How to mount on unstable surfaces

Very often it becomes necessary to fasten objects on unreliable surfaces, which include plasterboard walls, building structures in old brick houses, etc. When fastening on such surfaces, the following recommendations should be followed.

- It is better to choose dowel elements from nylon, while their diameter should be 10–12 mm. The diameter of the winning drill, with which the hole for the fastener will be made, must be 2 mm smaller than the transverse dimension of the selected dowel.

- Drilling must be performed in one step, without changing the drill, and the impact mode should not be used in order not to destroy the walls of the hole being formed.

Securing items to plasterboard walls with a butterfly dowel

To perform reliable fasteners, it is important to take into account the condition of the surfaces, choose the right cutting tool and competently carry out the drilling process itself

Important parameters that should also be taken into account are the dimensions and weight of the object to be fixed. In addition, it is necessary to choose the right screw for the dowel in order to ensure reliable fastening of the object to the surface of the wall or any other building structure.

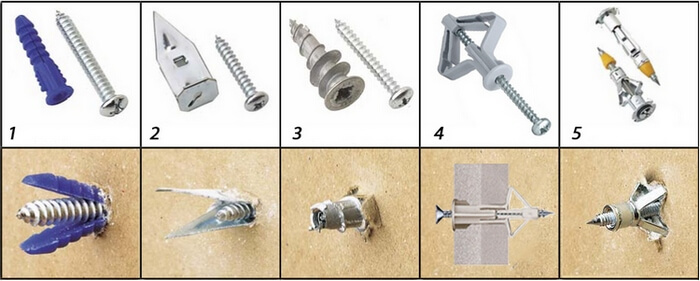

Types of dowels

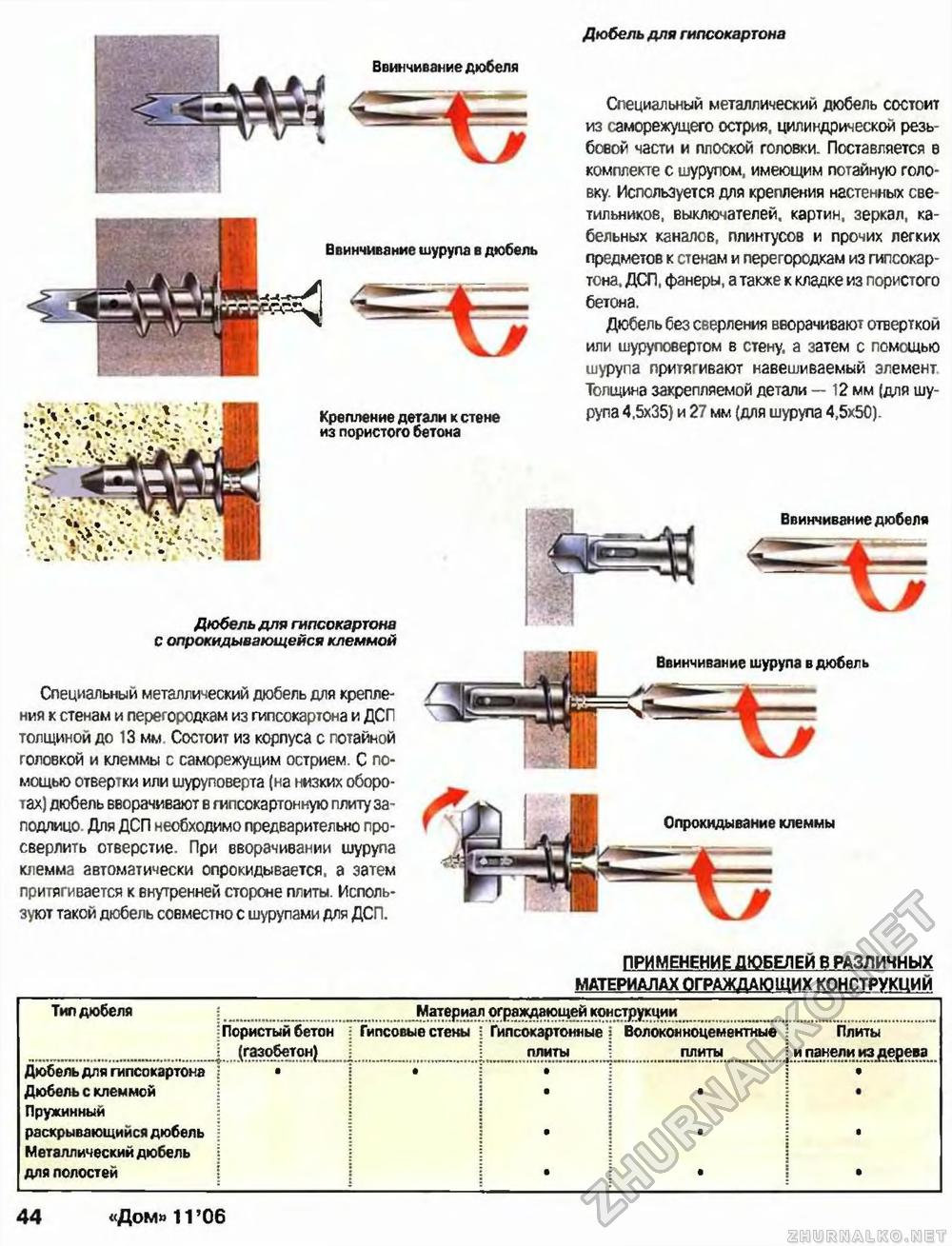

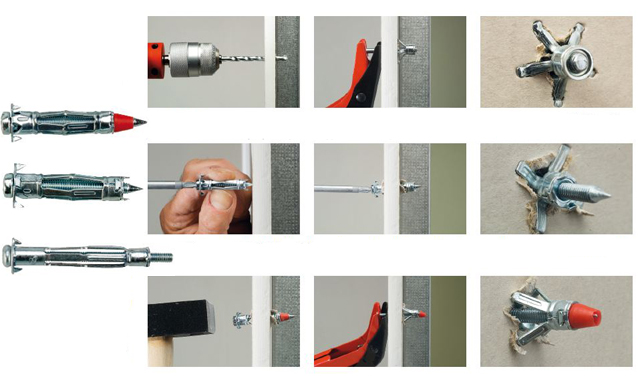

Drive type dowel

Perhaps the most popular plasterboard fastener. It can be with or without a drill, metal or plastic. Making a hole for its fastening, use a drill with a diameter of 8mm. The manufacturer declares a cut-off workload that the gypsum board can withstand using this dowel, at 25 kg, while the maximum load is up to 50 kg.

The popularity of the Driva dowel is due to its fairly high reliability and relatively low price. The strength of such an attachment is achieved by distributing the load over a large area, which is provided by the shape of the dowel.

Drywall plug for drywall is simple and effective

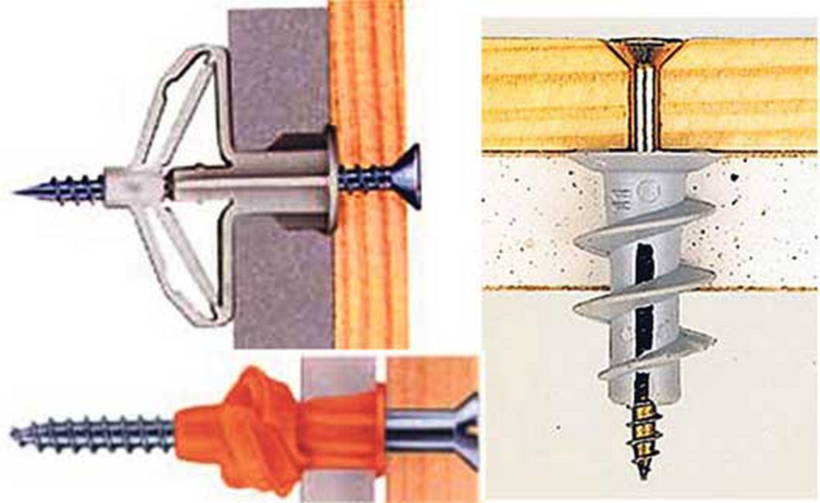

Flat dowel-nail

Such a dowel is made of refractory steel, it is quite simple and convenient to use, since it does not require additional drilling and, accordingly, will get rid of dust. It can be hammered into drywall with a hammer or pressed by hand if you can.

The principle of operation of the dowel-nail is that when a self-tapping screw is screwed into it, the initially flat front part opens up, forming a reliable stop.

It is used for sheets with a thickness of up to 12.5 mm inclusive. Self-tapping screws are chosen with a diameter of 3.5-5mm. The working load for pulling out, declared by the manufacturer, is 15 kg, for shear - 30 kg, the maximum shear load, obtained empirically, is 48 kg. Among other things, the nail dowel is reusable, that is, it can be dismantled and mounted in another place several times.

The flat dowel-nail for drywall is very easy to install, since it does not require drilling

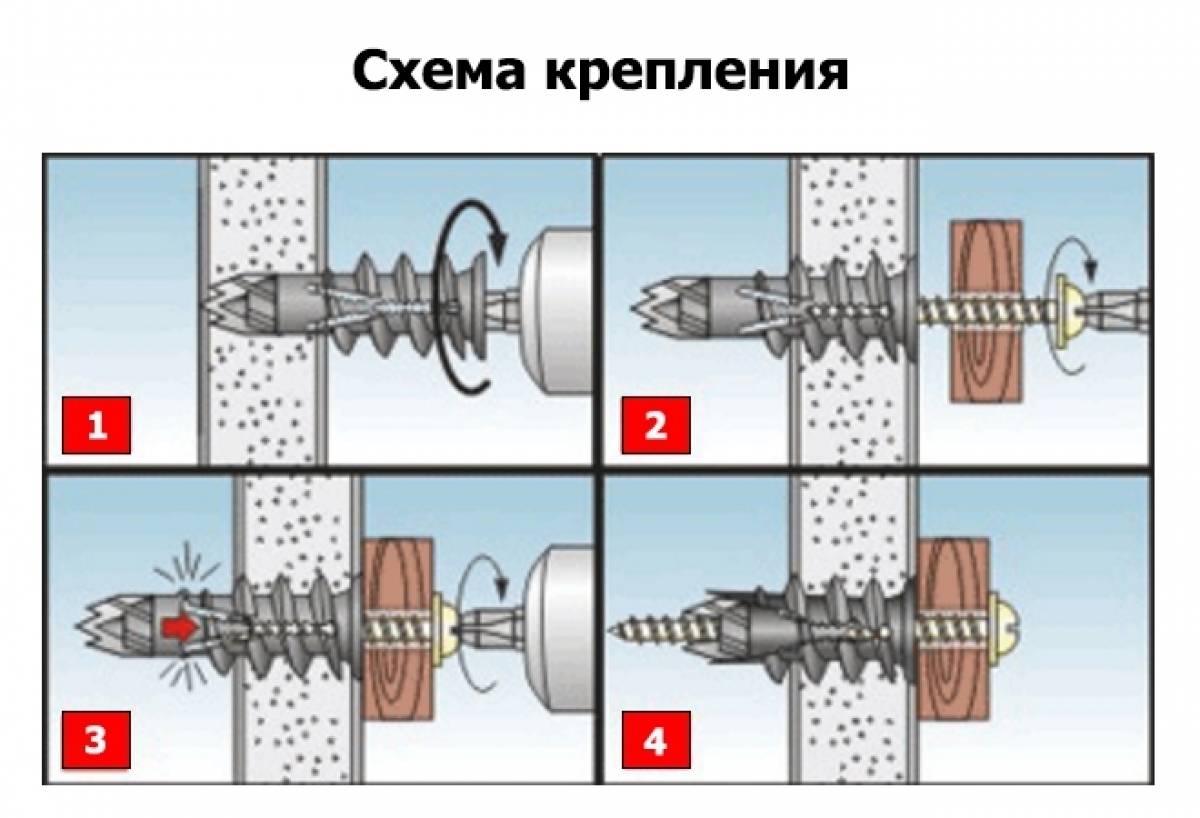

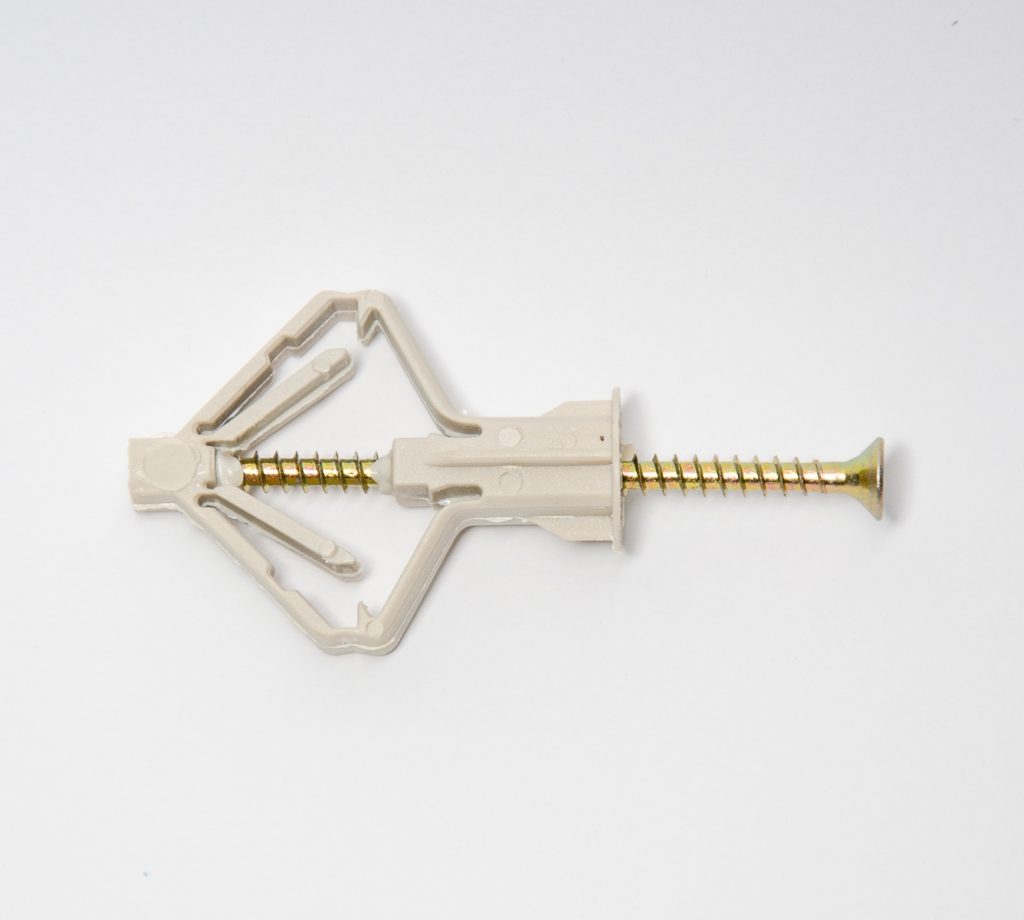

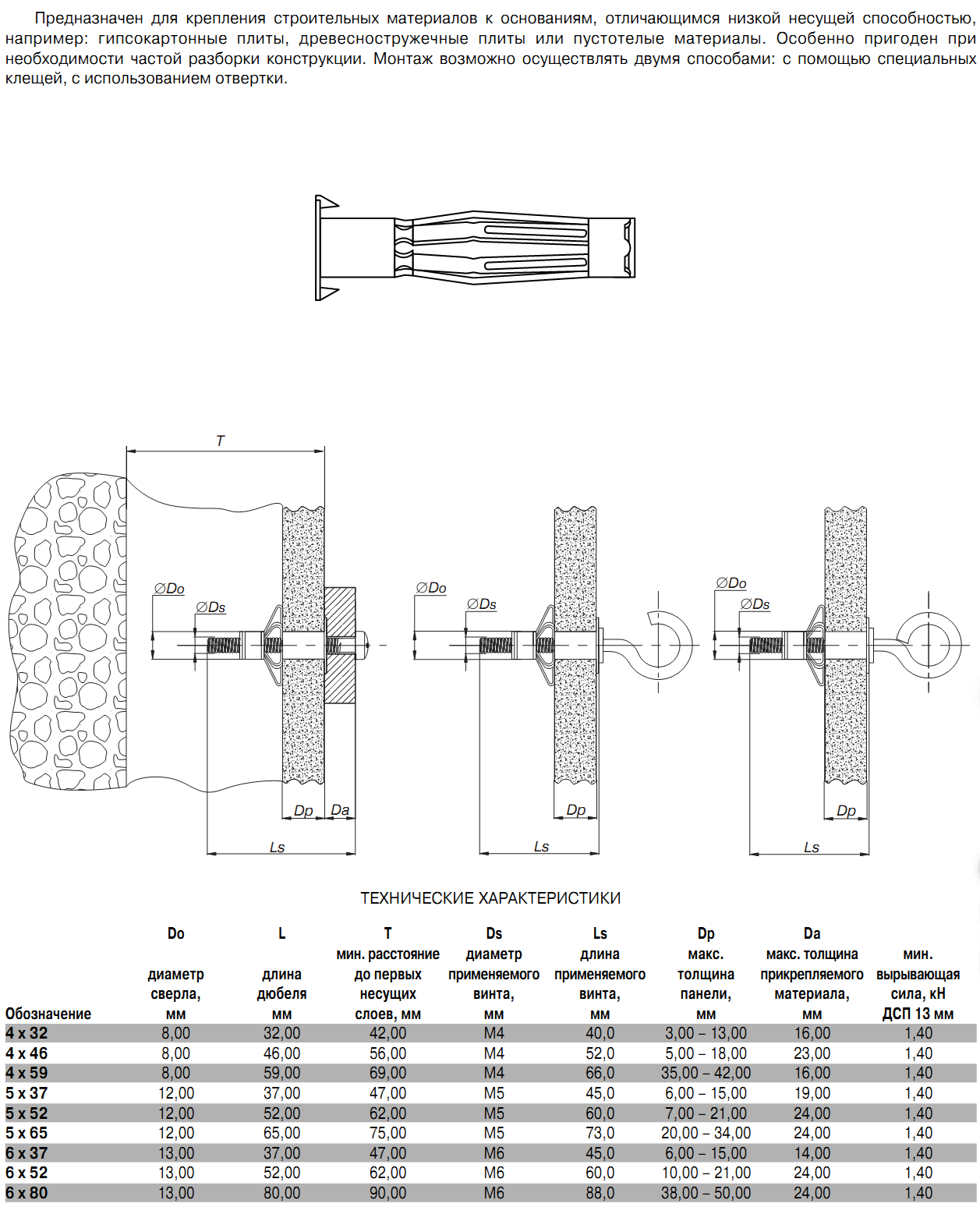

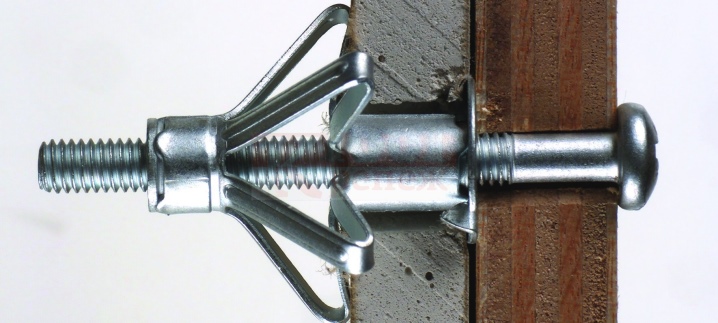

Universal expansion dowel Butterfly

The butterfly dowel is suitable for both drywall and concrete base. The hole for its installation is drilled with a drill with a diameter of 8 mm, the diameter of the complete self-tapping screw is 4.5 mm.

For the butterfly dowel, we recommend using self-tapping screws without skipping the thread, because when screwing, reaching the smooth neck, the screw will start to scroll, and the dowel will not take the desired shape in the form of a stop.

In general, the plastic butterfly dowel works roughly like the others, creating an emphasis behind the gypsum board when screwing in the self-tapping screw. In shape, such an emphasis is somewhat reminiscent of a butterfly, hence the name of the fastener.The design working load for the dowel is 25 kg, the maximum working load is 55 kg.

The Butterfly dowel for drywall is the most popular because it is equally inexpensive, convenient and effective.

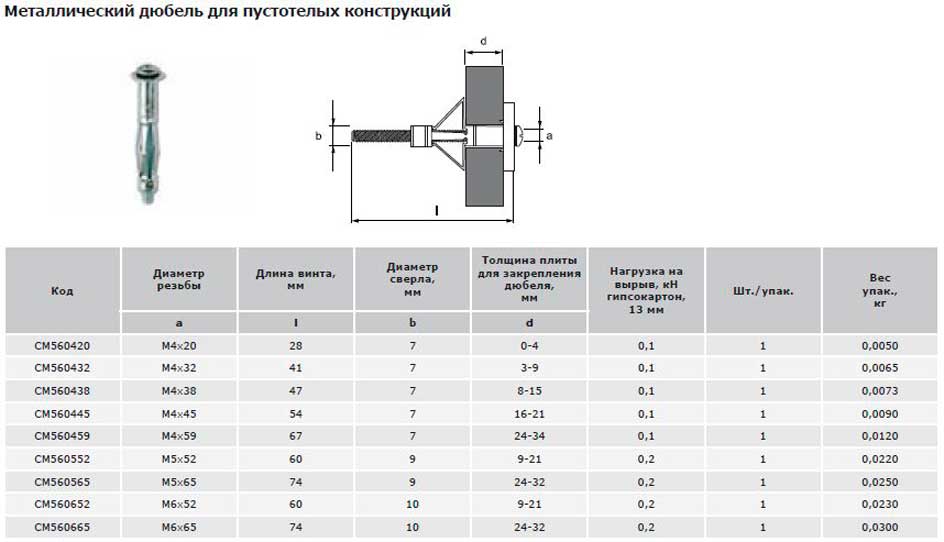

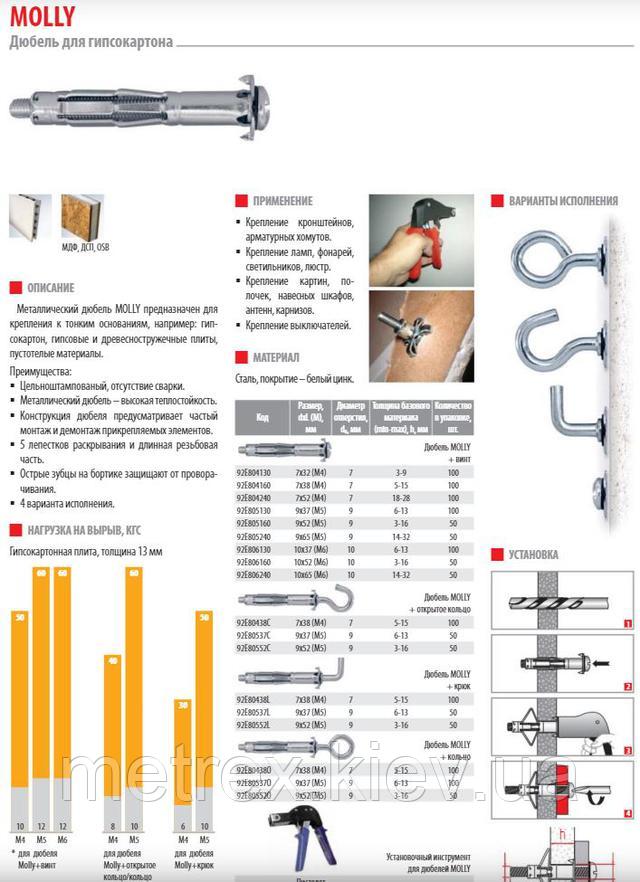

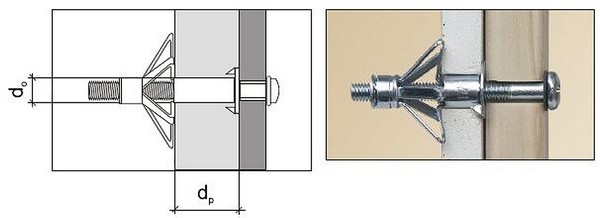

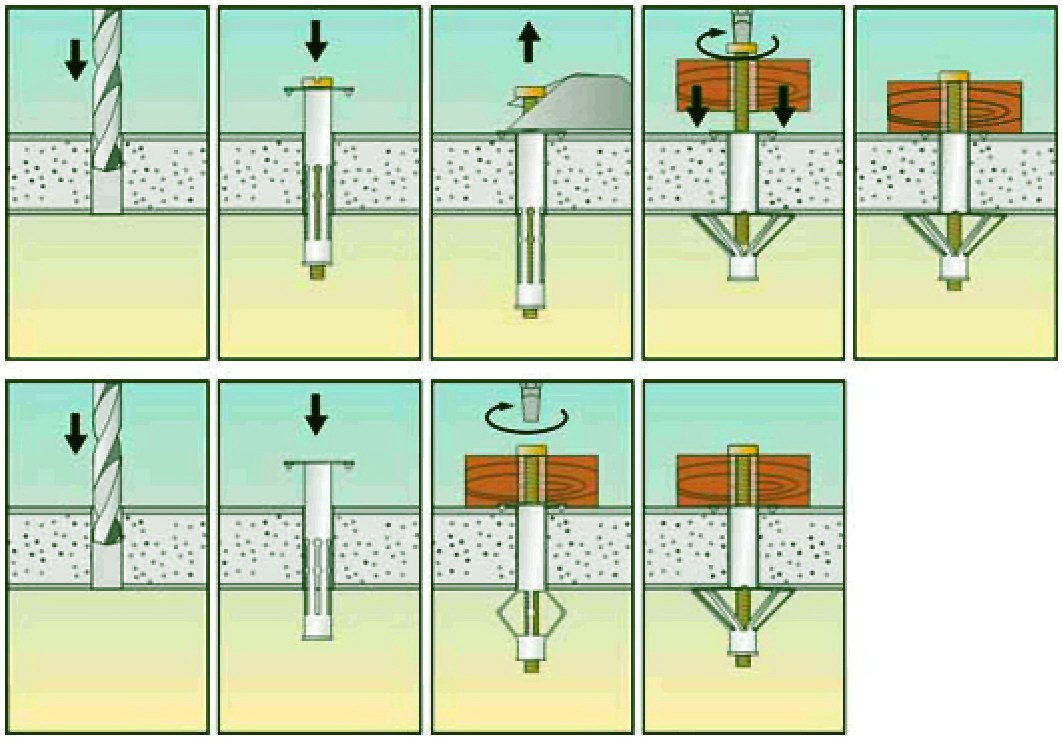

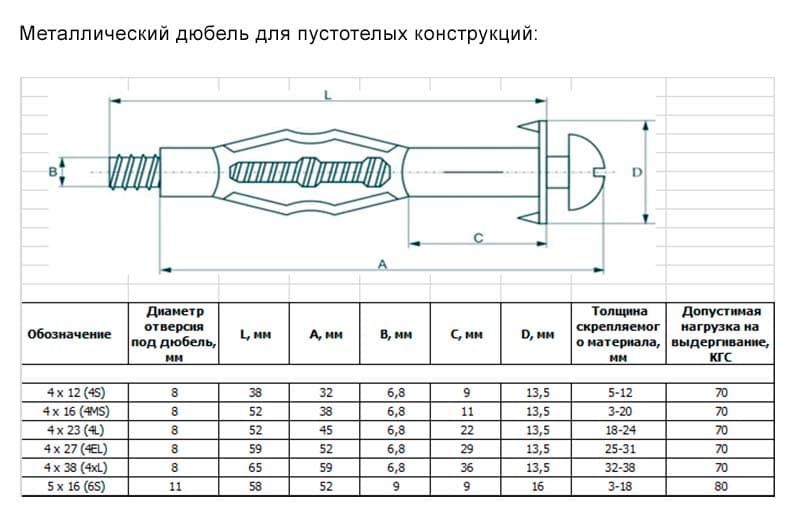

Dowel molly

The Molly dowel, or rather the Molly anchor (after all, this is an independent fastening unit that does not require an additional self-tapping screw) is another popular type of fastening for drywall, made of metal. This dowel, unlike the previous ones, is produced in various sizes and, accordingly, for different loads.

For example, for Molly, the minimum size marked 4/16/38 (4 is the screw diameter, 16 is the neck length and the maximum sheet thickness for which it can be used, 38 is the total length of the element), the working load is 25 kg, the maximum shear is 47kg.

To make holes for Molly, choose a drill 2 times larger than the diameter of the neck (the first number in the marking), that is, for a four it will be 8 mm, for a six - 12, etc.

To install the Molly dowel, you need a special tool that brings the fastener to "combat readiness". With its help, the screw is slightly pulled towards itself, while the hooks are bent. Then you can turn the screw with a screwdriver, bending the hooks until they stop. All this should be done by inserting the dowel into the hole in the drywall.

If there is no special tool, you can put the anchor into action using nippers (side cutters) or even an ordinary flat screwdriver.

Molly drywall plug - the solution for professionals

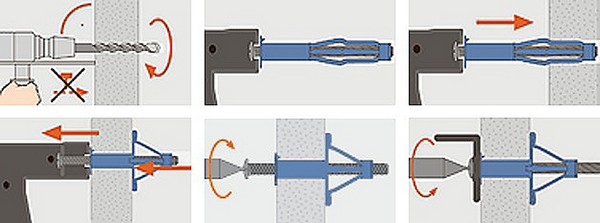

Fischer's twisting plastic dowel

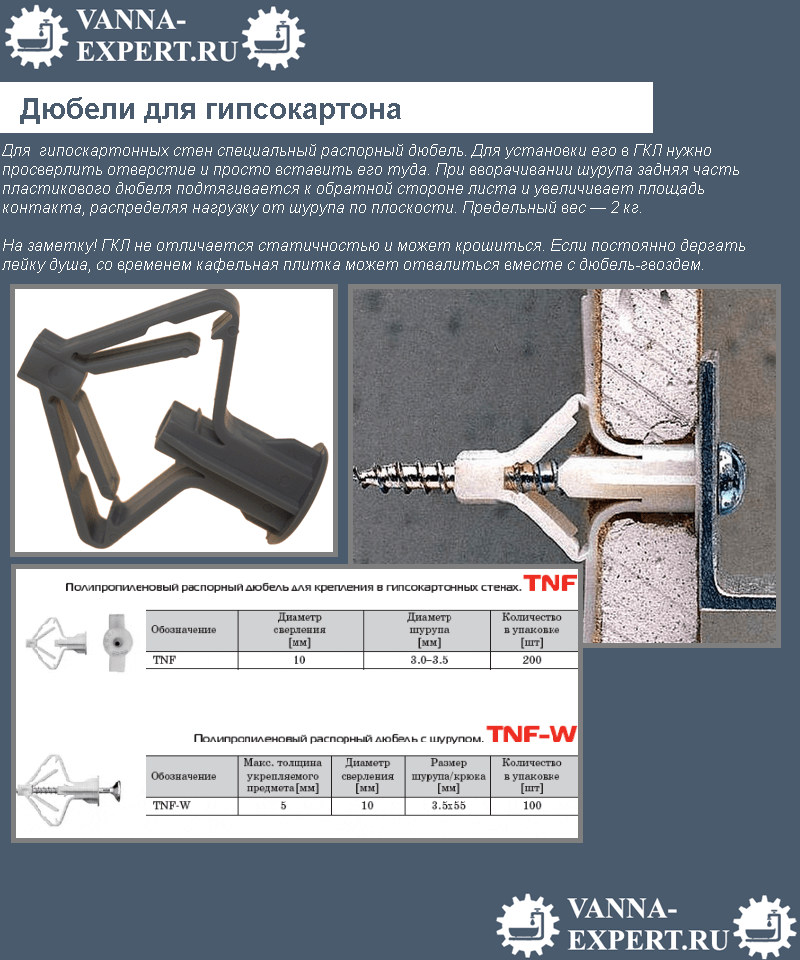

When screwing a self-tapping screw into such a dowel, the latter twists, forming an emphasis behind a sheet of drywall, hence the name of the fastener. The drilling diameter for such a dowel is 8 mm, the diameter of the self-tapping screw is 5 mm.

When tightening the self-tapping screw, the main task is not to squeeze too hard, otherwise it will begin to turn, and the fasteners will need to be done again. For this reason, when using a screwdriver for tightening, set the minimum speed on it.

The working load for the detachment of the twisting dowel is 10 kg, for the cut - 25 kg, the crash load - 70 kg.

The twisting plastic drywall plug is an interesting and effective solution, backed by Fischer's reliability

Varieties

There are many types of fasteners used when installing drywall products

But it is important to choose the most appropriate products for a particular case. In addition, you should know the rules for installing the described fastening elements, which will ensure the reliability and durability of the structure being formed.

The dowel used for fastening the gypsum board products must meet a number of requirements:

- have an anti-corrosion coating;

- be made of high-quality and high-strength metal;

- the spacer elements of the part must ensure high-quality fixation of the plasterboard base to the base surface of the structure.

All drywall anchors differ in that they are made according to the harpoon spacer principle, which ensures a strong and reliable fastening.

There are two main groups of drywall plugs:

- checkpoints;

- unclenching.

Walk-throughs are very convenient for ceiling mounting. Most often they are used to install massive chandeliers, interior spotlights and sports equipment. The spring-loaded dowel consists of a threaded metal rod, folding locking wings and a spring mechanism. In the void on the inside of the plasterboard structure, a spring mechanism opens the locking wing hooks, thereby creating a secure attachment.

The end of the drywall spring dowel can be made in the form of a ring, half ring, screw or rod. The required type of tip is selected based on the type of object that needs to be attached (for example, a ring-shaped tip is usually used when attaching electrical wires, and in the form of a half-ring of a hook - for hanging various lighting equipment).The spring dowel is ideal for mounting elements to tiled plasterboard walls. To decide which type of clamps of the described type is suitable for your design, it is worth considering in more detail the advantages and features of the use of each type of dowels.

Plasterboard plugs are made of polypropylene and offer many advantages over other fixing materials

Molly dowel

The molly dowel definitely cannot be attributed to cheap fasteners, the price for it is really high, but there is no doubt about the quality.

Molly dowel working principle:

- A hole with an eight-millimeter diameter is made with a drill for this dowel;

- After that, the molly is inserted into the gypsum board, the two-pronged side is pressed tightly against the sheet, which helps to prevent the anchor from rotating during the fixation stage;

- Then the screw, which comes with the molly dowel, is pressed against the sheet along the internal thread with a screwdriver.

It should be noted that the central part of the sleeve is twisted, which gives a reliable fixation of the molly in the drywall. The rivet will be in place.

Molly advantages:

- Ability to withstand high enough loads;

- There is an option to dismantle if necessary;

Molly screws come in one set with dowels.

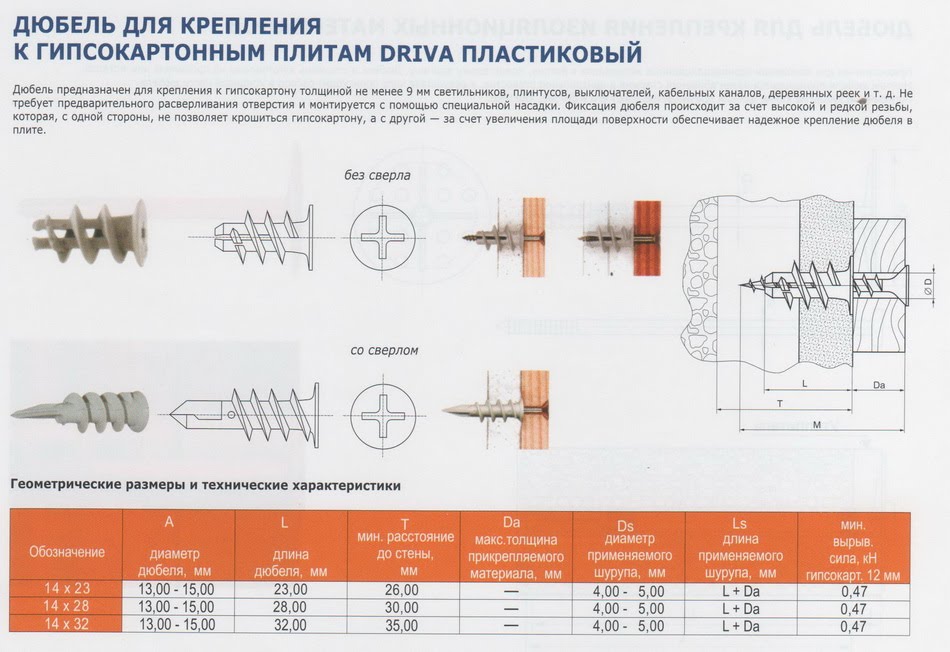

Driva

Driva is one of the most popular types of fasteners. The drive is produced in two types - plastic and metal.

The driva plastic dowel is purchased more often, and there is more of it on sale.

How to fix the driva dowel:

- Drill a 6mm hole;

- Insert the dowel;

- With a cross head, cut it into the gypsum board as a standard self-tapping screw;

- After that, screw a screw or self-tapping screw with a diameter of 3.5 or 4.5 mm into the inner cross-shaped slot of the driva dowel.

That's all. Difficulty can arise only in the selection of the right self-tapping screw. When choosing a self-tapping screw, keep in mind that driva has a length of 23 mm (plastic) and 33-44 mm (metal).

The Drive dowel for drywall has a fairly wide application and is available in two subspecies

It remains to mention one more well-known brand of fasteners - fischer.

Photo of dowel screws

We also recommend viewing:

- Threaded hairpin

- Wedge anchor

- Dowel nail

- Nails

- Cable ties

- Fasteners for wires

- Shelf brackets

- Screw nails

- Driven anchor

- Metal dowel

- Roofing screws

- Drywall dowel

- Sink mount

- Furniture fasteners

- Hex bolt

- Antenna bracket

- Wood grouse

- Steel chain

- Grover

- Wood fasteners

- Expansion dowel

- TV mount

- Construction shackle

- Self-tapping screws for metal

- Eaves bracket

- Metal fasteners

- Fasteners for windows

- anchor bolt

- Foundation bolt

- Plastic dowel

- Dowel clamp

- Wood screws

- Rigging bracket

- Crab system for shaped pipes

- Pipe bracket

- Clamp for cable

- Fasteners for pipes

- Chemical anchor

- Load hooks

- Self-tapping drill

- Plastic clamps

- Toilet mount

- High strength bolt

- Concrete screw

Application

When using electrical devices for screwing in dowels, you need to be very careful, as excessive force during installation can damage the drywall sheet. Drilling a hole in perforator mode for working with gypsum board is prohibited.

In tiled surfaces, a hole is made for the dowel in accordance with its size. In this case, it is better to stop at the molly dowel. To quickly perform the fastening, you can use the drive dowel. The advantage of this product is the fact that there is no need to make any additional holes in the material, which allows to preserve the integrity of the structure as much as possible.

There are some simple guidelines for screwing dowels into drywall:

- First of all, it is worth identifying what characteristics the drywall has, with which you have to work, and also determine the weight of the attached product.

- It is important to correctly select the screw, if it is not included in the standard package for the dowel, since the screw can damage the fasteners from the inside.

- The hole must be drilled slightly larger in diameter than the part itself. This feature of the work allows you to avoid cracking of the material during the installation of the part.

- Holes must be thoroughly cleaned of crumbs and dust. To do this, you can use an ordinary household vacuum cleaner.

- A screwdriver that can be screwed in without a screwdriver should not rotate at the end point of the installation. To do this, do not fix it in the base until it stops, leaving this work for the screwdriver with the appropriate setting.

- When the dowel-umbrella or fungus is already installed in its place, and the desired product is firmly located on the fastener, the hole formed in the drywall sheet must be carefully masked with acrylic, if it is small. In another situation, additional use of putty will be required. A positive feature of acrylic is its rubberized base, due to which the pressure level of the fastener on such a fragile material as drywall can be significantly reduced.

- The butterfly dowel has a certain installation technology - you need to press the folding blades of the product and push it inside. Even an ordinary screwdriver can screw this dowel to the required position.

Fasteners for drywall today are presented in a wide variety

Therefore, the choice in favor of this or that product should be made based on the level of complexity of the structure to be attached, its functional tasks and installation technique, taking into account the cost of the products

You can find out how to install drywall with your own hands by watching the video below.

Photo of an expansion dowel

We also recommend viewing:

- Crab system for shaped pipes

- What is a lifting shackle

- What is foundation bolt

- Why do you need a grover washer

- Dowel-clamp for cable fastening

- Lifting crane hook

- How to choose cable clamps

- Features of furniture fasteners

- Wood grouse wood screw

- Which toilet mount is better to choose

- Fasteners for timber structures

- Fasteners for plastic windows

- Advantages and Disadvantages of Screw Nails

- Best plastic dowels

- How to choose a threaded rod

- Self-tapping screw with drill

- How to choose self-tapping screws for metal

- How to choose a drywall dowel

- The most reliable pipe fittings

- The best screws for concrete

- How to choose pipe brackets

- High Strength Bolt Parameters

- Hex bolt

- Varieties of anchor bolts

- Construction nails

- How to use the drop-in anchor

- How to select and install a wedge anchor

- Features of dowel screws

- Hammer-in metal dowel

- What is a dowel-nail

- How to choose and apply a chemical anchor

- Sink bracket

- Types of brackets and fasteners for shelves

- How to choose a steel chain

- Choosing a bracket for the cornice

- Brackets for satellite dishes

- Choosing the best plastic clamps

- What is a construction bracket

- The best roofing screws

- What are wood screws

- How to choose a wall mount for your TV

Types of dowels for drywall profiles

Dowels for profiles - fasteners used in the installation of guide profiles and hangers for the frame under the gypsum board.

Distinguish:

- dowel nail;

- dowel-wedge (anchor);

- butterfly;

- Driva;

- Knauf-Hartmut;

- Fischer Pd ";

- umbrella;

- chemical anchors.

The main types of dowels used in the installation of the frame base

The main types of dowels used in the installation of the frame base

To understand which dowel should be used in a certain situation, all options are considered below.

Dowel-nail for drywall profile

The most common fasteners for mounting the GKL frame. According to the method of fastening, two types are distinguished: manual driving and with the help of an assembly gun.

The second type is a fastening element consisting of a nail and a washer.They are used for mounting heavy massive structures to a concrete base.

This type of fastener is not applicable to work with gypsum board

This type of fastener is not applicable to work with gypsum board

I mark the products by size. Dimensional specifications indicate the diameter of the base and the length of the nail. When working with a drywall profile, the best option is 6/40, 6/60 mm, where 6 is the diameter, 40 and 60 is the length. They fix the guide profiles to the rough base, and also fix the direct suspensions.

Dowel-wedge

A wedge or anchor wedge is a reliable fastener. Dowel for fixing profiles on concrete and solid brick walls. Withstands heavy loads. Fastening is possible even at a small distance from the edge of the base. Anchor wedge is produced in sizes from 8/45 mm to 16/150 mm.

Fasteners are used for through and pre-assembly

Fasteners are used for through and pre-assembly

Butterfly dowel

According to dimensional characteristics, there are:

- 8/28 mm. The smallest, suitable for attaching light objects. Self-tapping screws are not included. Must be purchased separately, size 3.5 x 35 mm.

- 10/50 mm. Self-tapping screws with a size of 3.5 x 55 mm. Withstands loads up to 24 kg. Suitable for fixing furniture shelves and cabinets.

- Metal dowel-butterfly. The second name is Molly. Suitable for use on walls made of hollow materials. Sizes range from 4/21 to 6/80.

Observing all the rules for fastening, "butterflies" serve as durability for a long time

Observing all the rules for fastening, "butterflies" serve as durability for a long time

You can find out more about the sizes and types of butterfly dowels on our website.

We advise you to watch a video about the process of attaching the "butterfly".

Driva

They produce two types of hardware: with and without a drill, from nylon, metal. For hanging heavy objects on a plasterboard surface, a galvanized part is used.

The shape is a conical cylinder. The thread pitch is large. Flat hat with cross recess. They are used for the installation of small-sized, lightweight structures. Sizes 12 x 38, 12 x 42, 14 x 38, 15 x 29.

Knauf-Hartmut

The fastener consists of:

- U-shaped profile;

- plastic antennae and bushings;

- screw with dimensions 5/60 mm.

Principle of operation:

- drill a hole in the wall;

- insert the profile plate into the hole using the guide antennae;

- break off the antennae;

- screw in the screw.

Withstands loads up to 55 kg.

Fastener for mounting heavy objects

Fastener for mounting heavy objects

"Fischer Pd"

Fastening device for working with drywall and profile. Plastic cylinder with sleeve and side blades. Principle of operation:

- drill a hole, the diameter is equal to the dimensions of the sleeve;

- insert a phisher;

- fix with a screw.

The mount can carry up to 16 kg. Sizes - 10/28.

When fixing, the side blades should be open and pressed against the base from the back.

When fixing, the side blades should be open and pressed against the base from the back.

Umbrella

It got its name from the principle of operation. After fixing in the hole, the side blades unbend and the fastener looks like an open umbrella. This contributes to the distribution of the load, the ability to withstand heavy weight.

Chemical anchors

It is a cartridge with a capsule containing an adhesive liquid. Under mechanical stress, the capsule bursts, the glue enters the hole.

Due to its properties, it is a monolithic fastener that can withstand heavy loads

Due to its properties, it is a monolithic fastener that can withstand heavy loads

What does it consist of

The dowel screw can be divided into two parts:

Working part, or spacer. When the screw is rolled inside the dowel, its working part expands and tightly wraps around the screw. In this case, the friction between the wall and the sleeve, the sleeve and the screw increases.

Non-controversial part. The so-called upper part that does not penetrate the wall. It retains its shape so that the screw does not come out of the fastener. Its other purpose is to prevent the screw head from contacting the wall.

Also, the dowel can contain various components, additions:

- Cutting the sleeve. Slots run along the length of the working fluid to facilitate deformation during twisting.

- Stoppers. Do not allow the dowel to twist and loosen.

- Spacers. Protrusions in the form of thorns, scatterers.In contact with the wall, the friction force is increased several times and the strength of the fastening is increased.

Species overview

By material

As already mentioned, this type of fastener is extremely rarely plastic, because it is designed to withstand the load as efficiently as possible. But the metallic element can vary significantly. Only 2 main types are known - there is a pronounced difference between them. Galvanized steel structures are mainly electroplated. Where there is an increased risk of corrosive processes, only stainless alloys are suitable.

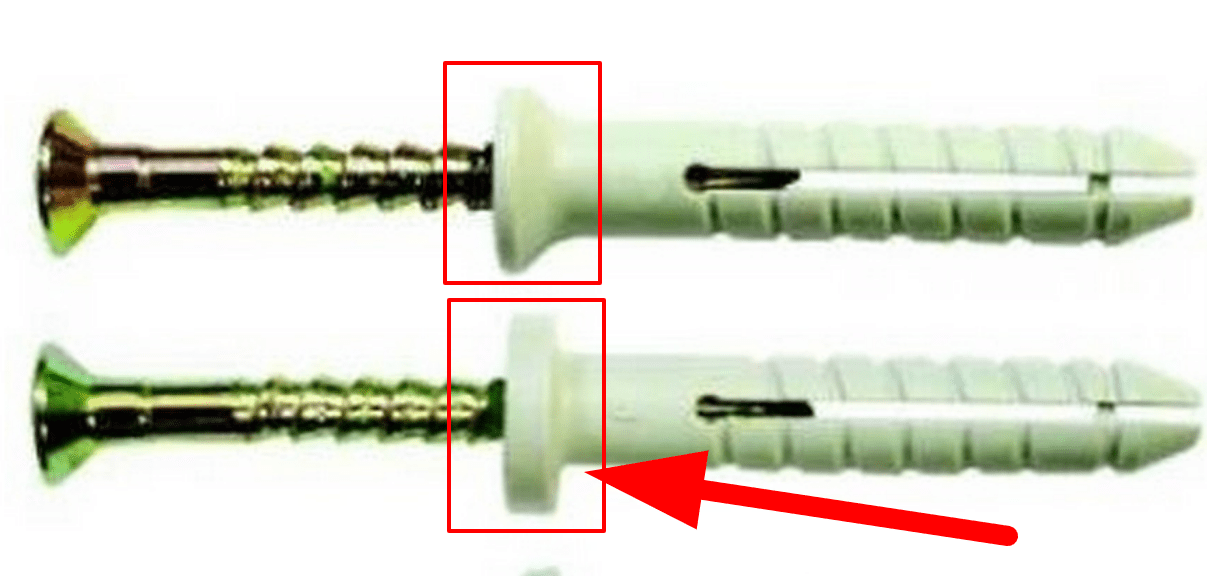

By design features

Molly dowels M10 and other sizes can have a rather different technical design. The differences, however, relate, rather, not to the fasteners in general, but to the main screw. Countersunk head models are quite common. They have a flattened cap that is recessed in the wall or in the material being processed. This design is very reliable, but it is extremely difficult to dismantle it.

However, this comes with significant aesthetic costs. Some models are available with a hook screw. This solution is optimal for a chandelier or other suspended luminaire.

It manifests itself especially well when installing lighting fixtures on plasterboard ceilings.

Sometimes you can find designs with a hook in the shape of the letter G. They are no longer used for ceiling, but rather for wall lamps. The help of such a dowel is invaluable when installing household appliances (TVs, microwave ovens) on the wall from the gypsum board. Of course, you can also fix various kinds of furniture (wardrobes, bedside tables, shelves), pictures, flowerpots in this way. Finally, to work with non-standard structures and communications (such as hanging chairs and swings), molly dowels with a special ring are used.

Installation of slabs

The efficiency of the workflow depends on how well the installation is carried out.

This screw is mounted as follows:

- You need to hammer it into drywall with a hammer so that the screw does not dangle there;

- Do not drill too large a hole - the mount will not hold;

- The thickness of the product, which is attached to the butterfly, will ideally not exceed 5 mm (if the structure is bulky, it must be attached to a self-tapping screw with a greater length);

- In order for the screw to tighten well, at least 35 mm should remain behind the gypsum board;

- It is easier to screw in the dowels with a screwdriver, otherwise the plastic edges of the stop may break off, and at high speeds the plastic itself often bursts.

To better understand how this mount works, you need to understand how it works.

Dowel in drywall Butterfly

Varieties of dowels for brick walls

Dowels are used to attach furniture, paintings or other objects to brick walls, since they are capable of withstanding heavy loads. In order for the fasteners to be reliably held in the base, it is necessary to choose the correct type and size, depending on the range of bricks or concrete. If the dowel is not used for its intended purpose, it may not withstand the load and fall out of the hole.

Types of dowels and their features

1. Externally, the dowel is similar to a cork, has a cylindrical shape with a cavity. When the screw is screwed in, its body expands and abuts against the walls of the hole. The most common are nylon and polyethylene expansion plugs. To prevent the screw or nail from falling inside, the fasteners are equipped with a special collar equal to the diameter of the screw head.

2. For walls made of porous or hollow bricks, anchor fasteners are used. As soon as such a dowel begins to be screwed into the brickwork, its end expands or twists in the form of a knot. The resulting "nut" inside the voids reliably holds any object.

3. Nail dowels are used for fastening the slats under the cladding with finishing material, they are small in size. They come with a nail. Install them together through the hole in the rail and wall.Then they hammer in with a hammer.

4. Special dowels-umbrellas are used for fixing the thermal insulation. An umbrella is inserted into the hole in the wall and through the insulation, and then a nail (plastic or metal) is hammered in. For heavy loads, for example, up to several tons, metal dowels for concrete and brick are used.

5. For suspended ceilings, metal fasteners are best suited. In the event of a fire, the plastic will melt and the ceiling will collapse.

- reliable mount that can withstand heavy loads;

- easy to use;

- use both indoors and outdoors is possible.

Due to the presence of thorns and whiskers on them, they do not scroll while screwing in the screw.

Selection nuances

Molly dowels are produced by a variety of companies specializing in the production of fasteners. Therefore, it is unlikely that it will be possible to choose a suitable product, focusing only on the "name" of the company, because the assortment now includes products from companies that are little known to Russian buyers. Unconditional leadership in the world was won by molly dowels under the Fischer brand. The German company produces all kinds of fasteners possible at the modern technical level; the price difference between them is quite noticeable.

Lovers of Finnish products should pay attention to products under the Sormat brand. This company supplies molly dowels for sheet materials

For 50 pieces in the original packaging, you will have to pay at least 650 rubles.

Russian counterparts are much more affordable. Depending on the specific brand and on the characteristics of the product, it will be possible to buy 100 dowels for 190-500 rubles. The price of installation work is practically independent of the use of fasteners. Even a special assembly tool is readily available. No special skills are required either; however, the fees for Molly are hefty when the workload is large.

Quite good results in practice are demonstrated by the products of the Liechtenstein company Hilti. It has passed the most severe tests and has proven itself from the best side many times. As for the already mentioned products from Sormat, as well as from German suppliers Tox and Kew, they are generally of high quality, but they have not been certified for particularly difficult conditions.

And one more consideration - this time in relation to the material from which the fasteners are made:

-

in the absence of special requirements, it is necessary to take modifications with zinc protection;

-

for bathrooms, kitchens, unheated rooms, alloyed stainless alloys are better suited;

-

Only the lightest objects can be hung on the plastic supports - regardless of the microclimate.

Description

Molly dowel is a type of fastener for drywall and similar materials. By default, such a product is formed entirely of metal. There are almost no structural differences from the "butterfly" fastener. However, the elimination of plastic elements increases the load-bearing capacity. True, this is achieved only when the design itself is more expensive.

The main components are screw and sleeve blocks. The screw is either included in the kit by default, or is customized according to your preference. A metal collet is an empty bushing inside.

Since the collet may contain grooves inside, this complicates the selection of a suitable screw. An alternative option is to complete the screw from the original kit with a support washer. This washer will have a pair of serrated tipped ridges. It is attached to the surface, which will prevent the collet from spinning uncontrollably during installation. Finally, there are modifications of screws with countersunk heads or with conventional tips in the form of a semicircle.

The principle of operation is quite simple: the molly dowel is inserted into the required hole when it is folded. Next, tighten the required screw inward. When this happens, the spacer is compressed. In this case, a support is formed in the form of many petals, reminiscent of a "tent" or an umbrella.It will press firmly against the wrong side of the material being cut.

It is necessary to fasten such an anchor a little differently than in the case of a simple "butterfly". The screw may not be screwed in, but, on the contrary, pulled out. To work with it, you need dowel pliers or assembly pliers. But a typical locksmith tool from a home workshop will not help. Molly dowels can be dismantled and reused (this is not possible with a simple "butterfly"); manufacturers even specifically emphasize that dismantling will not affect the operating parameters.

It is worth noting that the described type of dowels will require a fairly significant free space for installation. Manipulating pliers and pliers in a confined space is extremely difficult, because this tool itself has a certain length.

For your information: for double drywall, only special designs can be used. Such fasteners include a tip in the form of a drill. Only such an end part can be safely and reliably screwed into a thick sheet. Alternatively, you can use "self-aligning" dowels, strips and other types of fasteners. But this is a separate topic that requires special analysis; but for hollow structures, a typical Molly dowel is perfect.