General properties and characteristics

The construction business and the introduction of the latest innovations into it are moving forward. Natural wood as a cladding material for country houses and cottages still remains one of the most popular and in demand building materials.

Often, builders, using wood as a cladding material, can resort to facing the outside of the house. This allows you to achieve a beautiful, visible result, create the look of a "Russian hut" and sheathe the house with the highest quality. There are many reasons, referring to which it is safe to say that cladding a house is a desirable and sometimes mandatory building procedure.

In addition, there are a number of factors and prerequisites that should be considered when choosing a cladding material:

- Unfavorable climatic factors can always contribute to breakdowns and some kind of destruction. To avoid this, it is recommended to resort to the cladding of the house, mainly with additional protection against impregnation of sedimentary moisture and condensate.

- Thermal water and vapor permeability must be excluded, thereby providing the house cladding with material that assumes high-quality heat and waterproofing.

- Noise can also often interfere, so choose a material with good sound insulation.

- It happens that over time, the paneling often loses its former attractive appearance due to fading. To prevent an undesirable situation, it is recommended to choose a cladding material that will firmly react to the influence of sunlight and ultraviolet rays.

- The fire can overtake at any moment. To avoid this, there are materials for cladding home, the use of which will secure and protect the home from open fire.

- Specialists often put forward material requirements for ease of installation, as a result of which the use of special equipment is unnecessary.

However, home owners often have to choose between reliability and aesthetics, since it is quite difficult to find a material that meets both characteristics.

Natural wood materials used for the exterior cladding of a wooden house

When choosing the best way to sheathe a wooden house from the outside, natural wood materials inevitably come into view:

- lining;

- block house;

- imitation of a bar;

- planken.

All of them have obvious advantages as a natural material, but they also have the same disadvantages as any wooden product. This leads to the fact that, in addition to the cost of purchasing the material, it is necessary to incur certain costs for finishing with antiseptics and top varnishes and paints.

Lining

The cheapest and most technologically advanced type of cladding made of natural wood is slats with profiled sides forming a groove / ridge connection. During installation, the lining is firmly and tightly connected and forms an almost monolithic surface.

For finishing, exclusively dry lining is used, with a moisture content not higher than 10 - 15%. If you use insufficiently dried lining, then it will inevitably dry out and gaps will appear along the mating lines.

There are several standards for lining, its average dimensions are as follows:

- thickness - 12 - 40 mm;

- width - 76 - 200 mm;

- thorn length - 4 - 5 mm;

- length - 2 - 6 m.

The installation of the lining is carried out in a horizontal position, starting from the bottom, with a spike up. If you set it up with a groove, then the water flowing down the wall will fall into the castle and eventually destroy it and the lining itself.With proper installation and proper care, the lining from the lining will last 10 - 15 years, and if it is saturated with modern antiseptics, then even longer.

The advantage of such cladding is its low cost and ease of installation. Anyone who can hold a hammer in their hands and use a building level can cope with the installation.

Timber imitation

It is the same prefabricated surface as the lining, but slightly different in appearance. It is also installed horizontally, only visible joints are practically invisible. After final installation it looks like a wall made of profiled timber. It is made from spruce, pine, cedar or larch, due to the resinous nature of these species, it is quite durable.

The material is produced in the form of boards 2 - 4 m long, 20 - 35 mm thick and 105 - 175 mm wide. You can buy a solid board, cut from one log, or spliced, glued under pressure from narrower slats. In terms of performance, both types are approximately the same.

Pros and cons are similar to clapboard. The imitation of timber wins only in appearance - the material is more modern and decorative.

Block house

Excellent finishing material, made in the form of boards with a semicircular outer side. When assembled, the material creates the appearance of a log cabin. Very decorative, durable and no more difficult to install than lining. Compared to clapboard and imitation timber, the block house is more durable, keeps heat better and is much more durable.

For the manufacture of lamellas, conifers are used, in most cases pine and spruce. Impregnation with various stains, glazes and glazing materials allows you to give the finish the look of any valuable wood species. When painting with oil or alkyd paints, most of the effect of using a block house disappears (in the case of imitation of a bar, this does not happen).

The block house is also distinguished by good heat engineering properties. Compared to previous materials, it keeps the heat in the house better and passes the cold inside worse. But the cost of sheathing with this material is higher.

Planken

A relatively new material in our latitudes. It is a facade board with beveled or rounded side edges. Made from pine, larch or wood-plastic materials. The width of the board is in the range of 70 - 140 mm with a thickness of 15 - 20 mm, the bevel angle of the edges is 45 - 70. It is mounted on special fasteners in a tenon or overlapping.

It is very convenient for the installation of ventilated facades. As a rule, it is sold in a form treated with fire retardants and antiseptics, therefore it is resistant to biological pests and is safe in a fire sense.

In most cases, high-quality planken is impregnated with environmentally friendly products, but it will not be superfluous to check the certificate when buying. Cheap materials can be handled with toxic chemicals.

Choice of materials

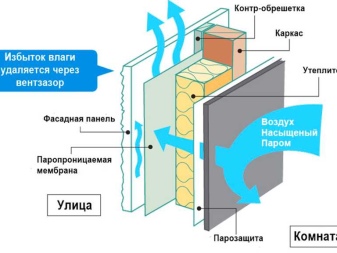

How to decorate the facade of a house from a bar? It is more convenient to sheathe a wooden case with materials that are easy to attach. Therefore, they choose lining, block house, imitation of timber, thermal panels, etc. The main condition for cladding is the presence of ventilation in the walls, which is created due to the gap between the wall and the finishing material. When using facing materials (bricks, tiles, plaster), they try to create ventilation holes so that the wood does not end up in thermal insulation. If the walls don't breathe, mold and mildew will form inside.

The building materials market is always ready to offer a suitable material for outdoor finishing of a wooden house... Options are chosen based on their capabilities and requests. Any building material has advantages and disadvantages:

- Imitation of a bar is an environmentally friendly material that allows you to decorate and insulate a house after standing; has unique characteristics of wood, since it is made from coniferous trees; resistant to external factors due to the resin content. The disadvantages are that there are too dense knots, increased fire hazard;

- Wooden lining is a wood material that preserves all natural properties; has high wear resistance with proper surface treatment; increases the steam exchange functions of the bar. Disadvantages: requires periodic processing and coating;

- Block house is one of the varieties of lining with imitation of a rounded surface of a log; easy to install; often ready-made structures are made from such material. Disadvantages: like other natural materials, it is susceptible to moisture;

- Vinyl siding is a lightweight, practical material that is resistant to weather conditions; available in different colors; budget option compared to natural wood. Disadvantages: does not always withstand loads, gaps may appear between the elements at high and low temperatures;

- Metal siding - imitates wood materials while remaining a fireproof material; the colors and shape are different; minimal surface care; easy to install, does not require a foundation. Disadvantages: does not allow the exit of the vapor formed in the walls;

- Thermal panels - made of high quality concrete with practically no water; the product does not crack, withstands low temperatures and retains heat; have a unique design solution, imitating brick, tile, stone, etc. Disadvantages: can be destroyed by moisture;

- Decorative brick - provides a high level of thermal insulation; durable and reliable material in a variety of shades. Disadvantages: requires a reliable foundation and sufficient roof overhang;

- Facade stone - used more often for laying paths; made of natural stone, therefore it is expensive; fits on walls according to the principle of tiles; withstands any temperature extremes, moisture resistant, but allows the house to "breathe". Disadvantages: expensive, requires professional skill when laying;

- Facing tiles - made from baked clay; for outdoor work, choose a frost-resistant product with a moisture-repellent coating; comes in different configurations and colors. Disadvantages: for laying on a timber requires preliminary leveling of the walls;

- Fiber cement panels - made using the latest technologies from cement, reinforcing fibers, mineral fillers; resistant to stress and temperature extremes; come in different colors or are painted after installation. Disadvantages: in the absence of ventilation, they retain the escaping moisture, exposing the wood to rotting;

- Plaster is a simple and affordable material that allows you to level any walls; gives the house a modern look; you can choose any color that is added to the finished mixture; the most resistant are acrylic paints. Disadvantages: tightly closes the wooden wall, making the room unventilated.

Having decided on the appropriate type of material for cladding a house from a bar outside, they prepare everything necessary for finishing work. If you plan to do everything yourself, make sure to purchase a sufficient amount of materials, as well as have the necessary tools and devices on hand. Decorating the walls in a house from a bar will require work at a height, so you must adhere to safety rules in order to prevent industrial injuries.

Which material is better and cheaper?

The choice of cladding material primarily depends on what the house itself is built from. The range of products for cladding is extremely large, and sometimes it is very difficult to understand it.

It is also worth considering the purpose of the house, if it is a small country house, then it would be advisable to choose such a material so that the finishing would cost you cheap and did not cause extra costs. What will be better and cheaper in your case?

Log houses

It is believed that a log house can be operated without external cladding, however, so that the wood does not rot for longer and the house does not sag, it is better to protect its walls. Especially if a rounded log was used during the construction.

A lining or euro plank is the best fit. These options are environmentally friendly, they are easy to use for cladding, most insulation materials are suitable for lining or Euro plank.

Wireframe

Frame houses require lighter sheathing material. It can also be lining or block house (rounded board), but siding would be the best option. It is a fairly lightweight material that is resistant to temperature extremes, which is also good in decorative terms. It is enough for them to simply decorate the house without special knowledge.

Various wood or plastic panels are also great. It is easy to sheathe them, the total cost of the material is low, since the panels are inexpensive. It is best not to use flammable plastic materials to keep your home safe.

From a bar

Squared houses can be sheathed from the outside with any materials, since the flat surface of the walls allows you to install frames of various types. However, it is still better not to use facing tiles or natural stone - under such a covering, the timber will quickly rot, and mold and dampness can settle in the house.

From SIP panels

Lightweight and durable SIP panels require the same sheathing. It's great if the material that you use for this purpose is resistant to decay. Lining and Euro-board are not very suitable for these purposes, but siding and PVC panels are a good option.

Finishing materials

Wooden lining is a type of material that will be ideal for restoring the natural appearance of a wooden house. The lining can be of different shades. By the way, interior decoration is often carried out with its help. For quick installation, special fasteners - "spikes" are used. The disadvantage of the lining is only that it needs to be additionally processed from harmful insects. In addition, once every few years, such a finish will need to be painted. A block house is one of the types of lining, which serves as an imitation of a rounded log. Sturdy and beautiful, it is installed using a thorn-phase. There is only one drawback - the high cost of the material. Vinyl siding is lightweight, easy to install, inexpensive, and at the same time aesthetic. There are many colors and textures on the building materials market, you can choose the optimal color solution. Easy to operate, does not require special maintenance. The panels can be nailed or fixed with self-tapping screws. The disadvantage of siding is its lack of strength. In addition, this material completely changes the look of a wooden house - from classic to modern. PVC panels are almost similar to vinyl siding in terms of operational and external parameters. Their appearance is interesting (you can imitate stone, marble and other materials). Their minus, again, is insufficient strength.

If you want to preserve the look of wooden housing, choose natural materials for its exterior decoration, but, for example, siding will help to create a completely new solution for the facade decor. Do not spare money to purchase material of decent quality, follow the installation technology - and your house will retain its spectacular, attractive appearance for a long time!

We recommend watching a video about decorating a house with siding:

Interesting ideas

Facade decor is far from the last thing in the conditions of modern construction. It is necessary in order to hide existing defects and imperfections in construction work. The decor is also often used to update the appearance of a country house, restore it and achieve greater attractiveness. The structure can be given a Gothic, Scandinavian, Byzantine look. It all depends on the desires and design imagination. Some practical aspects are an important argument in favor of decorating the facade. For example, insulation.

Currently, he identifies several of the most popular preferences for decorating the facades of private houses.

Decor of curved and frame facades

As a result of the past years, there has been an increase in the demand for various curved and frame facades, for the manufacture of which high quality MDF is used.With these materials, you can decorate well both the walls of the building and the corners of a country house. In addition, there are some developed technologies, following which you can carry out the installation of the facade of the house in accordance with any style and architectural direction that will emphasize individuality.

Provence

This style is most preferable for adherents of such natural facing materials as brick, ceramics, stone. Mainly the presence of light shades, in which the decor of the facade of the house is carried out. This finish is refreshed by a colorful, standout panel with a ceramic tile base. You can also decorate the facade using decorative plaster, overhead elements or painting.

Scandinavian

The founders of this style are lovers of laconicism, the predominant absence of a prominent decor and the presence of uniformity. Thus, the Scandinavian style of installation is aimed at visually increasing the size of the space. This style is characterized by cladding materials such as wood, brick or masonry. Light and warm shades of colors and lack of contrasts are suitable for Scandinavian style.

High tech

This style is characterized by a modern origin, it focuses on the use of various modern building technologies, assuming maximum convenience. The high-tech style is characterized by an extensive use of glazing in combination with various geometric shapes.

European style

The world architectural art is dominated by a considerable number of various styles of design, including characteristic features from the Gothic and Byzantine trends. Both in Western countries and in Russia, Gothic styles and designs that came from the Middle Ages are especially popular and in demand. The trend of combining the Gothic style with any other is popular. This style is characterized by difficulties in the installation of the facade.

In addition to the above styles, there are others, each of which has its own characteristics and practical aspects, namely:

- avant-garde;

- country;

- colonial;

- classic;

- minimalism.

Very interesting and original design solutions can be obtained as a result of the correct combination of two or more styles of facade decoration. Today, there is an opinion among designers that the most original and unusual design can be obtained by combining a modern "chalet" with some additions to the classic style.

For information on how to clad a wooden house with siding, see the video below.

For combined buildings

A combination of facades is a great way to create an original, stylish and unique structure. Combined facades are divided into functional zones and blocks in accordance with the different facing materials used. Having certain design ideas, you can realize a unique idea, transform or recreate an interesting style of the facade of the house.

Combined cladding of facades of a country house has a number of undeniable advantages, namely:

- if you correctly combine and plaster the facing materials, you can easily change the visual perception of the structure: lengthen, reduce, expand;

- this type of installation is not time consuming, does not involve high costs due to the fragmentary use of expensive high-quality materials;

- individual and original facade of the house is provided.

There are many types of combinations of various materials, among which the following are worth highlighting:

- finishing of different floors with various materials is welcomed if the house being designed is a multi-storey building;

- it will look good if you whitewash and emphasize some parts of the building by combining cladding materials around the entire perimeter of the house.

Vertical technology involves the use of materials in contrasting shades. The aesthetic appearance provides the design of the entire facade with one material, and the design of any parts and elements of the structure, window or door openings with another.

The horizontal technology for the design of combined facades is a direct selection of the horizontal parts of the facade, plinths, floors, and roofs. Most often, this technology is carried out with a combination of specific materials: stone and wood, brick and wood, and sometimes even tile and wood.

How to make cladding

As we have already said, the ease of use of the material allows you to mount it on your own: there is a chance to save on the finisher's salary. But nevertheless, it is recommended to carry out the installation on your own if you have at least initial knowledge in construction, as well as skills in using simple tools: a screwdriver, a saw, a level and others. We will learn how to properly install the imitation of timber on the walls of the house.

But how to decorate the facade of a private house with PVC panels, you can read here.

Stages

After the material has been delivered to you from the store, you need to open the sealed packaging, and lay out imitation of a bar for drying. But the imitation must be protected from sunlight and moisture. The material is dried for 2-3 days, after which it becomes usable. This procedure is necessary to avoid subsequent distortion of the elements.

On the video, how the cladding takes place:

Preparation

This is a very important stage of installation: you should never skip it. To prepare the walls, they must be cleaned of dirt: it is convenient to do this with a garden vacuum cleaner or with water from a hose. But in the latter case, the walls will then need to be given time to dry out.

If the house is made of timber, it is recommended to additionally dig in the gaps between the wall elements. After that, the entire surface of the walls is covered with an antiseptic compound.

The crate is mounted. It is attached to a wooden wall with self-tapping screws and dowels, if the wall is stone or brick.

It will also be interesting to know what materials exist for insulating the facades of private houses.

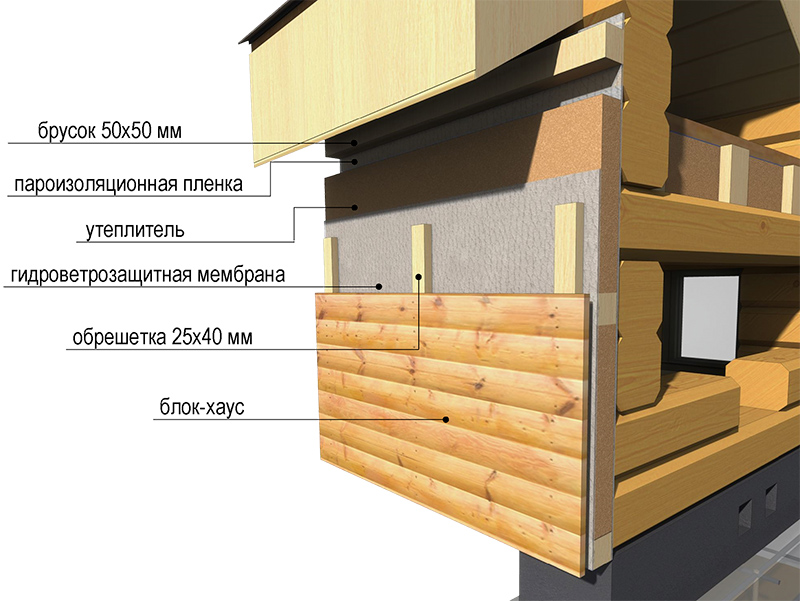

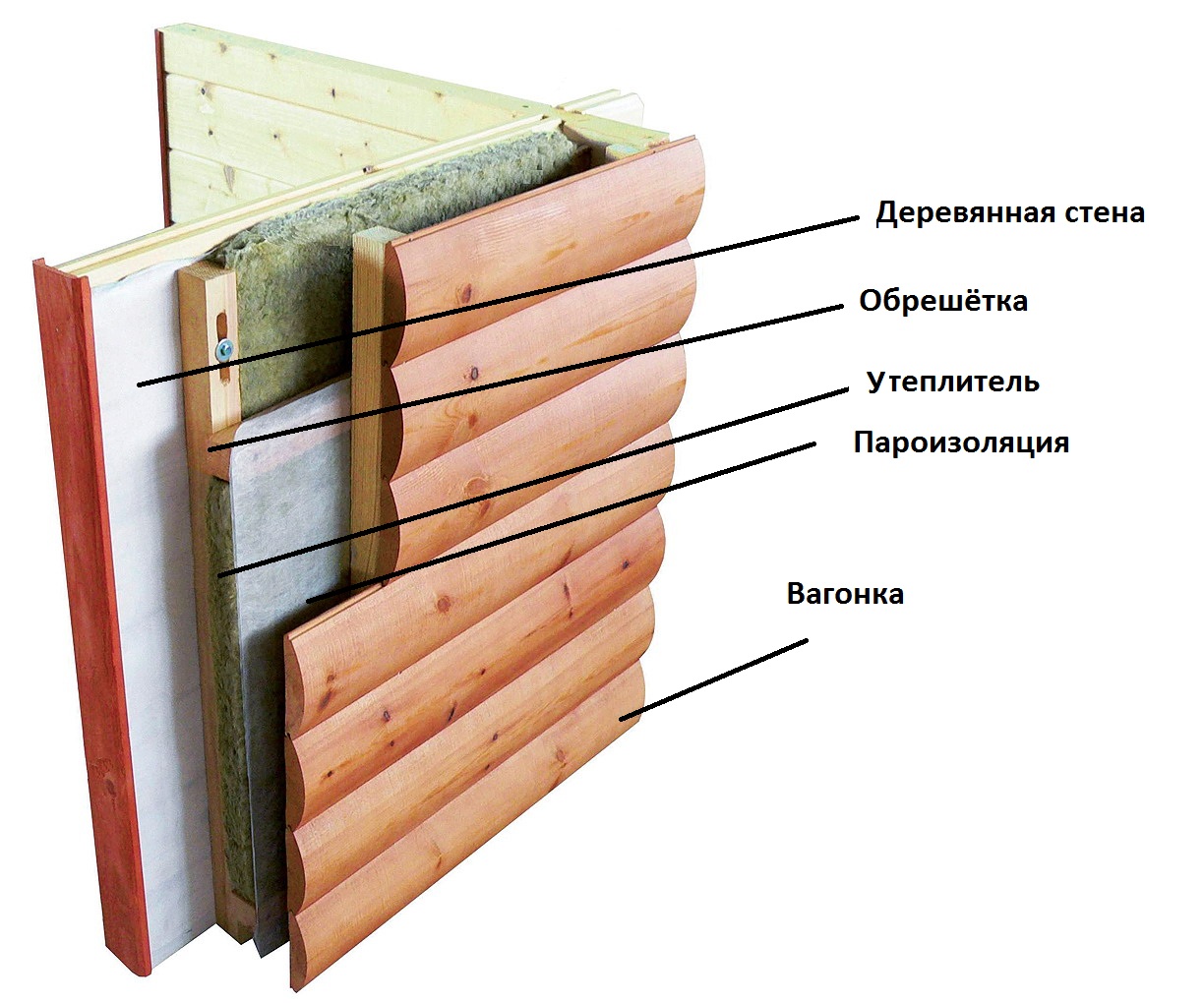

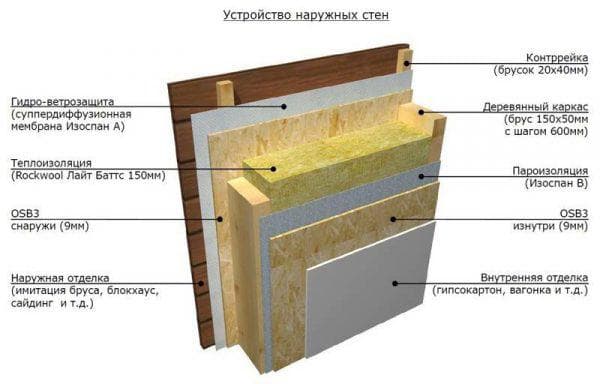

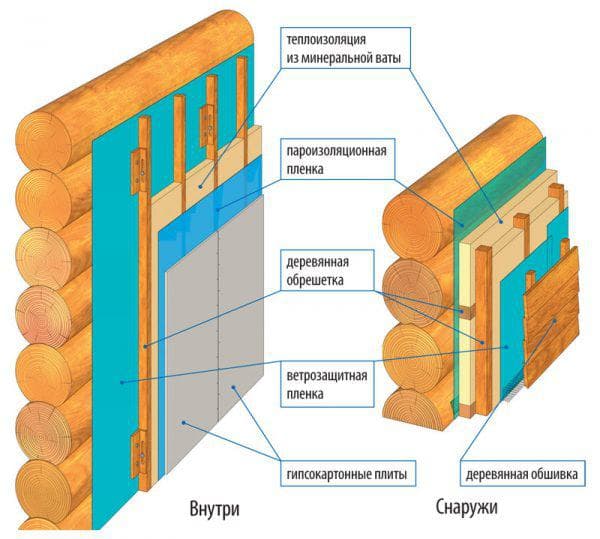

Vapor barrier

Vapor barrier

At this stage, a special film is attached to the walls to protect the building from moisture and condensation. The film is overlapped (15 cm) so that there are no gaps. The joints must be glued with construction tape.

Thermal insulation

In order for the house to be warm, and its residents to feel comfortable in any weather, it is necessary to insulate the building. Modern insulation along with an inexpensive price can offer high quality and a decent level of thermal insulation properties.

Thermal insulation

For this type of work, both insulation rolls and mats are suitable. This material is laid directly on the previous one - on the vapor barrier.

Panel mounting

The imitation planks are attached to the crate, the work starts from the bottom. The elements are fastened in this way: each new part is inserted into the groove of the previous one. The planks are fastened with a groove down to the ground, and with a ridge up. Thus, the locking connection is protected from dirt and precipitation. If there is a need for additional fastening, you can carry out this work using self-tapping screws or screws. However, experienced construction professionals recommend using nails, as these fasteners, unlike self-tapping screws, will give the planks some "freedom", which will help them avoid warping.

And here is how it is carried out installation of the facade of the house from aerated concrete, and how effective it is, is indicated here.

After installation of the entire surface, the material is coated with antiseptic impregnation, and after it - with varnish.

As you can see, the work is not so difficult, but it requires certain skills and at least minimal experience.

Attention: all installation work must be carried out during the dry season. At the same time, the air temperature should not be lower than 15 degrees of frost.

Suitable finishing time

The finishing of the facades is started after the final shrinkage of the log house. Porous wood fibers absorb and release moisture, this deforms and slightly changes the size of the wall, even if the wood was well dried before construction. Timber structures are subject to shrinkage from several months to two years. The construction season also affects the shrinkage time: construction in winter will take 7-8 months, in summer - at least 12 months. The most intense deformation process is observed in the first three months.

There are some differences in these terms for different materials. The exterior decoration of a house made of laminated veneer lumber can begin as early as three months after construction, since this material was dried using special technologies in production and does not lend itself to the influence of atmospheric moisture and does not deform. Due to the gluing of the timber, the wood fibers do not twist along their length. Round and sawn timber does not have these qualities, since the most dense wood of the outer layer of the log is cut off during processing. This reduces moisture resistance and makes the timber vulnerable to rotting and fungus. Experts recommend choosing the time of the end of autumn - the beginning of winter for construction because of the cheapness of construction, then in the summer it will be possible to start installing windows, doors, exterior and interior decoration without fear of cracking the cladding.

Preparatory stage

If you decide on your own to decorate your home with brickwork, then you should first carry out a number of preparatory work. You should not neglect them if you want to achieve a good and sustainable result. Make sure that the foundation of the house, as well as its structure in general, is designed for installation of brickwork. The foundation must be built in compliance with all building codes. It must necessarily withstand significant loads. Cheap and simple bases will not work in this case.

You should also make sure that the base of the house is made from raw materials such as monolithic concrete (concrete blocks are also acceptable). The foundation itself must be of sufficient width.

This requirement is especially important, because the facing brick will be based on the foundation structure. In some situations, bricks are placed on special steel corners, which are attached to the base using anchor bolts.

In addition, it is allowed to organize an additional foundation if the quality of the main one leaves much to be desired. Another base must be poured along the perimeter of the structure, stepping back about 30 cm from the first foundation.

Next, you should pay attention to the structure of the roof.

It is very important to take a closer look at the roof. In most cases, in old houses, the cornice part does not protrude beyond the perimeter of the structure by more than 25 cm

With such a structure, bricks will become infinitely wet and may even be destroyed. After about 5 years of such use, the brickwork will become unusable. This problem can be solved in one correct way - it will be necessary to coat the walls of the dwelling with a special water repellent compound every year, but keep in mind that such funds are quite expensive

In most cases, in old houses, the cornice piece does not protrude beyond the perimeter of the structure by more than 25 cm. With such a structure, the bricks will become infinitely wet and may even be destroyed. After about 5 years of such use, the brickwork will become unusable.This problem can be solved in one correct way - it will be necessary to coat the walls of the dwelling with a special hydrophobizing compound every year, but keep in mind that such funds are quite expensive.

If you plan to close the main walls of wood with brickwork, then before starting work you will need to coat the wood bases with antiseptic compounds. If you are decorating external walls, then you need to buy the appropriate product for them. For external work, you should not purchase internal impregnations - there will be little sense from them. In addition, it will be necessary to attach the vapor barrier to the wooden walls using a construction stapler. These coverings should be laid with an overlap (minimum - 10 cm).

You will also need:

- carefully examine the surface of the walls of the house, remove all unnecessary details, such as flashlights, gutters and other similar objects;

- the old paint and varnish layer, exfoliated elements, shedding should be removed;

- all noticed defects must be covered with a layer of putty;

- if the damage to the walls is too serious, then you will have to completely plaster them;

- in order to mount the insulating layer, it is necessary to put a layer of primer, which will be responsible for better adhesion of the wall and adhesive.

In addition, it will be necessary to properly prepare the solution. A simple cement mixture is hardly suitable here, because the facing brick is resistant to water absorption. This problem is especially acute when it comes to the installation of clinker bricks, which simply need specialized additives to ensure more effective adhesion.

The correct solution consists of the following ingredients:

- cement grade M500 - 1 part;

- sand - 4 parts;

- water.

Some craftsmen add a little clay to the solution in order to achieve greater plasticity of the composition. However, here the opinions of different masons differ - someone sees this only as harm due to the washing out of the clay component from the composition and reducing its strength, while someone, on the contrary, believes that clay makes the seams of brickwork more durable. In this matter, each user relies on his own opinion and experience.

Siding for the exterior cladding of a wooden house

A material specially designed for facades. It is produced in the form of lamellas of a special profile ("herringbone" or "ship"), with locks on the long side and a special perforation for nail fastenings. The lamellas are connected to each other with special latches and form a dense coating.

Siding is made from various materials:

- polymers;

- metal;

- cement-bonded materials.

The width of the planks ranges from 10 to 30 cm, and the length is 2 - 6 m. Like wooden facing materials, siding is installed in a horizontal position with the profile positioned so that rainwater would certainly flow down without getting into the wall.

A variety of colors and ease of installation have determined the exceptional popularity of siding in the cladding of various types of buildings - from residential buildings to industrial, commercial and public. In addition to the lamellas themselves, a wide range of profile parts is also produced - internal and external corners, cornices, connecting strips, etc.

The external texture of siding, regardless of the material of manufacture, usually imitates the natural pattern of wood. The lamellas are covered with a polymer coating or weather-resistant paint, which are also highly durable - it is quite difficult to scratch the siding accidentally. All materials used for the manufacture of siding are highly weather resistant and practically impervious to moisture. The service life of the siding is several decades.

Compared to wood paneling, siding has the advantage of being maintenance-free. From time to time, it is enough just to wash it with clean water or any of the household detergents without abrasive additives.

When considering what material to sheathe a wooden house from the outside, this feature must be paid attention to. No varnishes or paints required

Having paid once for the material and installation, you can be calm for the appearance and condition of the facades for 15 - 20 years.

Vinyl siding

Siding was created specifically to produce cladding of wooden, brick, panel board, block houses. The lamellas have special locks and holes for self-tapping screws, with the help of which they are connected to each other and attached to the base.

Slats are installed on the walls of houses so that rainwater flows down without getting between the individual elements. Horizontal arrangement is generally accepted.

The installation procedure for various types of siding is the same, so the instructions are also suitable for other types: metal, fiber cement.

Operating procedure:

- Assembly and installation of a frame made of wooden beams or metal profiles. If you plan to make thermal insulation, then the plates or rolls are fixed under the crate.

- Installation of the starting profile at the bottom of the facade, at the foundation.

- Installation of external and internal corner profiles.

- Installation of profiles for framing door and window openings.

- Installation of siding, starting with the starting profile.

Lastly, we sheathe the area under the roof and the pediment. We do not specifically punch holes for self-tapping screws, we use only factory ones.

Metal siding

The main distinguishing feature of siding made of metal is a long service life, up to 50 years.

It is made from rolled steel, sheet thickness - 0.40-0.65 mm. Finished parts have a complex configuration made by bending on special equipment.

Several protective layers are applied to the metal: zinc, anti-corrosion coating, primer. As a finish, polymer is used on the front side and a special varnish or paint on the back.

When purchasing, you can choose panels of the desired length - from 0.5 m to 6 m.The standard width is 20-25 cm.To allow air to circulate, perforated lamellas are produced, which are usually located on gables, for finishing slopes and cornices.

The color gamut is wide. In addition to monochromatic siding, products are presented "under a stone" or "under a tree". Metal siding can be done both in winter and in summer, regardless of temperature and other weather conditions.

Requirements

So that dampness does not form in the house in the country, it is always comfortable, warm and cozy, and from the outside the structure looks aesthetically pleasing, it is necessary to select such facing materials that meet a number of basic requirements.

- The cladding must be characterized by a low thermal conductivity. Only in this way will the heat be retained in the inner part of the building.

- The lining must be vapor-permeable. In no case should condensate appear in the inner part of the insulating layers.

- Moisture resistance is another important parameter that should be related to the cladding. The material should not absorb moisture into its structure and keep it there.

- The heat resistance of the cladding is either increased or absolute. Materials must be able to withstand high temperatures without any problems: they must not melt, ignite, or deform.

- It is desirable to select a lining that is chemically inert. It should not change its original properties when such substances fall on it.

- The cladding must be qualitatively protected from the harmful effects of various microorganisms. It does not have to be a breeding ground for parasites, insects, or rodents.

- The cladding material should not decompose or undergo a loss of physical qualities under the influence of aggressive ultraviolet rays.

In order for the cladding to be effective in all respects, it must not only be secured to the base as securely as possible, but also supplemented with a whole set of layers, each of which will perform its own specific functions.