Label elements and their designation

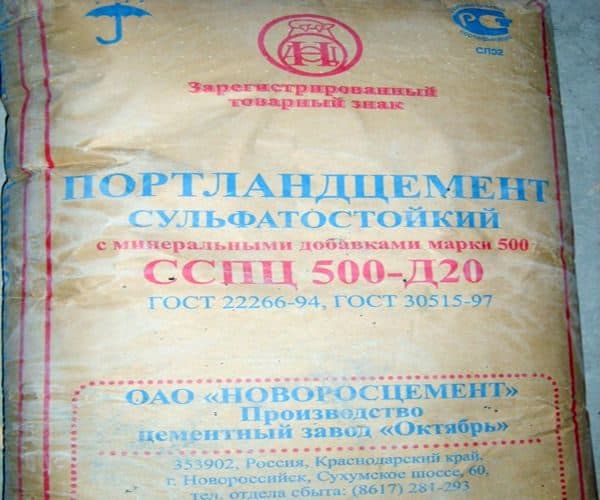

According to the first GOST (10178-85), the following information is located on the bag or other container in which the material is sold:

- cement grade - a number from 300 to 600;

- PC, SHPC - Portland cement or slag Portland cement;

- D0, D5 or D20 - the number of additives: D0 - no additives, D5 - no more than 5%, D20 - no more than 20%. Additives give special properties - resistance to sea water, corrosion resistance, accelerated hardening, etc.

- B - quickly hardening;

- PL - plasticized with increased frost resistance;

- H - standardized composition.

In the second GOST (31108-2003), the marking is as follows:

- CEM I, - without mineral additives;

- CEM II, - with mineral additives;

- CEM III, IV, V are not Portland cements (therefore, they are not considered in this article).

There is no concept of a brand, but there is a concept of a strength class. Designate it with numbers - 22.5; 32.5; 42.5 or 52.5 in megapascals (MPa). Subclasses: H - hardens at normal speed, B - hardens rapidly. Additives are indicated in the name of the cement.

There are several grades of Portland cement: 300, 400, 500, 550 or 600. The grade shows how much force the sample will withstand without breaking. Measured in kgf / cm 2.

Cements are divided into PC and SHPC - Portland cement and, accordingly, Portland slag cement. The difference is that slag pounded into dust is added to Portland slag cement during manufacture. Slag is not added to Portland cement.

Example of designation: Portland cement CEM I 42.5B GOST 31108-2003.

Scope of application

М400 is a universal grade cement. It is used in the construction of low-rise buildings, underground and underwater structures, for plastering and decoration of external and internal walls of premises. The main advantages of this mixture are:

- Ease of use and low requirements for breeding and use. It is enough to follow the instructions on the manufacturer's packaging to get a high-quality solution and a good surface of the finished product.

- The relatively low cost of the mixture and its availability. You can buy an M400 bag in any construction department, the difficulty can arise only when choosing one of the many manufacturers.

- Good operational durability of products. Even if small deviations from the technology of preparation or placement of cement were allowed, cracks on the surface are unlikely to occur.

The temperature range in which concrete products can be operated without damage is from -60 to + 300C, which provides a wide range of applications for this brand of cement.

Minimal shrinkage during hardening

This very important property will allow you not to make a mistake in the dimensions when pouring the foundation or making any other product. Also, a small amount of shrinkage ensures that there are no cracks on the surface of the product.

Cement of this brand hardens rather quickly.

The hardening time is sufficient to complete all work with the mixture (mobility is lost after about 6 hours), but the product acquires its final strength in a couple of weeks. With an increase in temperature or humidity, the hardening reaction of concrete from M400 cement is accelerated.

The possibility of using different additives gives the mixture plasticity, corrosion resistance, the ability to harden more quickly and other useful properties.

Usage tips:

To prepare a concrete solution, it is necessary to dilute the cement with water in a 2: 1 ratio, that is, the mass of water is approximately half of the weight of the cement. Water should not have impurities, dirt, branches and large inclusions - this will reduce the strength of the finished concrete

And it is very important not to add water to the ready-made mixture.

The remaining components of the solution - crushed stone, sand and filler - must also be free from dirt and uniform in size. It is better to use crushed stone of two fractions - large and small, this will give the concrete additional strength.

No need to buy cement long before work is done

In the warehouse of the manufacturer or supplier, as a rule, proper storage conditions for the mixture are provided - temperature and humidity are controlled. Storage at home or in a garage does not guarantee the same conditions. In addition, the shelf life of M400 cement is short - as a rule, from 6 to 12 months. High humidity can negatively affect the strength of the cement and the quality of its mixing into concrete.

There are approximate values of cement consumption: for example, to obtain 1 m3 of concrete, it is necessary to take from 180 to 260 kg of M400 material, depending on the required strength of the final solution

The recommendations on the packaging will give you more accurate values.

When deciding on the cement consumption, it is important to take material 10-15% more of the estimated amount. In this case, it is advisable to buy material from one batch and from one supplier and immediately use it for its intended purpose.

You can check with the seller about the possibility of returning surplus cement.

The amount of concrete that will be consumed in the next few hours, before the mixture hardens, should be mixed. Re-diluting the frozen mixture with water is useless, since chemical hardening reactions have already taken place in the mixture.

How to choose the right cement, see the video below.

How much concrete is the weight of the cement bag calculated for?

Despite the fact that the volume in the bag of cement varies depending on the grade of Portland cement, storage conditions, date of manufacture and other parameters, the weight of the bag of cement remains constant. When preparing a cement mortar, the proportions of the ingredients must be known, as well as when mixing concrete.

The volume of concrete is determined according to the standard recipe

The volume of concrete is determined according to the standard recipe

When performing calculations, a number of nuances should be taken into account:

- marking of the prepared concrete solution;

- the brand of used Portland cement powder;

- the amount of cement packed in a container.

For example, for the preparation of M200 concrete from one bag of M400 cement, the mass ratio of cement, sand and crushed stone is 1: 2.8: 4.8. The given proportion makes it possible to determine that at least 270 liters of concrete will be obtained from a bag of cement. Tables with proportions for different grades of material, which facilitate the calculation, are easy to find on specialized sites. The accuracy of the results is influenced by the volume of added water and the density of the feedstock. The calculator will allow you to calculate cement per cube of concrete with higher accuracy.

How much cement is in the bag and how much concrete can be made from it

The volume of cement in a bag is not specified by GOST. However, the normative document clearly regulates the mass of the material. Cement is packed in standard bags of 25, 40 and 50 kg each.

Cement is packed in standard bags

Cement is packed in standard bags

If it is necessary to calculate how many cubes of cement are in a 50 kg bag or a container of another volume, you should proceed according to the given algorithm:

- Read the weight and grade of the material on the package, for example, cement 50 kg, grade M400.

- Take from reference sources the specific gravity for a given cement grade, for example, 1500 kg / m3.

- Divide the weight of the material in the packaging by the density.

To do this, you must proceed in the following order:

- Find in the reference tables the weight ratios of cement, sand and crushed stone for the preparation of concrete of a certain brand.

- Calculate the volume of each component by dividing the weight of the material according to the recipe by the density.

- Sum up the volumes of the ingredients, adding the volume of added water to the calculation result.

The volume of the concrete mix varies for different types of concrete. Consider concrete based on cement grade M400. Its volume increases from 0.092 m3 for concrete grade M400 to 0.231 m3 for mortar grade M100.

Table of the ratio of cement, sand and crushed stone

What determines the bulk density of cement?

The specific gravity of cement as the main binder in the composition of the solution depends on its brand, the degree of grinding (grain size) and drying technology. So, freshly ground material will have a lower density (within 1100 kg / m3), since during grinding its particles are magnetized and, according to the law of electrostatics, are repelled from each other.

As a result of long-term storage or transportation, the opposite process occurs - the grains lose their charge and are compacted to about 1500 kg / m3. That is why experienced builders recommend buying cement that was made at least 1 month ago, that is, stale. But if the mixture is more than 6 months old, it is most likely that it has already lost most of its quality characteristics.

According to the technical norms and rules used by the majority of enterprises for the production of concrete and reinforced concrete structures, the weight of a cube of cement is taken as 1300 kg / m3.

Even in stale cement in bags, most of the volume is filled with air microvoids between its grains. But to obtain a high-quality construction, the structure of the mixture should not have voids. In order to ensure the required quality indicators, different sizes of aggregates (for example, sand) are selected. When cooking, large fractions are poured first, then medium fractions, and small ones are added at the very end of mixing.

How much cement is needed to prepare 1 m3 of concrete?

The amount of cement does not increase the volume of the finished mortar, as some builders believe. Excessively fine grinding contributes to its uniform distribution in the voids between the aggregate particles during mixing. You can add 300 and 400 kg of cement to a cube, while the volume of the finished product remains the same.

Standard weight of cement for obtaining 1 m3 of concrete of various grades:

- to obtain M500 - 450 kg of a binder;

- for М400 - 400 kg;

- for М300 - 350 kg;

- for М200 - 240 kg.

When buying cement for construction work, you should definitely pay attention not only to the brand of this material, but also to its volumetric weight. As we know, the brand of cement is responsible for its strength.

Cement grade 400 is capable of withstanding a load of 400 kg per cubic meter of area. This material is widely used in various types of repair and. It is used in everyday life, for minor repairs, and in large industrial buildings. But, when choosing this cement, you need to fix its volumetric weight (specific gravity). This is the ratio of the weight of the cement to the volume it occupies (bulk density). The bulk density of M400 cement must be taken into account when drawing up the optimal proportions for the mortar.

Cement that has just been ground has the lowest density. This cement is called Portland cement. This is due to the fact that during grinding, the particles of the mixture are magnetized, and during friction they are repelled from each other. During some subsequent processes, such as: transportation of material, pouring it into a container, long-term storage, this property gradually disappears and the mixture is compacted. Thanks to this, its volumetric weight increases.

- Volume weight of cement M400 (freshly ground) - 1100kg \ cubic meter

- Volume weight of cement M400 (after the expiration of time) - 1500kg \ cubic meter

Consider the shelf life of M400 cement.

The shelf life of cement proportionally affects its activity, that is, the bonding properties and brand. Also, activity slows down the process of hydration of building materials.

If you do not want to use it immediately after purchasing it, then you should think about the storage conditions for this material. To preserve all the qualities and technical characteristics of cement, you need to store it in special containers. It is imperative to put the packages with the solution on a wooden surface. The distance from the bag to the ground should be at least 15cm.It is advisable to cover the floor in the room where the cement is stored with roofing material. Storing cement in bulk means storing it in a barrel. The top of the container must be wrapped in polyethylene foil.

If the storage conditions do not meet the proper standards and requirements, then the cement quickly deteriorates. This material can be stored at home. It is necessary to ensure the tightness of the bags with cement, which it is desirable to wrap in polyethylene. The temperature regime in the room should be without sudden changes and be more than zero degrees. Manufacturers write on the bags the permissible air humidity during storage of the material. If you follow all the recommendations, you can increase the shelf life of the cement to one year.

Production

CPB is a binder based on crushed clinker with a standardized composition. There is a standard GOST 10178-85, according to which the content of magnesium oxide and the proportions of other ingredients are selected.

Organic minerals are used as feedstock, such as:

- Aliit.

- Alumina.

- Magnesite.

- Gypsum.

With the help of firing technology, clinker is created from this raw material. The base substance is combined with mineral additives that affect the final properties of the working mixture and stone.

Additives can also be added to the composition that increase plasticity, resistance to frost and aggressive environments. Their total concentration should not exceed 5% by weight.

For industrial purposes, plasticized cement subspecies are created, which are characterized by increased fluidity and guarantee improved compaction when arranging concrete structures. The mixture contains clinker and gypsum, as well as an active additive. It can be a concentrate of sulfite and alcohol, containing 0.2% of the total weight of cement m400.

Price

What is the price? Despite its positive technical characteristics, the M500 can be bought at a hardware store at an affordable price. Depending on the region, the cost of M500 is 3700-4100 rubles / ton. Approximately 80 rubles per bag of 50 kg.

The M500 brand is a frost-resistant, water-resistant and durable product that can be used in both private and industrial construction. Moreover, the construction process can be carried out even in severe frosts. Thanks to this, you can plan all your repair and construction procedures at any time of the year and not worry that this will somehow affect the quality.

Cement M500 D0 and D20, or as it is also called "five hundredth" - in the modern building materials market, the best offer in its class. It is used in masonry and plastering works, so it has a fairly wide range of applications.

This is the creation of concrete structures, beams, floor slabs, pouring foundations, housing, industrial and agricultural construction.

- "D - 0" indicates no additives. Therefore, it quickly sets, hardens and dries. Differs in high strength, water and frost resistance, durability, as it consists only of cement clinker. Cement clinker is created by firing in special furnaces at a temperature of 1450 degrees, the composition of the mixture is: limestone, clay of special quality. After that, the clinker is crushed, sieved, the addition of crushed gypsum is carried out in a percentage ratio - no more than one percent of the mass of the raw material. Cement M500 D0, due to its high-quality, long-term strength, is used for the construction of bridge structures, airfield pavements, reinforced concrete pipes, railway sleepers, supports and racks of power lines. Very effective when performing recovery, emergency work Cement M500 D20

in which the number 500 means that it will withstand a load of 500 kg per square centimeter. Cement M500 D20 is a powdery homogeneous mass - clinker, which is produced in several stages, in factories with modern high-tech equipment. Modification of cement with the addition of certain properties is carried out by adding special admixtures. The D20 marking indicates that the cement consists of 80 percent clinker and 20 percent additives. Its price, respectively, is less than the pure "five hundredth" cement M500 D0. And hence such characteristics as strength, speed of hardening, water resistance, frost resistance are obtained lower, although compared to the "four hundredth", there is a positive difference! Cement M500 D0 D20 is packaged in multilayer bags that prevent its contact with the environment. Fulfilling the storage rules, the buyer is provided with high quality goods guaranteed by the manufacturer for six months

Therefore, it is very important that the purchased bags must be protected from moisture, vapors and other liquids until they are opened and the solution is prepared. "Large-caliber" packaging in bags up to one ton, convenient for large construction companies, for which small, fifty-kilogram bags are not practical to use

Thank you for your help in preparing materials for Elitastar.by.

M400 specifications

Few owners of future houses realize that the durability of the structure will depend on the quality and density of the cement. When choosing a material, builders take good adhesion as a basis, and also study and analyze in detail the components that make up the composition, physical features play an important role here.

Today one of the most purchased cements is the M400 grade, which belongs to the type of Portland cement. It is often used in various construction areas, the reason is hidden in high quality and affordable pricing.

As for production, cement is obtained through grinding the intermediate clinker product with the further addition of minerals from the class of sulfates CaSO4 • 2H2O and other chemical elements.

The decoding of the abbreviation indicates that after complete solidification, the material will withstand the load without any problems, which will fluctuate around four hundred kilograms.

M400

The content of CaSO4 • 2H2O in the composition of cement according to the GOST under consideration cannot be more than 5%, active mineral components, as a rule, constitute from 0 to 20% of the total components. It was the additives that played one of the main roles in the water resistance and corrosion resistance of the material.

This can explain the possibility of using cement 400 when creating structures from reinforced concrete, they will also be resistant to moisture changes.

The material in question is considered durable. This characteristic is determined by manufacturers through a variety of freezes and thaws during the testing phase. For cement 400, this technical characteristic is equal to one hundred cycles.

It is often used during the construction of facilities that will be operated in the Far North. Few people know that in these parts the temperature readings often reach -50. The high water resistance of cement 400 was achieved thanks to special additives.

The production of the cement in question is carried out in accordance with technical standards. Finished products are subject to mandatory quality control.

Today the companies produce three types of brands:

- BEFORE.

- D2OB

- D2O

Each type is distinguished by its individual properties, composition, as well as the scope of use. If you want to achieve instant hardening of the solution, opt for the first type.

It is also characterized by high water resistance, due to which "DO" is often used for the construction of structures with high environmental humidity (underwater and underground structures). "DO" also showed itself excellently at the stage of collecting concrete and reinforced concrete structures.

The second type of the 400th cement is famous for the active mineral additives that are included in its composition, thanks to which it can be used during the construction of residential areas.Also "D2O" finds its application in industrial and agricultural construction.

This cement is actively used in the CIS countries and in Europe. It hardens significantly longer than the previous version, the average time is from 10 hours.

M400 D20

The last type of M400 can be attributed to a fast-hardening material. It is actively used during the construction of industrial facilities. The main feature of this brand is its high strength, which can be noticed within a few minutes after complete hardening.

TOP cement М400

Such cement is perfect for floors, screeds, masonry walls inside a house or apartment. The brand is characterized by an optimal strength value, therefore it is suitable for medium loads. It is also a good choice for waterproofing basements and damp areas.

Holzim M400

Manufactured by a Russian company that is well-known abroad and has many years of experience. Products are characterized by white, which will be up to 74%. The composition uses a special clinker, in which the minimum amount of iron, which makes the cement unique in its category. Diatomite and gypsum are also added to the composition to increase the degree of light reflection. Positive feedback on the product from ordinary consumers and experts was obtained due to the quality of the mixture and the strength of the finished solution. The only drawback can be considered the difficulty of buying at construction retail outlets.

Pros:

- Excellent quality.

- White color.

- Affordable cost.

- Versatility and the ability to use for construction or renovation.

Among the disadvantages are the difficulty of purchasing in stores.

Portland M400 Hercules

This product is considered the best for floor screed, since it is characterized by high strength and can withstand any household loads. In addition, the liquid solution dries quickly and makes it possible to walk on the screed one day after pouring. This helps speed up repairs and other work without harming the floor itself. The sale is carried out in small 5 kg bags with handles that are easy to carry. Another feature is a long service life, the exclusion of cracks.

Pros:

- Environmental friendliness, which can be seen on the packaging and the "ECO" badge.

- Can be used in a dry building or basements, cellars and buildings with high humidity.

- In the composition up to 5% gypsum.

- Includes active mineral additives to increase strength.

- Does not take over the effect of corrosion from nearby steel.

- Impact resistance.

- Long service life.

- It is not affected by frost and can withstand up to -40 degrees without changing its characteristics and properties.

- Grey colour.

Minuses:

- Small packaging, only 5 kg.

- For a small pack, a high price is obtained in the range of 50 rubles and more.

- Shelf life is up to 2 months, therefore, after purchase, repairs must be carried out immediately.

- Cannot be used for outdoor use.

Eurocement М400 D20 CEM II А-Ш 32.5

A quality type of cement from a Russian manufacturer, which is liked by specialists and ordinary people. The mixture meets all international requirements and is used in many countries. This option is suitable for domestic and industrial applications. Slabs, concrete products, screed, foundation and walls are made from the solution. It is packed in bags and has a shelf life of six months.

Pros:

- Affordable cost.

- Resistance to frost, temperature changes and moisture.

- Excellent quality of dry mix and ready-mixed mortar.

- Wide range of applications.

There were no drawbacks to the product from this manufacturer.

Cement CEM II 32.5 (M400 D20) gray De Luxe

Ideal for blind area and outdoor work, as the mixture is made for outdoor use. When solidified, the formation of cracks is excluded, they do not appear even after several years, which eliminates the need for constant sealing. The ready-made mortar has good strength, which helps to securely fix any materials and elements.The made blind area after drying will withstand up to 330 kg per 1 sq. Cm. packed in bags of 50 kg, so it is profitable to buy for large construction.

Pros:

- Affordable price, only about 260 rubles for 50 kg of cement.

- Resistant to moisture and low temperatures.

- Long period of operation of the frozen solution.

- Includes additives that increase strength, hardening time.

- The optimal temperature range for work, which is + 5-30 degrees.

- One month after pouring, the maximum hardness is reached and the ability to withstand peak loads.

- Curing takes place within 75 minutes, so it can be used to remove defects that appear when pouring.

- Meets the requirements of GOST.

Minuses:

- On sale there is only a package of 50 kg.

- Shelf life up to six months.

- Cannot be used at temperatures less than +5 degrees.

Varieties

Cement is an astringent that hardens in water as well as in air. Its main component is clinker. Cement is made by grinding the clinker from gypsum and adding mineral additives.

The clinker may include: limestone, nepheline sludge, marl. After the addition of 20% minadditives from the total mass of the prepared liquid, the characteristics of the trend of the starting material change. If the amount of additives is more than 20%, then pozzolanic cement is formed.

The types of cement include:

- marly;

- lime;

- clay cement in addition with bauxite and slag additives. It differs from all others in its waterproofness;

- sulfate-resistant, which hardens very slowly and has increased frost resistance;

Sulfate resistant

- backfill. It is designed for concreting oil wells;

- straining dries quickly;

- hydraulic;

PC M500 - technical characteristics, quality control and price level

Fast-hardening Portland cement, without mineral additives, plasticized can have one of the designations:

- PC 500-D0-B-PL GOST 10178-85. Technical characteristics: compressive strength - 49.0 (50.0) MPa (kg / cm 2), setting after 45 minutes, mineral additives are not allowed.

- CEM I 42.5B GOST 31108-2003. Technical characteristics: strength class - from 42.5 to 62.5 MPa, setting after 60 minutes.

PC m500 has more than 20 parameters, but they are of interest only to specialists.

Quality checking

When purchasing, carefully check the packaging to make the right decision. It should indicate: weight, manufacturer, brand, name of special additives. And buying by weight, you can get a fake. And do not chase after a low price, then you will bite your elbows, making an estimate for new construction works in 2-3 years.

How to identify a fake:

- Analysis in a special laboratory. A rather laborious method, therefore, it is not always suitable for consumers.

- Home method.

Wearing safety goggles and gloves, knead a portion of the proposed cement with mineral water. When mixing, the solution can heat up and boil, protective means for this. From the resulting "dough", quickly mold a thick pancake in the middle. High-quality cement will set in 15-25 minutes and the mixture will heat up. A counterfeit will not grab and heat up in an hour, although it can boil like a kettle on fire.

Poor cement grasps in parts, and then cracks badly. After 2 days of being wet, there should be no cracks in the plastic bag. On bad cement, the disc will crack and crack in the hands.

Sale

PC brand m500 is sold in bags or in bulk - in wagons or cement trucks at wholesale prices. This is due to the magnitude of the purchase.

Considering the retail market, the price, depending on the manufacturer and brand of cement, is from 170 to 250 rubles per bag of 50 kg. In particular, a bag of Eurocement M500 D0 (CEM I 42.5H) costs 200 rubles on the market. But it is worth remembering that having bought 50 kg of such Portland cement, you will bring to your dacha 35-40 kg of cement grade 400, and possibly 300.

Cement M500 is one of the most widely used types of building materials.Ready-made concrete based on it turns out to be durable, it perfectly tolerates both temperature changes and high humidity.

The characteristics of the M500 are more than decent:

1. Compressive strength - 500 kgf / cm2 or 59.9 MPa.

2. Flexural strength - 5.9-6.4 MPa.

3. High water repellency and frost resistance.

4. Drying time M500 is normalized in the range from 45 minutes to 10 hours, although it refers to normally hardening cements.

5. Bulk density, depending on the degree of compaction of the dry mix, can vary within 1100-1600 kg / m3. In the calculations, the average is taken - 1300 kg / m3.

6. Actual density: 3000-3200 kg / m3.

Application of the marking and what it means

Thus, all types of cement differ in quality factor and characteristics. They can be recognized from the labeling of this product, which contains the following information:

- what kind of load it can withstand;

- what is the percentage of the additional product in it.

On packages with cement you can see the inscription: МХХХ / ДХХ / АА. The letter M and the symbols behind it denote the brand and its maximum compressive strength. So, cement M300, when hardened, can withstand a weight of 300 kg per square centimeter.

M-300

Therefore, such numbers on the bag characterize the density and strength of this product. The most popular representatives of the binder are M300, M400 and M500.

M-400

There are also M600 and M700, they are used mainly in the defense industry. When buying cement, you should know its decoding of letters and numbers.

DHX indicates the percentage of additives. So, D10 indicates that this cement also contains 10% of additives - substances that give it certain properties, for example, resistance to low temperatures, fast solidification, insensitivity to the effects of salt water, etc.

AA is an indicator of the property index. If an SS stands in their place, then this suggests that it is able to withstand a destructible action. It is used in the construction of hydraulic structures that will be in corrosive salt water that contains sulfate minerals.

But there are other meanings of various impurities:

- PC - ordinary sulfate-resistant cement;

- ShPC - slag portland cement, the one that is made from inexpensive raw materials;

- BC - white cement, finishing work is performed with it;

- VRC - does not allow moisture to pass through, quickly (from 4 to 10 minutes) sets;

- H - a product that has the correct ratio of components;

- PL - cement, which increases the plasticity and workability of mortar and concrete mixtures, increases their frost resistance;

- GF - hydrophobic, does not react to dampness. By the way, it can be transported over long distances. In addition, it is very flexible and frost-resistant;

- B - means one that quickly hardens (used for urgent matters);

- But this is all classic labeling. And today the manufacturers of the product began to dignify it in a new way.

For more information about GOST 31108-2003, see the video.

Specifications

Portland cement has higher strength characteristics in comparison with other types of cement, which is due to the peculiarities of the composition. These or those additives can enter into reactions, changing the technical properties of the material. The latter are associated with its mechanical resistance and operational capabilities.

It cannot be said that one of the technical characteristics is of higher priority. So, for example, strong, but too slowly hardening Portland cement can increase the construction time. A frost-resistant, but corrosive composition can only be used to solve a narrow range of problems.

Today, manufacturers strive to create universal formulations in which the properties most important for cement are manifested equally strongly.

At the same time, there are specialized formulations with a special purpose. This can be considered pozzolanic Portland cement, which has maximum corrosion resistance and moisture strength, but rather low strength indicators at the initial stages of work (in the first days of setting).

Technical

Among the technical characteristics should be highlighted:

- The specific weight of the product is 1100 kg / m³ for bulk mixtures, 1600 kg / m³ for compacted ones.

- The fineness of grinding is on average 40 microns (determined by the ability of the mixture to pass through a sieve No. 008), which ensures the required strength of the cement and its hardening time, and also affects its performance.

- Water consumption, the optimal liquid content in the composition should not exceed 25-28%, since this indicator affects the strength of the composition (with excess, the concrete dough delaminates, with a shortage, cracks appear on the finished product).

- The setting time after mixing with water does not exceed 40-45 minutes, further hardening depends on the characteristics of the composition and environmental conditions (in winter, the process slows down), but does not exceed 10-12 hours (measured using a Vic's device).

- A change in volume during solidification means a decrease in the cement body in volume by 0.5-1 mm / m in the open air and its swelling to 0.5 mm / m in water. An important point is the uniformity of changes throughout the volume of the solution.

Physical

- Corrosion resistance is achieved due to the introduction of hydroactive materials into the composition, which prevent the chemical activity of salts, as well as the addition of impurities that reduce the porosity of concrete.

- The storage period is no more than 12 months, provided that the original packaging is preserved (3-4-layer, hermetically sealed paper bags), since after 3 months of storage, up to 20% of the activity of the composition is lost, after a year - up to 40%. It is possible to return such cement to its former qualities only by secondary grinding.

- Compressive strength. In accordance with this characteristic, 4 strength classes are distinguished - 22.5; 42.5; 42.5; 52.5. This indicator is directly related to the setting speed of the solution.

Mechanical

The indicators of the mechanical strength of Portland cement are at least 42.5 MPa on the 28th day after pouring. The determination is carried out in laboratory conditions using a sample as an example. In accordance with the results obtained, the cement is marked (for example, M 500). The coefficient in this case indicates what pressure the sample can withstand (measured in kg / cm³).

Strength indicators, in turn, affect the degree of setting of the mortar (determined using a Vicat needle).

Summing up

As you can see, the choice of cement is large. But, unfortunately, this is a perishable product. With a very long storage, it loses its activity. Its main enemies are humidity and carbon dioxide, which are present in the atmosphere. Therefore, it is not recommended to purchase it for future use.

But if, nevertheless, you are forced to do this, then do everything to save it and protect it from all kinds of influences.

If they pack the cement well, then if the product cannot be completely protected from dampness and petrification, some of it can still be preserved. After all, it hardens, as a rule, at the edges, but in the middle of the package it will not immediately be damaged by moisture. It can be applied somewhere.

Of course, the quality of such a product will become lower for what is indicated on the container, but it may well fit in the farm. Approximately, if you need to lay tiles for paths on a mixture of sand and cement, or prepare a cement mortar or concrete for pouring unreasonable structures.

At the same time, in order to replenish the properties of the lost grade, it is possible to increase the percentage of Portland cement in the concrete mixture. Just know that judicious use of any brand of cement can save you money, but it is very important, and save you from working on mistakes. You can also familiarize yourself with the material that will tell you in detail how and from what cement is made and about the finished masonry cement mortar of 100 GOST