Application features

The installation process is carried out in several stages. The main ones are:

- Hole preparation.

- Composition room.

- Installation of the anchor into the uncured polymer mass.

- Tightening the nut.

Each of these stages is associated with its own characteristics.

To install you will need:

- chemical anchor;

- injection gun;

- threaded stud or fittings;

- hammer drill or drill;

- Boer;

- torque wrench;

- metal brush;

- handheld or industrial vacuum cleaner;

- Remedies.

With the tools in hand, you can start installing the chemical anchor.

Cooking the hole

When working with brickwork, it is important to avoid splits and cracks in the brick. This requires refraining from using the hammer function on the equipment and drilling perpendicular to the plane.

To successfully install a hollow brick chemical anchor, a hole 2 millimeters larger than the diameter of the stud is required. It is necessary to mark in advance on the drill corresponding to the length of the anchor, or use the depth gauge.

To improve adhesion, it is required to thoroughly clean the hole from dust and crumbs. This is done using a metal brush and a hand pump, with which the hole is blown several times until there are no visible dust residues.

Introducing the composition

The polymer mass is introduced into the hole using an injection gun. If the mixture has a uniform gray color, then it can be applied. It often happens that initially it is not possible to achieve good mixing - such a mixture should not be used. To use the gun, you need to place the nozzle in the drilled cavity and fill it with the compound. After each dose of glue is placed in the hole, it is required to remove the instrument slightly until more than 65% of the cavity volume is filled.

The procedure for placing a chemical dowel in a hollow brick is characterized by a number of features. They are related to the fact that the presence of a large number of voids does not allow the formation of a natural hole. To achieve the goal, a special plastic sleeve is inserted, which is filled with glue. When the pin is immersed in a hollow brick, part of the chemical composition comes out through the mesh walls of the sleeve into the cavity. This promotes more grip.

There are also special ampoules. They are placed in the hole, the composition is mixed with a hairpin. The second option is more suitable for piece work, when there is no need to buy cartridges with a chemical composition.

Installing a metal anchor

We place the metal structure in the hole using rotational movements

It is important to distribute the solution evenly. To do this, it is recommended to periodically pull the fasteners towards you and only then tighten it

While the glue dries, you can correct the position of the anchor.

Tighten the nut

After waiting for the complete solidification of the polymer mass, you can proceed to the installation of equipment and structures. The manufacturer's instructions indicate the maximum force applied to tighten the nut. It is recommended to use a torque wrench in order to control the applied forces.

Chemical anchors are suitable for fasteners made of steel. Due to its positive properties, the anchor can be installed in high humidity or even under water. When used correctly, it is possible to avoid the destruction of the brick, which allows installation at the very edge of the surface.

Chemical anchor is a new direction in construction, thanks to which complex work is simplified.The offer market is becoming more extensive, there are more anchors with various new fastener characteristics.

About dowels

The dowel is a fastening element designed for fastening various building structures, insulation, cladding materials to the surface of various types of walls. Dowels are used when the free end of the rod (screw, anchor) is not accessible for the installation tool. The dowel is driven into the wall or the main part, a screw is screwed into it, while the dowel expands and it is impossible to remove it. Today the dowel is a versatile and popular fastener.

Dowels come in different designs and are made from different materials.

All dowels can be conditionally divided into two groups:

1. Dowels for monolithic (without voids) bases - have a spacer principle of operation.

2. Dowels for hollow bases - have an anchor principle of operation.

Dowel classification:

Standard nylon plugs: The plugs fit any wall and can be used with screws from 2 to 16 mm in diameter.

A hole is drilled in the wall, corresponding to the diameter of the dowel, in which it is held by the antennae directed backwards, and when wedged with a screw, it is "firmly" pressed into the walls of the hole with its large teeth.

Dowels for aerated concrete: A hole is drilled for such a dowel, corresponding to the diameter of its core. It is driven into the hole with hammer blows, and at the base it is held by spiral ribs and wedging under the action of a screw.

Frame dowels: 60 to 360 mm long. There are two main types - for solid solid substrates and for soft and hollow (slotted) materials. The elongated spacer part ensures that the dowel engages several lintels in the base with voids at once. They are used for fastening window and door frames, as well as cladding elements through a layer of plaster, thermal insulation.

Distance dowels (adjustment): fix the battens under the sheathing at some distance from the wall. They allow you to adjust the position of the battens of the lathing relative to the base in the range from 0 to 30 mm during their installation due to a dowel and a screw of a special design divided into two parts (one for the base, the other for the rail).

Universal: when fixing objects to a hollow base, they "determine" the presence of a hollow space. In the cavity, the dowel bulges out and is thus fixed in it. When attached to a solid brick or concrete base, it, unclenching, comes into close contact with the walls of the hole. Dowels with spring-loaded flap bars: for attaching objects to hollow partitions and false ceilings, for example, for hanging chandeliers. The dowel strips, passing through the hole into the cavity behind the casing, open under the action of the spring and abut against the inner surface of the casing.

Metal: for thin-walled hollow structures, they are able to withstand rather heavy loads.

When the screw is screwed in, the dowel plates bulge in all directions and press against the inner supporting surface.

Nail dowels: designed for quick fixing of skirting boards, battens under the sheathing, when you need to install a large number of them. They are completed with a nail with a "finish" (knurling in the form of inverse cones). The dowel with a nail is inserted into the hole in the wall through the fastened rail. The nail is driven in with a hammer.

Insulation holders: for attaching mineral wool or hard foam insulation. A hole in a concrete or brick wall is hammered into a hole without a nail or screw.

Dowels for concrete and solid bricks: designed for large (up to several tons) loads, made of metal and completed with threaded rods or bolts. Suitable for attaching sunshades, garage doors or hoists. Plastic and metal: for soft materials (drywall and aerated concrete).

Fastening the front masonry to the wall

From all that has been said above, it is quite clear that when erecting lightweight masonry, the anchor for a brick wall is the brick itself. So, when it comes to ordinary masonry, no fasteners are needed. But to fix decorative (front) masonry to it, completely different technologies are used.

Flexible connections

In general, when performing cladding, an anchor for masonry can be any available metal material. Many bricklayers believe that all means are good for this.

For anchoring the front masonry, which is carried out simultaneously with the construction of the main wall, they use pieces of steel rods and strips of plaster mesh, and even manage to make improvised anchors from scrap aluminum profiles with their own hands.

Anchoring with steel rods

Composite rods and dowels

The most common are anchor rods and facade dowels with flexible connections, made of basalt or fiberglass. The rods are used for monolithic cladding - in cases where it is not possible to ligate with the load-bearing wall.

For example, when the pattern of the front masonry is formed only due to spoon rows. The rod anchors, which are shown in the picture below, can also be used when erecting a decorative wall with a ventilation gap, but without insulation.

Brick anchor: GRP rods for monolithic cladding

Anchors in the form facade dowel with flexible connection, which you see in the photo below, are equipped with a spacer washer. They allow not only to connect two walls together, but also to simultaneously fix the thermal insulation plates. Therefore, they are used for a bundle of three-layer insulated walls, while simultaneously performing the functions of disc dowels for insulation.

Basalt anchoring rods

On this, all the differences between rods and dowels are exhausted. All of them withstand prolonged exposure to high temperatures, and are of the highest strength. By the way, basalt-plastic is ahead of even steel in this indicator.

It is also important that it has a low coefficient of thermal conductivity, and nullifies the possibility of the formation of cold bridges. This is precisely the main disadvantage of metal rods, since they accumulate condensate and corrode, which leads to the rupture of bonds.

Perhaps someone would think that since the rod is flexible, it can easily be pulled out of the wall. However, this is not at all the case. The force that needs to be applied for this corresponds to 408 kgf (4000 Newton). Such an impact only happens during an earthquake, but when the walls themselves collapse, hardly anyone will worry about the cladding.

How to install an anchor in brickwork

- The sleeve diameter of an anchor designed for brick walls is usually 6 mm. The length varies considerably, which is why, in fact, the price of the product also depends: from 6 to 14 rubles. a piece.

- The dowel is selected along the length so that it fits into the front brickwork by at least 9 cm (three quarters of the brick width).

- Its anchoring part is always 6 cm. Clamps for insulation are sold separately, and purchased as needed.

- There are also options for flexible connections for attaching brick cladding to bases of a different type: monolithic, aerated concrete. The exact number of connections is determined by calculation, and depends on the presence or absence of a wall of insulation in the cake.

- Its variety also matters. For example, mineral wool needs to be fixed more often than expanded polystyrene. But on average, the consumption of composite anchors is 4 pieces per 1m2. Additionally, they are installed at the corners, around openings, at the locations of expansion joints, and the spacing of the fasteners is made no more than 300 mm.

Fixing the brick cladding to the concrete wall

What else are flexible anchors good for when a brick wall is being erected with brick cladding? The fact that they allow you to connect two walls even in the case when the horizontal seams of the masonry do not match.

A flexible connection can also be laid in a vertical seam, which cannot be done in any other case. So that the fasteners do not loosen, before fixing the anchor for the brick, they mount the thermal insulation on glue, and then, flashing it through, they establish flexible connections.

What is the difference between a concrete dowel and a brick dowel

High reliability of fastening obtained with the help of dowel-type products will be achieved only if they are correctly selected not only taking into account their size, but also the material of the structure in which they will be mounted.

Experts do not recommend the use of a concrete dowel for installation in brick building structures. This recommendation is especially relevant when it comes to hollow brick. In this case, special fasteners are used for installation, which differ from the usual dowel-nail both in the device and in the features of use.

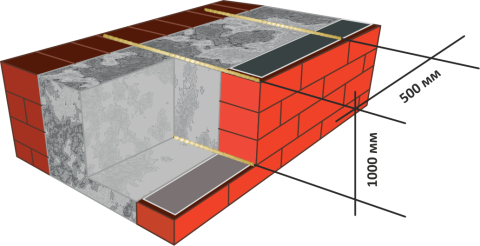

The elongated dowel for hollow bricks has certain design features

Fasteners for masonry have elongated dimensions and a double expansion mechanism. Like a dowel designed for concrete work, such a fastener can be plastic or metal. The reliability of fastening the dowel for a brick is ensured due to the fact that at least one of its spacers does not fall into the cavity in the brickwork, but into its solid part, it is he who provides the required fixation of the anchor in the wall or any other building structure. The expansion sleeve of the dowel is unclenched when a threaded rod or screw is screwed into it, the diameter of which must be selected correctly.

Some types of universal dowels (click to enlarge). It is simply impossible to show all the numerous assortment

The dowel for concrete works in a completely different way and can only be used for installation in solid solid materials. Such a dowel with an interference fit is hammered (therefore it is often called a nail) into a previously prepared hole. If you try to fix fasteners for concrete in a brick wall, in the internal structure of which there are many air cavities, then you can simply destroy the landing hole. Even if such a dowel is metal and has a considerable length, you still will not achieve its reliable fixation in a brick or in any other porous, hollow and not very strong material.

Considering all of the above, one should very responsibly approach the choice of fasteners for structures made of various materials that differ both in their hardness and in the features of the internal structure. To understand what a particular fastener is intended for, the marking applied by manufacturers to the packaging of such products helps.

Types of dowels for drywall profiles

Dowels for profiles - fasteners used in the installation of guide profiles and hangers for the frame under the gypsum board.

Distinguish:

- dowel nail;

- dowel-wedge (anchor);

- butterfly;

- Driva;

- Knauf-Hartmut;

- Fischer Pd ";

- umbrella;

- chemical anchors.

The main types of dowels used in the installation of the frame base

To understand which dowel should be used in a certain situation, all options are considered below.

Dowel-nail for drywall profile

The most common fasteners for mounting the GKL frame. According to the method of fastening, two types are distinguished: manual driving and with the help of an assembly gun.

The second type is a fastening element consisting of a nail and a washer. They are used for mounting heavy massive structures to a concrete base.

This type of fastener is not applicable to work with gypsum board

I mark the products by size. Dimensional specifications indicate the diameter of the base and the length of the nail. When working with a drywall profile, the best option is 6/40, 6/60 mm, where 6 is the diameter, 40 and 60 are the length. They fix the guide profiles to the rough base, and also fix the direct suspensions.

Dowel-wedge

A wedge or anchor wedge is a reliable fastener. Dowel for fixing profiles on concrete and solid brick walls. Withstands heavy loads. Fastening is possible even at a small distance from the edge of the base. Anchor wedge is produced in sizes from 8/45 mm to 16/150 mm.

Fasteners are used for through and pre-assembly

Butterfly dowel

According to dimensional characteristics, there are:

- 8/28 mm. The smallest, suitable for attaching light objects. Self-tapping screws are not included. Must be purchased separately, size 3.5 x 35 mm.

- 10/50 mm. Self-tapping screws with a size of 3.5 x 55 mm. Withstands loads up to 24 kg. Suitable for fixing furniture shelves and cabinets.

- Metal dowel-butterfly. The second name is Molly. Suitable for use on walls made of hollow materials. Sizes range from 4/21 to 6/80.

Observing all the rules for fastening, "butterflies" serve as durability for a long time

You can find out more about the sizes and types of butterfly dowels on our website.

We advise you to watch a video about the process of attaching the "butterfly".

Driva

They produce two types of hardware: with and without a drill, from nylon, metal. For hanging heavy objects on a plasterboard surface, a galvanized part is used.

The shape is a conical cylinder. The thread pitch is large. Flat hat with cross recess. They are used for the installation of small-sized, lightweight structures. Sizes 12 x 38, 12 x 42, 14 x 38, 15 x 29.

Knauf-Hartmut

The fastener consists of:

- U-shaped profile;

- plastic antennae and bushings;

- screw with dimensions 5/60 mm.

Principle of operation:

- drill a hole in the wall;

- insert the profile plate into the hole using the guide antennae;

- break off the antennae;

- screw in the screw.

Withstands loads up to 55 kg.

Fastener for mounting heavy objects

"Fischer Pd"

Fastening device for working with drywall and profile. Plastic cylinder with sleeve and side blades. Principle of operation:

- drill a hole, the diameter is equal to the dimensions of the sleeve;

- insert a phisher;

- fix with a screw.

The mount can carry up to 16 kg. Sizes - 10/28.

When fixing, the side blades should be open and pressed against the base from the back.

Umbrella

It got its name from the principle of operation. After fixing in the hole, the side blades unbend and the fastener looks like an open umbrella. This contributes to the distribution of the load, the ability to withstand heavy weight.

Chemical anchors

It is a cartridge with a capsule containing an adhesive liquid. Under mechanical stress, the capsule bursts, the glue enters the hole.

Due to its properties, it is a monolithic fastener that can withstand heavy loads

Which one is better to use?

What type of dowel fasteners is best suited for certain works, it can be difficult to determine, first of all, due to the huge variety. When purchasing a dowel, of course, it is always advisable to consult the store so that you do not have to go to the store again. Let's try to give general recommendations. For solid bricks, almost the same dowels are suitable as recommended for concrete. If the walls are made of this kind of material, you might say you're in luck. Most universal anchors will work fine. Even heavy and bulky items can be securely fixed, not to mention shelves and cabinets.

It is quite another matter if the brick is hollow. For hollow bricks, most universal dowels are completely unsuitable. It is dangerous to hammer a dowel-nail into such a wall, as this can cause the formation of cracks not only on the surface, but also in the partitions inside the brick, in this case it will be simply impossible to fix anything in the same place, and the hole in the wall will have to be repaired.

For slotted and hollow bricks, special plastic dowels are required, which roll up into a knot, or metal anchors with petals resting against the partition from the inside

Work with such consumables should be very careful, since, unlike a solid brick, which has voids, as a rule, it is more fragile. A facing brick, combining strength with some decorativeness, requires special care.

The appearance of chips and cracks in this case is simply unacceptable.

It is also important to remember that such a brick usually has voids to reduce its weight, which greatly limits the use of some anchors and dowel-nails.

For facing porous bricks, elongated plastic dowels are most preferable, during the installation process they form complex nodes that can reliably fix them in the voids of such structures. Fasteners for red and silicate bricks are somewhat different. Red is usually softer, and there is a danger of twisting the dowel in the hole if the diameter of the drill is incorrect or during the drilling process the master could not withstand the perpendicular and the hole turned out a little larger.

Varieties of chemical anchors

Such a dowel consists of special adhesives and a metal insert. This is a bushing, inside of which the thread is cut. Also, the structure includes a hairpin and a reinforcing bar. This element is made of various grades of stainless or galvanized steel. The process of joining with fasteners of this type is carried out due to a special chemical composition - according to its characteristics, it is glue. It must be stuffed into a pre-drilled hole. And then, through the polymerization process, a strong bond between the hollow brick and this connector will be ensured.

Hollow brick

What is this material? In modern construction, two types of bricks are used - hollow and solid. The main function of the first materials is the construction of buildings, which must be as strong and durable as possible.

This brick is good in all respects. The material is lightweight, strong, easy to install. However, it has a significant drawback. It retains heat poorly in rooms. Although hollow brick practically does not differ in strength from solid brick, it is more often used in finishing work. The internal void in such a building material can be, depending on the type and manufacturer, from 30% to 50%. Low-melting types of clay are used as raw materials for such blocks. It is from it that red brick is made. There is also another option. It is a silicate hollow white appearance. Let's take a look at the features and properties of mounting blocks.

Fastening a dowel for a brick wall - step by step diagram

Step 1: Preparing the bore hole

First of all, of course, you need to drill a hole, but it also needs to be done correctly. If you decide to use a hammer drill, then initially be sure to turn off the impact mode, or use an electric drill. Your main task is not to break the future hole. For drilling, use a drill of the corresponding dowel diameter, if the fasteners are 8 millimeters in diameter, then the drill should also be 8 millimeters.

Step 2: Obligatory cleaning of the hole from debris

After the hole is ready, thoroughly clean it of dust and crumbs after drilling, take this step responsibly, otherwise the crumb will simply not let the dowel fit into place as expected. Insert and pull the plug several times into the seating position, making sure it enters without significant obstruction.

Step 3: Installing the dowel with tile adhesive

Now is the time to dilute the dry tile adhesive and continue the installation, after the mixture is ready, take a rubber spatula and fill the hole into which we are installing the dowel with it. In order to push the glue as deep as possible, you can use our brick dowel or use a regular pencil. After there is enough glue in the hole, insert a dowel into the still fresh solution.Now, in this position, you need to leave the fastener and let the glue grab, a day is usually enough for this.

Step 4: We tighten the self-tapping screw, we get a strong mount

After the glue solution is completely dry, you can install a self-tapping screw or stud directly into the dowel itself. During installation, you will feel that the fasteners are firmly in the mounting hole, and the mounting bolt is tightened with a certain amount of effort. We guarantee that such a connection is much stronger than usual and will withstand the permissible load without problems. By the way, this method of installing fasteners can be successfully used when installing fasteners in a softer material. For example, a metal dowel for aerated concrete will perfectly adhere to a loose base if it is initially "glued".

- Purchase a vibrating screed:

- Any suspended sliding gates from the SART company.

Conclusion

Hollow brick is a building material that helps trap heat in a room. It is inexpensive and effective to build from it, especially since there are so many different fasteners for it.

What does the shape of your nose say about your personality? Many experts believe that looking at the nose can tell a lot about a person's personality.

Therefore, when you first meet, pay attention to the nose of the unfamiliar

Contrary to all stereotypes: a girl with a rare genetic disorder conquers the fashion world This girl's name is Melanie Gaidos, and she burst into the fashion world quickly, shocking, inspiring and destroying stupid stereotypes.

These 10 little things a man always notices in a woman Do you think your man knows nothing about female psychology? This is not true. Not a single trifle will hide from the gaze of your partner who loves you. And here are 10 things.

Why are some babies born with the "kiss of an angel"? Angels, as we all know, are kind to people and their health. If your child has the so-called kiss of an angel, then you have nothing to do.

How to look younger: the best haircuts for those over 30, 40, 50, 60 Girls in their 20s do not worry about the shape and length of their hairstyles. It seems that youth is created for experiments on appearance and daring curls. However, already the last.

7 parts of the body that should not be touched by hands Think of your body as a temple: you can use it, but there are some sacred places that should not be touched with your hands. Research showing.