Dismantling stages

Demolition of boiler houses can be roughly divided into three main stages.

The preparatory stage is the design of the organization of demolition, the implementation of measures to disconnect the boiler house and equipment from communications.

Dismantling stage - sequential removal of boiler equipment elements, starting from chimneys. Disassembly and cutting of boilers, metal pipes, control panels, etc. Dismantling the boiler room building (if necessary).

The final stage is the sorting of scrap, weighing and evaluating it. The object is cleaned from construction waste with its subsequent removal.

Reasons for parsing chimneys

Leaving a pipe (especially a brick one) just like that, in the middle of a white sky, is quite dangerous and costly. Seasonal temperature changes have an extremely negative effect on brickwork, gradually causing cracks, and, as a result, destroying it. During operation, hot air is regularly found inside the chimney, which excludes temperature drops, however, it is economically inexpedient to warm up an unused structure.

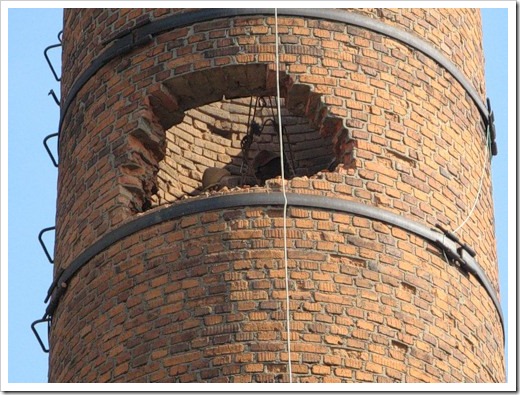

Old chimney

As a result, it is much easier to make a one-time dismantling of the chimney than to maintain the pipes in a safe condition, spending financial resources on a monthly basis.

As for metal pipes, their dismantling is required in cases where a replacement occurs - dismantling the old one and then installing a new pipe. Or, when the work of the boiler room stops forever. Naturally, in this case, it is dangerous to leave a metal mast, especially since pipes with a minimum wall thickness are used for boiler rooms - over time, they can rot at the base.

Dismantling a brick pipe

Brickwork is reliable and durable, but in a number of situations, disassembly and demolition of the pipe is required. Depending on its size and diameter, various dismantling techniques are used:

- Manual disassembly using punchers, hammers and sledgehammers. Work at height is carried out by specialists who have access to this type of activity. Even domestic chimneys should be disassembled very carefully.

- Industrial mountaineering - manual disassembly in an orderly manner, starting from the top. The detached parts of the structure are thrown inside the trunk so as not to damage the adjacent structures or structures. The dustiness of the site during the dismantling process is minimal, as is the noise accompaniment. Most often, they order industrial mountaineering for disassembling boiler pipes and chimneys at enterprises.

- A directed explosion is carried out only after obtaining permission from the relevant authorities.

- Robotic demolition using special equipment. A vertical lift is attached to the pipe, moving through the scaffolding. Disassembly begins from the top using remote-controlled robotic arms.

- Roll in a specific direction. It is not often used for brick structures, since the masonry collapses when it falls and the bricks can fly far apart.

You cannot dismantle brick pipes yourself. Only specialists analyze the condition of the chimney before disassembly and take into account all the nuances of safety. When demolishing high-rise buildings, a dismantling project must be developed and approved. Engineers calculate the possible consequences and select the best disassembly method.

When breaking is harder than building

Comparing the existing technologies for dismantling industrial chimneys, it is worth noting that, although the methods of directional blasting and felling with the help of ropes, although they are less expensive, can be used when there is enough free space around and there is absolute confidence that the surrounding structures and communications will not damaged. It is practically impossible to do this in conditions of dense building and layout of production facilities. The only viable method is belt stripping by industrial climbers.

|

Together with this service, order:

|

High-rise works associated with the dismantling of massive structures always pose a particular danger, both for the performers and for the surrounding objects. Therefore, the dismantling of the boiler room chimney is carried out according to a special project developed by our engineers and agreed in the relevant instructions.

Painstaking work of installers

The most common are brick pipes, and their disassembly is the most difficult. The fact is that over time, various cracks and deformations appear in such a structure, which, when removing the shroud rings, can cause unpredictable destruction with the separation of massive large pieces. To minimize the likelihood of such a phenomenon, our specialists use a proven technology for dismantling a brick chimney:

- initial inspection is carried out with special care to identify weak points and existing cracks in the pipe; - secure places for fixing and insurance of workers are equipped; - the sequence of disassembly of individual elements is determined and the direction of their discharge is established (inside the pipe or outside), means of protecting the adjacent buildings and communications are prepared; - the separation of bricks and blocks is carried out using a hand or electromechanical tool, which minimizes the impact on the damaged masonry.

Dismantling of a metal chimney is carried out using a different technology, since its division into small pieces is impractical. Our specialists cut it into sections (if it is welded) or disassemble it at the joints. The separated pipe parts are removed using a lifting technique.

Our work experience allows us to make optimal decisions in any, even non-standard situations. Thanks to this, we are able to dismantle industrial chimneys in the shortest possible time, without taking up the space of the industrial site and without limiting the functionality of the current production process. You can order a project and a team of our specialists on the website or by calling the phones indicated here. You will also be pleasantly surprised by our affordable prices and the ability to perform work at any facility in the Moscow region.

To order

The ways

There are several ways to disassemble a boiler pipe. Why pipes? They are the most difficult of all the premises as a whole, because the premises are usually not higher than one floor, and the pipe, as we noted above, is a rather tall structure made of different materials. Let's take a closer look at each of the methods.

Industrial mountaineering method

A method of disassembly, in which the chimney is disassembled by workers manually, and the process goes from top to bottom. The process is very laborious, time consuming, but also the safest way. In addition, there is no unnecessary bureaucracy with the registration of permits. Also, manual parsing does not harm the structures located near the boiler room.

With the help of specialized equipment

This method is also called "pipe roll". It is used when demolishing a pipe made of metal in several segments, but can also be used when dismantling brick or reinforced concrete structures. Rarely, when the base is cut off at the chimney, thereby provoking its fall.

Directional blast

Perhaps one of the most difficult methods in terms of obtaining various permits in government services. In addition, for the application of this method, there are a number of conditions, for example, the radius of the fall of the chimney and fragments during blasting must be at least one and a half times greater than the height of the chimney.

Robot manipulators

Demolition takes place with the participation of special sliding scaffolding, such robotic manipulators work remotely. The pipe is disassembled from above, going down to the base. The method is quite costly, since the management requires maintenance personnel.

Remaining recycled material

Dismantled metal pipes that are unsuitable for further operation can, in part, offset the cost of the work. Usually these are steel structures with a wall thickness of up to 10 mm, which, after disassembly, can be handed over to scrap metal collection points. But it so happens that the pipes after dismantling are in good condition - this is a business metal. Such pipes can be used for other purposes, for example, put under the road, for draining or making non-critical containers.

Nice chimney used after dismantling

The destruction of a brick chimney, especially by the roll method, is accompanied by the presence at the site of the collapse, an abundance of building material - broken bricks. Part of the brick remains intact and suitable for use in the arrangement of your own site.

Dismantling methods

Dismantling of chimneys is carried out in different ways, depending on the material from which the chimney is made, its functionality, free space around where it is planned to collapse the structure and other conditions.

Chimney pipes can be demolished by methods:

- Industrial mountaineering;

- Directional explosion;

- Rolls using special equipment;

- Using robots - manipulators.

Industrial alpinism

The use of the method of industrial mountaineering is that the building is disassembled by hand, provided that it is brick or reinforced concrete. Dismantling the chimney starts from the top, gradually moving downward. This method eliminates the paperwork for obtaining an explosion permit. Its cost is much lower than when using special equipment. The risk of damage to nearby buildings and structures by fragments of brick or reinforced concrete is eliminated, as if it had happened during an explosion.

When using the method of industrial mountaineering, dustiness of the site is excluded, there is no noise, which is mandatory when using construction equipment or an explosion. It is possible to work in a confined space.

Disassembly of a brick structure can be done in two ways - disassembling outward and disassembling inward.

In the first method, a working platform for industrial climbers is arranged inside the pipe. The pipe itself, with the help of special hand tools, is disassembled in order or in blocks that are dumped down. In this case, a safe zone must be provided around the chimney, equal to 0.3-0.5 of the chimney height. There are few advantages in this method and they consist in the fact that a small area is required for work and in the method itself, which does not require complex equipment and devices.

In the first method, a working platform for industrial climbers is arranged inside the pipe. The pipe itself, with the help of special hand tools, is disassembled in order or in blocks that are dumped down. In this case, a safe zone must be provided around the chimney, equal to 0.3-0.5 of the chimney height. There are few advantages in this method and they consist in the fact that a small area is required for work and in the method itself, which does not require complex equipment and devices.

Dismantling a structure up to 35-40 m in height can take from 10 to 20 working days. The cost of such work is extremely high.

Dismantling brick chimneys by disassembling inside is longer, respectively, and its price will be higher.

For this method, it is necessary to arrange a mobile station around the working platform, and from the bottom to make protective screens made of mesh, protecting people and machines from accidental falling of debris.

The main obstacle for the accelerated dismantling of the chimney with the help of industrial climbers can be the emergency state of the chimney, which entails a loss of time.

Pipe roll

Dismantling of a metal chimney can be carried out using a special  construction equipment. Iron pipes consist of several segments that are welded together or bolted together. The method consists in sequentially disconnecting the links and rolling them using a construction crane or hoist. When welding, gas welding equipment is used.

construction equipment. Iron pipes consist of several segments that are welded together or bolted together. The method consists in sequentially disconnecting the links and rolling them using a construction crane or hoist. When welding, gas welding equipment is used.

If space permits, the entire metal structure can be dumped. To do this, the pipe is cut at the base, while exposing temporary fasteners.

After that, with the help of braces and construction equipment, they are laid on the ground.

Directional blast

Dismantling the boiler room chimneys can be done with a directional explosion. However, prior to carrying out such an operation, you must obtain permission from the relevant authorities. In addition to permitting, it is necessary to accurately calculate the trajectory of the fall of the pipe, prepare a site of the required dimensions, corresponding to the height of the chimney.

Before blowing up the chimney, it is necessary to take all measures to evacuate the personnel of the enterprise and to suspend the technological process. Despite the speed of the whole process, preparation for it takes a lot of time and this pleasure is more expensive than all other methods of dismantling the chimney.

Robots - manipulators

Dismantling of a reinforced concrete chimney, as well as a brick one, can be carried out using robots - manipulators, which disassemble the pipe from above, gradually reaching the very bottom.

This requires the installation of a mast vertical lift, with the help of which the sliding scaffolds are installed. On the forests there are people and the equipment itself in the form of robotic manipulators. The robots are controlled by remote control.

Dismantling of reinforced concrete chimneys is the most laborious due to the fact that during the installation a material of high strength was used, which surpasses the grades of ordinary concrete several times.

The most inexpensive method for dismantling industrial chimneys is a roll, especially if it is made of bricks.

Technologies that we use

One of the activities of Technolider SPb is pipe dismantling. The work is performed by professionals after the approval of the project. We use the methods of felling the entire structure with special equipment, manual disassembly for small chimneys and industrial climbing for high-rise pipes.

Complete chimney roll

The demolition of the chimney with the help of a roll is allowed only after determining the fall sector, protecting nearby objects and marking the territory. Complete dismantling using the roll method takes place in 4 stages:

- Accurate measurements of the trunk, the surrounding area, its marking. Protecting nearby objects to prevent debris from flying into them. The calculation of the fall sector is a 60⁰ radius of 1.5 of the height of the structure to be demolished.

- Installation of temporary supports made of timber, metal or hydraulic cylinders, depending on the condition and dimensions of the pipe. Cutting the base with a hydro-pneumatic-electric hammer or a diamond tool.

- Controlled removal of temporary supports for controlled fall of the structure.

- Elimination of construction waste. Removing protective coatings, marking the territory. Dismantling the base of the dismantled pipes.

- Our company transports heavy waste by road to special landfills. After dismantling, a clean area remains where new structures can be erected.

Industrial alpinism

A reinforced concrete or brick pipe is disassembled by hand, starting from the top. The industrial mountaineering method eliminates the need to fill paperwork for a blast or felling of a structure. The cost of work is lower, but the speed is much less than in the method with the use of special equipment.

Dismantling by industrial mountaineering is carried out in 2 ways:

- Disassembly outward. Climbers are inside the chimney. They remove the layers of the structure with a special tool in rows or blocks and throw it out. In this case, it is imperative to fence the territory by 0.3 - 0.5 height parameters.

- Dismantling the pipe inward. The opposite method to the first option.

According to safety standards, special protective screens made of mesh are erected around the base of the pipe. They are designed to rescue people from accidental falls and to protect vehicles and buildings from shrapnel.

The advantages of industrial mountaineering:

When performing high-rise dismantling, great attention is paid to the safety of the work performed.Therefore, all employees of Razvitie LLC, performing work at height, constantly confirm their rank in mountaineering.

This is the key to the timeliness and safety of work.

2. Demolition of the chimney by explosion

The most important factor in the demolition of a pipe by an explosion is the availability of free areas for the fall of the demolished structure. The current standards require that the radius of the sector in the direction of the intended fall be at least one and a half pipe height, and the sector on the opposite side of the pipe - at least 15 m.

If the demolition of the pipe takes several minutes, then the preparatory work can take several days or even weeks.

Dismantling with the help of a directional explosion is carried out in the following technological sequence:

(the calculation of the charge being laid is performed, the scheme of the fall of the dismantled pipe is calculated, and more);

The construction site is being prepared and equipped;

Bore-holes are drilled manually or mechanically;

The complete demolition of the structure is carried out by detonating the charge and the subsequent removal of waste.

This method of dismantling requires highly qualified specialists, as well as accurate calculation of the fall of the dismantled pipe.

Technology

The manufacture of chimneys most often occurs from materials such as metal, brick, reinforced concrete. Depending on the material, each structure must be dismantled using different methods.

Dismantling a metal pipe

To demolish the metal chimney, you will need the help of a crane. Special brackets are welded on top, a hoist hook is attached to them. If the pipe is dismantled as a whole, then bolts and metal braces that hold the chimney are cut off at the base, then using a lift it is lowered onto a special platform or next to the boiler room. If the pipe is high enough, then in addition to the crane, an aerial platform is needed. The whole process will take place in several stages.

Then they release it onto the site, weld the eyelet to the resulting top of the edge, hook the hook, cut it off according to the marked, lower it and put it on the site. Thus, the entire pipe is dismantled.

Dismantling a brick pipe

To disassemble this type of pipe, a roll or explosive is used. The method of blasting is considered very dangerous, therefore it is necessary to ensure the safety of people by evacuation. It is also necessary to correctly calculate the explosives, to determine the places for laying the charge. The method is very fast, but at the same time complex and expensive. In addition, quite a lot of fragments are scattered from the bricks. Felling a brick chimney is time consuming, but much cheaper and less complicated. The roll is carried out in several ways.

Beating off pieces of pipe or a whole sector

With this method, special scaffolding is installed outside at a certain distance, after which the bricks are hollowed out with a tool, thereby reducing the strength of the surface. After all these manipulations, the level is broken into parts.

With the help of special props

With this option, bricks are knocked out with the installation of supports made of durable material. Further, the part that is held by the supports is demolished by heavy equipment.

Roll with the elimination of dangerous parts of the pipe

The pipe is disassembled in parts, starting from the very top. Fragments of masonry are dumped from the inside or outside.

To speed up the parsing of a brick chimney closer to the base, heavy equipment is used.

Dismantling a reinforced concrete gas pipe

For parsing, the method of undermining or cutting sectors with diamond equipment is used. Undermining is carried out in the same way as for a brick pipe. Sections are cut in two ways.

Cross cutting on a circle

The method using a lift: the chimney is divided into sections, two grooves are cut out at the top of the section exactly opposite each other, a cable passes through them, which is attached to the lift, then the sector is cut off, lifted and placed on the site, the next sector is cut in the same way.

Longitudinal cutting

The chimney is cut from above in small pieces, cutting out either with rectangles or triangles. Discharge of cut pieces goes inward or outward.

Kunstkamera

- The boiler went into operating mode, that is, hot gases were flowing through the pipe at a calculated flow rate, then the burner went out abruptly - the fan stopped, the gas continued to move by inertia, and accordingly left behind a vacuum zone. The boiler was started in violation of the regime map, without preliminary warming up ... more

- Photo 1. Thermal insulation in the form of soft mineral wool mats with a density of 25 kg / m3 instead of 120 kg / m3 according to the project.

Photo 2. Absence of a condensate drain in the lower part of the vertical flue gas shaft of the boiler.

Photo 3. Foreign objects on the diaphragm of the explosive to ... more - Project Notes

The shape of the load-bearing lattice tower does not meet the requirements of SP 43.13330.2012 “Constructions of industrial enterprises. Updated edition of SNiP 2.09.03-85 ". The use of this constructive solution (rigid struts in the form of a system of volumetric trusses) is ... more

- 1. The adopted design solutions of the “KM” section do not meet the requirements of SP 43.13330.2012 “Constructions of industrial enterprises. Updated edition of SNiP 2.09.03-85 ":

- the shape of the supporting exhaust lattice tower does not meet the requirements of Sec. 9.4.8, 9.4.11; … More - The only reason that can cause tensile stresses in a wall located along the generating cylindrical surface is water. When water turns into ice, its volume increases by 9.05%. The breaks of seamless pipes, as they look in the photo, are typical for damages at m ... more

- This chimney calculation cannot be considered sufficient and reliable, since:

- collection of loads in accordance with the requirements of clause 7-14 of SP 20.13330.2011 “Loads and impacts. Updated edition of SNiP 2.01.07-85 * "; - combinations are not shown ... more

Dismantling a brick pipe by climbers

If industrial climbers need to be used to demolish chimneys, they will manually dismantle them using technical tools:

- Perforator.

- Dry cutter.

- Jackhammer.

Dismantling begins with the upper stack of chimneys, so that its elements are either thrown into the chimney opening, or down, where there is a specially fenced piece of land allocated for these purposes. If there is a possibility that fragments of chimneys may fall out, then additional measures are introduced - a grid, and warning signs are placed that will help to protect human life.

Advantages of the work of specialists in this category of chimneys:

- No harm to the environment.

- No need to use large, expensive equipment.

- No extraneous noise.

- The package of documents for the implementation of work is significantly reduced.

- All work is carried out accurately in compliance with important safety measures.

Methods for dismantling a brick pipe

Demolition of a brick pipe is carried out in the following ways:

- Disassembly by hand using rock drills, hammers and sledgehammers. Since all work is carried out at a height and the workers are on the chimney, a high-quality organization of the whole process is needed.

- Industrial alpinism. The construction is disassembled manually in an orderly manner. Starts from the top. Materials are dumped inside the trunk. No permission is required. Demolition in this way will be inexpensive compared to the use of special equipment.Risks of damage by fragments of bricks to neighboring structures, dustiness of the site, and the presence of noise inherent in equipment and explosions are excluded. It is used most often in enterprises, boiler houses.

- Directional explosion. This event requires a permit. We need an accurate calculation of the trajectory of the fall of the chimney, a platform with dimensions corresponding to the height of the pipe. Before the detonation, the personnel are evacuated, the technological process is suspended. Preparation is time consuming and more expensive than other demolition methods.

- Robotic dismantling. The pipe begins to disassemble from above, gradually reaching the very bottom. It is required to install a mast vertical lift, which is used to secure the sliding scaffolding. There are people and equipment on them - robotic manipulators, controlled remotely.

- Classical felling with a special technique. Refers to an inexpensive method.

Precautions and common problems

Before the demolition of brick pipes, the chimney must be inspected to prevent accidents. Dismantling technology is determined only after that. First of all, the safety of personnel must be taken into account. Wrong definition of demolition methods, lack of pipe inspection can lead to the following problems:

- Due to the failure to detect areas affected by erosion and cracks, vibration can destroy the trunk. To prevent this problem, it is necessary to carry out preliminary inspections of the chimney, which will show it to be disassembled in large parts or choose less dangerous methods.

- Deviations of structures from the established directions due to incorrect calculations or the performance of work by non-professionals.

- During the demolition of a massive pipe of a boiler room, another industrial building, when the trunk falls, a significant shock wave is created, from which glass can crack on neighboring buildings. Therefore, seismic risks must be taken into account: carry out preparatory work, secure weak structures, bring them into compliance with safety regulations.

- During the demolition of the chimney, there are risks that the trunk will break or sag, and this can lead to the destruction of the entire pipe and accidents, to prevent which reinforcement with metal reinforcement is carried out.

Stages of work

Carrying out such a responsible event requires preliminary preparation, which includes:

- Contacting the customer for information exchange.

- Departure in order to inspect the territory, measure the trunk, study nearby buildings, underground and air communications.

- Determination of the place and area to which the chimney fragments can fly.

- Study and analysis of the information received.

- Negotiating, choosing a dismantling method, reaching an agreement on price and terms.

- Signing a contract, payment of an advance.

- Establishing the boundaries of the territory on which the work will be carried out and carrying out its fencing.

- Carrying out demolition in the chosen way.

- Organization of the removal of a broken chimney.

- Signing of acts, payment of the bill.

Demolition of such pipes is carried out quite often, since brick has been one of the main materials for their construction for over a century. A long service life leads to the fact that chimneys become unusable, become emergency, wear out, and require replacement. The choice of technology is influenced by their design.

Dismantling process

If it is required to dismantle the chimney in the boiler room, demolish the window sill in the house or the fence, then for such work it will be necessary to prepare in advance. In some cases, such activities can free up more space in the room and improve the layout.

According to the legislation, chimneys or exits to balconies and loggias must be dismantled by specialists after preliminary calculations of the bearing capacity of the structure. It is also recommended to call specialists to draw up the project. After that, all documentation is agreed with the utilities and the redevelopment process is determined.

For the demolition of such structures, the impact method is usually used, which can only be provided with power tools.

It is important to pre-secure the area and determine the thickness of the walls or chimney. The choice of equipment and its power depends on this.

If the wall will be on concrete masonry, then it is necessary to use a diamond tool with which you can achieve cutting accuracy. This equipment is also used when it is required to carefully dismantle and ensure accurate cutting.

The need to dismantle the chimney in the boiler room may arise in cases when the structure itself is in an emergency condition or the re-profiling of the enterprise in the building of which this chimney is located is required. Therefore, even those chimneys that are in good technical condition and can serve for several more decades are often subject to demolition.

All work is carried out with the help of industrial climbers, which allows you to achieve the following advantages:

- low noise level;

- no dust.

If the pipe is in poor condition, then the directional blast method or roll is preferred. But industrial mountaineering is the cheapest and most practical way to demolish such structures.

Features of the method:

- dismantling of bricks is done one by one, and the material is dumped inside the pipe, which makes it possible not to use the space near it from the outside;

- the dismantling period can be delayed for several weeks, depending on the size of the structure;

- special techniques and tools are used.

Removing partitions and walls

Depending on the purpose of the structures, the methods of dismantling are determined. If it is a partition between rooms, then all work can be done independently using a conventional puncher or hammer. If the base is load-bearing, then this involves the use of props that will not allow the structure to collapse. You need to start dismantling from the door, knocking out gradually over the brick with a hammer. When carrying out work, you need to periodically remove debris.