Tips & Tricks

If the facade is decorated with such a material on its own, it is necessary to take into account some recommendations so that the finishing will serve for many years and retain its positive characteristics. Installation should be done only if the temperature is above zero and in the absence of high humidity. There are a few more styling rules that are useful to know about.

- It is not worth laying out more than six rows, as you should wait some time for the composition to grab. This is necessary to avoid deformation.

- If you need to highlight window openings, you can decorate them with fragments of a different shade. In such places, anchoring should be carried out along the entire perimeter.

- The elements must be moistened so that they absorb water from the solution more slowly.

Show finishes for facade facing bricks: types and characteristics

All the variety of facing bricks can be attributed to its three main types:

Clinker.

Hyper-pressed.

Ceramic.

All of them have their own characteristics of production and field of application.

Clinker bricks of "real" brick color are always in trend

Clinker brick

The technology for the manufacture of clinker bricks is based on the firing of a special type of clay with increased plasticity. It is pressed and high-temperature roasted until baked. Colored dyes from natural raw materials can be added both during the firing process and at the stage of mixing the mass. It is noteworthy that the color of the finished product depends on the temperature and duration of the firing.

The combination of clinker bricks with hyper-pressed bricks together with plaster looks very modern

Due to the fact that the production of clinker takes place at very high temperatures, its strength is very high. Even roads and squares are paved with bricks and tiles made using this technology. Resistance to aggressive environmental influences makes this material indispensable for use in places with high humidity. Masonry made of this material can withstand over 100 years. The disadvantage of clinker is its high cost. It is more than 2 times higher than that of ceramic bricks.

Ceramic bricks remain "classics" when decorating facades

Hyper pressed brick

Strictly speaking, it is more correct to call this material an artificial stone. It is produced by the method of semi-dry pressing of bulk components. These include crushed limestone, cement, and colorants. All this is mixed and compressed to the required shape. Then the workpieces are kept for 3 to 7 days on pallets and go on sale.

Durable hyper-pressed brick facade

Hyper-pressed brick has the following advantages:

- High strength.

- Frost resistance.

- Moisture resistance.

- Weakly prone to wear.

- Easily tolerates temperature changes.

- Excellent decorative characteristics. Has a variety of colors and surface types. Some of its types successfully imitate natural stone.

Facade decoration with hyper-pitted bricks, together with the adjacent territory looks gorgeous

When using hyper-pressed facing bricks for the facade, each owner of such an object can show the options for finishing geometrically complex architectural forms. This is possible due to the ease of machining the material. The disadvantages of this brick include high cost and greater weight than other types.

Hyper-pressed bricks go well with siding

Ceramic brick

This type of brick is made from a special type of clay. Formed blanks are dried and fired at temperatures from 1000 to 1200 degrees. Due to this, ceramic bricks have sufficient strength and frost resistance. It has a regular shape with straight ribs. The surface of the faces can be flat or embossed.

Ordinary ceramic bricks covered with facade paint

This is the most common type of brick. Due to its relatively low cost, it is used not only for facade cladding, but also for the construction of fences, as well as internal walls that do not require additional work. Its disadvantage is the penetration of moisture into the structure of the brick, which leads to the emergence of salts on the surface, creating a whitish coating.

Hyper-pressed facing brick successfully replaces natural stone in facades

Weight and dimensions of facing bricks

Facing bricks differ in their technical characteristics, weight, cost, appearance, dimensions. There are optimal standards stipulated by GOST, which relate to the size of this material. Therefore, lots are usually accompanied by certification documents. According to GOST, a brick should have dimensions with dimensions of 250/120/65 mm, where the first indicator is the length, the second is the width, and the third is the thickness. A single standard for brick production was established back in the 27th year of the last century and has remained unchanged since then. This standard applies to both facial and construction. The product can be manufactured using various technologies, but its size will always be standard:

-

Double brick measures 250/138 mm;

-

Standard single 250/120/65 mm;

-

Thickened 250/120/88 mm.

Designation of the sides of a brick on a fragment of masonry

However, at the request of the customer, it is possible to manufacture facing bricks of a different shape, but even these non-standard shapes are stipulated in the GOST. Most often, a brick is ordered with a size of 0.7 NF, which has parameters of 250/85/65 mm. It is used in the restoration of the facades of old buildings to reduce the load on the foundation. The standard product weighs from 3.2 to 5 kg so that the builder can lift it with one hand for ease of installation. The standard size of facing bricks helps to correctly calculate the required amount of material per cubic meter or square meter. Construction experts say that it is the standard proportions of the product that make it possible to obtain the required strength of the facade. This makes it possible to evenly distribute the loads and provide crack resistance. In addition, the set size allows you to lay out a cube.

Table of sizes and designations of bricks according to GOST 530-2012

| Nominal dimensions | Product size designation | ||

|---|---|---|---|

| Length | Width | Thickness | |

| 250 mm | 120 mm | 65 mm | 1 NF (Single) |

| 250 mm | 85 mm | 65 mm | 0.7 NF |

| 250 mm | 120 mm | 88 mm | 1.4 NF (One and a half) |

| 250 mm | 60 mm | 65 mm | 0.5 NF |

| 288 mm | 138 mm | 65 mm | 1.3 NF |

| 288 mm | 138 mm | 65 mm | 1.8 NF |

| 250 mm | 120 mm | 55 mm | 0.8 NF |

Siding

When deciding what is better to sheathe a brick house, many owners stop at siding

When deciding what is better to sheathe a brick house, many owners stop at siding. There are many varieties of this material that accurately imitate stone or wood wall covering. On sale there is a siding made of metal, vinyl and asbestos cement. The most popular is vinyl siding. Its price is the most reasonable, and installation and processing are the simplest.

Among the advantages of this material is the following:

- The product is quite elastic and resistant to mechanical stress, namely, scratches and impacts.

- The panels do not lend themselves to damage by microorganisms and insects, do not fade in the sun, do not rot.

- Siding reliably protects the walls of the house from wind and atmospheric moisture.

- The material is very easy to clean. To refresh the façade, just wash it under running water.

- A large selection of colors and textures allows you to create beautiful and original facades.

- The product is not subject to burning.

- The material is not toxic.

- Affordability and ease of installation are additional advantages.

As a rule, siding is mounted on a crate. When installing vinyl siding, it should be borne in mind that the material reacts by changing its linear dimensions to temperature changes, therefore, when installing it, you should adhere to the following rules:

- Siding is mounted using corner, profile and connecting elements, that is, all panel ends are hidden inside the additional elements. To compensate for thermal deformations from the end of the panel to the additional element, there must be a gap of 10 mm.

- Installation of fasteners is allowed only in special oblong holes on the panel. In this case, the fasteners must be screwed into the central part of the hole.

- It is forbidden to tighten the fasteners tightly, since in this case the panel is deformed and may crack from temperature extremes.

Bricklaying technology

The quality of the finished decorating the house with bricksMuch depends on the correct choice of material and on its quantity.

The last point is important because bricks must be purchased from the same batch,

since the products in it will be of the same color and shade - thus, it will be possible

avoid the checkerboard effect after the masonry has dried.

To accurately calculate the number of products required for brickwork, you should

take into account that 50 bricks are used for 1 m2. Their quality can be determined by

appearance:

- the presence of shells and pores is not allowed on the surface of the brick;

- the front side of the product should be smooth and even;

- the size of the material must correspond to the standards of 250/120/65 mm.

The next step is to prepare cement

solution... Its composition is the same for all types of finishing works, in addition,

no professional equipment is required for its manufacture. The whole process

occurs in the presence of improvised tools: deep plastic or

a metal container, a shovel for feeding the mixture, as well as an electric drill with

mixer attachment.

The ingredients are mixed in the following order:

1) we take sand and mix it with cement in a ratio of 1 to 5;

2) then pour water into the resulting mass (it is advisable to pour it gradually and

in small volumes so that the solution does not turn out to be too liquid as a result);

3) if necessary, you can add drugs to improve

plasticity of the solution (it is recommended to do this in accordance with the instructions for

factory packaging);

4) stir the resulting mass with a mixer until it is brought to a pasty

condition. It is also important to note that it is advisable to use fine-grained sand and good

sieved. It needs to be completely cleared of stones and small debris, then we

we will be able to prepare a cement mix of good quality.

Brick cladding should be erected

at a distance of 50 millimeters from the outer wall. This will give us the opportunity

perform its strapping without violating the integrity of the structure. For this purpose

long nails, metal reinforcement or wire diameter 6

mm... This event makes the finishing coating resistant to various loads.

and does not allow it to deform.

To protect the finished masonry during drying from rainwater or

snow, it can be covered with plastic wrap. The edges of the polyethylene must

go down and cover the part protruding above the ground

foundation.

When constructing a covering over door or window openings, it is desirable

use reinforced concrete lintels, as they will help evenly

distribute the load and prevent the masonry from collapsing under its own weight.

Types of bricks for facade cladding

The facades of brick houses can be made of different materials. The best is brick. It can be of different types, colors. In addition, on sale you can find original substitutes for this material, for example, facades made of artificial stone look beautiful. So, which material to choose for cladding the facade of the house? Let's take a look at the popular types.

Classical

This material is also called silicate brick. It is often used in construction for the construction of various structures. In addition, it is often used for cladding the outside of many private houses, windows.

The advantages of this material:

- performs excellent protection of the facade from negative external influences;

- has a simple masonry - no difficulties arise during its installation;

- different colors - you can often see silicate brick facades that have different colors - light, white brick, red brick, and so on;

- low cost - this material has a low cost, so it is in high demand.

Hyperpressed

The hyper-pressed look is made from a moistened mixture of crushed stone, limestone and cement. Pigments for color are also added to this mixture, this process is carried out under increased pressure. During hyper pressing, all elements are soldered at the molecular level, which allows obtaining high strength of the material. The finished material is able to withstand a load level of up to 250 kg per 1 square meter.

Features of this material:

- hyper-pressed porous material is highly resistant to severe frost;

- increased moisture resistance - a brick of this type does not allow liquid to pass into the walls during rain or snow;

- has high strength and durability;

- the cost is not too high, compared to the excellent qualities of the material;

- wide assortment - on sale you can find material that imitates an artificial stone facade.

Modern products of the hyper-pressed type may have unstable colors. The design of buildings from yellow, from red, from brown material looks pretty nice. Also, these products can be used for window cladding.

Ceramic

Ceramic material for decoration is considered the most expensive, and it also presents certain difficulties during installation. But despite the fact that it belongs to the decorative varieties of stone, it is able to withstand a load of up to 150-200 kilograms per 1 square meter.

Positive qualities of the material:

- long service life - this material can last more than 20 years;

- has increased resistance to moisture, sunlight, temperature extremes. In addition, it does not collapse, does not fade;

- has a solid structure;

- the design of the appearance of ceramic bricks is attractive, therefore it is often used to decorate the appearance of the house;

- does not require increased maintenance - in order to wash off all the dirt, you just need to rinse everything with water from a hose.

Ceramic-type material is available in various shapes and surfaces - smooth, rough, wavy, even. It can be used for wall cladding made of wood, as well as for decorating windows.

Clinker

Clinker brick for the facade is a type of material for construction and decoration. The durability of clinker finishing has long been proven by many European houses that were built several centuries ago.

It is worth highlighting the main advantages of this material:

- Due to the fact that during the production of this material, traditional firing of clay brick is used, its strength and wear are increased. 1 square meter of this material can withstand a load of almost 400 kg;

- high frost resistance, the material is able to withstand frosts down to - 150 degrees Celsius. For this reason, clinker brick cladding is used in northern regions with a cold climate;

- has a high moisture resistance - wall decoration made of this material is able to withstand the effects of heavy rains, snow and other atmospheric precipitation;

- clinker material has a variety of textures, different colors, which makes it possible to use it for wall cladding with various architectural styles.

However, this imitation brick has a very significant drawback - it is its high cost. Its cost is sometimes almost double that of the ceramic material.

Cork and wood flooring

The mounted panels are varnished on top

The mounted panels are varnished on top

Cork panels are used to decorate bedrooms and children's rooms. This material has good sound insulation, has a pronounced texture and intricate pattern, and its installation is not difficult:

- the cork is attached with self-tapping screws to a wooden frame made of a bar, previously installed on the surface to be finished;

- the seams between the panels are sealed with a special sealing material;

- the process is completed by coating the panels with varnish.

Various wooden materials are actively used for interior decoration. They do not require additional finishing, as they have an attractive appearance and go well with wooden furniture.

Various wooden materials are actively used for interior decoration. They do not require additional finishing, as they have an attractive appearance and go well with wooden furniture.

When decorating interior brick walls, the following important features must be considered:

- Do not allow such coatings to come into contact with moisture.

- When installing wooden coverings, a membrane vapor barrier must be used, and it must be fastened on top of the crate.

- Wooden finishing boards, lining and other materials are connected to the frame and to each other without gaps, which eliminates the need for additional processing of the seams.

- Wooden coatings have good thermal insulation properties. For more information on how to sheathe walls with drywall, see this video:

The color scheme of this material is quite diverse, which allows you to choose the necessary color, harmoniously combined with the surrounding interior.

Facing the house with aerated concrete, foam concrete and gas silicate bricks

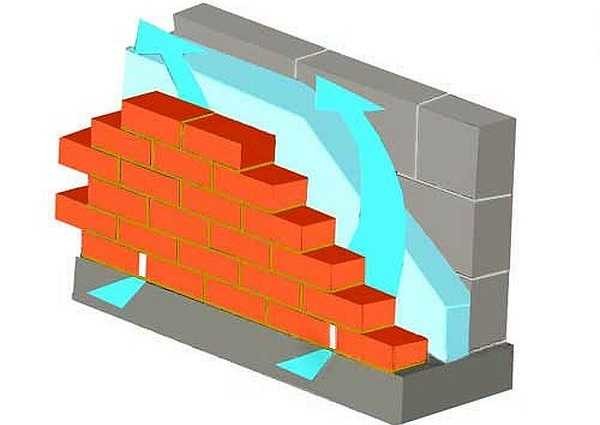

The vapor permeability of cellular concrete is also higher than that of bricks. That is, the situation is exactly the same: inside the room there is a material that better removes vapors. Therefore, to ensure a normal indoor climate and a long service life, a ventilation gap is required between the brickwork and the wall and foam blocks.

If you impose a house made of aerated concrete (foam concrete, gas silicate) with a brick without a gap, its service life will decrease by about 60%: condensate will accumulate at the border of two materials. At low temperatures, the frozen moisture will destroy the bubble shell, gradually destroying the entire material and significantly degrading its performance.

Options for facing an aerated concrete house with bricks and their characteristics

Additional heaters are used very rarely, if they are still needed, all the rules are the same as when facing a wooden house: basalt wool, protected by wind insulation.

The size of the ventilation gap is from 60 to 150 mm. The number of ties between two walls: at least 3 pieces per square meter of masonry, their cross-section is at least 5 mm2 per 1 m2. For connection, you can use screw or stainless steel nails with a length of at least 120 mm... They are not driven perpendicular to the wall, but at an angle of at least 45 °. You can use perforated galvanized strips, which are nailed to building blocks on one side, and the other end is fed into the brickwork, where it is bent at an angle

Please note: the ties should not be embedded in the masonry seams of the main wall. Only nailed to the face of the blocks

The best wall cladding made of aerated concrete and aerated concrete - bricks with a ventilation gap

Two-storey houses

The facade plays an important role in attractiveness and is not inferior in this regard to the interior, and two-story houses look especially impressive.When thinking about buying or building a two-story brick house, it must be borne in mind that there are two types of structures: brick cladding and brick monolith.

Looking through photos of brick buildings, it seems that they are all made entirely of brick, however, many brick houses built over the past few decades are not actually built from it.

Monolithic structures are definitely sturdy, they are also very expensive and time consuming. Therefore, in order to get the finished look of a brick house without additional work, brick cladding siding was invented.

Cladding brick laying technology

Usually, facing bricks are laid for joining

Usually, facing bricks are laid for joining

Usually, facing bricks are laid for joining. At the same time, they adhere to the following technology:

- Brick laying is carried out on a fine day at a temperature not lower than + 5 ° С. You cannot perform work at temperatures below zero, as the cement slurry will change its properties.

- Before proceeding with the installation on the mortar, the stone is laid "on dry". This will allow you to determine the amount of stone that needs to be adjusted to size, to select products for decorating door and window openings.

- Before laying the first row, the base must be leveled.

- A grinder with a stone disc is used for cutting stones. Chipping of elements with a hammer is prohibited.

- For laying, a cement mortar is used, which is prepared from 1 hour of Portland cement, 3 hours of sifted river sand and 1 hour of water. The mortar mixture must be stiff enough so that the element does not "float" during installation.

- The mortar is applied to the flat part of the brick in a thin layer. Moreover, it should not reach the front edge by 1 cm.

- When performing masonry, corner rows are first made to a height of 4-6 bricks. For the reliability of the dressing to be higher, it is not advised to use halves of the stone. It is better to take elements of length ¾.

- A cord or fishing line is pulled between the two corners, along which intermediate bricks are laid and aligned.

- To prevent the facing brick from taking moisture from the cement mortar, the products are moistened with water before installation.

- The height of the horizontal seam is 1.2 cm, of the vertical one - 1 cm.

- To ventilate the brickwork in the lower row, every three vertical seams are made without mortar and filled with insulating material, in the upper part of the facade ventilation is carried out due to the fact that 1 row of brickwork does not reach the cornice.

- Every 5 rows, it is recommended to use a wet cloth to remove any cement on the front surface.

- The cladding layer must be bound to the walls of the building. To do this, during the masonry, anchors with a diameter of 0.4-0.6 cm are hammered into the walls. At the same time, at least 45 anchors should fall on each square meter of the facade plane, and 8-12 attachment points are made above the window openings.

- If it did not work out in advance to lay the dowels into the masonry of the walls of the house, then the dowels are hammered into the walls, to which the wire is tied. It should reach the middle of the facing layer and go 20 cm in each direction. Thus, the wire is hidden inside the masonry. The installation step of such dowels is 50 cm. In frame and wooden houses, nails with a length of 120 mm are used to arrange the dressing. In a block structure, clamps are suitable for these purposes.

- When the cement has set a little, the seams are sewn with a wooden rod. The solution is simply pushed inward.

- Window and door openings are always lined with bonded masonry. For more attractiveness, you can use elements of a different shade.

Video guide for laying facing bricks:

Brick veneer school

Most often, brick cladding of the facade is carried out in houses with stone walls.Not only materials of natural origin are called stone in construction, but also materials created by man - various types of concrete, fired and pressed bricks.

Facade moldings and forging will only decorate the brickwork

If desired, you can, of course, revet wooden walls, but this is done mainly during their overhaul, in order to ensure the lost rigidity of the enclosing structures. So in the article we will mean exactly the stone walls.

What is face masonry

First of all, let's clarify what is front and what is decorative masonry.

Samples of the facades of brick houses

The facade of a brick house with conventional front masonry, but using decorative bricks

Cladding with decorative elements

V Bavarian masonry combine brick at least four shades

Facial schemes are used more often, since they are suitable for both outdoor and indoor work. The main thing in them is that the brick has clear geometric shapes, without defects of edges and surfaces, with the same color tone, and the seams have high-quality jointing. That is, at the same time, the material must meet high requirements, while anyone can be used for backing up (internal versts).

Features of performing facial masonry

The system of dressing in the front verst is usually multi-row: after five spoon rows, one butt is laid, which is rigidly connected to the main masonry.

This happens when the facade of a brick house is revetted with it in the process of building walls. That is, both the cladding and the load-bearing wall are brick.

This is what brickwork looks like with the front side

- But finishing can be done even when the building has already been built. In this case, it is impossible to make a ligation with bonded rows, therefore, the front wall is fixed to the main one with the help of anchoring.

- The front masonry scheme can be slightly changed if the load-bearing walls are not built from bricks, but from concrete stones, which are always of a larger format. In this case, a preliminary calculation should be made, which will show how many rows the horizontal seams of the masonry of the two walls will coincide.

How to make a cladding with your own hands

- If the levels of horizontal joints do not match, a brick of a larger format can be used for laying the connecting rows - for example, one and a half. This is the most optimal option when the cladding is carried out close to the load-bearing wall.

- But there are other ways as well. For example, when a ventilated brick facade is arranged, the issue of ligation is solved with the help of flexible ties, or using a metal mesh for this purpose. Today, stainless steel subsystems are also on sale, on which, among other things, you can hang heavy brickwork.

The result of improper dressing or lack of it

Note: Of course, all these are additional costs, then there is no other way out - it is impossible to make bandaging with butt rows when laying between the walls of the insulation. Although, in principle, the gap between the walls can remain empty. It depends on the thermal design of the walls. The main thing is to have a high-quality dressing! Yandex.DirectFace recognition from Macroscop18 + Gambling and traffic arbitrageBaby beds with a side

Here are some options for facing the facade of a house with bricks:

Non-insulated ventilation facade for expanded clay concrete walls with mesh binding

Foam block masonry with parallel brick cladding without ventilation gap

Ventilated cladding with aerated concrete wall insulation, with flexible connections in the seams

Bookmark between the front and main walls of bulk insulation

Walls made of ceramic blocks with external facing with bricks

Well masonry from two front walls, filled with heat-insulating concrete

Brick cladding of the facade of the house using a hinged stainless steel subsystem

Fiberglass flexible ties for connecting heavy cladding to a load-bearing wall

Summarizing the above, we note once again that the front verst can be part of the load-bearing wall and be performed in the process of its construction. Or it can be an independent wall located at some distance from the main building envelope.

However, the ventilation façade system is not always acceptable when it comes to decorative masonry. Why? Further instructions will tell you about this, supported by the video in this article.

Clinker thermal panels

The main advantage is that clinker thermal panels simultaneously serve as insulation and decorative finishing

The main advantage is that clinker thermal panels simultaneously serve as insulation and decorative finishing

This is a modern finishing and heat-insulating material that has recently appeared on the construction market, but has already gained popularity. Among the advantages of this product are the following:

- The main advantage is that clinker thermal panels simultaneously serve as insulation and decorative finishing.

- The product accurately imitates the surface of masonry and is available in a wide range of colors and textures, from which it is easy to choose the finish that suits the style of the house.

- Having finished the building with such panels, you will get a stylish and respectable home.

- The panels are easy and quick to assemble.

- Clinker products are suitable for cladding a brick or wooden house, as well as buildings made of aerated concrete.

- Since the panels are lightweight, there is no need to further strengthen the foundation of the house.

- Low water absorption of the product allows you to wash the facade of the house with a stream of water from a hose.

- High tightness of the cladding is achieved by tight joining of the panels.

- Such cladding can last up to 60 years with the preservation of its original appearance and without repair.

Panels can be produced on polystyrene foam or polyurethane foam base. Clinker tiles are pressed into them. The product is made in the form of elements with a lock connection (groove-comb) in the end part. On sale there are wall straight thermal panels and corner elements for decorating corners, windows and doors. The products are reinforced with plastic guides that reliably protect the facing layer from mechanical damage and deformation. For the installation of panels on the surface of the walls of the house, a crate is made. After fixing the products, the seams are filled with a special grout.