Comparison of extrusion plexiglass with cast

Let's compare two types of organic glass in order to identify the advantages and disadvantages of each type:

- extruded plexiglass, in contrast to cast, has a lower percentage of thickness variation (5% versus 30% for cast);

- cast plexiglass has a larger range of thicknesses, but a shorter permissible sheet length;

- plexiglass made by extrusion has less resistance to chemical attack, impact;

- to work with extruded plexiglass, lower temperatures are used (150-170 ° C versus 150-190 ° C for cast) and lower efforts during thermoforming;

- cast glass is worse to glue, and extrusion glass is subject to the formation of internal stresses;

- shrinkage during heating of extrusion glass is 6% versus 2% for cast glass.

Transportation, storage, care

Transportation of organic glass is carried out using closed road and rail transport. Transportation by open means of transport is allowed, but in this case the glass must be carefully covered with a waterproof film.

Plexiglass is stored in warehouses with an air temperature of 5 to 35 ° C. In this case, the relative humidity should not exceed 65%.

During transportation and storage, they are shifted with paper to reduce the likelihood of mechanical damage.

Attention! Do not transport, store organic glass together with chemicals!

Water is used for routine maintenance, old dirt is removed with a warm aqueous solution of detergents. Windows are cleaned with water using high pressure sprays. It is unacceptable to rub a dry surface - scratches will remain on it.

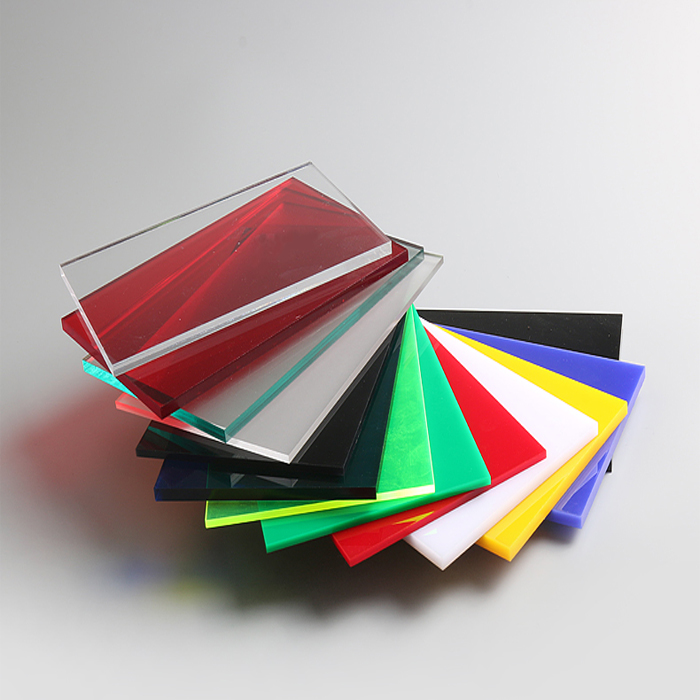

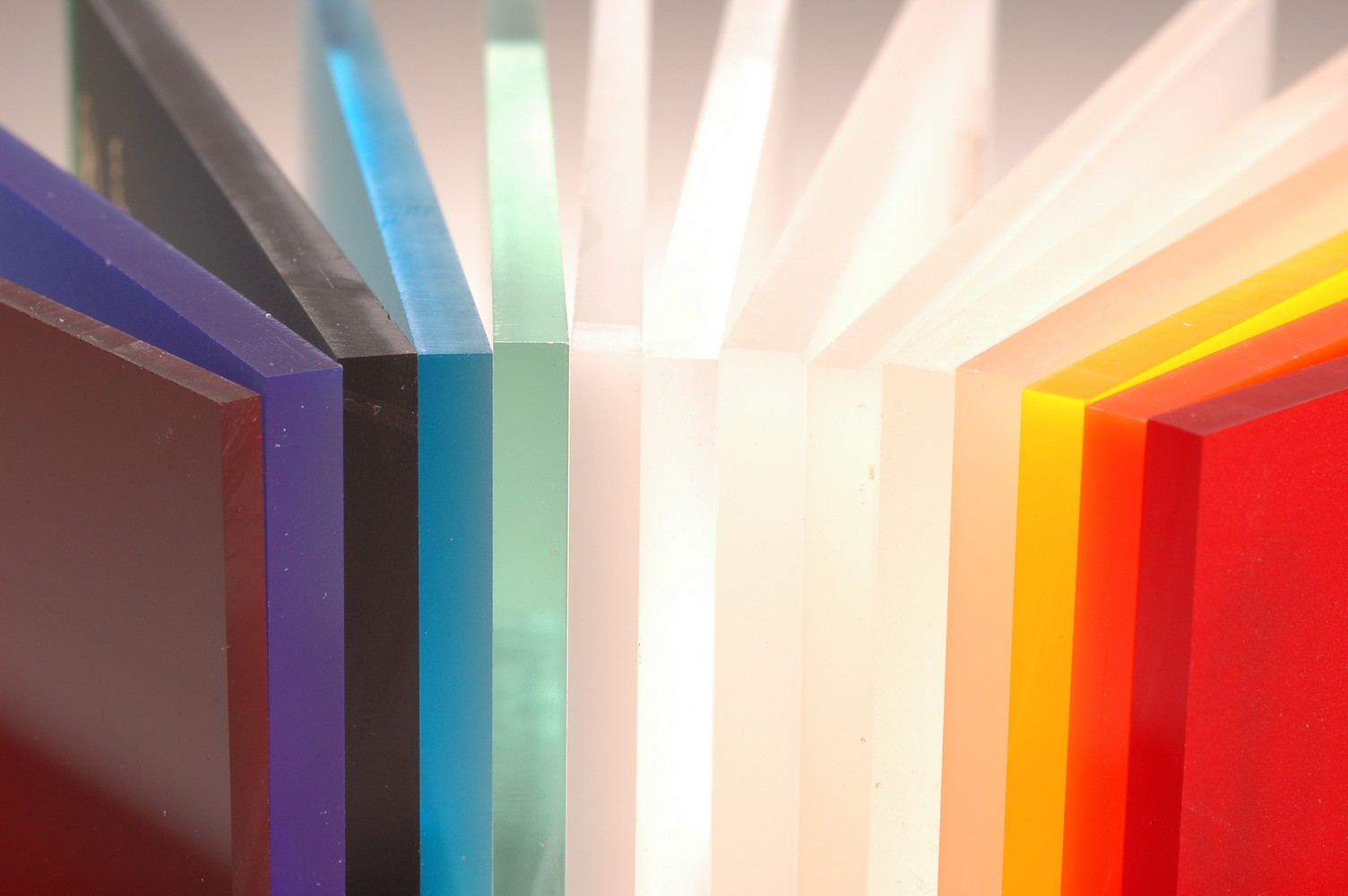

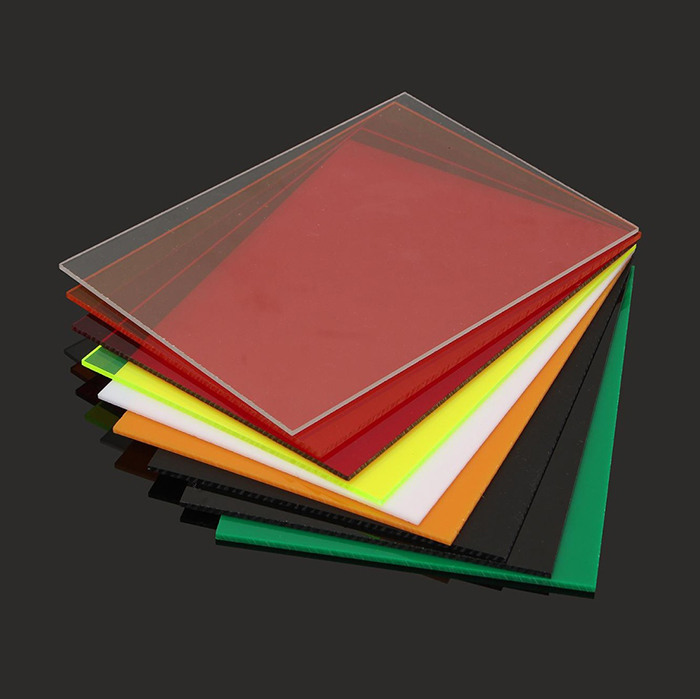

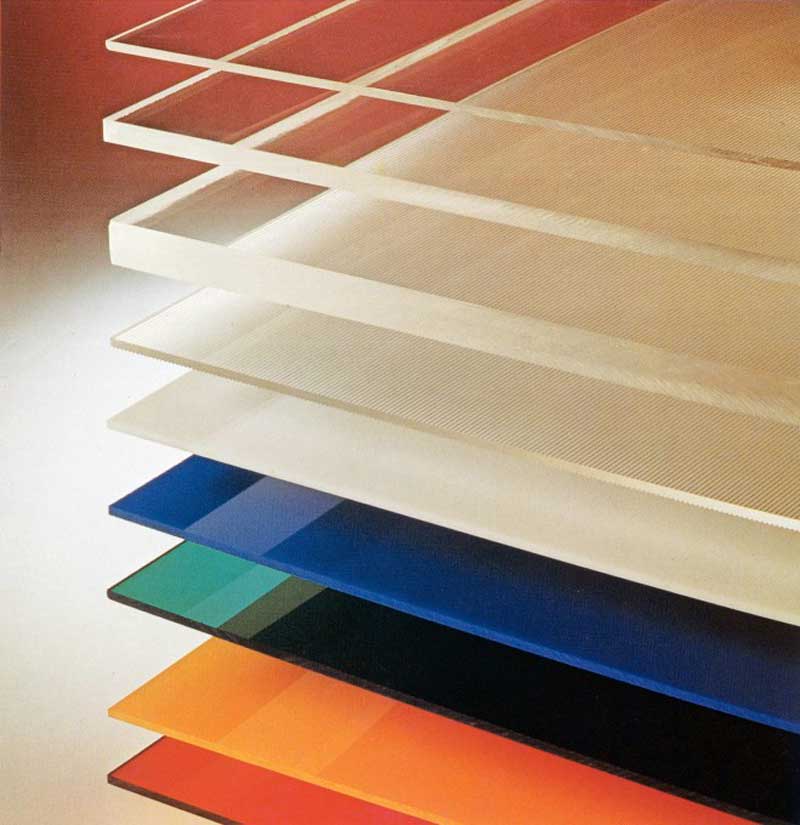

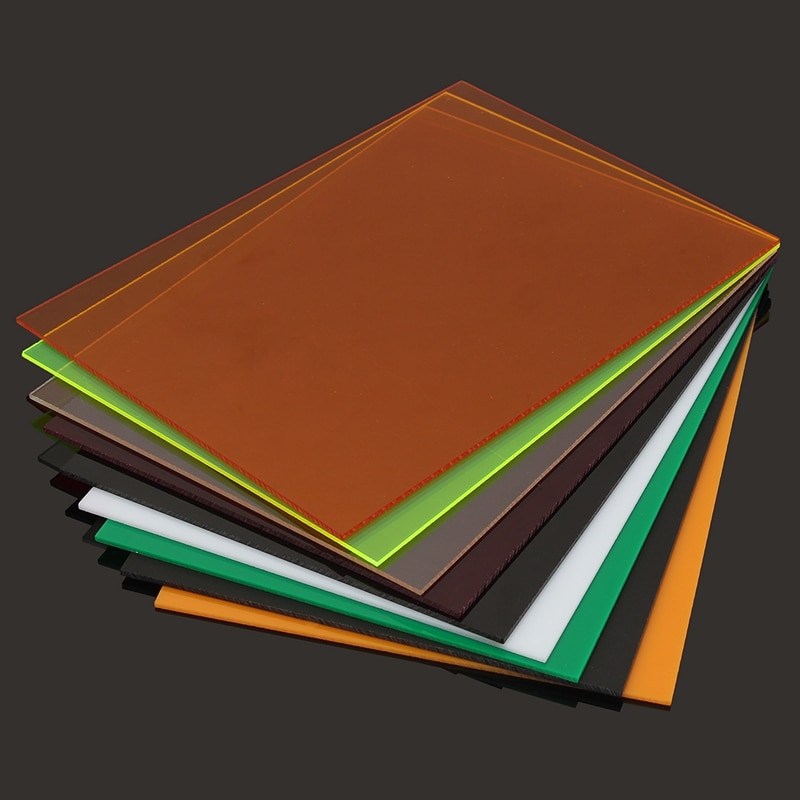

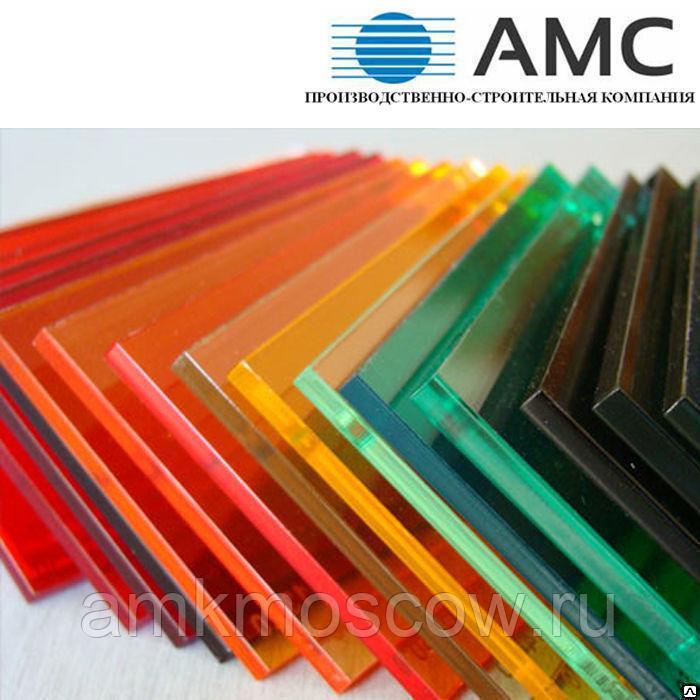

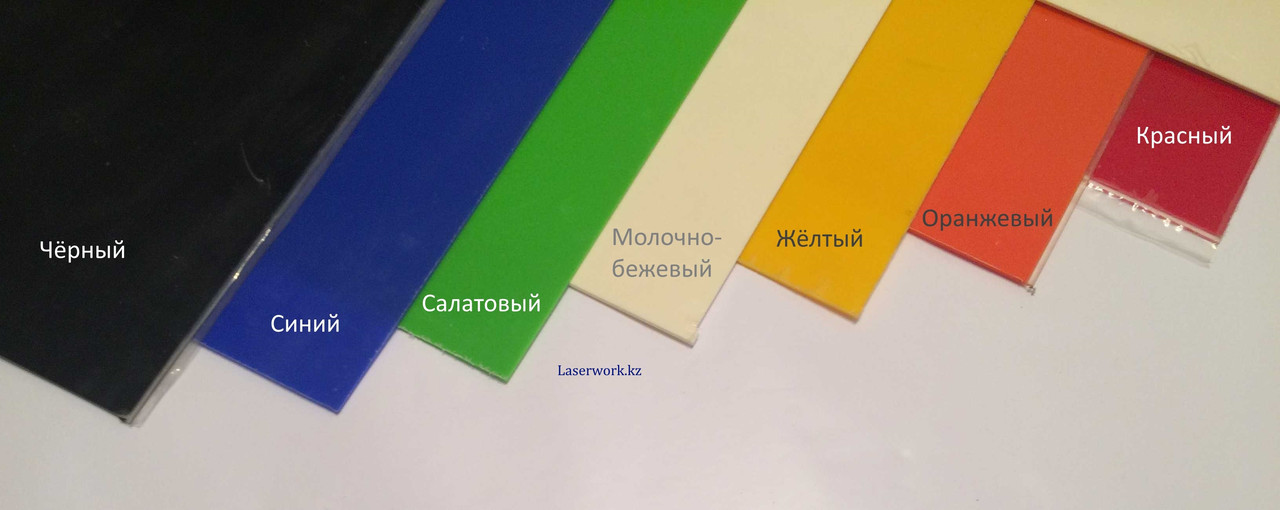

Variety of colored plexiglass

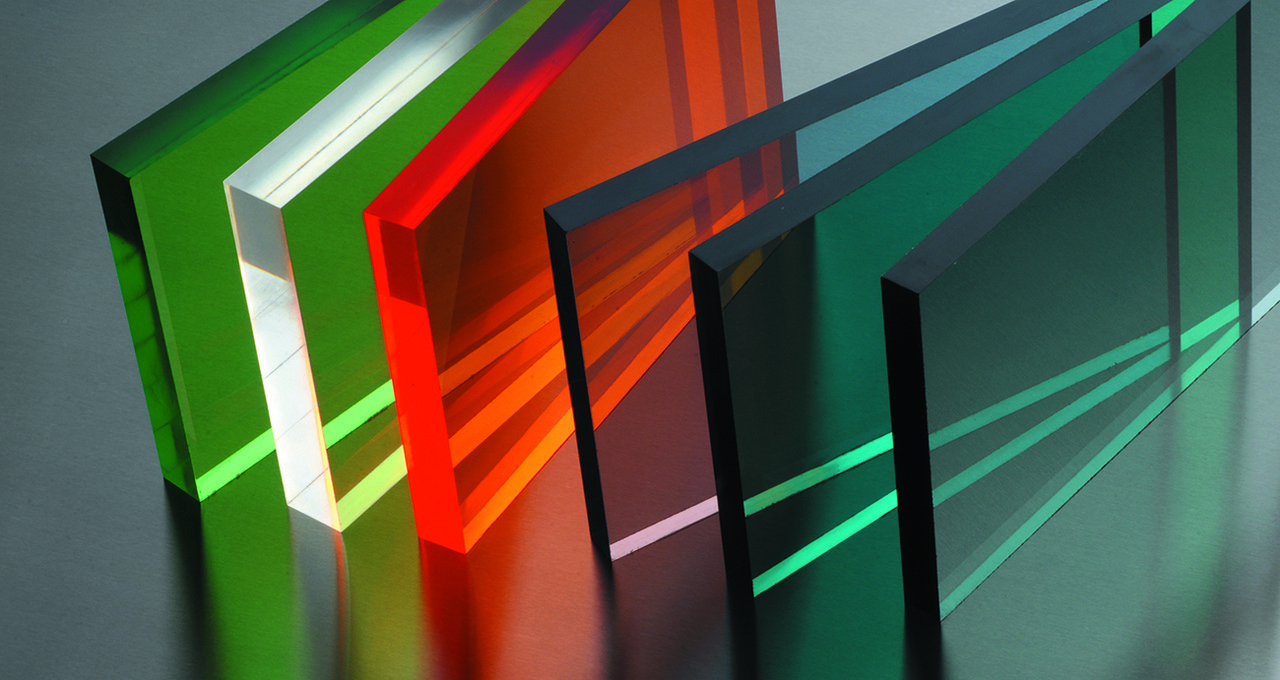

Painted acrylic is produced in a very wide range of colors. In addition to standard colors (red, green, yellow, blue, etc.), manufacturers produce plexiglass of various shades (brown, milky, orange, light green, purple, blue, etc.), and also offer custom color matching. It should be noted that the color gamut of cast acrylic is richer than extrusion, since many coloring pigments are not able to withstand the high temperature effect that accompanies the process of melting PMMA before extrusion.

Video: "Matt white plexiglass"

The range of available textures of cast acrylic is wider than that of extrusion. The surface of the painted plexiglass can be glossy or matte. Satin-finished acrylic, while maintaining uniform light diffusion, completely hides objects on the back side.

The surface texture of colored PMMA also differs - it can be waves, "crushed ice", drops, honeycombs, etc. With a sufficient level of light transmission, such a texture creates a special light scattering effect, in which the contours of an object on the other side of the plexiglass become blurred.

Some manufacturers produce colored acrylic with anti-reflective or UV protective coatings.

The standard sizes of colored acrylic are determined by the way it is produced.

Cast

|

Length * width, mm |

Thickness, mm |

|---|---|

|

1340*1170 |

12,5 |

|

1700*1500 |

2,524 |

|

3000*2000 |

1424 |

Manufacturers offer a wider range of sizes and thicknesses, it is also possible to manufacture a painted plexus to order according to individual dimensions.

Popular brands

Below are the top manufacturers that offer a variety of quality products at affordable prices. The price is indicated for an average sheet with a thickness of 3 mm.

- JSC "DOS".The Russian company supplies extrusion organic glass with a glossy surface to the market. Primary colors are milky and luminescent varieties. The company also manufactures custom-made acrylic sheets in any color scheme. Price - within one and a half thousand rubles per square meter.

- SafPlast. Another Russian manufacturer offering extrusion glossy acrylic at a cost of 700-800 rubles per 1 sq. meter. The colors are white, yellow, red, blue and black.

- Evonik Industries AG. The German company is engaged in the manufacture of a wide range of acrylic sheets. Both cast and extrusion versions are available commercially. Matte, glossy, textured, mirrored pieces are presented. The color range is 250 different shades, including gold, silver and bronze. Price for 1 sq. m varies from 1.5 to 4.5 thousand rubles, depending on the series.

- Lucite International. Production - England, type of products - cast, colors - green, shades of red, black, blue, blue, yellow, orange. There are options with fluorescent shades. Cost for 1 sq. meter - 1200 rubles.

- Rexglass. The Taiwanese company exports molded organic glass in a variety of iridescent shades. The price is affordable - from 900 rubles per 1 sq. meter.

You can find out what acrylic or plexiglass is from the video below.

Types of plexiglass

Extrusion (squeezing) and casting are methods of making organic glass. According to the manufacturing method, the final product is called cast or extrusion. The production method affects the characteristics of plastic, introduces a number of restrictions on its use.

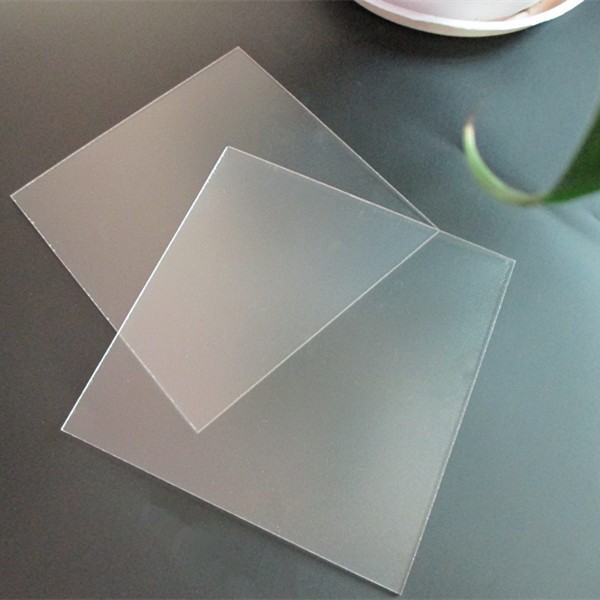

In appearance, plexiglass is classified into:

- transparent;

- matte;

- colored.

You can buy plexiglass in the form of a finished product or a semi-finished product. On the market there are:

- sheets;

- rods;

- pipes;

- blocks;

- other products.

To determine the manufacturing method, you should familiarize yourself with the marking of the finished material:

- HT - extrusion;

- GS - injection molded.

Extrusion

Extruded polymethyl methacrylate (PMMA) plexiglass is characterized by weak intermolecular bonds (low molecular weight). Because of this, it is used for products with simple shapes. Extruded plexiglass is made by continuous extrusion of molten mass, consisting of PMMA granules, through a slotted forming "head" of the extruder. Then they are cooled, cut into pieces according to the given dimensions. The production of extruded plexiglass is carried out on extruder lines. The manufacturing process is continuous.

Extruded plexiglass of domestic production is marked: SEP, ACRYMA.

Casting

Block or cast transparent thermoplastic is characterized by stronger intermolecular bonds (high molecular weight). This allows us to obtain products with improved performance in comparison with extrusion. Cast plexiglass has a smooth surface, high transparency, impact resistance, crack resistance. It can be polished, molded. Cast organic glass is heat resistant. The possibility of secondary re-forming of products is allowed. Also, cast plexiglass is characterized by higher chemical resistance, high thickness stability.

The method of manufacturing cast plexiglass is pouring liquid MMA monomer between 2 glass planes, followed by polymerization and hardening. In the production of block plexiglass, the thickness difference reaches 30%, and shrinkage during heating - 2%.

Domestic molded plexiglass is marked: TOSP, TOSP-N, TOSP-U, TOSN.

Sheet

Sheet plexiglass is produced in accordance with the requirements of GOST 10667-90.

Sheet lighting glass is produced in accordance with GOST 9784-75. To give the required technical characteristics during production, polyvinyl chloride or polystyrene is introduced into the composition (to impart light scattering to varying degrees).

Sheet sizes: thickness 0.8-30 mm, length - 100-1600 mm, width 100-1400 mm.Other sizes are available.

Frosted plexiglass, or double satin, is found on the polymer market. Through additional machining, the material acquires a rough, matte surface. Also, this effect can be obtained due to the introduction of special additives into the composition. The light transmittance of a matte sheet is from 20 to 70%, while that of an ordinary sheet sheet is up to 92%.

The area of application of sheet organic glass is very extensive: advertising signs, partitions, decorative elements and much more.

Plexiglass rods (rods)

Polymer round or square bar made in accordance with GOST 17622-72 and other tech. conditions. Supplied plastic: matt, transparent, painted.

The technical characteristics of these products correspond to the brand of plexiglass from which the product is made.

For square rods, the diameter of the circumscribed circle is from 10 to 40 mm. Round rods are available in diameters from 2 to 100 mm. The standard bar length is 2 meters. By agreement with the customer, the dimensions may vary.

Plexiglass rods are used in different areas: the implementation of design solutions, decor items, the furniture industry, the manufacture of some equipment, etc.

Stamps

Sheet lighting plexiglass is produced by grades:

- SE - extrusion;

- SB - block;

- BOT - transparent, made by extrusion;

- SBS - flame retardant block;

- SBPT - block with increased heat resistance.

BOT is transparent, other brands are cloudy.

Technical domestic plexiglass is produced plasticized (TOSP) and unplasticized (TOSN).

TOSP, in turn, can be designed for:

- TOSP-N - production of acrylic bathtubs, shower trays, sanitary ware, etc. (plumbing);

- TOSP-U - thermo and light stabilized.

According to GOST 10667-90, plexiglass sheet is also marked: CO (organic), then indicate the temperature at which the polymer softens (for example, 95, 120, 133) and a letter designation indicating the field of application (K - structural, A - aviation) ...

Plexiglas TOSP

Technical plexiglass of domestic production, manufactured in accordance with the requirements of GOST 17622-72, TU 2216-271-05757593-2001. According to this standard, this material can be produced:

- opaque colored (primary colors are blue, red, yellow, green, orange and white);

- transparent colorless;

- transparent colored.

It lends itself well to machining. The plasticizers included in the composition increase the plasticity, slightly reduce the softening point of the polymer.

According to GOST, technical characteristics of TOSP:

- impact strength of organic glass TOSP from 8.8 to 13 kJ / m2 (determined by the sheet thickness);

- tensile strength - not less than 61.7 MPa;

- softening temperature - not less than 92 ºС;

- density at 23 ° C - 1180 kg / m3;

- elongation at break - not less than 2%;

- linear shrinkage - about 3.5%.

TOSP plexiglass is the most popular, it is used in a variety of areas: from decor and everyday life to parts for various purposes in industry.

Organic glass TOSN

According to GOST 17622-72, TOSN organic glass (unplasticized) has the following technical characteristics:

- density at 23 ° C - 1180 kg / m3;

- elongation at break - not less than 3.5%;

- tensile strength - 70 MPa;

- linear shrinkage - about 3.5%;

- softening temperature - not lower than 110 ºС;

- impact strength of thermoplastic - from 8.8 to 15 kJ / m2 (depending on thickness).

The plastic is characterized by high resistance to stress and cannot be molded. Withstands higher operating temperatures than TOSP (90 versus 80 degrees Celsius).

Manufacturers and prices

Below are the most popular manufacturers of colored plexiglass and the cost of products. The price is indicated for 1 sq.m. sheet with a thickness of 3 mm.

Evonik Industries AG (Germany)

Cast

|

Series name |

Colors |

Surface |

Price, rub / sq.m. |

|---|---|---|---|

|

Plexiglas GS |

250 variants |

Glossy |

1 158 |

|

Plexiglas GS corrugated |

Red, green, blue, gray |

Textured |

3 874 |

|

Plexiglas satinice |

Standard, fluorescent |

Matt |

1 645 |

|

Plexiglas Sunactive |

Purple, red, orange, blue |

Matte / Glossy |

4 580 |

Extrusion

|

Series name |

Colors |

Surface |

Price, rub / sq.m. |

|---|---|---|---|

|

Plexiglas XT |

Standard |

Glossy |

1 650 |

|

Plexiglas XT fluted |

Shades of bronze |

Textured |

2 740 |

|

Plexiglas XTMirror |

Gold Silver |

Mirrored |

2 530 |

|

Plexiglas DF Satinice |

Standard |

Matt |

1 550 |

JSC "DOS" (Russia)

Extrusion

|

Series name |

Colors |

Surface |

Price |

|---|---|---|---|

|

Acryma XT |

Opal, milk, others to order |

Glossy |

1 520 |

|

TOSP, TOSN |

Luminescent |

Glossy |

1 465 |

SafPlast LLC (Russia)

Extrusion

|

Series name |

Colors |

Surface |

Price |

|---|---|---|---|

|

Novattro |

White, black, blue, red, yellow |

Glossy |

753 |

Lucite International (England)

Cast

|

Series name |

Colors |

Surface |

Price |

|---|---|---|---|

|

Moden glas |

Green, blue, yellow, red, dark red (transparent), orange, blue, black, fluorescent |

Glossy |

1 206 |

Rexglass (Taiwan)

Cast

|

Series name |

Colors |

Surface |

Price |

|---|---|---|---|

|

Rexglass |

Red, black, blue, orange, green, yellow. |

Glossy |

941 |

The combination of various advantages has brought colored acrylic to a leading position among other materials with similar light transmission (polystyrene, polycarbonate, PVC). Choosing colored acrylic, first of all, you should focus on the manufacturer's reputation and quality. The price issue in this case is of secondary importance, since the plexiglass of inadequate quality will soon require replacement, which will neutralize the savings.

Advantages and disadvantages

The main difference between acrylic sheet and ordinary glass is that the material in question is easy to process:

- safe cutting and grinding (you can use a tool for cutting metal, the process of work is no more difficult than with wood);

- drilling holes without cracking for fastening to other elements;

- fixation with various types of glue (specialized adhesives, adhesive tapes for plexiglass, solutions based on glue and solvents);

- bending and shaping by heating (while the optical properties of the material do not change).

In addition, acrylic sheets have a number of advantages due to which they are widely demanded in the market.

- A light weight. Plexiglas weighs several times less than traditional glass with the same thickness and size. Thus, the acrylic sheet structure does not require reinforced supports or frames, which will not overload the space.

- High light transmittance - over 90%. At the same time, the material does not lend itself to ultraviolet radiation, retains its color, does not turn yellow, and does not form burnt spots on it.

- Impact strength. To break plexiglass, an impact force is required that is several times higher than that required to break ordinary glass. In addition, when broken, the material does not disintegrate into small sharp fragments.

- Resistance to biological and natural factors. Plexiglas does not destroy moisture, it is resistant to the growth of microorganisms, mold and mildew, therefore it is often used in wet rooms, in the production of water transport, aquariums. In addition, it has high frost resistance.

- Resistance to aggressive environments. The material demonstrates increased resistance to chemical compounds, due to which various household cleaning agents can be applied to the products.

As for the disadvantages, they are mainly associated with technological difficulties in the manufacture of products. In the domestic use of acrylic sheet, there are two main disadvantages.

- High flammability. As noted above, the material is highly flammable, therefore, for safety reasons, it is forbidden to use it near open flames, heating devices, as well as in baths.However, it should be noted that when ignited, plexiglass does not emit toxic substances, as it is environmentally friendly.

- Susceptibility to mechanical damage. The acrylic sheet often leaves unsightly scratches from sharp objects, so it is unreasonable to cover kitchen work surfaces with such material.

Processing methods

Plexiglas can be: welded, glued, stamped, molded, heated, cooled, annealed, glued, bent, pulled, cut. Milling, drilling, turning, tapping - these operations are also used when working with plexiglass. In addition, the thermoplastic is ground and polished.

Recently, the method of processing PMMA laser is often used. This technology uses CO2 lasers, whose laser radiation length is 9.4 - 10.6 microns, coinciding with the absorption peak of PMMA. The cut obtained during this operation is smooth and does not contain traces of combustion products. For transparent plexiglass, no color change is observed on the cut. For colored thermoplastic, in rare cases, a change in shade on the cut is allowed.

Composition, properties and characteristics of plexiglass

The basis of organic glass is thermoplastic resins. The chemical composition of standard types of plexiglass from different manufacturers is identical. But the sheet material, which has specific qualities: the ability to protect against noise or exposure to ultraviolet radiation, pass or scatter light, resist impacts (anti-vandal property), withstand temperature effects; are already manufactured using various technologies. Accordingly, thermoplastics with different structures and chemical compositions are obtained.

Advantages

A number of advantages of plexiglass should be pointed out. Among them:

- the ability of plexiglass to transmit light, which does not change over time, is 92%;

- environmental friendliness, the possibility of disposal and recycling;

- easily machined;

- it is inert to water and various bacteria. Therefore, the material is used for the production of aquariums, yacht glazing;

- the lightness of plexiglass makes it possible to operate it without the construction of bulky frames and supports, giving the structure transparency;

- plexiglass withstands shock loads well. In comparison with ordinary glass, this figure is five times higher;

- using heating technologies, the material can be given various shapes without compromising optical properties;

- organic glass can be operated at low temperatures, it is resistant to chemical attack, corrosion;

- can be used as an electrical insulating material;

- transmits up to 70% of UV rays, without yellowing and without losing transparency.

disadvantages

This material:

- highly flammable (at 260 ° C);

- prone to damage to the surface layer (hardness 180 - 190 N / mm²);

- prone to the formation of microcracks, which appear due to internal tension in the places of bending, during vacuum and thermoforming.

Organic glass interacts with diluted hydrofluoric and cyanic acids, as well as concentrated acids: sulfuric, nitric, chromic. Organic glass solvents are chlorinated hydrocarbons (trichloromethane, dichloroethane, chloromethane), aldehydes, ketones, esters. In addition, the material is influenced by alcohols: butanol, ethanol, methanol, propanol. In this case, a short interaction of 10% ethyl alcohol with plexiglass is allowed.

Scope of application

Multi-colored acrylic glass can be found almost everywhere in the modern world. For room decor, plexiglass is used in the creation of shades for lamps, decorative pendants, shop windows, podiums, partitions in offices and apartments, aquariums, suspended ceilings. In street conditions, colored organic glass is often used in outdoor advertising, facade decoration, stained-glass windows, as domes for public transport stops.

In the manufacture of various structures, acrylic sheets of different thickness are used.

- From 1.5 to 2 mm - the thinnest and most flexible version, used in the production of sunglasses, helmets and protective helmets, contact lenses, business card holders, badges, stands for advertising brochures.

- From 3 to 5 mm - the scope of application affects advertising, but already in structures that require increased strength. These can be shop window elements, signboards, illuminated signs. Often, colored glass of this thickness is used in design structures, as well as in the design of side car windows.

- From 6 to 10 mm - used for glazing of various kinds of structures - premises, verandas, yacht canopies, domes of stops and metro entrances, presentation stands.

- From 12 to 20 mm - the densest variety of colored organic glass, used to create steps, podiums, stages, dance floors, pavilions.

Plexiglass cutting

Cutting plastic requires certain skills, since it is quite easy to damage the plexiglass. When working with large volumes, industrial cutting methods are used on specialized equipment. Use:

- cutting with saws (disk or tape);

- laser cutting;

- milling cutting.

Milling

The milling cutting operation is performed on milling machines where the shaft rotation speed is more than 4000 rpm. This method is applicable in cases where rapid heating of the material at the cut is unacceptable. After milling cutting, additional operations are performed, including polishing, engraving. The disadvantage of this method is the formation of internal stresses. It is not recommended to glue parts obtained by cutting with milling cutters.

For cutting in industrial volumes, machines with vertical placement of cutters are used. With the help of the software, the parameters of speed, frequency of rotation of the cutter, and the cut contour are set. The sheet is attached to a special table, along which the cutter moves, cutting out a given part. If the cutter is replaced with an engraving tool, it becomes possible to perform engraving on the same equipment. With the help of such a universal method, it is possible to get a detail of the desired contour with a pattern inside.

Laser

This method is the most progressive, practically waste-free. Its main advantage is accuracy. By using a laser cut (beam) with a width of about 0.1 millimeter, cutting precision of up to 0.005 mm can be achieved. The cut edges are smooth, do not change color (remain transparent).

Plexiglas is laser cut on production lines. For small volumes or for individual orders, machines with PU are used, which can be quickly reprogrammed for the next batch of products.

Plexiglas laser cutting is performed by qualified specialists. The main problem in performing this operation is the possibility of ignition of the glass sheet. Laser cutting is carried out at high speeds. Example: glass with a thickness of 3 mm is cut at a speed of 25 mm / s. The specialist cutter must ensure that the cutting equipment is correctly set up in order to obtain a quality cut. Blurring of the transparent thermoplastic at the cut site is considered a disadvantage.

The advantages of laser cutting include:

- high cutting accuracy (up to 0.01 mm);

- no contact between glass and cutting tool. Non-contact cutting starts from a thickness of 0.1 mm;

- the ability to carry out orders according to individual sketches of any complexity;

- small amount of waste during work.

The price of laser cutting works is calculated for 1 lm. and ranges from 10 to 200 rubles.

Disk or tape

The use of band saws for cutting out organic glass parts is quite common. The disadvantage of this method is an indirect cut. A better cut is obtained when working with a circular saw, but this method requires compliance with safety rules and the presence of a certain professional skill.

A semi-finished product cut by a saw quickly heats up and melts. It can even smoke. Therefore, the plexiglass must be constantly cooled during cutting. This can be done with a strong air stream or water. Water is poured into a special fixed container. The water consumption is low. For one hour of work, about a liter of water is consumed. The cooled cut is smoother, more straight, without melted areas.

There are many enterprises, workshops that specialize in cutting plexiglass. They are equipped with special equipment, including laser cutting equipment. The professionals working there will quickly and efficiently fulfill your orders.

An excursion into history

For the first time, plexiglass was created in Germany in the XX century, in the period between the two world wars. At that time and for some time after the plexiglass was called "plexiglass", since it was under this brand that the German chemist Otto Röhm patented it.

Industrial production of this material from thermoplastic acrylic resin began in the early 1930s. It was found that such a substitute for conventional glass has a lot of advantages and is perfect, first of all, for aviation - the safety of the cockpit was ensured by increased strength and the absence of sharp fragments when plexiglass was destroyed.

Soon this transparent material found application in all types of military equipment - in addition to aviation, in waterborne and land. However, already during the Second World War, it was discovered that in addition to advantages, plexiglass also has a significant disadvantage - it is highly flammable. It is clear that for military aviation, this disadvantage fundamentally crossed out the advantages of acrylic polymer, and designers began to turn to other transparent materials.

Color spectrum

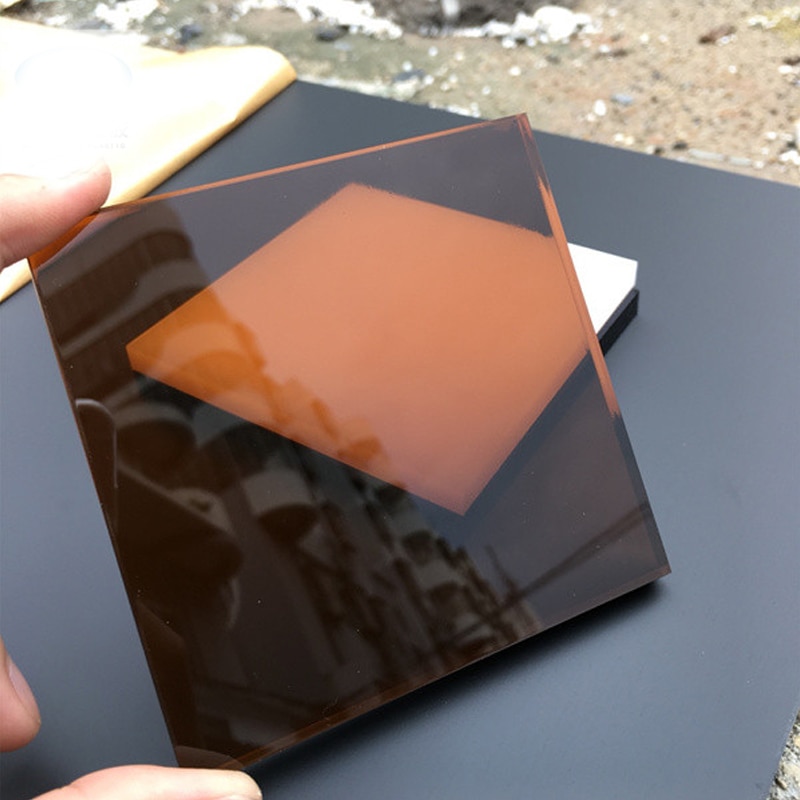

Colored glass is presented on the modern market in the widest color palette. On sale you can find options in classic colors - white and black acrylic glass, as well as all the traditional colors of the rainbow spectrum - from saturated to paler shades of red, green, blue, yellow, orange, purple, blue. At the same time, coloring substances in multi-colored glasses do not affect the degree of transparency and do not distort visibility through the glass.

According to the statistics of sales in interior design, the most popular types of colors are:

- white (beige, ivory, coffee with milk);

- brown (golden glow, dark bronze);

- gray (opal, silver, smoky).

The listed options are considered universal, not cutting the eyes, and therefore are suitable for decorating rooms in any style.

Along with transparent multi-colored glasses, matte varieties are also in demand. They perfectly diffuse light, they are often used for shades of lamps.

Specifications

Acrylic glass has the following properties:

- high light transmittance - up to 92%;

- low thermal conductivity, retains heat well;

- 2.5 times lighter than ordinary glass;

- 5 times stronger than glass;

- does not form dangerous fragments when dropped;

- operating temperature range - from -40 to +80 ° C;

- flexibility - amenable to thermoforming at a temperature of 150-190 ° C;

- ease of mechanical processing even at home;

- soundproofing qualities;

- resistance to aging under the influence of moisture and ultraviolet radiation;

- transmits UV rays;

- resistant to alkalis and aqueous solutions of inorganic salts;

- does not generate static electricity and does not attract dust;

- hygiene - does not contribute to the development of bacteria;

- does not emit poisonous gases when burning;

- recyclable and fully recyclable.

Among the shortcomings, it is worth noting:

- flammability - flash point is 260 ° C;

- fragility and instability to scratches;

- high coefficient of linear expansion - 8 times more than glass.