What is the main advantage of self-tapping screws

Many builders still compare professional fasteners and old Russian slate nails.

Of course, slate nails are a time-tested reliable and inexpensive material for roof fastening. They differ from ordinary nails in galvanizing, rubber gasket and a fairly wide washer.

This is where the advantages of slate nails end.

Also, for a nail, unlike a self-tapping screw, you must first drill a roofing material in which it will not hold so firmly in any case, and most importantly, a slate nail is categorically not suitable when working with metal.

In addition, in the manufacture of slate nails, steel is used, which is much lower in quality than the option used in the manufacture of a marked self-tapping screw.

Parameters for choosing a dowel for a self-tapping screw

For reliable fastening, you should choose the dowel for the self-tapping screw accurately and correctly. It is necessary to take into account the dimensions of the self-tapping screw and dowel, as well as the thickness of the product to be fixed. If the diameter of the screw exceeds the diameter of the dowel, the screw will break the dowel. If, on the contrary, the diameter of the dowel is greater than the diameter of the self-tapping screw, the spacers will not open completely and the fastening will not be strong enough. The same will happen if the screw is shorter in length than the dowel used.

The choice of a dowel must begin with its dimensional characteristics. Larger dowels are able to withstand heavy loads. Dowels of various diameters are designed for a certain load:

· 5 mm - low load;

· 6−8 mm - medium load;

10-12 mm - heavy load;

· 14 mm and more - very heavy load.

In addition to the dimensional characteristics, you need to know the density of the material in which the dowel is fixed. Dowels of the same size withstand heavy loads in denser materials. Also, the dowel is selected by type depending on the purpose of use and the structures to be fixed.

What is a screw, screw, self-tapping screw, bolt, washer and nut, what does it look like, what is it for?

Washer is a fastener that is auxiliary and is placed under the nut head. The main purpose of such a product is to increase the pressure area, as well as prevent the destruction of other fasteners. In addition, the washer prevents the fastener from loosening and makes it more resistant to all kinds of mechanical stress.

Washer

A screw is a fastening element, which is a type of screw, differs from it in that it has a thick rod, an external thread, and a pointed tip. This makes it easier and easier to enter a hard surface. Namely, in wood or concrete. Most often, special holes are made for the screws, which are filled with a relatively soft material. This is usually a tree.

Screw

A screw is also a fastener, a type of which is a self-tapping screw or screw. The main feature of the fastener is that it is a rod with an external thread and a large enough head for screwing in. Most often, special holes are made on the head so that the screws can be tightened with a screwdriver. Or they make special notches to screw in products with a special wrench.

Screw

A bolt is a fastener that is a cylinder with a sufficiently tall hex head. Most often it works together with a nut in pairs, and is used to connect some parts.

Bolt

Nut - a fastener, inside which there is a thread, is used in a set with a screw or bolt. Usually the nuts are made in a hexagonal shape so that they can be fastened with a wrench.

screw

Fastening to an unreliable surface

Modern homes have many surfaces made from materials that are not very durable. These include drywall, old bricks, wood planks, or pressed sawdust slabs. When working with them, it is better to use nylon fasteners with a diameter of more than 10 mm, the installation depth should not be less than 6 cm. It is better to choose a bit smaller in size.

The drilling process must be shock-free, as excessive stress can damage the surface. Using the impact mode may not leave visible damage, but the internal structure of the wall may suffer. If the drill diameter is too large, the fasteners will move freely in the hole, gradually increasing its diameter, especially if the work was carried out with aerated concrete.

For plasterboard walls, it is not necessary to use a drill of a smaller diameter, the main thing is not to press on the drill and do not use the impact mode. Drywall is a very delicate material, even a small load can lead to the destruction of a section of the wall. The hole should be drilled with light force to match the size of the plastic dowel with a self-tapping screw.

It should be understood that it is not necessary to attach heavy structures to such surfaces, even if the material initially copes with the load, over time, under heavy weight, collapse may occur.

If you take into account the material from which the wall is made, choose the right dowel and drill for it, and also having a quality tool on hand, you can make a high-quality installation, and not worry about the safety of your furniture or household appliances. Observing the recommendations, even an inexperienced master will cope with such an installation.

If you find an error, please select a piece of text and press Ctrl + Enter.

Peculiarities

The dowel screw is a fastener for structures, which has special antennae for fixing to the surface. When spaced with a screw or screw, a frictional force arises, which holds the dowel in the structure and prevents it from turning. Dowels are made from different materials, they can have different weights and sizes. Depending on the material of manufacture, self-tapping screws have their own characteristics. For example, polypropylene products do not withstand low temperatures. They are not recommended for outdoor use. Nylon elements are versatile. They can be used both outdoors and indoors.

The dowel can be with a retaining collar. The screw is made from nylon and is used for external installation work. Its peculiarity lies in special stoppers. They do not allow the self-tapping screw to fall into the hole.

Self-tapping screws without a collar also have their own distinctive feature. The product is made of polyamide, and it has a through hole with longitudinal ribs and a non-expansion top. The structure of the product makes screwing in the screw much easier and increases the expansion force. The unbreakable top protects the surface from cracking due to its immobility.

It is also worth noting that these dowels are weather-resistant. They can be used for outdoor facade work. There are types of dowels for a construction gun. The products are practical, efficient and securely fix parts to the surface.

All fasteners are manufactured in accordance with GOST. Some specifications are subject to change. These include weight, diameter, length, structure. But the basic rules must be strictly adhered to. Manufacturers strictly adhere to the following GOST standards:

- material of manufacture;

- min and max are the curvature index of the rod;

- protection from a galvanized layer - galvanizing is carried out in compliance with the rules of galvanizing and passivated technology (coating thickness - 6 microns);

- diameter of washer and metal rod.

It is worth familiarizing yourself with the numerous types of products and their properties.

Technique for fixing corrugated board using self-tapping screws

When planning the use of a profiled sheet, it is necessary to take a responsible attitude to the selection of the necessary material and the calculation of the fastening scheme. Having made the crate or frame according to the recommendations, you can proceed with the installation.

Materials and tools

- Profiled sheet - it is advisable to buy immediately the desired length, they produce a profiled sheet up to 12 m long. Select metal thickness and wave height based on strength recommendations. The number of sheets is rounded up, taking into account the side overlaps between the sheets of 8 cm and vertical 20 cm.

- Self-tapping screws - roofing or with a press washer, depending on the requirements for waterproofing, for metal or wood, depending on the material of the lathing / frame.

- Screwdriver or drill with a bit for hexagonal heads. For thin sheets, a wrench can be used.

- Roulette, pencil.

- Hacksaw, scissors for metal. The grinder can only be used for low-quality work with the subsequent full painting of the coating.

- Cord, level.

Sequence of work

Calculation, selection and delivery of the necessary materials. The professional sheet must be bought on special pallets and carefully unloaded to avoid damage to the protective layer.

Installation of lathing for roofs or walls, a frame for a fence, according to strength requirements. The vertical beams should fall on the side overlaps of the sheets.

For wall cladding - installation of heat-insulating material.

Stretch the cord horizontally to align the bottom edge of the profiled sheet.

Installation of the first block of three sheets in a side overlap by one wave. Installation is carried out starting from the bottom extreme sheet, the side is selected based on the convenience of the installers

The sheets are carefully attached first to 1 self-tapping screw, after carefully aligning the block - completely.

Subsequent fastening of the profiled sheet along the entire length of the structure. Fasteners are made in each lower part of the wave along the lower and upper purlins, and through one wave along the rest of the surface

The self-tapping screw must be screwed strictly perpendicular to the surface.

If the length of the sheet is not enough, additional rows of the profiled sheet are mounted with an overlap from above. The size of the overlap is 20 cm, if there is no lathing under the overlap - the sheets are fastened together with rivets in each wave, if necessary, the overlap is treated with a sealant.

Cutting and installation of edge sheets or sheets with technological holes. Fastening the sheet with self-tapping screws to a continuous horizontal crate for such zones should be carried out in each wave, to the vertical - in increments of 30 cm.

Installation of additional elements, the step between the fasteners is 30 cm.

Checking the structure for scratches, treating problem areas with an anti-corrosion solution or paint.

Fastening self-tapping screws

Before considering some of the nuances of fastening the roofing material with self-tapping screws, you should return to a more detailed examination of the sealing washer. The combined washer significantly affects the quality of the roof fasteners, which in turn significantly increases the trouble-free service life of the entire structure.

When choosing self-tapping screws, it is necessary to pay special attention to the quality of the cushioning material, which is vulcanized rubber. Too porous or, on the contrary, rigid structure indicates a poor-quality performance of the fastening element and will not provide sufficient cushioning of the roofing material under wind loads

Also, failure of the rubber gasket will irreversibly lead to leakage of the roof in the places of its attachment with self-tapping screws.

The size of the hardware is of no small importance. When choosing self-tapping screws in length, it should be borne in mind that after full twisting, they must enter the body of the wooden lathing by at least 45 mm

And the length of the self-tapping screw that extends beyond the metal profile should be at least 5 mm, excluding the drilling part.

For installation of the roof, it is recommended to use a screwdriver with a speed control function. For drilling holes it is recommended to use a higher speed, and for threading in a metal profile, a lower rotor speed of the apparatus.

Particular attention must be paid to the screwing force of the hardware. An insufficiently tightly twisted self-tapping screw will not ensure proper pressing of the material to the crate, which can lead to its tears

On the contrary, too overtightened hardware will simply crush the cushioning material on the washer, destroying its structure, with the logical consequences that follow.

Also, when screwing in the fasteners, strict perpendicularity should be observed with respect to the cross-section of the lathing. That is, the angle between the screw and the roof plane should be 90 degrees. The slightest distortions will also lead to unfortunate consequences in the form of roof leakage and material breakage under wind loads.

Why do you need special screws for corrugated board?

- The absence of a wide washer will lead to rapid wear of the corrugated board at the attachment point under the influence of variable loads, this can lead to separation and complete failure of the corrugated sheet.

- Simple screws do not hold well in a thin metal base, this leads to the impossibility of mounting a profiled sheet on a metal profile structure.

- The corrugated board is treated over the entire surface with protective coatings; when screwing in the fasteners, their local destruction occurs, the place of which must be sealed with an elastic gasket.

- The screws need to be pre-drilled, this reduces the strength of the joint and doubles the workload.

How to choose a screw for a dowel

December 10, 2017

The dowel and the self-tapping screw are two complementary elements, if the task is to connect some kind of rigid structure to a solid solid wall: concrete, brick, assembled from foam blocks, finished with plasterboard. If the wall were wooden, then you can do without a dowel, because the screws are easily screwed into soft wood, where they are firmly fixed. The selection of one to the other is based on the dimensions: the length and diameter of the self-tapping screw and the length and inner diameter of the dowel. It will also be necessary to take into account the thickness of the material to be bonded.

The situation when the wrong choice is made is not common, but such cases are known. If the sampling was done incorrectly, for example, the inner diameter of the dowel was chosen less than the diameter of the self-tapping screw, then the latter simply breaks the first one. If everything was done the other way around, then the fasteners will dangle inside the plastic insert, while it will not open up, which will sharply decrease the strength of the fastener. The same can be said if the end of the self-tapping screw does not reach the bottom of the dowel.

In general, you need to approach the selection process correctly. And for this you need to start with the dowel. The larger it is, the more loads it can withstand. Here, the loads are distributed in this way relative to the size of the plastic insert.

- If the loads are small, then a dowel with a diameter of 4-5 mm can be used.

- If the loads are medium, then it is better to choose an insert with a diameter of 6-8 mm.

- For heavy loads, a size of 10-12 mm is suitable.

-

For very large ones - 14-16 mm.

For example, when scaffolding is being assembled.

But here it is imperative to take into account the density of the material where the fasteners will be inserted. The higher the density, the more loads the mount will withstand. Therefore, dowels with self-tapping screws inserted into concrete products withstand the greatest loads with their insignificant dimensions.

So, the dowel is selected in size, now the self-tapping screw is also matched to it. Here are just a few of the ratios.

| Dowel diameter, mm | Self-tapping screw diameter, mm |

| 4 | 2 |

| 5 | 2-3 |

| 6 | 3,5-4,5 |

| 10 | 5,5-6,5 |

| 14 | 8,5-10,5 |

| 16 | 10,5-12,5 |

Now you need to choose the lengths to each other. The length of the dowel is selected according to its diameter. The main thing here is not to be mistaken, because according to the standards several lengths are suitable for one diameter.For example, a dowel with a diameter of 6 mm can be from 25 to 50 mm in length with a graduation of 5 mm.

As for the length of the self-tapping screw, it depends on the length of the dowel and the thickness of the material to be attached. In this case, it is taken into account that the thickness of the material to be attached depends on the density of the base to which it is attached. If the fastening is made on a loose surface, then the thickness of the material to be attached should not exceed the length of the dowel by 35%. If the base is dense, then the thickness should not exceed 60% of the dowel length. It is necessary to drill a hole in the supporting structure a little more than the length of the dowel, and the self-tapping screw can be screwed in to the end. Even if its end pierces the insert, it's okay.

Determination of the required number of fasteners and their dimensions

High-quality self-tapping screws are a rather expensive material, so it is worth calculating everything before buying them.

It is important not only the number, but also the necessary parameters of the screws. The length of the self-tapping screw must exceed the total thickness of the profiled sheet and the base by at least 3 mm

When fastening to metal, it is worth giving preference to self-tapping screws of a larger diameter - 5.5, 6.3 mm. The calculation of the required number of fasteners has some peculiarities depending on the place of installation.

To fasten the corrugated board to the fence:

- each sheet with a width of 1.1 m is attached to 10 - 15 self-tapping screws, depending on the number of lags - horizontal bars between the posts, 6 self-tapping screws in 1 lag;

- the extreme screws are screwed into the overlaps and fasten 2 sheets, which means that 8 - 12 screws are needed per sheet;

- to count the number of sheets, you need to take the length of the fence and divide by the width of the sheet without overlap, for a standard 118 cm sheet, this length will be 110 cm;

- the number of lags is calculated based on the height of the fence. The lower log is attached at a distance of 30 cm from the ground, the upper one - at a distance of 10 cm from the upper edge of the sheet, if the gap between them exceeds 1.6 m, it is recommended to add another horizontal bar in the center.

For fixing the corrugated board to the roof:

- two types of self-tapping screws are used: short ones for screwing sheets to the crate, long ones for attaching additional elements;

- short self-tapping screws are calculated based on the roof area, 9 pieces per square meter will provide the necessary supply of fasteners based on the horizontal lathing with a step of 0.5 meters and fixing the 1st profiled sheet 1.1 meters wide by 3 self-tapping screws to each lathing bar;

- depending on the material, a larger pitch of the lathing is possible (no more than 0.8 meters) and a proportionally lower consumption of self-tapping screws;

- the remaining screws are used to strengthen the edges of the roofing surface;

- long self-tapping screws are calculated by dividing the length in meters of each additional element by the installation step of fasteners - 0.3 m, and rounding up.

For work with facades and buildings:

- the calculation of self-tapping screws is made approximately, similar to the roofing one for each lathing transverse beam, 3 screws per sheet;

- transverse lathing can be performed in increments from 0.5 to 1 meter, depending on the material and strength requirements;

- the longitudinal lathing is performed with a step of 1.1 meters, if the step of the transverse bar exceeds 0.8 meters, then 1 additional fastener must be installed in each span in the center;

- windows, doors, corners of the building along the contour need additional fastening with a step of 0.3 m.

How many screws are there per sheet of corrugated board - calculation by weight and per 1 square meter of coverage:

- on average, for each square meter of coverage, it takes from 6 - 7 self-tapping screws for a fence, up to 8 - 9 for roofs;

- when buying self-tapping screws, you should not calculate everything to pieces, a small stock will come in handy in case of marriage or accidental damage;

- self-tapping screws are sold in packages with the indicated weight, if their approximately required number is calculated, it is enough just to weigh the required amount of material.

Tip 1: How to choose a dowel

d .:

The KMG dowel performs anchoring in aerated concrete and other materials:

The aerated concrete dowel provides a strong hold with this porous material:

Dowel "Driva" is designed for fixing various fixtures on drywall with a thickness of at least 9 mm:

The "Butterfly" dowel is a special dowel designed for fastening to drywall, gypsum board, chipboard and other building materials with a thickness of 10 - 12 mm:

All these dowels are tightly attached to the wall due to their special design, which provides for a spacer part in it, the diameter of which is less than a properly selected self-tapping screw.

Therefore, when the self-tapping screw is screwed into the dowel, the spacer part expands, forming a strong, reliable connection with the wall.

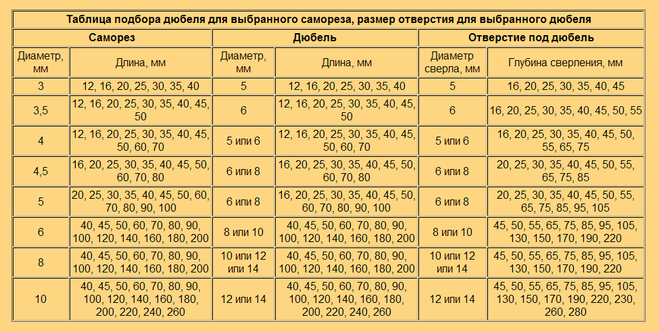

Below you can see a table that will help you choose the right screws and dowels in accordance with their length and diameter. Also in this table there is data on the diameter of the drills and the depth of drilling in each case.

To select a self-tapping screw for a dowel, you need to pay attention to two parameters:

- screw length

- screw thickness

The length should be such that the self-tapping screw, when fully screwed into the dowel, has a protrusion from the self-tapping screw by a few millimeters (3-7) less than the thickness of the material, which must be fixed taking into account the fasteners you need (flush, flush or other)

The thickness of the self-tapping screw should be such that the working surface of the dowel diverges in width, but the self-tapping screw itself, meanwhile, was spinning with a certain slight effort to the very end without applying a large force.

Also, pay attention to the thread itself, it should be just such that it can be screwed tightly into the dowel, since the self-tapping screw can be pulled out of the dowel. For fastening various building materials to building structures in modern construction, fastening with a dowel and a self-tapping screw is often used

For fastening various building materials to building structures in modern construction, fastening with a dowel and a self-tapping screw is often used.

A self-tapping screw is selected for the dowel of a certain diameter, which, with a slight stretch, enters the inner hole of the dowel, that is, the self-tapping screw should be smaller in diameter than the outer diameter of the dowel, by about 1.5 - 2 mm, and must be equal to the inner diameter of the dowel hole.

The length of the self-tapping screw should be equal to or slightly more, up to about 5 mm, the length of the dowel.

The hole for the dowel is drilled with the same diameter as the dowel you are using.

The depth of the hole is 5-6 mm longer than the dowel, so that the self-tapping screw can be screwed into the dowel completely, and not rest against its tip, in the hole, in the building structure. Good luck.

More questions on your topic:

leave a comment