Types and grades of bricks for the basement

Since the basement of the building must be made of the most durable and high-quality material, many developers are interested in what material it is best to make it from. In construction, the following types of brick materials are used for facing the basement.

Clinker brick

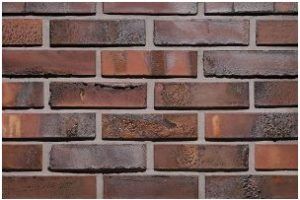

The material for the manufacture of clinker bricks is a special type of clay, which is fired in special furnaces at a temperature of about 1200 degrees Celsius. Clinker consists of refractory clay (chamotte), feldspars and clay materials.

After firing, bricks can have different color shades. This type of building material belongs to the expensive elite class and is distinguished by high strength characteristics and an attractive appearance. Sometimes clinker bricks are used as paving stones for sidewalks.

If we compare it with ordinary ceramic bricks, then the clinker material will have a clear advantage:

- The strength indicator (the ability to withstand a load without destruction) is more than 300 kg per 1 cm2.

- Water absorption (the ability of the material to absorb water until full saturation) is not less than 6%.

- Frost resistance (the ability to withstand repeated freezing - defrosting without complete destruction of the material) is more than 100 cycles.

- Heat resistance.

- High sound insulation properties.

Possessing all these advantages, the basement clinker brick perfectly protects the ground part of the foundation and gives a beautiful elegant look to the building.

Clinker base brick

Clinker base brick

Acid-resistant basement brick

This type of brick, without exaggeration, can be attributed to the "eternal" building material. Acid-resistant bricks for the basement are made from special clay raw materials with high technical indicators of plasticity, refractoriness and resistance to fire. The clay contains silica, alumina and iron oxide. After firing in special kilns, the brick acquires a rich yellow color. The chemical composition and improved technical performance provide resistance to high temperatures and aggressive environments.

The production of such material is standardized and manufacturing plants produce the following brands:

- Straight brick with dimensions of 230 x 113 x 65 mm.

- Double-sided end brick 230 x 113 x 55 mm.

- Double-sided wedge rib brick 230 x 113 x64 mm.

Acid-resistant brick has a low water absorption rate, such a brick practically does not get wet, which makes it an ideal material for cladding a basement.

Acid resistant brick

Acid resistant brick

Silicate brick

In the case of using sand-lime bricks for the basement of the building, an external protective finish in the form of various plasters will be a mandatory requirement. The main advantage of silicate-based building materials is a low and affordable price. Silicate bricks are made from a mixture of quartz sand and lime using autoclave steam technology, so this building material is not recommended for use in high humidity environments.

Silicate brick plinth

Silicate brick plinth

Under the influence of moisture, the brick will become soaked, lose its technical strength indicators and eventually completely collapse. It is possible to use silicate brick for the basement installation only in arid regions with a low amount of atmospheric precipitation.

When using silicate for the basement of a building, it is best to perform a high-quality underlay waterproofing from 2 layers of roofing roll material.

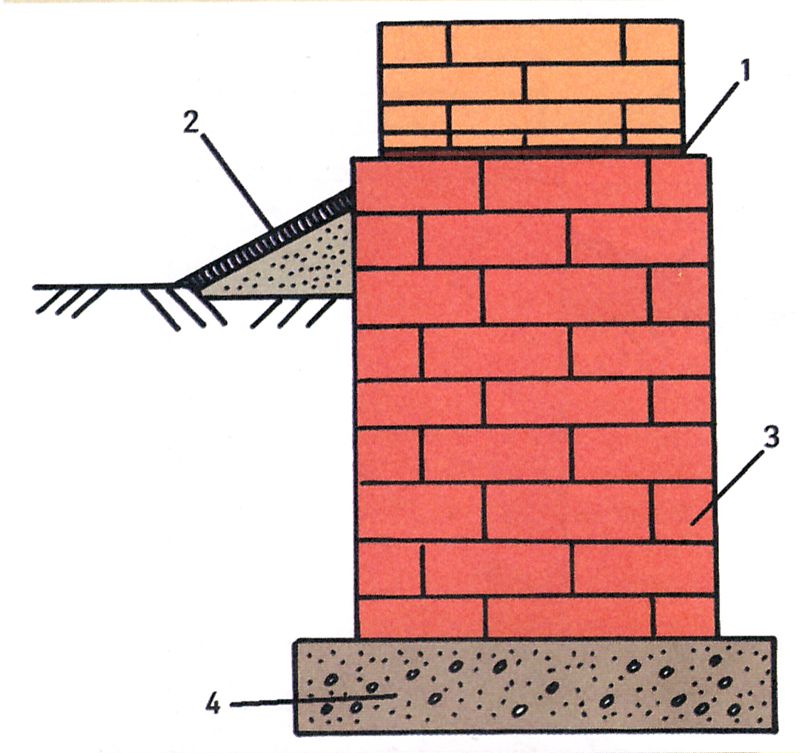

Red ceramic brick for plinth

Basement ceramic brick for laying the ground part of the foundation

Basement ceramic brick for laying the ground part of the foundation

Red ceramic brick belongs to the universal building material known since ancient times. It is made from clay by firing in ovens and subsequent drying in drying chambers. It gained its popularity among builders due to its excellent performance, durability and reliability.

The red base brick has good resistance to both capillary and atmospheric moisture. The red brick for the construction of the basement of the building must necessarily be solid with a dense structure, since atmospheric moisture will condense in the hollow body, which will lead to the destruction of the array of brickwork. Of all types of building materials for the basement, red ceramic brick is the most popular and widespread type.

Brick types

Basement brick is a conventional name that is used to refer to ordinary masonry bricks in the conditions of facing the old and building a new basement. A number of requirements are imposed on it:

- Resistance to water, snow, temperature changes. This is due to the fact that it is located on the outside of the building, often without additional protection from a plaster layer or siding;

- Unified dimensions. An important parameter that is used at the stage of project creation;

- Environmental safety, no unpleasant odor;

- Affordable price and satisfactory appearance.

Silicate brick

White in color, made from a mixture of lime and sand. Rarely used for lining plinths. It's all about the high rate of water absorption. In silicate bricks, it reaches 16%, which is unacceptable for the construction of structures that will come into contact with water during operation. After saturation with moisture, it darkens, internal connections begin to break down and the brick literally "crumbles".

In rare cases, plinths are faced with sand-lime bricks in areas with a dry climate, with improved waterproofing and a protective layer of cement-based plaster.

Red clay brick

A common building material for arranging a basement. It is made from clay in special ovens. Red bricks have a lower moisture absorption coefficient than silicate bricks.

Saturated with moisture, it freezes in winter and thaws in summer. From this, its structure is gradually changing. The brick begins to collapse, small surface and through cracks appear. There is a high probability that the base / plinth, separated by simple ceramic bricks, will lose its attractive appearance after several years of operation.

To increase the service life, it is necessary to use brick of the M250 brand and above.

Hyper-pressed brick

Durable finishing material with low water absorption coefficient. For its production, the screening of marble, dolomite and shell rock is used. High quality Portland cement acts as a binder. The ingredients are mixed with each other and pressed in special forms.

Hyper-pressed brick is often used for finishing a basement, not only because of its high strength, but also because of its beauty. The outer side of the stone can be smooth or made to look like "torn stone".

Clinker brick

A kind of red ceramic stone. It is made by firing, only clinker clay is used instead of the usual one. As a result, the brick has a very low percentage of water absorption (up to 6%). It is also more durable than simple clay counterparts.

Since the clinker brick practically does not absorb moisture, it does not crack in the cold. The service life of a structure made of it can be up to 100 years.

Choice of materials

The basement of the house, in addition to protecting the main structure from moisture, performs a number of functions, each of which imposes serious requirements on the choice of material.

In the absence of a basement floor, the space inside the base, under the floor, is filled with soil using the backfill method, which creates pressure on this part of the structure. The option of a building with a basement also does not exclude a mechanical effect on the basement, but now the variable pressure (depending on the season it changes, but is constantly present) is exerted by the soil outside the building. The building itself has a constant effect with its weight.

The choice of material for it hardly allows you to use less expensive options than for the house itself. There are no trifles in construction. The building material for the basement must have sufficient frost resistance, minimum moisture resistance, strength under load.

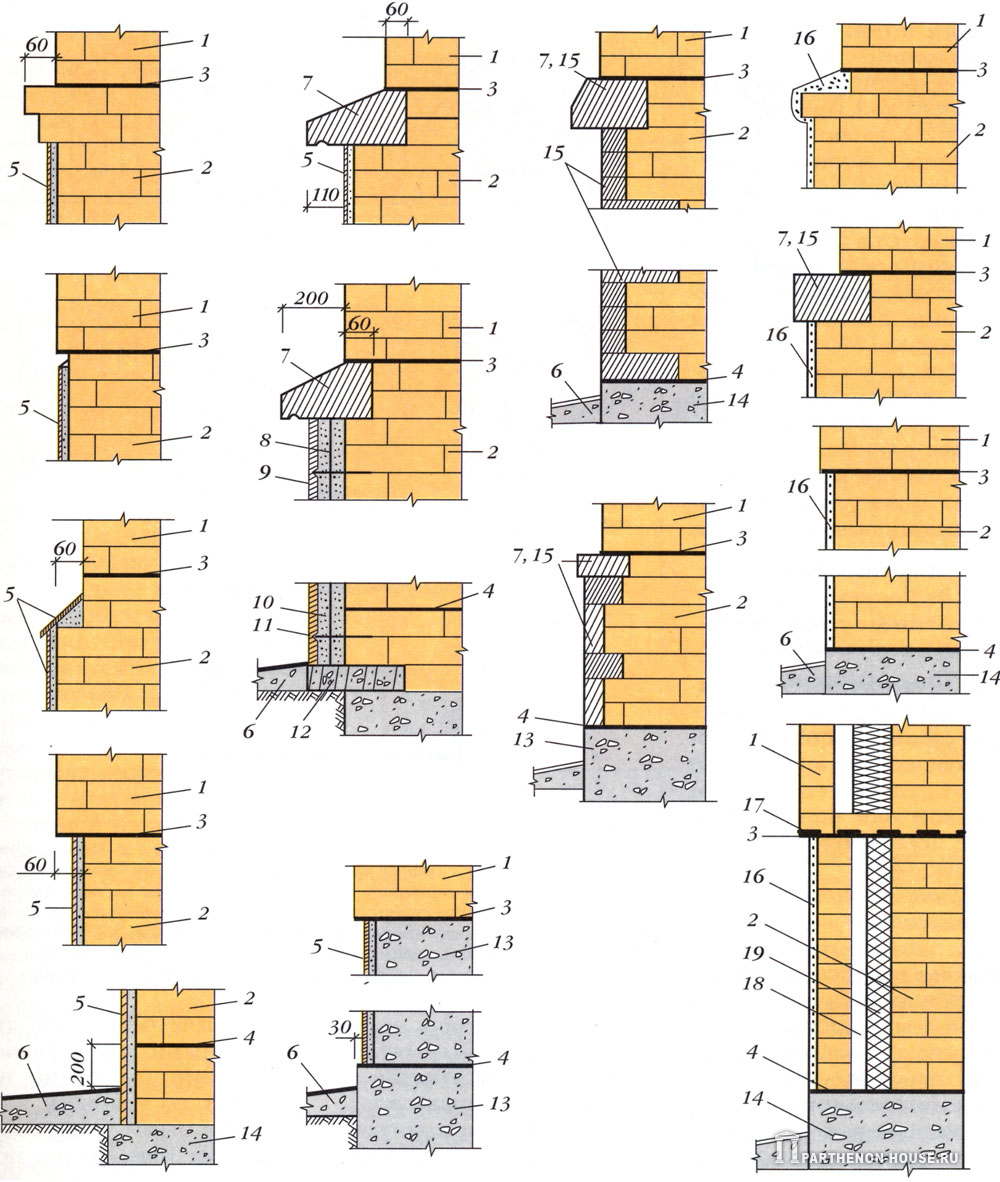

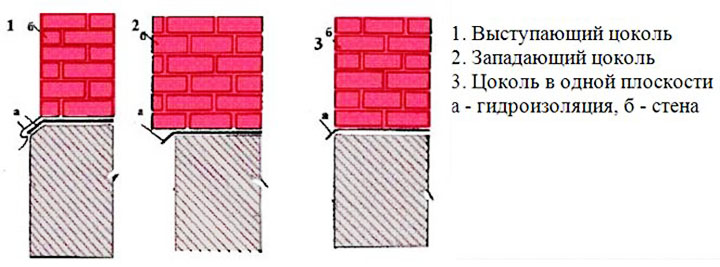

The base / plinth design is chosen between the following options:

- A strong and reliable base made of concrete blocks will require the use of lifting mechanisms, a large amount of concrete mortar for strapping, careful selection of proportions, when using blocks of different sizes.

- An even greater consumption of concrete and related materials (wood for formwork, reinforcement) will be required by the installation of a base made of monolithic concrete.

The method using natural stone will exclude the stage of ennobling the basement, the stone is used, in addition to strength and other characteristics, with its beauty. But for this work, you will need a certain skill, or the involvement of specialists.

The cheapest, and at the same time not inferior in reliability, option is a brick plinth on a strip foundation. First of all, laying bricks with your own hands will significantly reduce the final figure in the estimate for construction. Such material for construction is not very expensive, it is possible brick masonry used, of course, provided it is in good condition.

The answer to the question of which brick is suitable for the basement follows from the requirements for the basement. It should be a full-bodied product M-100. Otherwise, the structure will not withstand horizontal and vertical loads; condensate in the voids will gradually destroy the structure.

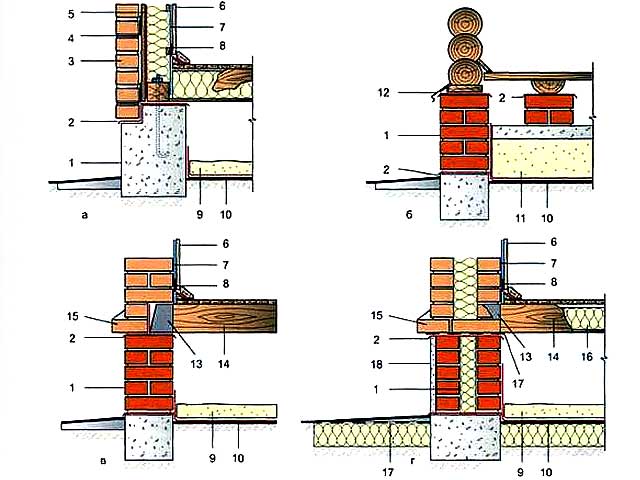

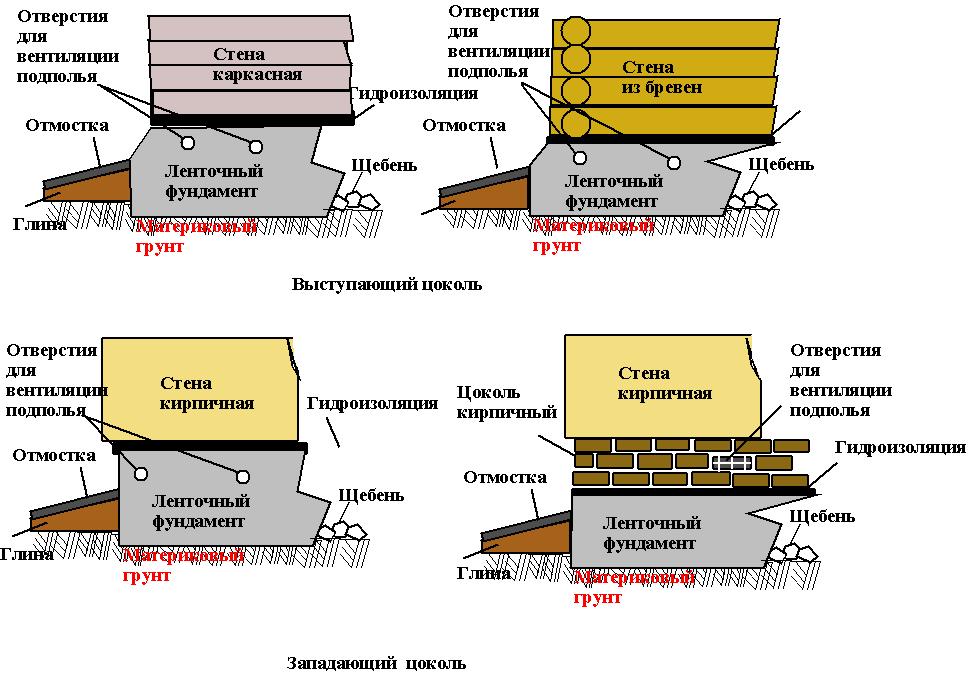

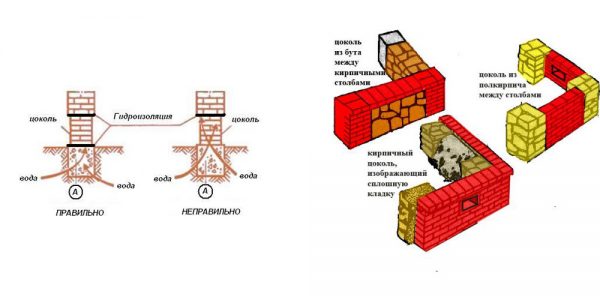

There are three types of plinths, the classification depends on its geometric fit into the outer walls of the house. The first type extends beyond the walls. and visually, the structure seems more stable, but in this case it is necessary to provide cornices to protect the place where the house joins with the basement from precipitation.

Stability visually and practically will not suffer when using the second option, in which the geometric dimensions of the perimeter and basement and the building are equal. The last option, in which the basement is smaller than the contour of the house itself. the best, according to many builders. Water does not physically fall on the upper part of the base, it is reliably waterproofed from below, the blind area does not allow water to get through from the outside.

How to determine the amount of facing bricks in 1 m2 of masonry

The construction of any building begins with an estimate of the building materials that will be required for the implementation of a specific project.

The consumption of facing bricks required to form the walls depends on the linear dimensions of the brick blocks, the thickness of the seam of the cement mixture, as well as the height of the walls and the method of briquetting.

It is unlikely that it will be possible to determine the number of blocks with an accuracy of a brick, but it is quite possible to calculate the approximate number of pieces in 1m2.

Why is the consumption of blocks in m2 calculated? The answer is very simple and lies literally on the surface: this parameter allows you to understand how many briquettes are required for the construction of any building, even the most complex architecture.

Features of counting the number of bricks

To correctly calculate the consumption of bricks, you need to follow these steps:

- Decide on the thickness of the masonry.The walls are formed in half a brick, which is 120 mm, a whole brick, the length of which is 250 mm, one and a half briquettes - 380 mm, two blocks - 510 mm, as well as 640 mm, which is equivalent to two and a half clinkers. The warmer the climate at the location of the building being erected, the thinner the walls can be made. For middle latitudes, a masonry of 2.5 bricks is considered ideal. Also, the thickness of the walls is directly influenced by the number of floors of the building being erected, the type of arches used, as well as the type and depth of the foundation. The higher the structure, the greater the load the walls will have to withstand, therefore, for multi-storey buildings, masonry is made of 2 or more bricks.

- Select blocks for masonry. To understand how many facing bricks are needed to form 1m2 of a wall, you need to know exactly the dimensions of the purchased briquettes. Bricks are produced in single size (250 × 120 × 65 mm), one and a half (250 × 120 × 88 mm) and double (250 × 120 × 138 mm) formats.

- Increase the dimensions of the brick spoon and poke by the thickness of the seam. As a rule, on horizontal surfaces, the cement mixture is laid out with an interlayer of 10 mm, and on vertical surfaces - 12 mm. Since two building blocks are in contact with the seam, to take into account the thickness of the seam when calculating the number of bricks in 1m2 of the wall, half of the seam value is taken, that is, the length of the spoon is increased by 6 mm, and the height of the poke is increased by 5 mm. Based on these data, the area of the spoon is calculated.

- Then 1m2 is divided by the area of the recalculated brick spoon. The resulting value is the approximate number of facing bricks that will be consumed in the formation of each m2 of a wall half a block thick.

- We divide the thickness of the walls by the recalculated width of the brick poke and get the coefficient by which it is necessary to increase the previously obtained number of bricks.

There are several techniques for laying building blocks, but all of them are used to give the facade of a building a certain aesthetic appearance and practically do not affect the amount of bricks per m2 of the wall.

The exception is patterns that are specially formed from bricks when erecting the outer walls of buildings.

In any case, it is the dimensions of the briquettes used that are the key parameter that determines the consumption of materials during construction work.

Important nuances

After calculating how many building blocks are needed for laying each m2 of the wall, the resulting value is increased by 5-7%. This gap is necessary to cover scrap and breakage, which is inevitable when transporting building materials.

How many blocks do you need to build a specific building? To determine the final consumption of briquettes, first calculate the total area of all walls of the object being built. To do this, the height of the walls is multiplied by their length and the dimensions of the windows and entrance doors provided for by the construction project are subtracted.

The total area value is multiplied by the number of bricks in each m2 of masonry. The target number is the number of clinkers required for the construction of this facility.

Correctly carried out calculations will allow not only to determine how much brick will be needed for the construction of a building, but also to significantly reduce the cost of purchasing building materials.

Recommendations for choosing a brick for a basement

All recommendations do not apply to residential buildings. They are being built strictly according to plan. Each project specifies the quality requirements for the building material. Recommendations apply not to residential buildings, but to outbuildings. What are the main characteristics taken into account when choosing ceramite?

- strength;

- durability;

- appearance.

The appearance should be in harmony with the overall structure. Depending on the material from which it will be erected, the width of the base is also taken into account. Usually it is laid in 1.5-2 bricks.

For good strength, durability and moisture resistance of the base, install additional waterproofing.

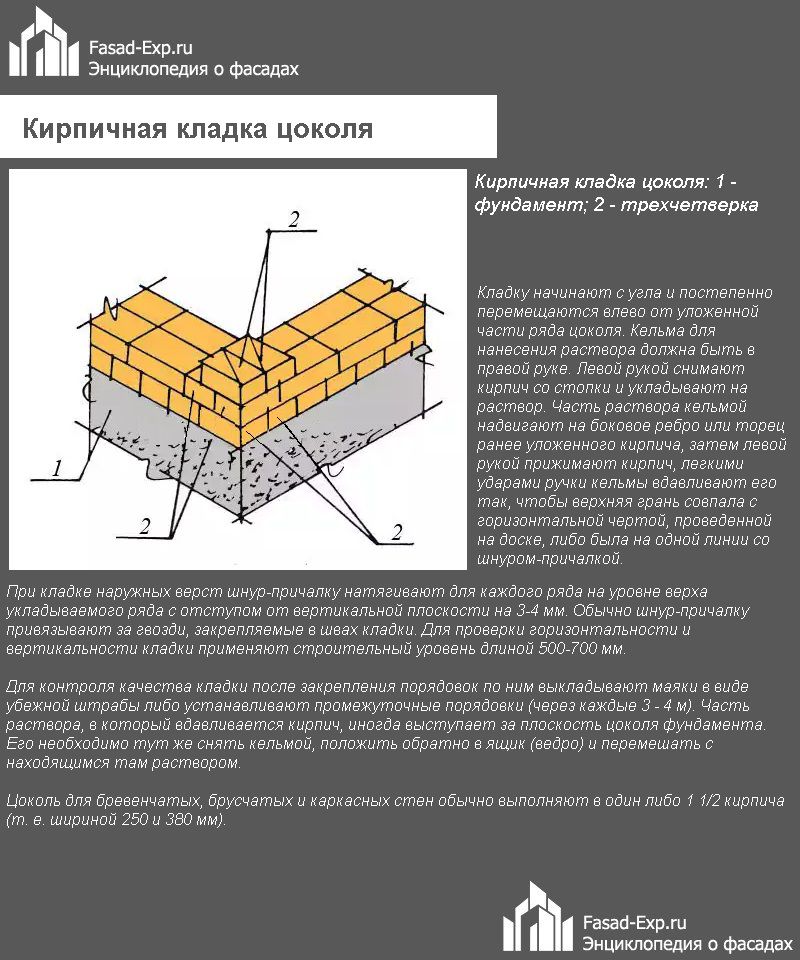

Features of brickwork basement

It is important to be careful about the phased execution of work, to do everything in the prescribed manner. This will make it possible to get a high-quality structure.

Expose the corners of the structure: bricks are placed along the width of the planned structure

It is important to apply a level for the accuracy of the position of the corners. Once the position is established using the level, the bricks do not move.

Then the sides and diagonals of the surface are measured: they must be equal

This makes it possible to establish the correct placement of bricks. The maximum error can be 2 cm. Correct setting of the corners affects the strength of the house.

There are a number of nuances when laying bricks.

Brickwork during the construction of different stages of the building has its own subtleties:

- The brick for the basement is placed on a mortar of cement and sand: in it, one part of cement corresponds to three parts of sand.

- The thickness of the basement structure is determined by the material that will be used for insulation. When using foam, the thickness should not be more than 38 cm.

- Usually the laying is done in 2 bricks, this technique is optimal. Do not forget about the thickness of the planned walls. It is not advised to lay out the basement thicker than the walls. Then, at the junction of the basement and the walls, water can accumulate, which will entail accelerated destruction of the room.

- When laying out, you can use different bricks. The choice depends on the installation. Both solid bricks and halves can be used. When laying, it is recommended not to forget about the ventilation holes, they should be at a distance of 2 meters from each other.

- It is recommended to reinforce the masonry every 2-4 rows; for this purpose, a mesh mesh of 5 * 5 cm is used.

- In relation to the walls, the plinth can be flush or sink. It is better to prefer the second option, this will not allow moisture to get from the walls.

Masonry base / plinth mortar

The process of preparing a mortar for laying a basement must be approached with all seriousness, since it is required to create a plastic mass. In this case, it is worth taking into account the parameters of the selected building mixture, which differs in the following content of cement and sand:

- 3/1 for М75;

- 4/1 for М50;

- 5/1 for M25.

It is recommended that you choose the first two options. To be sure of the quality of the mortar, you can first assess the quality of the dry mix - for this you need the following:

- Firmly squeeze a handful of dry mixture in your hand.

- Having loosened the grip, we evaluate the result.

- A high-quality solution is poured onto the ground - this means that there is no or practically no clay in the composition. If the mass has formed a lump, which contains more than two-thirds of the original mixture, then too much clay in the sand will not allow a good solution to be obtained. Clay is undesirable, since it causes the solution to crack in winter. If the initial mixture is of low quality, then when preparing the solution, the mass turns out to be inelastic. You can correct the situation by adding a little detergent to it - a couple of caps are enough to get a mixture with the required parameters.

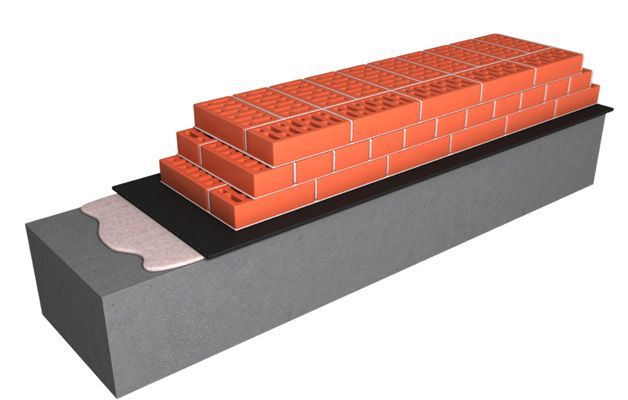

The brick basement is laid on a strip reinforced concrete foundation

The choice of brick for the basement

The use of ceramite with dry technology for the plinth is unacceptable. They not only have low strength, but also low moisture resistance. Laying a base of this type of brick will lead to destruction. The choice of bricks for the base must be approached responsibly.

There are many types of bricks

There are basic types of ceramite that will do this job well. What kind of brick is needed for the basement, we will analyze below.

Red brick

This choice will be the most deliberate, optimal. Due to its characteristics, this ceramite is best suited for the role of laying the load-bearing walls of an underground floor. It will serve you for a long time, regardless of the amount of moisture and other vagaries of the environment.

But the absorption of water into ceramite still cannot be avoided.When buying, be sure to check the brand of the material. The M-150 brand will not survive more than 60 times of freezing. Look for more frost-resistant options. Better buy the M-250 brand.

Why is moisture resistance and strength preferred when choosing between red and silicate ceramite? Silicate is fragile and absorbs moisture. Water gets into the cracks, pores of the brick. When freezing, it increases in volume, begins to destroy ceramite from the inside

For this reason, it is important to choose the right material.

Even when building the main house with silicate, it is better to cover the upper part of the foundation with red. After all, to hold the entire structure to the lower structure, and this requires durable material.

Also, red ceramite is chosen for financial reasons. It is relatively inexpensive and it is not a problem to find it in every city.

Red ceramite for the plinth is the right choice.

Clinker brick

This is the strongest brick in existence at the moment. It has great compressive strength, long life and looks aesthetically pleasing. No additional cladding is required. Moisture resistant.

It meets all the characteristics, but it is not used so often, as it is too expensive. They are mainly used for cladding stoves and fireplaces.

Silicate brick

Silicate ceramite is not the best choice. The manufacturing technology of this product will not allow the material to be moisture resistant. If moisture acts on the silicate for a long time, it will swell and lose all performance characteristics. After a while, it will collapse. You can use such a brick if the climate is arid, there is not a lot of rainfall.

But even when laying with such material, additional waterproofing will have to be done. The silicate is quite strong, so it will last long enough under these conditions. The construction will be reliable. Laying with silicate bricks will be much cheaper than any other. In addition to your finances, you will save time and effort.

Acid resistant brick

A very complex composition. For its manufacture, specialized clays with the addition of dunite are used. It is a mineral rock.

Poured out at a temperature of 1300 ° C. The result is a material that can withstand harmful substances. Neither acid nor alkali will harm acid-resistant ceramite.

This type of brick is one of the most durable

Very durable. It is not affected in any way by temperature extremes and high humidity. Does not conduct sound and heat. Does not absorb moisture. The size is equal to a regular brick.

Keep powder out of the reach of children and pets.

Decoration options

In addition to the operational properties of facing bricks, important characteristics are the color and texture of its surface.

Tools and fixtures

Compact concrete mixer will simplify the process of working with concrete

Compact concrete mixer will simplify the process of working with concrete

In order for the cladding of the basement of a house or fence to be not only interesting in design, but also durable, it is necessary to observe the technology of its implementation.

To finish the surface of the supporting structure from the outside, the following is necessary:

- container for solution;

- concrete mixer;

- trowel (trowels);

- level, plumb line, tape measure and cord;

- hammer;

- device for joining seams.

In addition, fine clay sand, water, cement and pigment will be required to tint the solution to the color of the building's foundation cladding. The number of bricks is calculated in accordance with the overall dimensions of the basement and the perimeter of the house.

Cladding colors

Hyper-pressed bricks can be of different colors

Hyper-pressed bricks can be of different colors

Hyper-pressed bricks are colored by adding pigment to the molding mass. Due to the absence of firing, all bricks have the same color throughout the volume, and different batches of material have the same tone. However, the addition of cement mutes the brightness of the colors, so this finish of the basement of the house has a grayish "concrete" shade. Her palette is presented in a variety of colors, including: black, white, terracotta, straw and chocolate.The facing of the foundation of a peach, pistachio, bright green or sky blue shade looks interesting.

The colors of clinker and ceramic bricks are presented in all sorts of variations of red, brown, beige and other tones. The intensity of the color can be changed using various impurities and additives. Affects the color of bricks and exposure to high temperatures during firing, so different batches of material do not match in brightness. Such products are used for a foundation or a mixed fence, which allows you to create the effect of a smooth transition of shades on the surface.

A specific color of sand-lime bricks can be obtained by adding pigment to the molding mix, or by coloring the face layer on both sides. The latter finish is less durable and quickly loses its attractiveness and brightness.

We recommend watching a video on how to choose a brick for cladding.

Surface texture

You can also diversify the decorative design of bricks for facing a house with the help of reliefs, which are created by a combination of depressions, depressions and roughness. The resulting pattern can be chaotic or orderly. Other ways to form an interesting brick texture for finishing the basement of a house are:

- gunning or application of mineral chips to the surface, which is performed before clinker firing;

- ceramic coating (engobing), obtained by spraying a liquid mass and subsequent firing;

- glazing with a special composition.

How to lay out with your own hands?

It is quite possible to build a basement structure made of brick with your own hands. The main thing is to use only high-quality building materials and take into account all the features of such work. Let's get acquainted with them.

It is important to take into account that the thickness of the basement structure will always depend on the materials from which the facade is made. If it is made of brick, then the width of the base must be at least 51 cm

If we are talking about a log house, then a 25 cm base will be enough here.

As a rule, masonry is made 1.5 or 2 bricks wide. The parameter for the total height of the base must be at least 30 cm.

To lay the brick correctly and reliably, it is advised to use a cement mortar with a grade of at least M200 with lime and sifted sand. The proportions should be as follows: 1 part of cement to 6.7 sand, as well as 0.7 clay or lime.

It is important to monitor the consistency of the composition. It should be thick like dough.

For 1 part of cement, about 0.8 part of water is usually taken. In order to make the overly liquid composition thicker, it is permissible to mix more lime or clay into it. Also, experts advise mixing a small part of plasticizers (it is allowed to use washing powder in the role of these components).

In order to effectively waterproof the basement structure, you can use sheets of roofing material or roofing felt. They need to overlay the base, covered with bituminous mastic. The waterproofing is laid in 2 layers with the addition in the form of the same mastic.

The brick base must be properly insulated with suitable coatings.

In order for the outside of the basement to be reliably protected from adverse external factors and atmospheric precipitation, it will need to be completed with a high-quality finish. It will not only protect the structure, but also make it more attractive and aesthetic.

Calculation of the material for the base

Before you start laying the basement, you need to calculate the required amount of bricks. First, it will allow you to purchase material from one batch. Secondly, you can save on this without buying an extra amount of products.

Only an experienced specialist can calculate the exact amount of bricks, taking into account the thickness of the mortar and the percentage of defective material. However, there are several methods that allow you to independently carry out the calculation.

Method 1

To do this, you need to know the volume of one brick, the dimensions of the structure and the height of the basement.

Brick calculation

- First, we calculate the volume of the brick. A standard product has the following dimensions 25 * 12 * 6.5 cm. Therefore, its volume will be 0.25 * 0.12 * 0.065 = 0.00195 m3.

- Now we determine the volume of the base. For example, a building has a size of 9 * 10 m, the optimal height of the basement is 1 m, its minimum thickness should not be less than half the length of the brick. This means that the volume of the base will be (9 + 10) * 2 * 1 * 0.12 = 4.56 m3.

- Further, the volume of the basement is divided by the volume of one brick: 4.56 / 0.00195 = 2338.46. That is, for the construction of a basement for a house of 9 * 10 m, 2339 bricks will be required.

Method 2

In this case, the length of the brick, the length and height of the base are taken into account.

- We calculate the number of bricks required for one row of masonry. For this, the length of the structure is divided by the length of the brick: (9 + 10) * 2 * 0.25 = 152.

- To determine the number of rows, you need to divide the height of the basement by the height of one brick: 1 / 0.065 = 15.38.

- Further, the number of bricks in one row for the resulting number of rows of masonry: 152 * 15.38 = 2338.

Comparing the results, we get approximately the same amount in both cases.