Dowel Butterfly for drywall - 4 product options and features of use

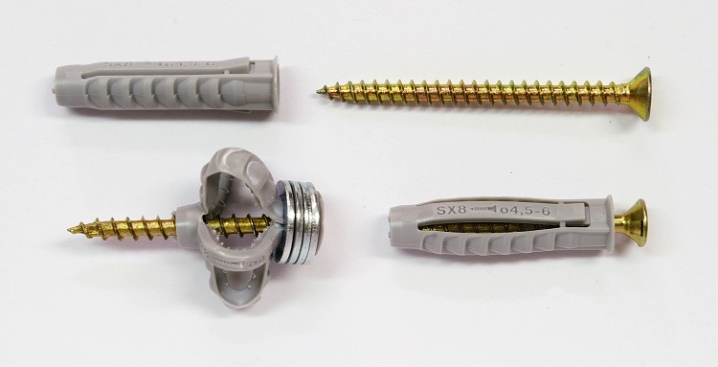

All of the options I have discussed below can be used for certain jobs, I consider only proven solutions that have proven themselves well among buyers and specialists. It is possible that in your city there are not all types of products, but the most universal are usually presented everywhere. Different manufacturers produce different configurations of dowels, so it is not a fact that you will purchase the same option, it may differ in its design, the only common details are a hole in the end for a self-tapping screw and two or more slots along the element.

Naturally, the material of manufacture must be elastic, the ideal solution is a dowel made of nylon. This option differs primarily in the material of manufacture, its second name is "Molly", which, by the way, is also called plastic Butterflies. Unlike plastic options, the size range of such elements is quite wide, and they can be made not only in the form of self-tightening fasteners, but also have a protrusion in the form of an L-shaped screw, ring or hook.

This significantly expands the scope of use. Products can be made of different materials: nylon, polypropylene, polyethylene, etc. When choosing, be sure to check the elasticity of the material, if it is too hard, then when attaching the dowel, they will break. a glass on the drill as shown in the photo, all debris will be collected in it and the room will remain clean.

Types of dowels

Drive type dowel

Perhaps the most popular plasterboard fastener. It can be with or without a drill, metal or plastic. Making a hole for its fastening, use a drill with a diameter of 8mm. The manufacturer declares the shear workload that the gypsum board can withstand using this dowel, 25 kg, while the maximum load is up to 50 kg.

The popularity of the Driva dowel is due to its fairly high reliability and relatively low price. The strength of such an attachment is achieved by distributing the load over a large area, which is provided by the shape of the dowel.

Drywall dowel for drywall is simple and effective

Flat dowel-nail

Such a dowel is made of refractory steel, it is quite simple and convenient to use, since it does not require additional drilling and, accordingly, will get rid of dust. It can be hammered into drywall with a hammer or pressed by hand if you can.

The principle of operation of the dowel-nail is that when a self-tapping screw is screwed into it, the initially flat front part opens up, forming a reliable stop.

It is used for sheets with a thickness of up to 12.5 mm inclusive. Self-tapping screws are chosen with a diameter of 3.5-5mm. Working load on the pull-out, declared by the manufacturer, is 15 kg, for a cut - 30 kg, the maximum load on a cut, obtained experimentally, is 48 kg. Among other things, the dowel-nail is reusable, that is, it can be dismantled and mounted in another place several times.

The flat dowel-nail for drywall is very easy to install, since it does not require drilling

Universal expansion dowel Butterfly

The butterfly dowel is suitable for both drywall and concrete base. The hole for its installation is drilled with a drill with a diameter of 8 mm, the diameter of the complete self-tapping screw is 4.5 mm.

For the butterfly dowel, we recommend using self-tapping screws without skipping the thread, because when screwing, reaching the smooth neck, the screw will start to scroll, and the dowel will not take the desired shape in the form of a stop.

In general, the plastic butterfly dowel works roughly like the others, creating an emphasis behind the gypsum board when screwing in the self-tapping screw. In shape, such an emphasis is somewhat reminiscent of a butterfly, hence the name of the fastener. The design working load for the dowel is 25 kg, the maximum working load is 55 kg.

The Butterfly dowel for drywall is the most popular because it is equally inexpensive, convenient and effective.

Dowel molly

The Molly dowel, or rather the Molly anchor (after all, this is an independent fastening unit that does not require an additional self-tapping screw) is another popular type of fastening for drywall, made of metal. This dowel, unlike the previous ones, is produced in various sizes and, accordingly, for different loads.

For example, for Molly, the minimum size marked 4/16/38 (4 is the screw diameter, 16 is the neck length and the maximum sheet thickness for which it can be used, 38 is the total length of the element), the working load is 25 kg, the maximum shear is 47kg.

To make holes for Molly, choose a drill 2 times larger than the diameter of the neck (the first number in the marking), that is, for a four it will be 8 mm, for a six - 12, etc.

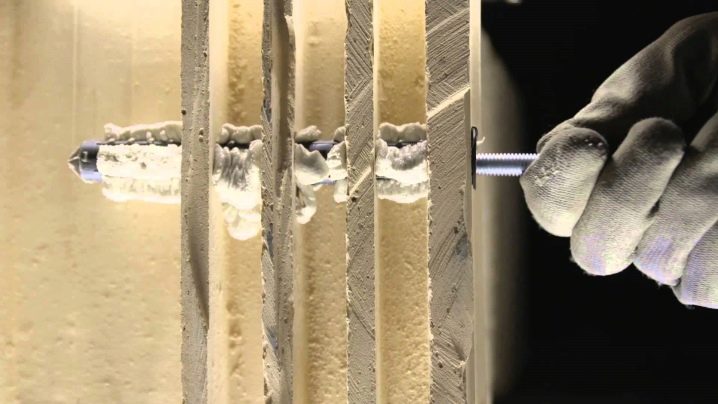

To install the Molly dowel, you need a special tool that brings the fastener to "combat readiness". With its help, the screw is slightly pulled towards itself, while the hooks are bent. Then you can turn the screw with a screwdriver, bending the hooks until they stop. All this should be done by inserting the dowel into the hole in the drywall.

If there is no special tool, you can put the anchor into action using nippers (side cutters) or even an ordinary flat screwdriver.

Molly drywall plug - the solution for professionals

Fischer's twisting plastic dowel

When screwing a self-tapping screw into such a dowel, the latter twists, forming an emphasis behind a sheet of drywall, hence the name of the fastener. The drilling diameter for such a dowel is 8 mm, the diameter of the self-tapping screw is 5 mm.

When tightening the self-tapping screw, the main task is not to squeeze too hard, otherwise it will begin to turn, and the fasteners will need to be done again. For this reason, when using a screwdriver for tightening, set the minimum speed on it.

The working load for the detachment of the twisting dowel is 10 kg, for the cut - 25 kg, the crash load - 70 kg.

A twisting plastic drywall plug is an interesting and effective solution, backed by Fischer's reliability

Description

Molly dowel is a type of fastener for drywall and similar materials. By default, such a product is formed entirely of metal. There are almost no structural differences from the "butterfly" fastener. However, the elimination of plastic elements increases the load-bearing capacity. True, this is achieved only when the design itself is more expensive.

The main components are screw and sleeve blocks. The screw is either included in the kit by default, or is customized according to your preference. A metal collet is an empty bushing inside.

Since the collet can contain grooves inside, this complicates the selection of a suitable screw. An alternative option is to complete the screw from the original kit with a support washer. This washer will have a pair of serrated tipped ridges. It is attached to the surface, which will prevent the collet from spinning uncontrollably during installation. Finally, there are modifications of screws with countersunk heads or with conventional tips in the form of a semicircle.

The principle of operation is quite simple: the molly dowel is inserted into the required hole when it is folded. Next, tighten the required screw inward. When this happens, the spacer is compressed. In this case, a support is formed in the form of many petals, reminiscent of a "tent" or an umbrella. It will press firmly against the wrong side of the material being cut.

It is necessary to fasten such an anchor a little differently than in the case of a simple "butterfly". The screw may not be screwed in, but, on the contrary, pulled out. To work with it, you need dowel pliers or assembly pliers. But a typical locksmith tool from a home workshop will not help.Molly dowels can be dismantled and reused (this is not possible with a simple "butterfly"); manufacturers even specifically emphasize that dismantling will not affect the operating parameters.

It is worth noting that the described type of dowels will require a fairly significant free space for installation. Manipulating pliers and pliers in a confined space is extremely difficult, because this tool itself has a certain length.

For your information: for double drywall, only special designs can be used. Such fasteners include a tip in the form of a drill. Only such an end part can be safely and reliably screwed into a thick sheet. Alternatively, you can use "self-aligning" dowels, strips and other types of fasteners. But this is a separate topic that requires special analysis; but for hollow structures, a typical Molly dowel is perfect.

Fastening heavy objects to drywall

- With a large distance of the cladding from the load-bearing wall, it is impossible to fix massive elements.

- Anchors can only be used with appropriate wall materials (brick, concrete), fragile gas and foam blocks or raw brick will not withstand the load.

- A fixed heavy part cannot be moved to another area.

- The section of the mortgage must be selected so that it practically touches the back side of the drywall sheet. The process of installing embedded plasterboard

- Installation of bookmarks is possible only at the stage of assembling the frame; if there is a finished finish, it is unrealistic to apply this technique.

Where and how to use the butterfly dowel

The Butterfly dowel has the shape of a rhombus, while its flexibility allows you to easily insert it into a narrow hole drilled in drywall, and then, when clamping with a self-tapping screw, expand the fastener in another plane. So, we figured out the characteristics and installation rules of one of the most popular fasteners - dowel Butterfly. It is easy to install, quite accessible and capable of carrying a fairly large load. In this article, we will consider the characteristics of the Butterfly dowel, tell you how much weight it can withstand, and also tell you about the features of its installation.

In the process of screwing the self-tapping screw into the dowel, the latter takes a special shape in the form of a stop spaced across the area on the back of the plasterboard sheet. It is thanks to the large area of distribution of the load on the drywall that it is possible to achieve the possibility of increasing the bearing capacity of the gypsum board. For example, a wall-mounted bookshelf with two hinges (that is, with two attachment points), with a maximum load of up to 50 kg, will hang quite reliably, even with a margin.

At the same time, for a shelf of 70 kg, it would be better to add one more attachment point, otherwise there will be a risk of its separation.

- Checkpoints. They are used for fixing to the ceiling. They are ideal for installing massive chandeliers or sports equipment.

- Decompressing. Used for hanging household items and interior no heavier than 15 kg.

It is worth noting that butterfly dowels are made in different sizes, but 9x13 mm and 10x50 mm are the most popular. It should be remembered that for full disclosure of the butterfly dowel, you need to take a self-tapping screw no more than 55 mm long. In addition, the masters are advised to take into account the distance between the drywall and the wall. Then squeeze the butterfly with your fingers and place it into the prepared hole until it stops. Next, fasten the self-tapping screw of the required length.

As a result, you will have a reliable design that can withstand a load of no more than 16 kilograms. According to the promises of the manufacturers, the “butterfly” nail dowel can withstand a maximum load of 28 kg. However, the recommended load for the fasteners is approximately twenty kilograms.

And how many kilograms can a double sheathing of a partition or a wall made of gypsum plasterboard hold? It is capable of withstanding 15 kg and more per one fastening unit.The reason for this strength of the device is the properties of the material and its construction. The installation principle of the fastening device is as follows:

Additional information on the topic:

- How the profile is attached to the wall and ceiling when installing drywall

- Is it possible to sew up heating pipes with plasterboard according to the law

- Is it possible to paint drywall with water-based paint for wallpapering

- Is it possible to stick a self-adhesive film on drywall

- Is it possible to glue drywall to a concrete wall with tile adhesive

Photo of dowels for drywall

We also recommend viewing:

- Crab system for shaped pipes

- What is a lifting shackle

- What is foundation bolt

- Why do you need a grover washer

- Dowel-clamp for cable fastening

- Lifting crane hook

- How to choose cable clamps

- Features of furniture fasteners

- Wood grouse wood screw

- Which toilet mount is better to choose

- Fasteners for timber structures

- Fasteners for plastic windows

- Advantages and Disadvantages of Screw Nails

- Best plastic dowels

- How to choose a threaded rod

- Self-tapping screw with drill

- How to choose self-tapping screws for metal

- The most reliable pipe fittings

- The best screws for concrete

- How to choose pipe brackets

- High Strength Bolt Parameters

- Hex bolt

- Varieties of anchor bolts

- Construction nails

- How to use the drop-in anchor

- How to select and install a wedge anchor

- Features of dowel screws

- Hammer-in metal dowel

- What is a dowel-nail

- How to choose and apply a chemical anchor

- Sink bracket

- Types of brackets and fasteners for shelves

- How to choose a steel chain

- Choosing a bracket for the cornice

- Brackets for satellite dishes

- Choosing the best plastic clamps

- What is a construction bracket

- The best roofing screws

- Expansion dowel

- What are wood screws

- How to choose a wall mount for your TV

How to install

Drywall is known as a finishing material with not the highest strength. In the process of work, it can crack, break and crumble. But since it is easy to install, builders love to use it in their work. In order not to subject the plasterboard wall to mechanical destruction, a butterfly dowel was created. With its help, installation to drywall can be performed not only by experienced specialists, but also by beginners.

Most often, such fasteners are used when it is necessary to hang a shelf or a heavy picture on a drywall wall. Securely fixed in the wall, the butterfly dowel can withstand a structure weighing up to 10 kg. Provided that the wall is made of two layers of gypsum board, you can hang an object up to 25 kg on it.

It is very easy to screw a butterfly dowel into drywall. This is done, as a rule, in a couple of minutes. At the same time, to carry out high-quality work, you need to adhere to some rules:

First you need to determine the place of attachment, assess the complexity of the work and choose the required type of dowel-butterflies. You should not be surprised that there may not be self-tapping screws or screws in the kit - they will need to be purchased separately.

- Usually, dowels are bought with a small margin. Their versatility lies in the fact that it is possible to fasten the butterfly dowel not only to drywall, but also to many other materials.

- It is best to make markings, along which the installation of dowels will then be carried out, using a building level. This will help to avoid mistakes in work.

- Drilling drywall must be done with a drill. For punching, you can use a wood drill. It will be more convenient to drill with a screwdriver.

- Before starting drilling, you must make sure that the screwdriver works with the impact mode disabled.

- The hole must be sized to accommodate the plastic dowel. Usually it is made 4 mm larger than it, since it should expand slightly when the self-tapping screw enters it.

- A fastening element is put on the self-tapping screw, on which the desired object is subsequently suspended.

- The dowel is clamped with fingers and threaded into the hole drilled in advance, up to the fastener head. Then you should tighten the screw.

- The self-tapping screw is required to be tightened until it is firmly fixed. This is the only way to expand the dowel components to the maximum and securely fix on the plasterboard wall. At the same time, the use of a screwdriver in the installation significantly reduces the likelihood of thread breakage in plastic.

- Then, with a little effort, you need to pull on the external fasteners. In this way, the firmness of the fastening can be checked.

Plasterboard dowel butterfly fasteners and its device

The butterfly dowel is a self-tapping fastener that is clamped when screwed, which is achieved due to its unique design.

- Special feet fit snugly against the back surface of the drywall, which allows you to significantly increase the area that receives the load coming from the mass of the suspended object.

- That is, such fasteners contribute to the even distribution of the entire load entering the drywall sheet.

- Such a dowel is characterized by the following design features and characteristics:

- It is used to fix a single or double layer of drywall (thickness 10-12 and 20-24 mm, respectively);

- The complete set also includes self-tapping screws suitable for the type of thread and length, although its use is possible with other screws, provided that they correspond to the required standard sizes;

- The part of the butterfly dowel located inside the drywall sheet has a number of ribbed elements that prevent the anchor from turning around the axis;

- The presence of an internal thread on the head ensures that the dowel is clamped and folded, and the internal tabs guarantee increased rigidity of the element in the twisted position.

Varieties of butterflies for drywall

Depending on the conditions of use and the type of material to be fixed, the butterfly dowel for drywall can be made of:

- Metal;

- Plastic;

- Nylon.

Photo dowel butterfly metal

Photo dowel butterfly made of plastic

Metal dowels are characterized by improved practicality and reliability, but at the same time they have an increased cost. They are able to withstand heavy loads, and to increase their service life, many manufacturers treat them with special anti-corrosion compounds. Butterfly metal dowel is most popular with professional drywall makers. It is more convenient to work with it, you will not twist it or tear it like a plastic one, and even more so a nylon one. But the price of such dowels can significantly increase the estimate, especially for large-scale works with gypsum board.

Nylon and plastic dowels are modern variations that are distinguished by their lightness, accessibility and resistance to rusting, but with reduced mechanical stability and a reduced threshold for permissible loads. These butterflies for GKL are much cheaper and provide significant savings.

Current prices for butterfly dowels made of various materials for a pack of 4 pieces:

- Dowel butterfly plastic size 10x50 with a screw: 32 rubles.

- Dowel butterfly polypropylene size 10x50 with a screw: 26 rubles.

- The metal dowel butterfly already has other dimensions due to the design features.

For example, the price for a metal dowel a butterfly with a 4x24 screw: 74 rubles.

If you compare prices, then you can immediately see that metal butterfly dowels are more expensive than plastic and especially polypropylene ones more than twice!

What's better?

Driva

In order to make the right choice in favor of one or another dowel, and the screwed-in screws or self-tapping screws were firmly held in the wall, you need to know the technical characteristics and purpose of each fastener.

Let's consider each type of dowels separately.

Dowel-drive. The driva fastener is used very often today. At the moment, on the construction market, the drive has two options:

- plastic.It can be either polyethylene or nylon;

- metal. For the production of such a dowel, a zinc alloy is used.

Such a dowel with a screw is especially popular, since its price is quite acceptable. This is especially true for a plastic product.

The driva dowel is fastened as follows:

a hole is drilled in the wall;

After that, we screw in a screw or self-tapping screw and you can safely hang any object. The main difficulty in this process lies in the selection of the correct size of the self-tapping screw.

His choice is made according to the following parameters:

- dowel length;

- the weight of the item to be mounted on the wall.

The pluses of the driva fastener include:

- no need for free space behind the wall;

- affordable cost;

- withstands loads up to 32 kg for metal and 25 kg for plastic.

Dowel-molly

Dowel - molly. The main difference between this element and the previous one is its installation. Here you need to use a drill with a diameter of 8 mm. The installation process is as follows:

- a hole with a diameter of 8 mm is drilled;

- molly is inserted into the cut hole. In this case, the side, which has two teeth, tightly presses the device against the sheet. In such a situation, the drywall anchor will not scroll, which prevents it from falling out and a better fastening is achieved.

The molly attachment method is also quite common. Many people choose it because of the following advantages:

Anchor

- one set contains both dowels and screws, which facilitates the installation process and eliminates the need to search for self-tapping screws;

- easy dismantling possible;

- the mount can withstand a load of up to 35 kg.

The disadvantages of molly include their rather high cost.

Sometimes, instead of molly, some use a drywall anchor. Such fastening is carried out according to the same scheme, while the anchor can withstand a slightly higher load.

Tips & Tricks

If you have never encountered installation and finishing work, then it is best to entrust this work to professionals. They get the job done quickly and you don't have to redo anything.

And for those who decided to install the fasteners on their own, it is important to know a few key points that will significantly affect the efficiency and the final result of your work.

- Hammer in the butterfly dowel. It is not enough to simply screw in the anchor as it can dangle in the hole without being secured tightly enough.

- Observe optimal dimensions. If you make too large a hole in the drywall sheet, then the fasteners will not hold well and will not bring the necessary benefit.

- Keep track of the thickness of the sheet. "Butterfly" works great on products with a thickness of less than five millimeters. For larger structures, a different fastener should be selected. At the very least, it should be longer.

- Leave enough space behind the plasterboard. Remember that there must be at least thirty-five millimeters of free space behind the drywall sheet. Only in this way will you be able to optimally tighten the anchor by pressing the stop.

- Use a regular screwdriver. Take the time to put the powerful drill aside. Since high turns of technology can easily damage the plastic edges of the stop. While a screwdriver will not harm them at all.

The "butterfly" dowel for work on drywall is one of the most effective and modern types of fasteners. Experts note that this type of anchor can compete with reliable metal fasteners. And in some cases even surpasses them.

In the next video, see how to use the butterfly dowel.

Diversity in the construction market

To carry out reliable fastening in drywall, it is necessary to use not ordinary self-tapping screws, but special dowels designed for gypsum materials.To figure out which type of mounts is best, let's look at each of the proposed options.

Dowel "Driva"

The main purpose is to mount lamps, wooden slats and other decorative and functional products to drywall.

The thickness of the web must be at least 9 mm.

Most often, “Driva” dowels are made of plastic, but there are also metal ones.

Metal “Drive” - this type does not allow tearing off the edges of the dowel, reliably fixing the hinged structure

- They are considered the lightest type of fastening for drywall.

- The fixation is carried out by means of a rare and wide thread. This method does not allow the gypsum to crumble, providing a reliable fixation of the drywall dowel.

- Drives do not require pre-drilling a hole. The dowel can be screwed in with an ordinary screwdriver or screwdriver.

This is not to say that such fasteners are the most reliable, but it can be used when hanging any objects, such as: photo frames, paintings, sconces and other light decorative items.

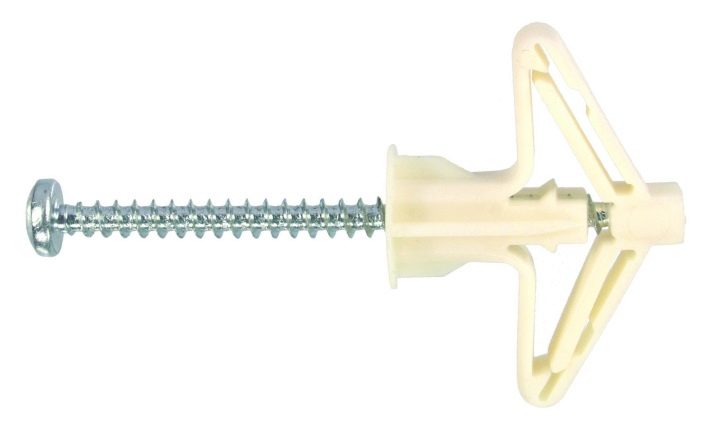

Dowel "Umbrella"

Another type of attachment that looks like an umbrella.

It can be used not only for drywall, but also for other materials: chipboard, reinforced hollow ceilings.

- If we compare it with other types, then it is rightfully considered the most powerful fastener. Therefore, it is more often used for hanging cabinets, water heaters and curtain rods.

- Opening in the void, “the umbrella distributes all the load over a large area, which prevents the drywall from experiencing stress at one point.

- Can be completed with L-Hooks, Hooks and Eye Screws.

Various types of plugs available on the market

Dowel “umbrella is often used for suspended ceilings, for example, this type of fastener is able to withstand a weighty chandelier.

"Umbrella", aka "Molly" - suitable for various designs and materials

Dowel "U"

Fastening type, which is made of polypropylene.

Quite a practical fastener that perfectly fixes light objects on drywall.

- There are two options: with a flange (thrust washer) and without a flange. The only difference is that the presence of the side does not allow the dowel to fall into the material.

- The price is quite reasonable, it is plastic after all.

Standard polypropylene dowel: top for concrete, bottom for drywall

Dowel "Butterfly"

And now the butterfly dowel for drywall, which everyone has probably heard of, will appear to your attention. This dowel is the most common, since it is used not only by builders, but also by people who have nothing to do with the construction site.

Its merits will answer the question, why is it so popular?

- The thickness of one plastic dowel is 10-12 mm, which is quite enough to withstand several cycles of screwing and unscrewing the screws.

- The stop, which is formed on the opposite side of the drywall, distributes the load over a large area, making the drilling site less vulnerable.

- Longitudinal ribs prevent the dowel from spinning, which increases the service life of the drywall fastener.

As you can see, the above characteristics make it possible to say that this type of mount is perfect for working with drywall. You can hang on it not only lamps and paintings, but also mount wall cabinets, TV brackets and much more.

Look at the photo how the butterfly dowel behaves in the material.

It can be seen that the emphasis is quite tight, it allows you to avoid accidental disruptions of the attachment.

How to use?

Novice craftsmen, who first took butterfly dowels in their hands, are slightly lost. They know the technology of their application, but in practice in working conditions they only watched the experienced specialists from the outside. For this reason, you need to practice a little at home before starting work.

In fact, the principle of working with nail dowels is very simple and very convenient.

First of all, you need to check the complete set of butterfly dowels. In some cases, you have to additionally buy screws.

Then it is required to determine the place of installation of the structure.

Next, you need to make the markup. This requires the use of a level. It is this tool that will help to expose even indicators, otherwise the wall will be damaged.

Now you need to take a screwdriver and insert a drill into its head. It is worth noting that drywall is a pliable material, so a drill for wood with a diameter of 8 mm will be enough. Many people know that the power of a screwdriver is not too high, but more is not required. Experienced builders recommend putting a plastic cup on the drill. Thus, it will be possible to protect your airways, and not to clog the floor with debris from drilling structures. A hole is drilled.

Next, a dowel is taken, it must be tightly clamped with your fingers and pushed into the hole made.

After planting the dowel, it remains to screw in the screw.

The fixing element is supposed to be fixed at the very end. Its size depends on the thickness of the screw. For example, for a 3 mm dowel, it is preferable to take a 3.5 mm screw

It is very important that the screw goes into the dowel to the very end. With this dimension, the dowel wings open as much as possible, due to which they are attached as tightly as possible to the wall.

If it was not possible to install the dowel at the first attempt, it is necessary to pull it out and check the internal condition of the hole

It is possible that debris has formed inside, which has become an obstacle to the entry of the element.

Interior designers and decorators most often use butterfly dowels in their work. With their help, it is possible to hang various decorative elements on the walls and ceiling. Butterfly dowels are a favorite type of fastening for theatrical scenery - they are easy to assemble, easily removed.

In the next video, you will find a presentation of the Sormat OLA multifunctional plastic anchor (butterfly dowel).

How to mount on unstable surfaces

Very often there is a need to fasten objects on unreliable surfaces, which include plasterboard walls, building structures in old brick houses, etc. When fastening on such surfaces, the following recommendations should be followed.

- It is better to choose dowel elements from nylon, while their diameter should be 10–12 mm. The diameter of the winning drill, with which the hole for the fastener will be made, must be 2 mm smaller than the transverse dimension of the selected dowel.

- Drilling must be performed in one step, without changing the drill, and the impact mode should not be used in order not to destroy the walls of the hole being formed.

Securing items to plasterboard walls with a butterfly dowel

To perform reliable fasteners, it is important to take into account the condition of the surfaces, choose the right cutting tool and competently carry out the drilling process itself

Important parameters that should also be taken into account are the dimensions and weight of the object to be fixed. In addition, it is necessary to choose the right screw for the dowel in order to ensure reliable fastening of the object to the surface of the wall or any other building structure.

Varieties of fasteners

Drywall screwdrivers are usually classified according to various bases. To begin with, we propose to figure out how the drywall dowel can differ in the types of fastening:

- Classic. They are also called anchor. They are characterized by durability and long service life. They can be used to fix both metal and wood profiles. The drywall anchor is the base into which the self-tapping screw must be installed. Their advantage is the perfect grip, which provides them with different sized barbs. As a result, it will be impossible to pull them out.The disadvantage is the need to drill holes in the wall in advance. The disadvantages include the limited surfaces on which they can be installed. So, the wood will surely begin to crumble when applied.

- Nails. They can withstand quite heavy loads, in certain cases hundreds of kilograms. This indicator depends on the size of the leg. The plasterboard nail dowel is used directly for fastening to the frame. As in the case of anchoring, it can be used for wood and metal profiles.

- A butterfly is a combined product with a plastic base that resembles a butterfly. It is into it that the screw should be screwed. By fixing the dowel in drywall, the base is tightly pressed against the joint and provides good adhesion to the screw. A product such as a dowel for gypsum board can be made of different materials. This is one of the grounds for classification. In this regard, it is customary to distinguish the following types:

Varieties of fasteners

Choosing between metal and plastic dowels - we advise you to give your preference to the second type, because metal rusts over time.

- Metal - made of zinc alloy. This significantly increases their cost, but guarantees a high load threshold.

- Plastic and nylon are modern designs. Their main advantage is that they do not rust and are also lighter in weight. It is better to use them on lightweight structures.

Advantages

The popularity of this fastener in modern finishing works is explained by its several advantages:

Versatility. Today in any store you will find a dowel as an independent product, as well as an addition to a self-tapping screw. This means that, if necessary, you can easily replace the threaded part with hangers or a ring.

Fixation reliability. This quality is achieved by the design feature of the fastener, which implies the presence of a ribbed surface. There is no doubt that the dowel will be securely fixed in the gypsum board.

Providing additional rigidity. If you screw in the butterfly anchor, its legs will spread apart

Due to this, additional rigidity of the entire structure is achieved, which is especially important when working with gypsum board from two layers.

- Simplicity of installation work. You can easily cope with this type of fastener, even if you do not have a lot of experience in construction and finishing work.

- Long period of use. The 12mm plastic dowel can be used multiple times. It is very convenient and saves time and money.

- Availability. You do not have to search for the required anchor for a long time. "Butterflies" today are easy to find in any hardware store.

Varieties of butterfly dowels

Such self-tapping fasteners are tightly clamped when screwed, respectively, the dowel is quite reliable. The meaning of the design is that the clamping legs fit as closely as possible to the back surface of the gypsum board sheets, thus suspended chandeliers and other lighting fixtures will not bear the load only on a limited area of the ceiling. The load will be uniform.

As for the thickness of the dowels, they can be either from 10 to 12 mm or from 20 to 24 mm, which corresponds to a single or double layer of drywall. The complete set differs with self-tapping screws of various lengths and threads, although other screws can be used there if necessary. Rotation of the anchor around its axis is practically excluded due to the presence of several ribbed elements located inside the structure.

Dowel Butterfly

Dowel Butterfly

"Butterflies" for drywall are made not only of metal, but also of plastic and nylon. Metal products are more practical to use and last longer, but this affects their cost.Large loads are not terrible for them, as well as corrosive processes, since products are processed with special compounds even at the manufacturing stage. It is almost impossible to break or twist such a “butterfly”.

A more modern variation of dowels is nylon and plastic. They are impervious to rusting processes, are affordable at their cost, but cannot compete with steel products in terms of the threshold of permissible loads and mechanical stability. As for the cost, plastic will have it about 32 rubles, and a nylon dowel will cost 26 rubles.

We are considering products with the same size - 10 × 50, but steel dowels have completely different parameters, for example, you will have to pay about 75 rubles for a “butterfly” with a 4 × 24 screw.

Dowel Butterfly photo

Dowel Butterfly photo