Features of production

For the production of the described material, the same types of wood are used as for the production of conventional plywood.

In particular, we are talking about such types as:

- Birch;

- poplar;

- coniferous trees;

- aspen and others.

Increased performance properties are achieved through lamination, as a result of which plywood acquires the following characteristics:

- high density;

- increased strength;

- resistance to mechanical damage;

- increased level of moisture resistance.

How is lamination done

In order to perform lamination, manufacturers use certain formulations.

Among them:

- melamine;

- phenol;

- polyvinyl chloride.

Melamine is a special, unique material that contains special melamine-formaldehyde resins. The use of melamine makes it possible to create plywood characterized by increased moisture resistance, as well as a high level of wear resistance.

Phenol is an amazing chemical type compound found in almost all organic type resins. If only phenolic resin is used for surface treatment, then this will not allow increasing the level of moisture resistance.

The last type of compound, which is polyvinyl chloride, is the most common processing option for plywood when laminating it.

The main characteristics of this composition:

- low chemical activity;

- high level of environmental friendliness.

Therefore, plywood treated with this type of coating is used for interior decoration of premises, as well as for creating furniture.

Quality standards

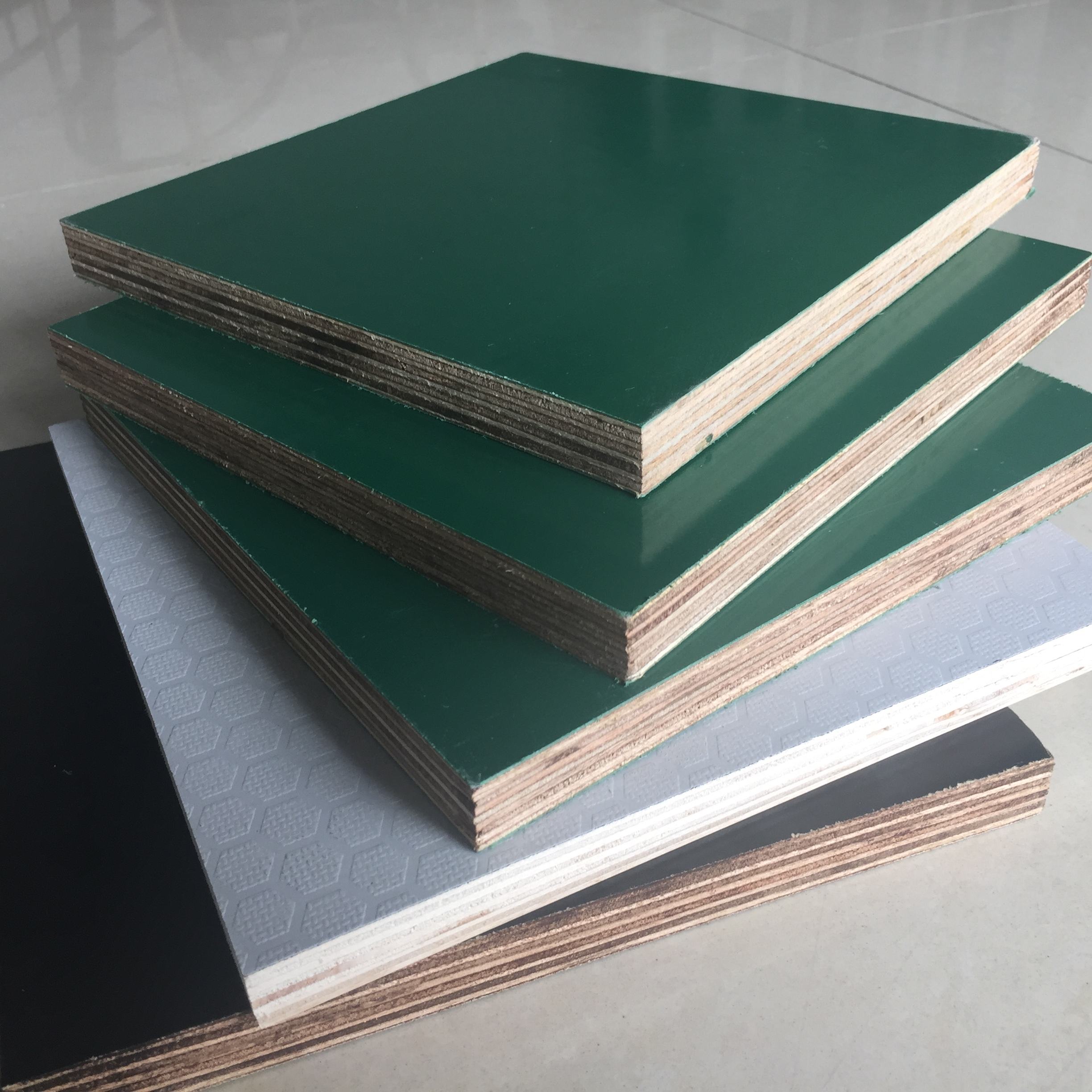

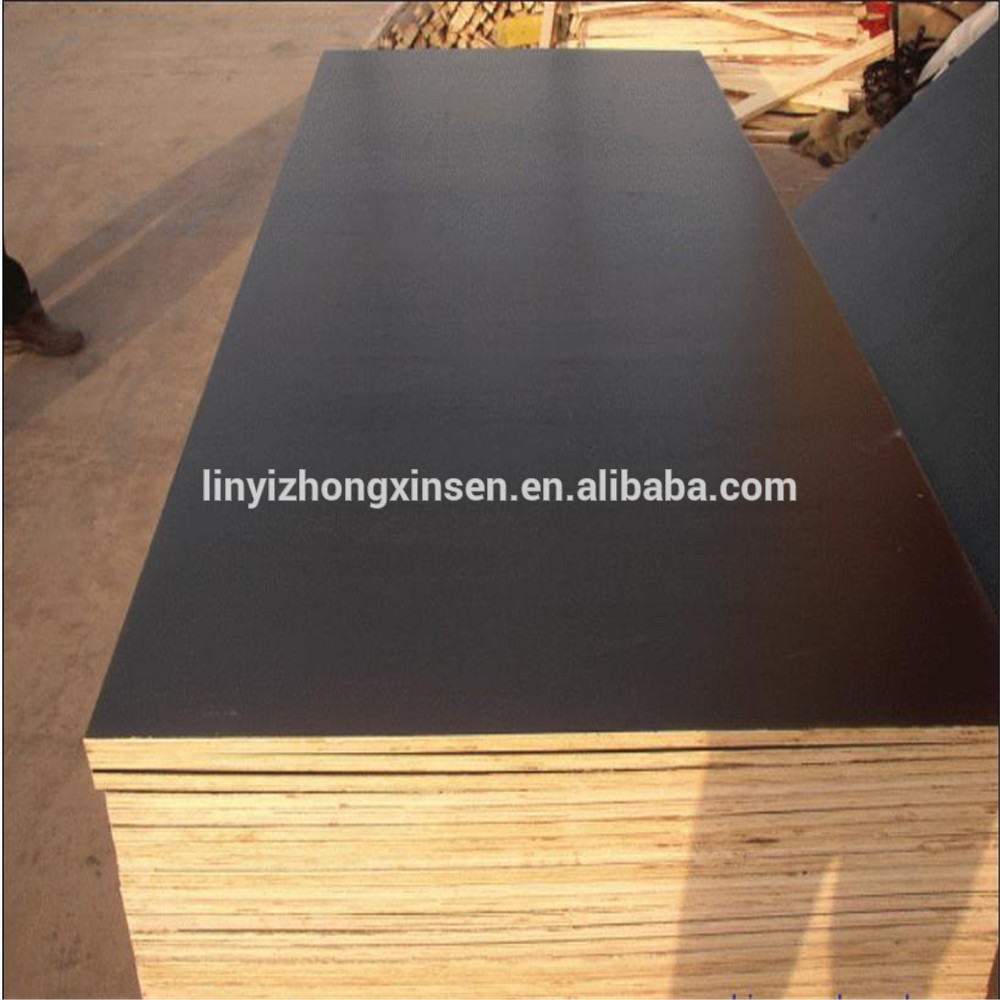

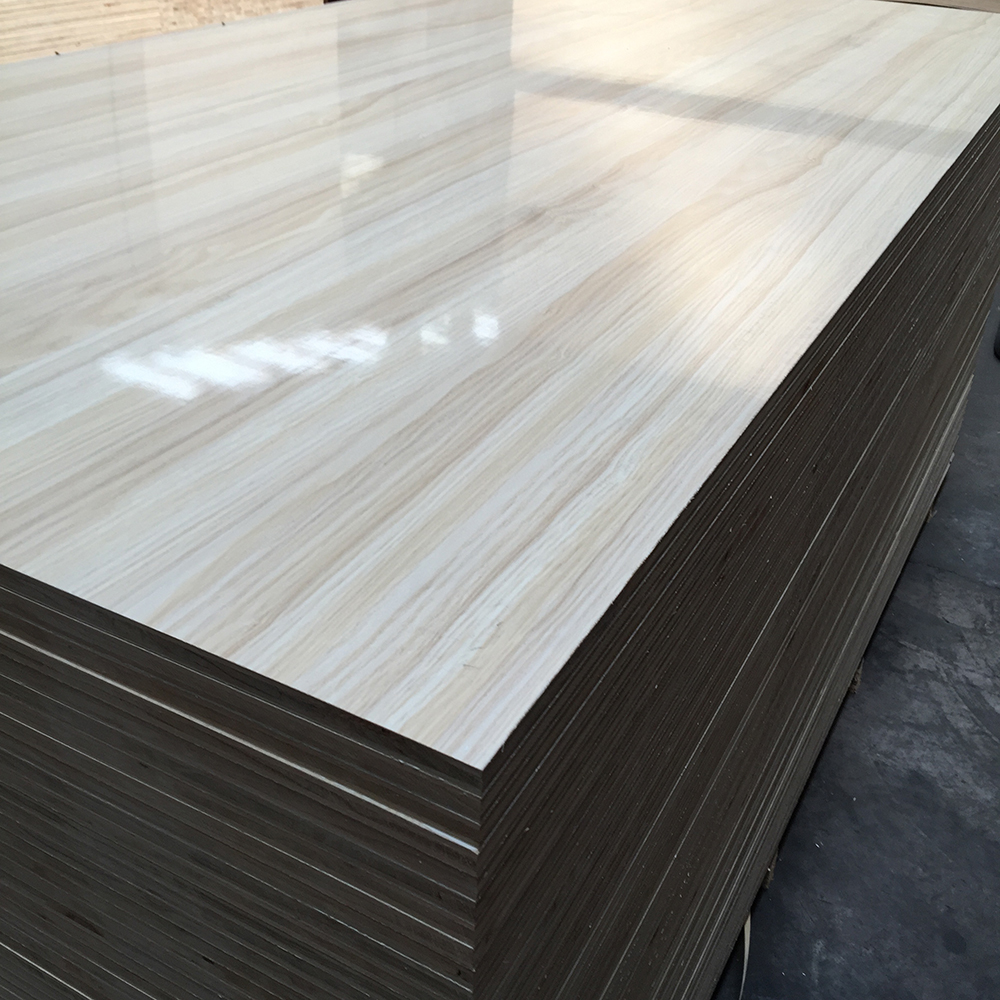

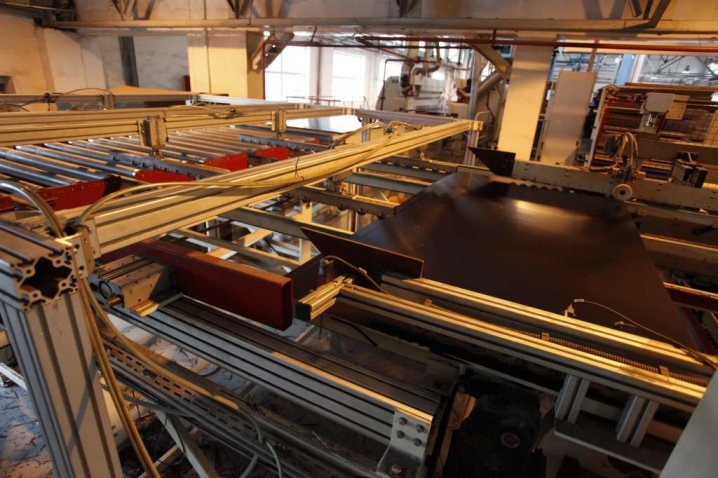

There is even a special GOST for film faced plywood - 53920-2010 “Veneered plywood. Technical conditions ". If we talk about the date of appearance of this GOST, then, in comparison with other technical conditions, it appeared relatively recently, and therefore many specialists in the field of construction and repair work are not even aware of its existence.  Photo of dark plywood

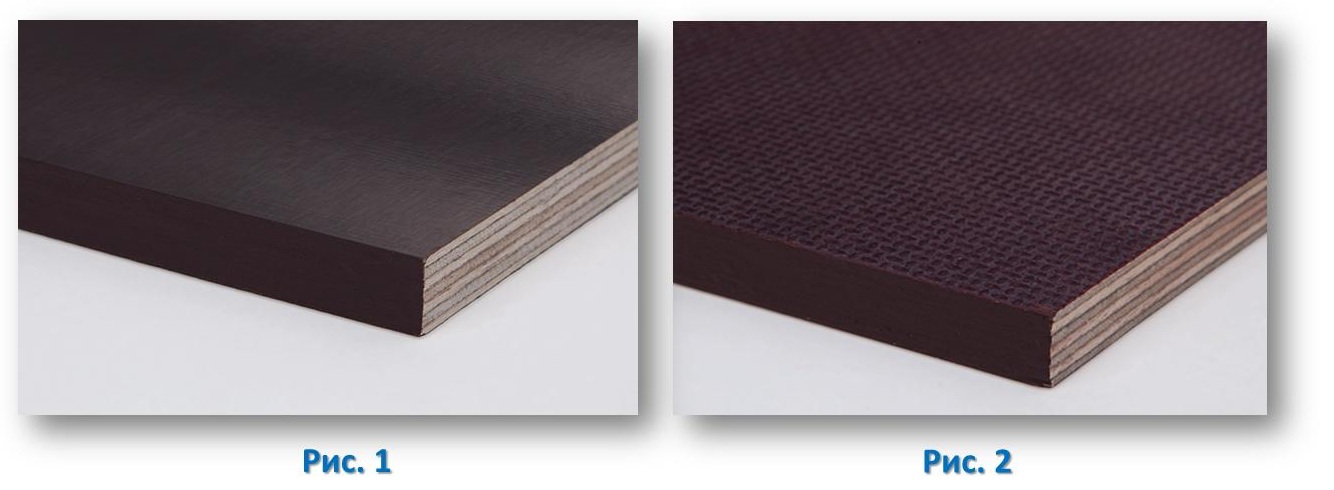

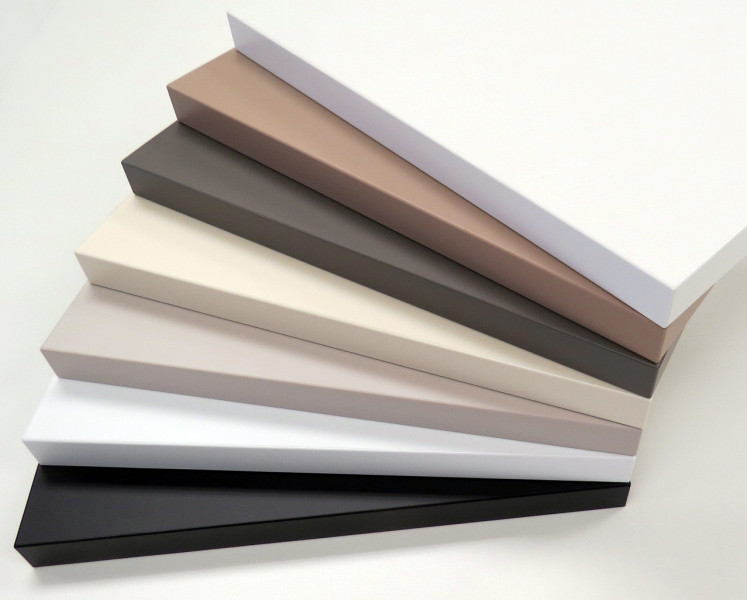

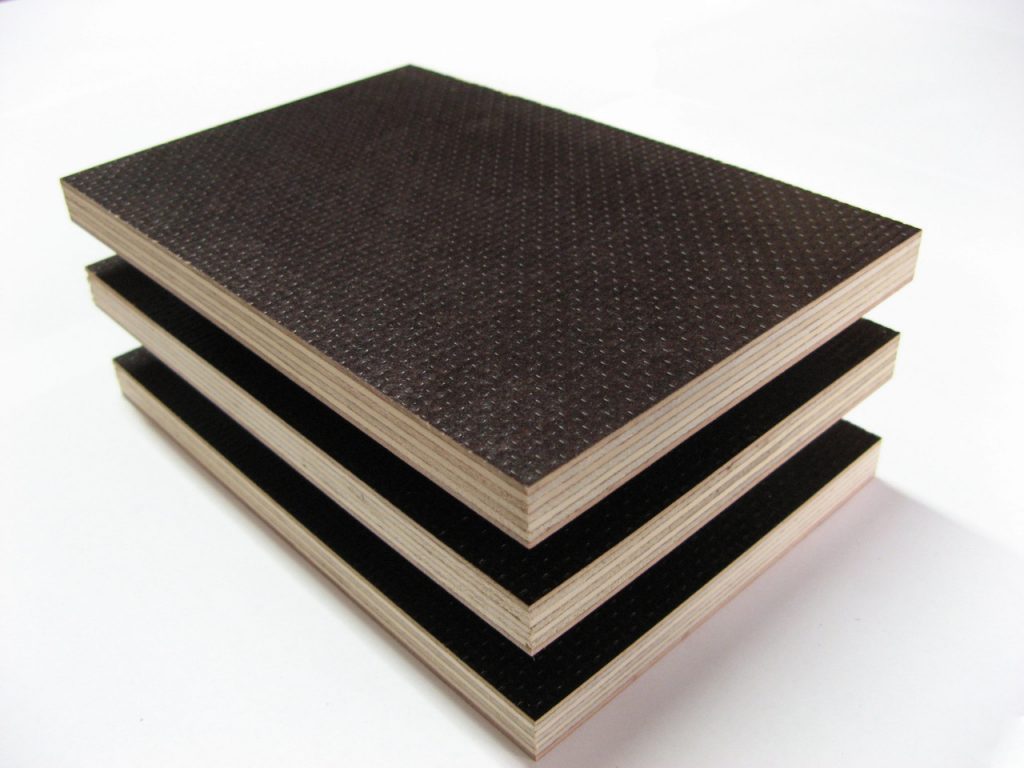

Photo of dark plywood

Therefore, we will consider this document in more detail.

In particular, it applies to products:

- increased moisture resistance;

- lined with polymer film or special polymer type resins.

This document provides for the availability of several grades of film faced plywood:

- FF - means a material that is lined with a special film on both sides;

- FW - we are talking about a material that is covered with a smooth film on one side, and with a mesh on the other;

- SP / SP - the material used for painting, and therefore covered with a special type of film;

- F / SP - a material that is coated on one side with a film suitable for painting, and on the other with a regular smooth film;

- F / U - a material that is covered with a smooth film only on one side.

In accordance with GOST, these products must necessarily undergo strict labeling, which will display the following information:

- plywood brand;

- name of the material;

- overall dimensions of the product;

- the brand of film used for lamination;

- Class;

- and also have a designation of the standard by which the plywood was made.

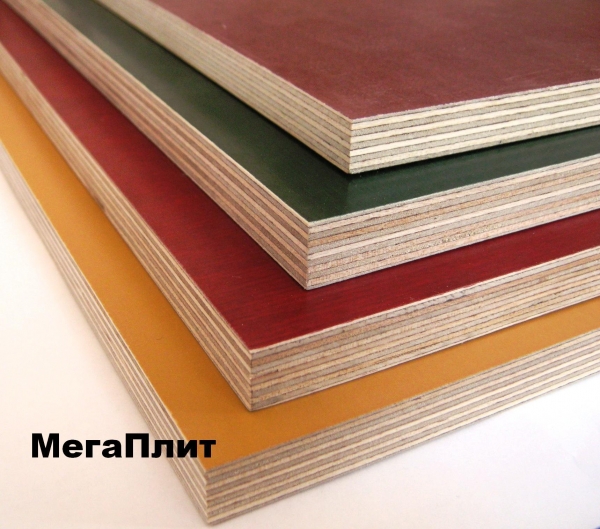

Film faced colored plywood

Film faced plywood is widely used in exterior design - both in the construction of modern and in the reconstruction of old buildings. The increased water resistance allows the use of film faced plywood all year round, in all weather conditions. Due to the wear resistance and durability of a special coating, film faced plywood is widely used in the creation of original facades.Plywood can be easily combined with other materials, easy to install and assemble structures, so it fits well into the most daring design decisions. High strength and non-slip surface, increased surface wear resistance and moisture resistance allow the use of film faced plywood for a long period of time.

Fields of application of film faced plywood:

- wall panels, window sills, partitions

- sound and heat insulating panels

- educational institutions, classrooms and laboratories

- conference rooms and concert halls

- decoration of bars, restaurants

- decoration of medical institutions, pharmacy stores and kiosks

- partitions in massage and beauty parlors

- finishing of laundries, beach houses, showers

- seats for spectators in stadiums and sports grounds.

Transport engineering, carriage and shipbuilding

Due to its high moisture resistance and end-face processing, the use of film faced plywood is also possible in conditions of high humidity and large amplitude of temperature fluctuations. Corrosion resistance, light weight with high strength, wear resistance and the ability to manufacture bent-glued parts - all these properties are highly valued in transport engineering, automotive, car building and shipbuilding. Due to the special physical and mechanical properties of film faced plywood, domestic and foreign transport manufacturers use this material as the most economical in terms of price and quality.

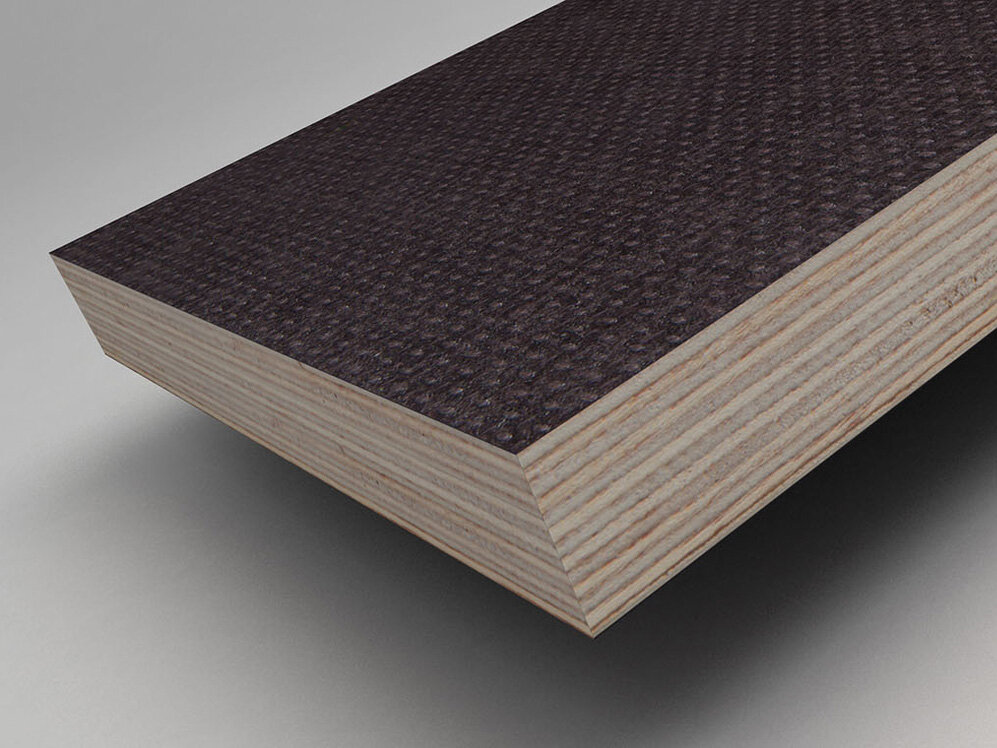

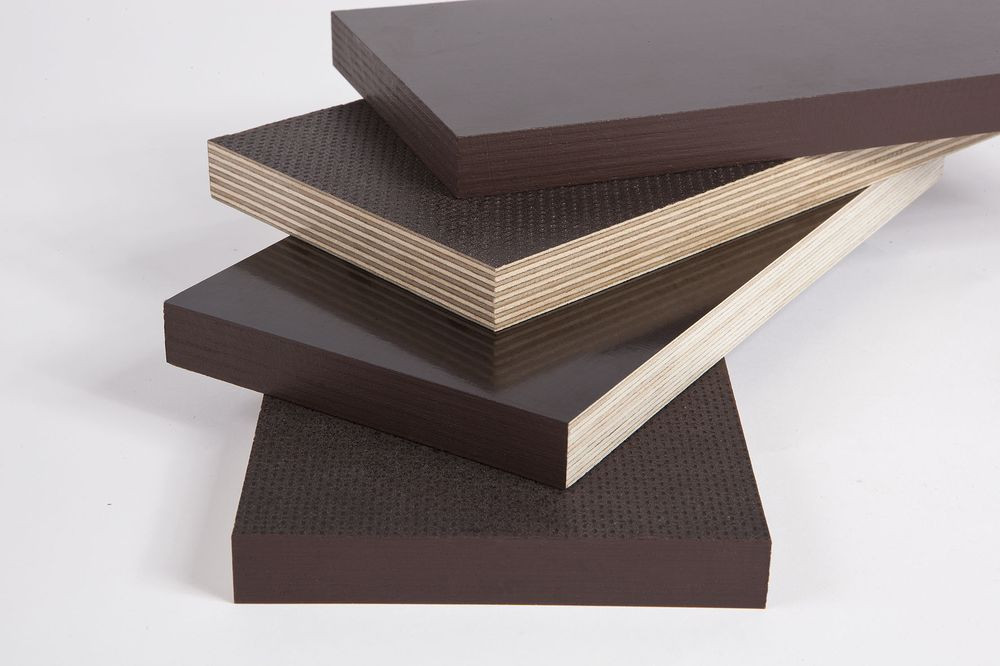

Applying a mesh pattern to the surface of the laminated board increases the coefficient of friction of the board surface, preventing slipping, which makes embossed plywood indispensable in the manufacture of floors for trucks, loading and unloading bays, storage bridges and containers. The price for film faced plywood is slightly higher than for ordinary plywood, but the quality is much better. Areas of use:

- trucks (gates, body linings, non-slip floors)

- vans, pickups and trailers

- buses and trolleybuses

- containers and trailers

- railway wagons

- finishing of yachts, boats and ships

- seating on boats, catamarans and passenger ships.

Home decor options

You can decorate the room with various plywood crafts, for example, candlesticks, frames, sconces. But this is only a small part of what can be created from this material. To decorate a children's room, you can use volumetric plywood figurines of animals or fairy-tale characters.

Today, the walls of many houses are decorated with figured inscriptions of various themes - from small ones to the achievements of family members. Housekeepers with hooks and hangers are hung in the hallway and corridor.

Plywood can be used to make multifunctional screens that hide heating radiators. As well as lambrequins and even flower shelves. In the workshop, you can order unusual designer watches and stylized calendars, where digital elements are burned out images.

For the dining area, you can create plywood coasters for dishes. Figurines with movable elements and music boxes where jewelry can be stored look unusual and interesting.

Rooms decorated with panels made of pieces of plywood look very impressive. Anyone can make such beauty. It is enough to put the image on paper and transfer it to the base of the panel by burning or cutting out. These paintings can be ordered from a workshop or purchased from an art store.

Plywood is a versatile material that allows you to create a wide variety of designs and products. For example, a cup holder for large breed dogs. The design for placing cups can be stationary or folding, solid or colored.

In addition, unusual door handles and interesting bottle holders can be made of plywood to decorate a festive table. The mirrors look quite unusual, the edging of which is decorated with a carved pattern.

Peculiarities

Plywood is a multi-layer material used by mankind for more than a dozen years. The woody texture gives the plywood panels a beautiful natural pattern, used as a decorative element in the design industry.

This material has sufficient strength, which is provided by the structural characteristics of the placement of layers. Each successive plate is laid out in a different direction of the grain, thereby reducing the risk of sheet splitting, reducing the possibility of shrinkage and guaranteeing a stable size. This feature allows you to create different designs and details, the design of which is unique and has no analogues.

Plywood is an excellent material for construction, decoration and design work. However, harmful compounds are used in its manufacture. We are talking about adhesives. Connecting impurities in the form of phenol and formaldehyde are harmful to human health.

Main areas of application

The application of film faced plywood is quite diverse. This is due to the fact that the technical characteristics of film faced plywood are quite high. This is especially true of this type of product as fof, which indicates a high level of moisture resistance.

So, the main areas of application of film faced plywood:

- construction;

- repair work, in particular, on finishing the premises;

- furniture manufacture;

- automotive industry and the creation of various vehicles;

- manufacturing of commercial and warehouse equipment.

Features of use in construction

If we talk about construction, then first of all it is worth noting the creation of formwork. Formwork arrangement

This is due to the fact that the film used for plywood processing helps to protect the material from the following negative influences:

- mechanical damage;

- abrasion;

- the negative effects of moisture;

- negative effects of chemical compounds.

All this makes it possible to use plywood formwork multiple times.

In addition to the arrangement of foundations, this type of building material is used in the following cases:

- when creating floors and partitions;

- when erecting columns;

- when creating fences;

- during the construction of storage facilities;

- during the construction of bridges, etc.

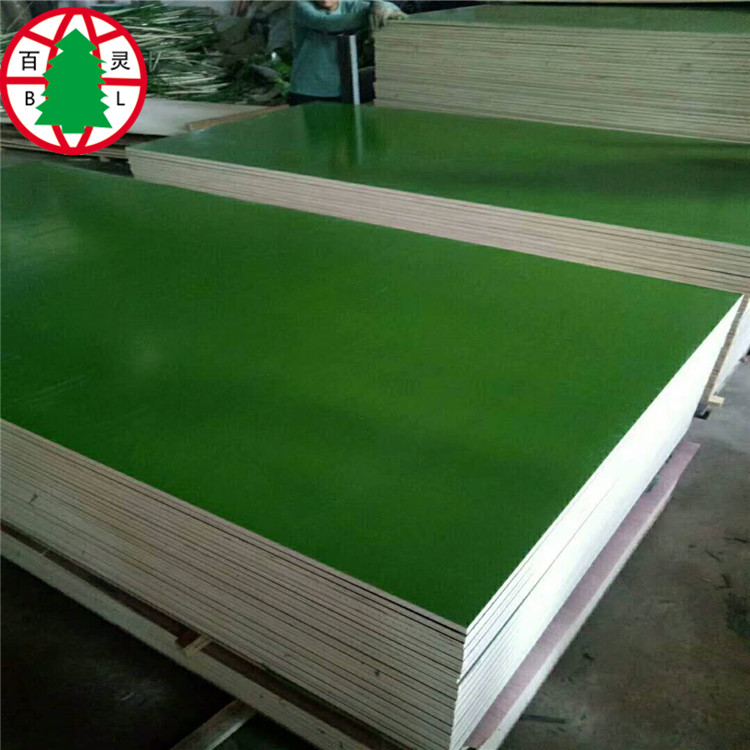

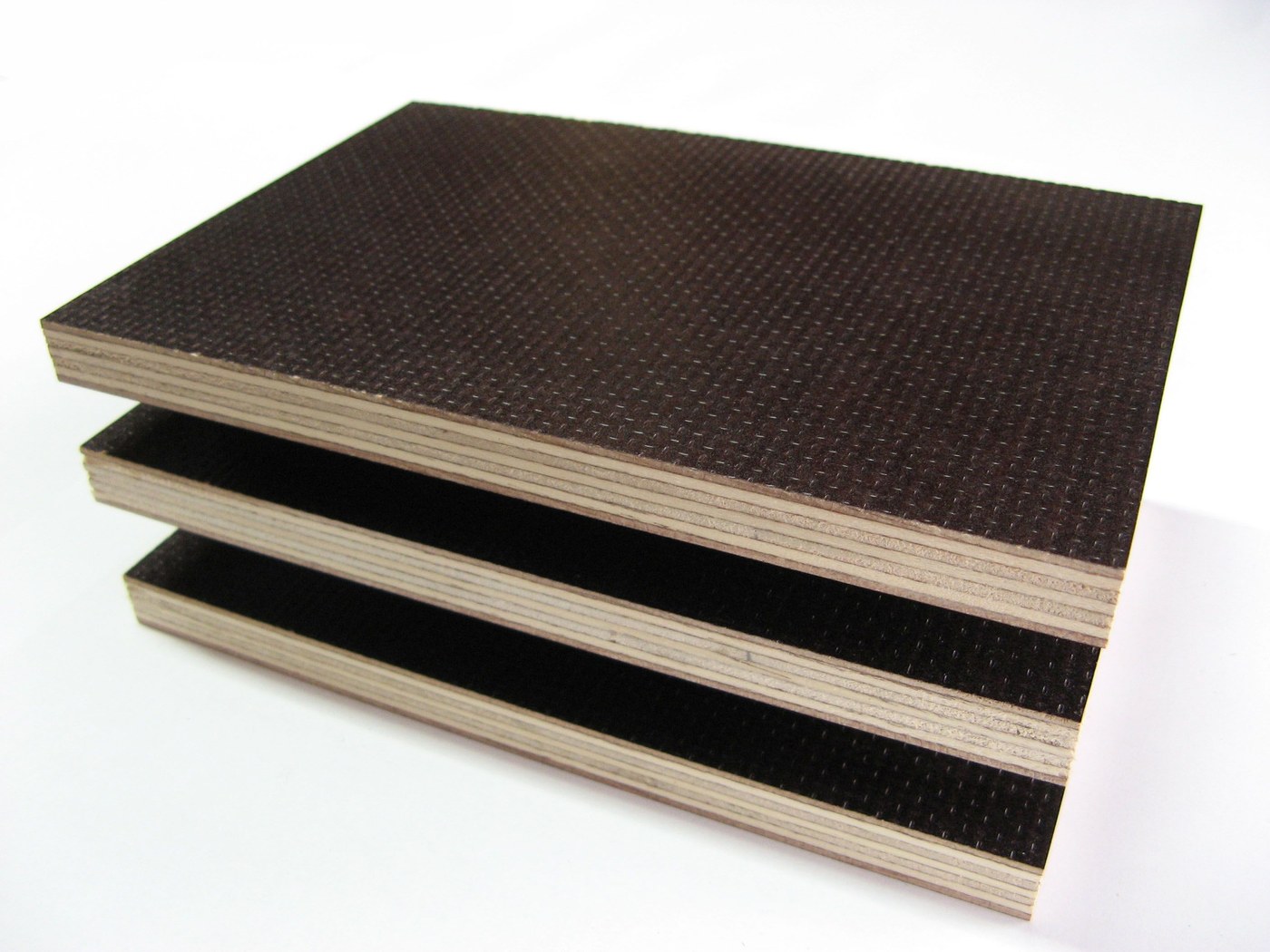

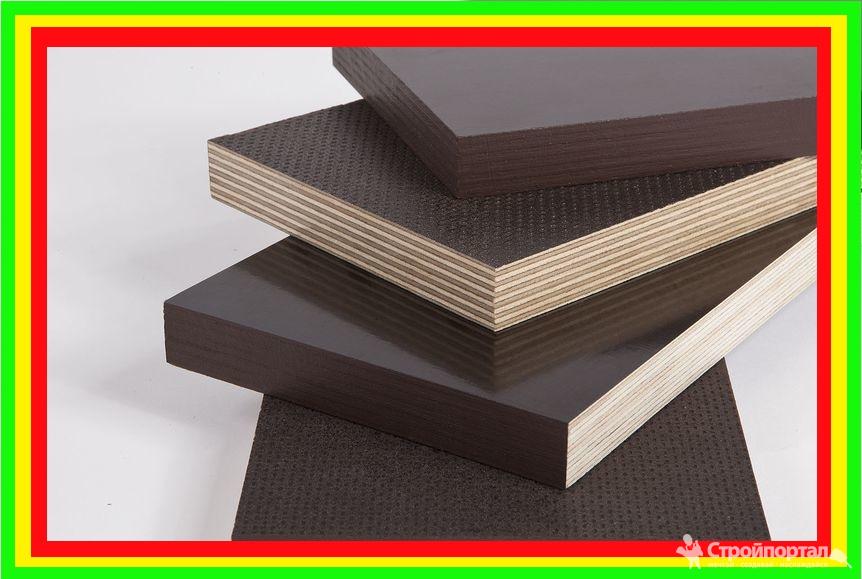

Special attention should be paid to plywood with WISA-WIRE mesh, the price of which may slightly differ from the usual material of the type described. The essence of such plywood is that it is lined on both sides with a special corrugated surface that prevents slipping.  Plywood with mesh

Plywood with mesh

There are other positive characteristics of this type of plywood, among which the following stand out:

- additional safety margin;

- resistance to mechanical abrasion and damage;

- resistance to moisture;

- resistance to chemical attack of various types;

- resistance to the formation and spread of mold, mildew.

Plywood, which uses the WISA-WIRE mesh, in addition to construction, is successfully used in various branches of human life, for example, when creating floors in vehicles of any type.

Application features for finishing works

In this case, laminated products are used to create interior partitions, decorative panels, as well as:

- movable partitions;

- window sills;

- ceilings.

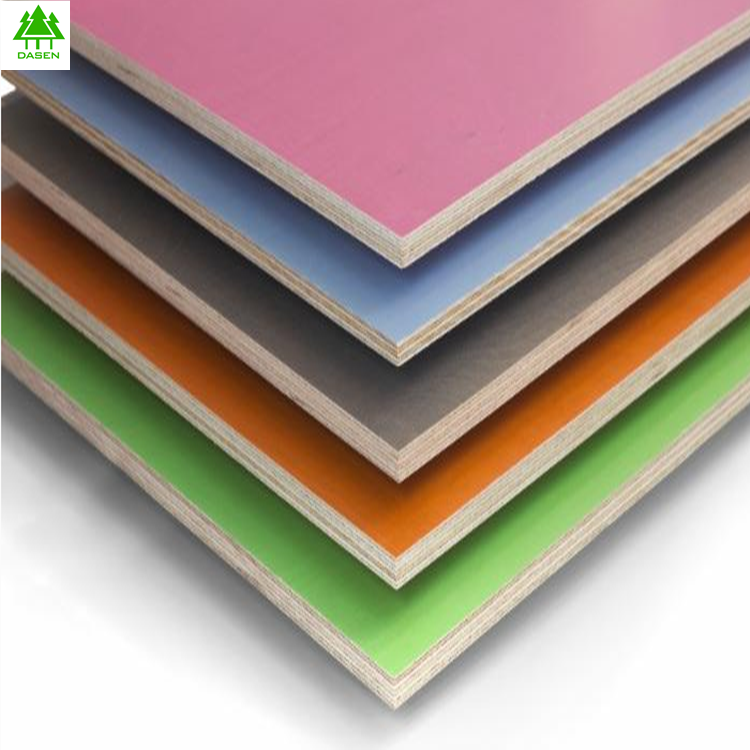

Taking into account the variety of color solutions, you can create a unique design in the room.

Therefore, plywood is successfully used not only in residential buildings, but also in the following types of buildings:

- offices;

- public buildings of various types;

- sports and cultural centers;

- cinemas, etc.

Film faced plywood floor

Film faced plywood floor

Other areas of application

Considering the increased aesthetic and decorative properties that are characteristic of laminated plywood, it is customary to use it in the manufacture of furniture.

In particular, they make from it:

- shelves of all types;

- kitchen sets;

- cabinets of all types;

- boxes and more.

And already increased operational properties allow the use of this material in the structure of various vehicles:

- cars;

- trailers;

- trolleybuses;

- buses;

- ships, including yachts;

- wagons, etc.

For example, they make from it:

- counters;

- fitting rooms;

- advertising stands and much more.

Plywood laminated with mesh

For the convenience of work, the plywood surface is marked in the form of a grid, which simplifies the cutting of sheets and the laying of reinforcement, significantly

labor costs are reduced and the productivity of construction work increases. Moreover, such a type of surface as a smooth mesh of film faced plywood,

retains high wear resistance with repeated use. The grid lines have a pitch of 25, 50 and 100 mm, thereby simplifying

the procedure for cutting off complements, flanging and cutting right angles.

This material is most widely used in the installation of removable and non-removable formwork, but it is also widely used in internal and external

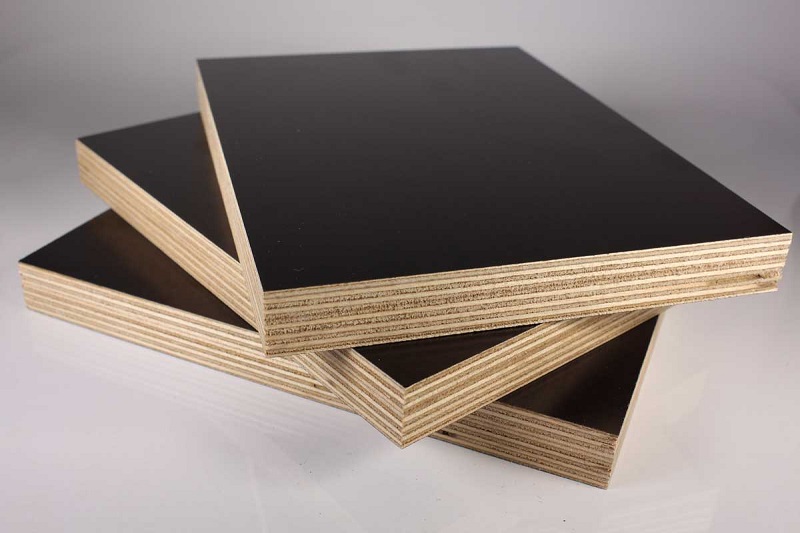

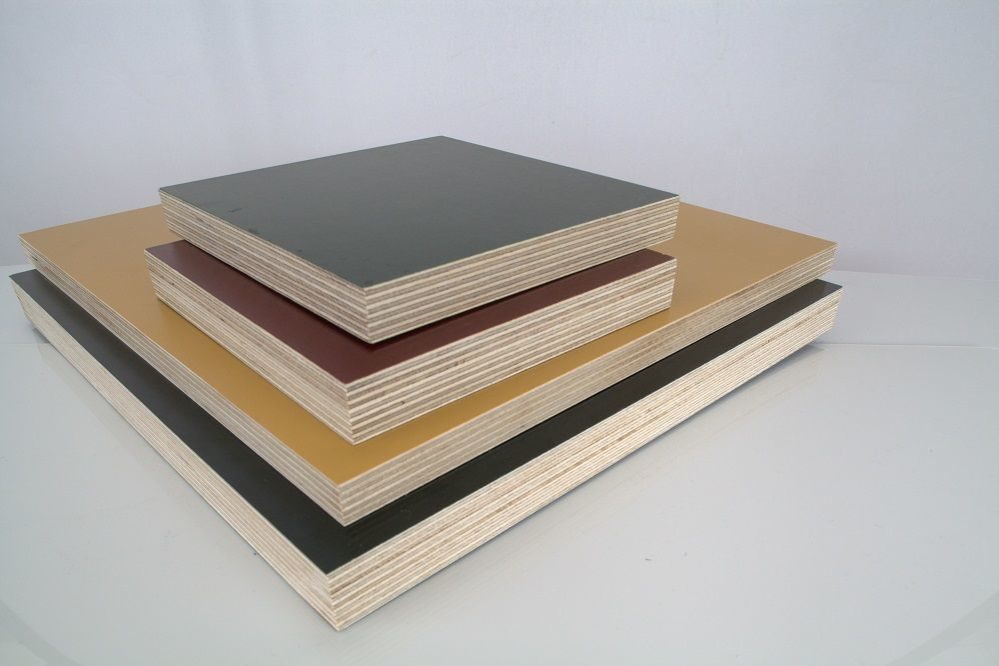

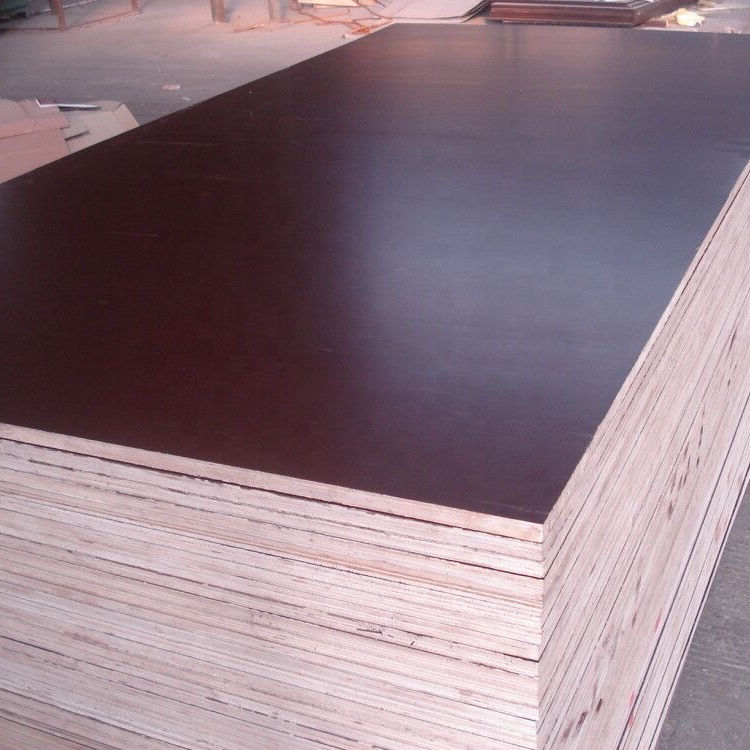

decoration, furniture and decorative production. On the outside, the sheets are mostly brown or black, but depending on the density,

coloring may vary.

Birch Film Faced Plywood

Film faced birch plywood combines the best qualities of the wood itself and the final product from it. Rotary birch veneer

glued under pressure using moisture resistant glue and melamine resins, which makes the product more durable and dense

throughout the structure, while maintaining flexibility. In addition to moisture resistance, it is possible to note the absence of odor and safety for health. TO

additional advantages include resistance to warpage, the presence of a perfectly smooth birch base structure, aesthetic

light color, easy processing and good compatibility with other materials.

We are one of the leading organizations involved in the manufacture and supply of a unique range of moisture resistant laminated plywood

birch, poplar and softwood for our clients. It is made from high quality hardwood and is one

of the best in the country. The inner layer and the outer surface are made of the highest quality wood with formaldehyde resin.

We supply this plywood according to client's requirements in terms of design, pattern, size, etc. Main competitive

The advantages of our company are high quality products, timely delivery, competitive prices.

Laminated birch plywood is the most common building material due to a good combination of price and quality.

Applications

As mentioned above, film faced plywood is a popular and demanded option among buyers. This widespread use is due to the fact that this material is used in various spheres of human life.

Construction. In the construction industry, film faced plywood is popular due to its characteristics: wear resistance, moisture resistance, strength, reliability, etc. Thus, film faced plywood can be used in a wide variety of climatic conditions. Various floors and columns, as well as foundations, are made of the material.

Thus, we were able to make sure that laminated wood material plays an important role in the daily life of almost everyone, as it is used in many areas.

At the same time, it is important to carefully approach the choice of material so that it meets all your needs and can fully perform its functions.

For information on whether it is possible to paint film faced plywood, see the next video.

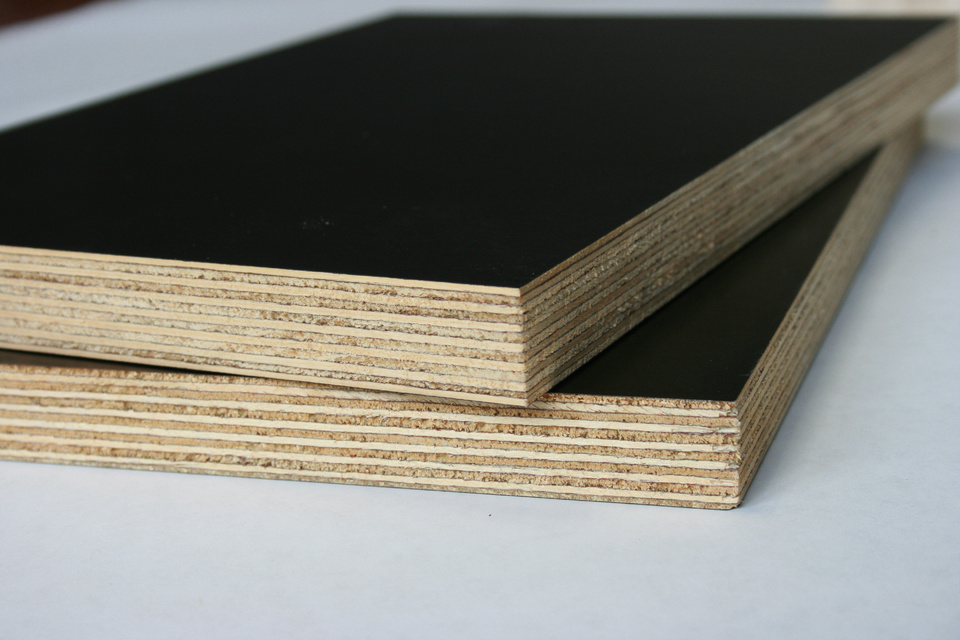

Film faced plywood price per sheet

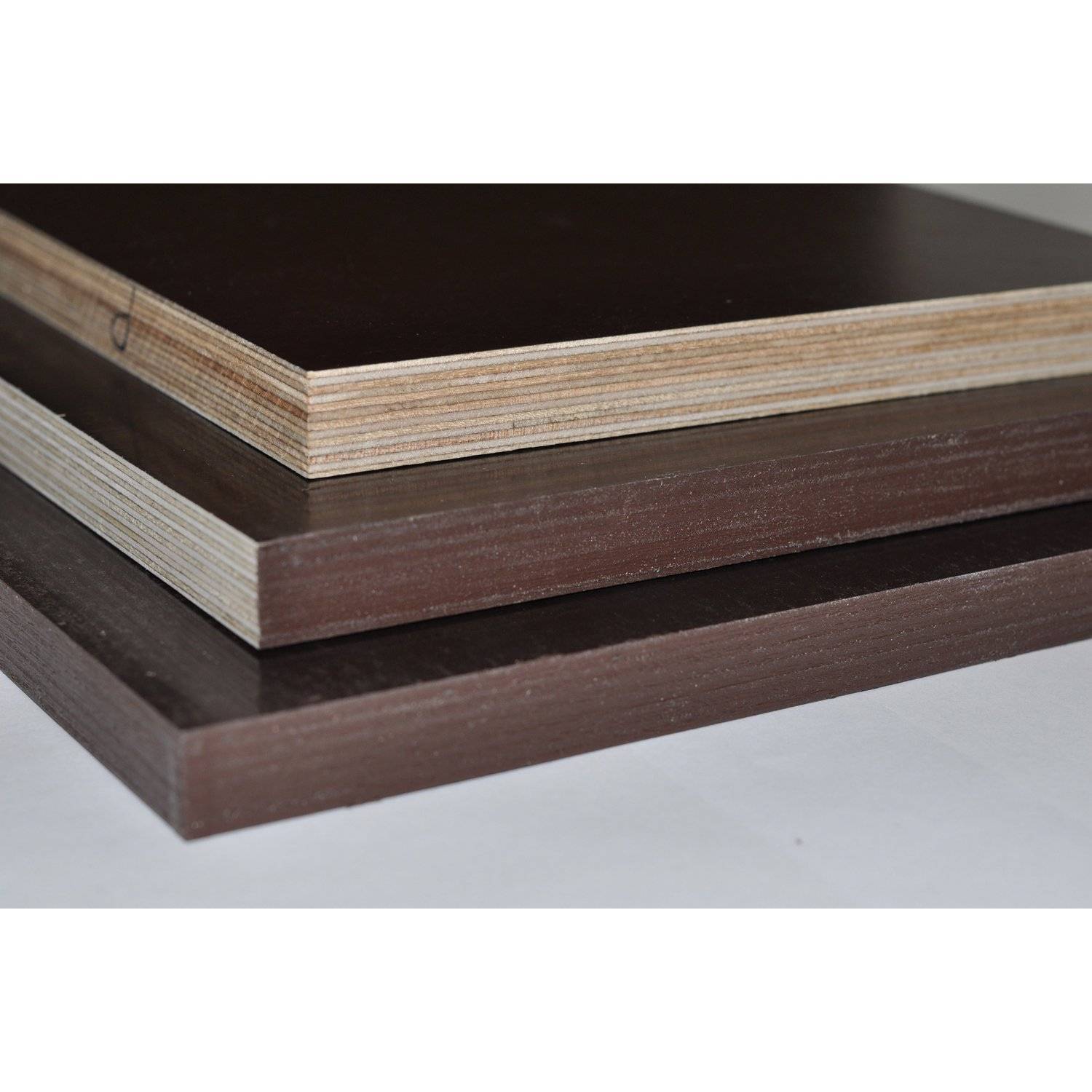

Film faced plywood has many areas of application. Laminated waterproof plywood is in the greatest demand.Film faced plywood is made of high quality materials using modern woodworking technologies at the level of world standards. Laminated plywood of increased water resistance, used in construction, consists of veneer layers of various types of wood and glued with glue based on phenol-formaldehyde resin. Below is a brief classification of plywood that the modern building materials market offers. One of the main features for the classification of film faced plywood is its purpose. For example, film faced plywood can be used as a structural material used in construction and as a decorative material for finishing, for example, in furniture production. The outer layers of plywood are faced with a phenolic film coating. The standard coating is dark brown with a density of 120 g / m2. At the request of the customer, film with a density of 117 g / m2, 167 g / m2, 174 g / m2, 205 g / m2, 214 g / m2 or 220 g / m2 can be used. A variant of the surface is possible that has increased wear resistance due to repeated coating with standard films (240 g / m2, 440 g / m2).

Peculiarities

The most important distinguishing feature of laminated wood material is the presence of a special film on the surface. In its role, both special processed paper and plastic can act. In the process of making plywood of this type, a large number of veneer sheets are used (for example, birch or coniferous).

After the direct procedure for making plywood is over, a special procedure for applying the film to the building material takes place. In addition, without fail, all layers are impregnated with a special composition that increases the water resistance indicators.

The advantages of laminated material include the following characteristics:

- high level of resistance to moisture;

- flexibility (plywood can stretch and bend, but this does not violate the integrity of the material);

- reusability (if necessary, plywood can be used several times), etc.

Despite the presence of such important advantages, do not forget about the negative factors:

- high price for the material (accordingly, not everyone can afford to purchase such laminated wood);

- toxicity (during the production of plywood such a harmful component as formaldehyde, which is an element of the adhesive composition, is used), etc.

It should be noted that there are a wide variety of types and types of film faced plywood on the market. They can differ in terms of such indicators as density, thickness, length, width, color, and more. etc. Accordingly, each user will be able to choose a material that will meet all his individual needs and preferences.

Views

Due to the fact that film faced plywood is a fairly common and demanded material, a large number of varieties and types of products can be found on the market. For the convenience of users, there is a classification of types of plywood, consider the most popular types.

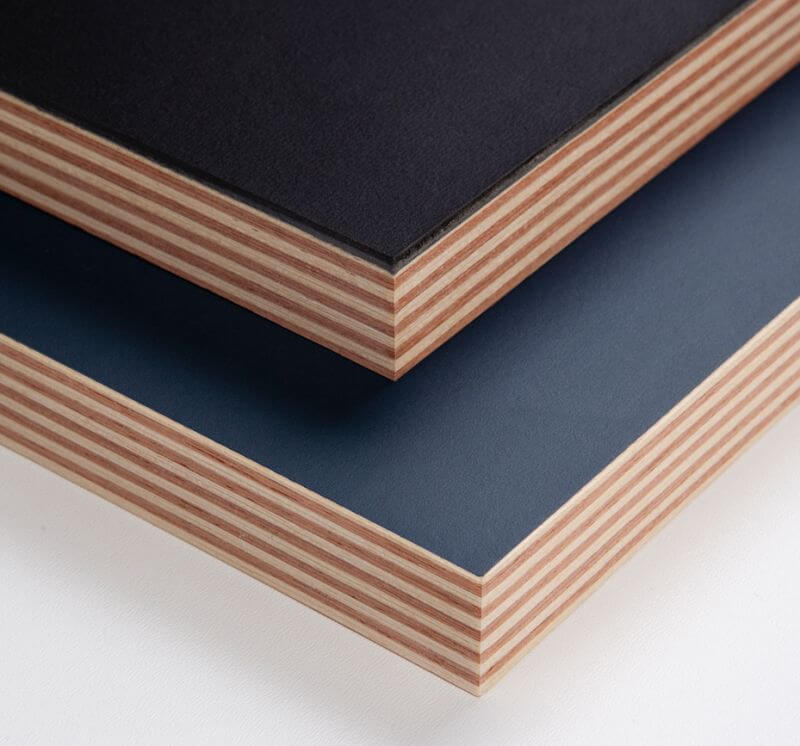

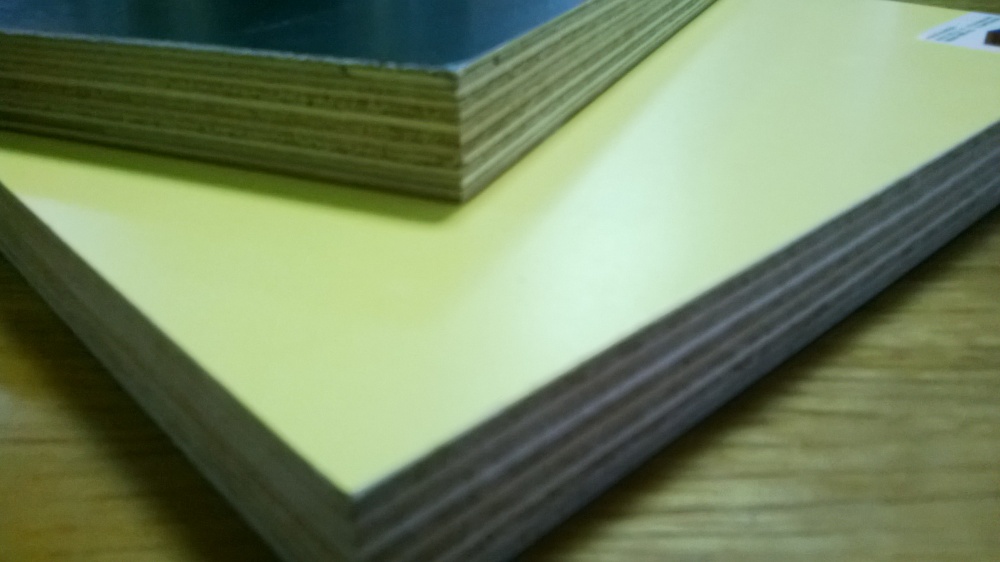

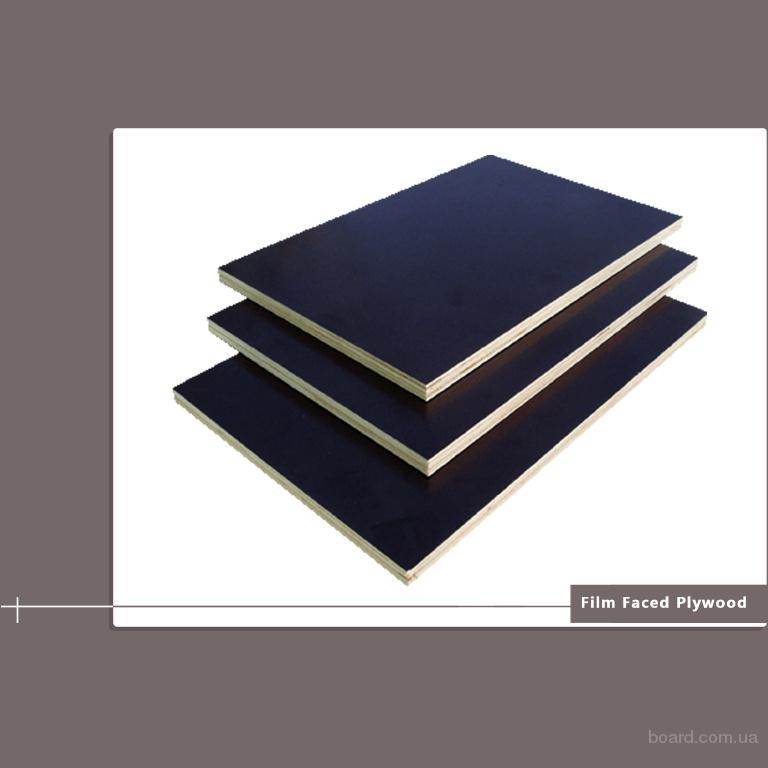

Colored

There are a huge number of color options for plywood: white, black, brown, green, gray, etc. The colors of the material should be selected depending on your individual desires and preferences. Colored film faced plywood is actively used in the production of furniture, packaging, as well as during construction and repair work.

Formwork

This material is suitable for creating frames, partitions, fences and other temporary structures. The thing is that this type of plywood is characterized by such characteristics as ease of installation and stability.

Transport

Transport plywood can be laminated in different ways: there are variations on the market with lamination on one or two sides. Like the material is actively used for decoration vans, semi-trailers, cars and trucks, boats, ships (as you might guess from the name).

In addition, it is important to note that plywood is subdivided into grades and grades (the markings on the material will tell you about this). So, for example, the varietal classification is based on the quality of the material:

- 1st grade has the highest quality, plywood is smooth;

- 2nd grade allows for blistering and scratches (but a small amount);

- The 3rd grade is considered to be of the lowest quality and allows a large number of defects.

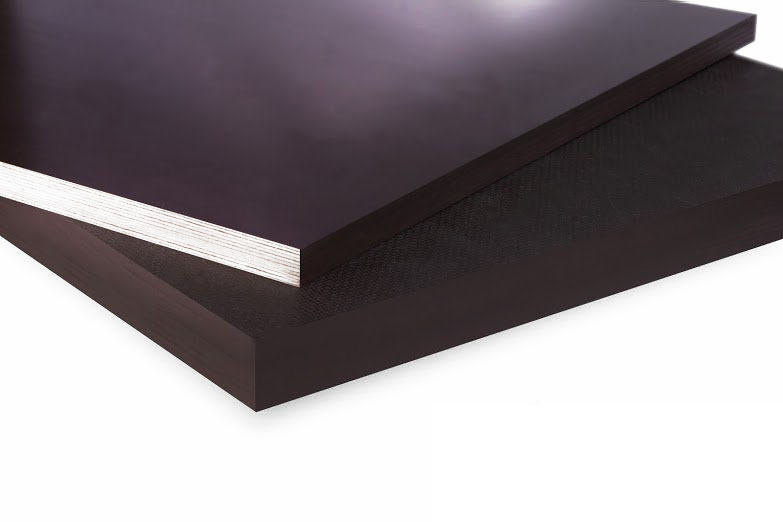

It is also important to note the presence of different brands of plywood:

- F / F - this type has a laminated coating on both sides;

- F / W - this grade of material is covered with a smooth continuous film only on one side, while the other side is mesh;

- SP / SP - I use this plywood if the material will be painted in the future;

- F / SP - one side of the material is completely smooth, and the other is suitable for painting;

- F / U - plywood lamination is present only on one side, and on the other side there is an untreated birch veneer.

Properties and applications of film faced plywood

Laminated formwork plywood foundations, walls, columns and other structures are made according to the same principle with other types. Wood veneer sheets, glued with phenol-formaldehyde glue, are covered with a special film - laminate. In this case, a special technology for applying the material is used, which is called lamination. As a result of this process, film faced plywood is obtained, which has an advantage over other types of plywood due to its greater strength and moisture resistance. These differences and characteristics allow film faced plywood to find wide application in the construction industry, namely in the form of formwork, as well as in auto, ship and car building.

Film faced plywood at the manufacturer's price 495 / 589-49-79

The color of the film faced plywood coating can be as follows:

- dark brown transparent (120 g / m2);

- dark brown opaque (120 g / m2);

- dark brown (220 g / m2);

- chestnut brown (117 g / m2);

- light brown translucent (117 g / m2);

- yellow (167 g / m2);

- green (117 g / m2);

- red (220 g / m2);

- white (melamine film, 205 g / m2);

- black (122 g / m2);

- gray (174 g / m2);

- colorless film (117 g / m2);

- paintable paper (291 g / m2).

The surface texture of film faced plywood can be: F-smooth, W-embossed. Finishing of the ends: the ends are covered with waterproof acrylic paint (mesh) or SP-paper for painting. Storage of film faced plywood should exclude direct sunlight and precipitation on the surface.

Application area of film faced plywood

The presented building material has many distinctive properties: for example, increased impact resistance, durability and improved resistance to loads. Among other things, film faced plywood can be used in construction all year round, despite bad weather conditions.

The possibility of multiple use of formwork forms makes the use of film faced plywood very profitable. With proper operation and mandatory special processing of the ends of the board after sawing, film faced plywood has a long service life if used correctly. It is recommended to clean and reapply a special lubricant after each shuttering cycle to ensure a smooth concrete surface.

Colored plywood

| blue plywood | green plywood | yellow plywood | red plywood |

| white plywood |

Film faced plywood GOST 53920 2010

Our well-known organization offers high quality laminated anti-slip plywood GOST 53920 2010, with a higher

surface finish and improved shear strength, using an adhesive that provides flawless adhesion.

Available in several attractive designs, patterns and colors, our range effectively satisfies

numerous requirements of customers. GOST 53920 2010 film faced mesh plywood is extremely durable, cost effective and

easy to maintain. In addition, our regular customers can benefit from very cost-effective as well as customer-oriented

prices.

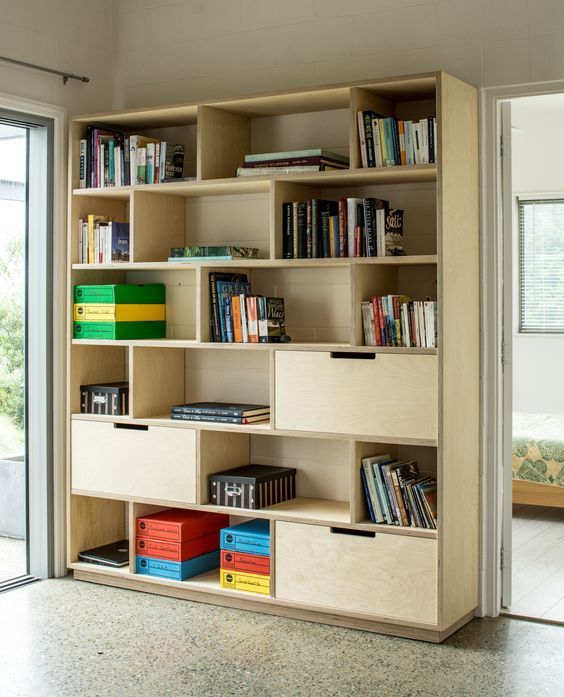

Plywood cabinet furniture

Cabinets, racks, plywood chests of drawers

|

|---|

|

Rice. 50. Shelving unit with movable shelves |

|

|---|

|

Rice. 51. Large shelving made of plywood in living room |

|

|---|

| Rice. 52. Air chest of plywood |

|

|---|

|

Rice. 53. Chest of drawers made of plywood with drawers and doors |

|

|---|

| Rice. 54. Plywood wall |

|

|---|

| Rice. 55. Large plywood cabinet |

|

|---|

|

Rice. 56. Wardrobe made of plywood throughout the wall, even "bypasses" the doorway |

|

|---|

| Rice. 57. Plywood sliding doors |

|

|---|

|

Rice. 58. Chest of drawers made of plywood with facades nice pastel colors |

Sleeping place and beds made of plywood

|

|---|

|

Rice. 59. The sleeping place is fenced off from rooms with plywood boards |

|

|---|

|

Rice. 60. Which is better - just a mattress on floor or is this an option? |

|

|---|

|

Rice. 61. Bed on wheels and a wardrobe plywood |

|

|---|

|

Rice. 62. The sleeping place is fenced off plywood shelving |

|

|---|

|

Rice. 63. Plywood bed with drawers below and cupboards above |

|

|---|

|

Rice. 64. Curbstone for a sink made of plywood in bathroom |

|

|---|

|

Rice. 65. Bathroom furniture from plywood |

Plywood writing desk

|

|---|

|

Rice. 66. Transformable wall with shelf mounts |

|

|---|

|

Rice. 67. Elegant writing desk with cover made of thick plywood |

|

|---|

|

Rice. 68. Writing desk from separate colored plywood modules |

|

|---|

| Rice. 69. Plywood secretaire |