There is nothing easier than fixing the dowel in a hollow brick, porous ceramic block or in aerated concrete. In addition, specialists install a perforated sleeve in such structures. It prevents strong leakage of glue into the voids of the building material. The joint created in this way has high strength and reliability. There are no analogues today.

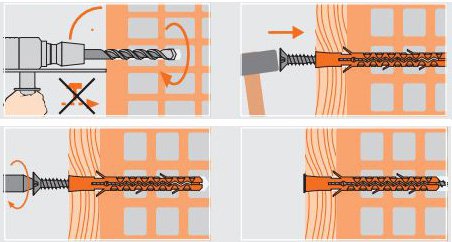

How to drive a nail dowel

In order to fix technological and decorative elements on concrete and brick surfaces during repair work, in many cases, dowel-nails are used, in other cases, ordinary self-tapping screws can be used. Due to their high frictional force, they provide a high degree of connection reliability. Driving in the dowel-nail can be carried out by performing only preliminary preparation of the mounting hole for it.

To drive a dowel-nail, you will need a dowel-nail, a drill for concrete, pliers, a hammer, a hammer drill or a drill.

You need to select and prepare all the necessary tools that you will use in order to hammer in the dowel nails. If the work will be carried out on concrete, you can use a hammer drill or electric drill with a bump stop. If you intend to hammer dowels into a brick surface, you can use a hand drill or a rotary wheel. For both cases, you will need a concrete drill. It must have a diameter (stuffed on the shank) corresponding to the same parameters of the dowel, the length of the working part (where there is a groove) must be at least five mm longer than the full length of the dowel. In addition, you need to prepare a center punch with a hammer.

You must choose the place where the dowel-nail will be driven in.Check if the wall (floor, ceiling) is thick enough for you so that it does not pierce through during drilling. You must make sure that there is no electrical wiring in this place hidden in the grooves and channels located inside the boards. When drilling a concrete surface, you need to try to choose a place in such a way that it does not hit the metal reinforcement. When working with brick structures, you need to avoid the cement areas of the masonry, so the dowel will not hold so well here. You need to mark the selected place.

Drill the dowel hole. To prevent the drill from moving away from the intended location at the beginning of drilling (especially when working with a hammer drill or concrete drill), you need to knock out a small hole in the surface using a center punch and hammer. Next, you need to place a drill in it and start working at low speeds. After deepening the drill by 5 mm, you can increase the rotational speed of the drill. Be careful when drilling bricks, do not use the chipper mode.

Next, you need to hammer in the dowel-nail, but before that you need to get rid of the dust accumulated in the mounting hole. Next, you need to insert the end of the dowel there and, using light hammer blows, hammer it to its full length. If the dowel is damaged during the driving process, you need to remove it using pliers and use a new one. If you need to attach heat-insulating materials, then for this there is a special dowel for thermal insulation.

Construction of energy facilities

Construction of energy facilities  Construction of the substation "Kutuzovskaya"

Construction of the substation "Kutuzovskaya"  Sitemap: 1, 2, 3, 4, 5

Sitemap: 1, 2, 3, 4, 5

Classic dowels for concrete surfaces

Naturally, the dowel fasteners of various objects on concrete must be of high quality. The classic option is a plastic sleeve with notches along the length and the so-called "whiskers" used to prevent the fasteners from turning through the hole. The main element of such a fastening is a special rod, which contributes to the strength of the fastening in the wall, because when using it, the sleeve expands in the mounting hole. The classic mount is also fairly easy to dismantle. The notches on the rod make it easier to unscrew with a screwdriver.

Varieties of chemical anchors

Such a dowel consists of special adhesives and a metal insert. This is a bushing, inside of which the thread is cut. Also, the structure includes a hairpin and a reinforcing bar. This element is made of various grades of stainless or galvanized steel. The process of joining with fasteners of this type is carried out due to a special chemical composition - according to its characteristics, it is glue. It must be stuffed into a pre-drilled hole. And then, through the polymerization process, a strong bond between the hollow brick and this connector will be ensured.

Things to remember when installing anchor systems

Everything that used to be fastened to the walls with nails, screws, screws and bolts, today they are mounted using anchor systems. Brick wall anchors are the most reliable way to hang, connect any elements or objects to the brickwork. But in order for the fasteners to be durable, one must not forget about a number of rules.

You cannot use a puncher to make holes in the brick, since this material is quite fragile. Under the influence of impacts from a hammer drill, it can crumble and crack. In this case, you will need to make a new hole.

Anchor holes must not be drilled into brickwork seams. Cement mortar, due to the presence of sand in it, has a lower strength than brick. The mount, especially if the load on it is large, can fall out over time, and the consequences can be unpredictable.

The holes in the wall must be perfectly horizontal.Even a slight downward slope reduces the pull-out resistance of the fastener.

When installing a driven structure, you should not hit the metal with a hammer; it is better to put a piece of wood so as not to damage the thread edge.

Before screwing in the bolt, clean the inner surface of the sleeve so as not to damage the threads.

Observing these rules, you can firmly and reliably mount a visor above the entrance, a sports wall for your son, shelves for flowers and books, or any other items necessary in a house or apartment.