Equipment for diamond drilling and hole drilling

Tools for diamond drilling of holes in concrete are divided into dry-running and water-fed attachments. Water supply to the hole prevents overheating of the tool, its premature wear and the formation of dust. The last factor is taken into account when renovating an apartment from which furniture, flowers and household items cannot be taken out.

With regard to the degree of mobility, the installations are divided into the following categories:

- light and heavy;

- anchor, vacuum and spacer fastening;

- manual and stationary;

- air and water cooling;

- power supply from 220 V and 380 V;

- shallow and deep drilling.

Additional equipment can be purchased for the installations, which increases the quality of work and speeds up its implementation. Such equipment includes water pumps, fastening systems, construction vacuum cleaners, extension cords and adapters.

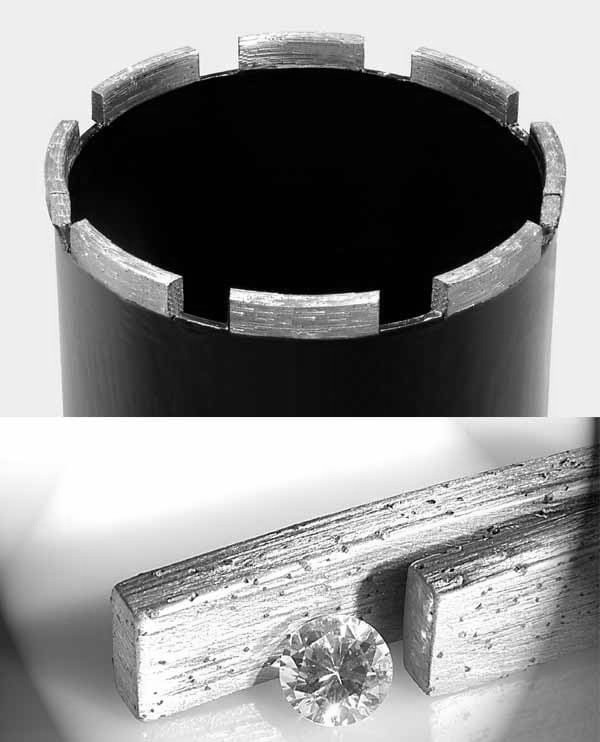

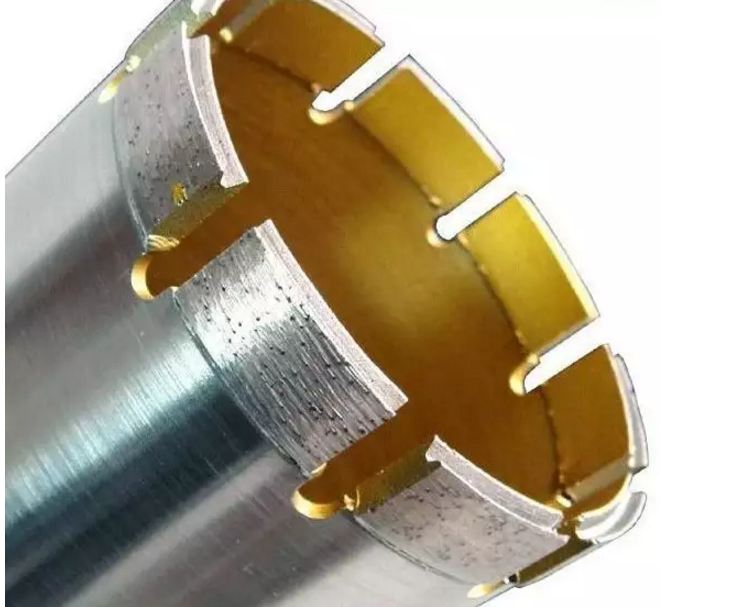

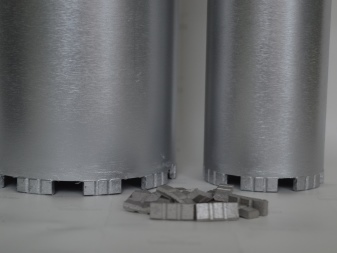

Diamond core bits

Diamond core bits can be used to make neat holes in concrete that do not require further processing. The crowns are made of high temperature resistant hard alloys. The diamond component is applied by soldering or laser welding. Bits are attached to equipment for diamond drilling using a shank of various configurations. The special cutting tool of high quality is well centered and has a sharp cutting edge.

The video below shows testing of various crowns:

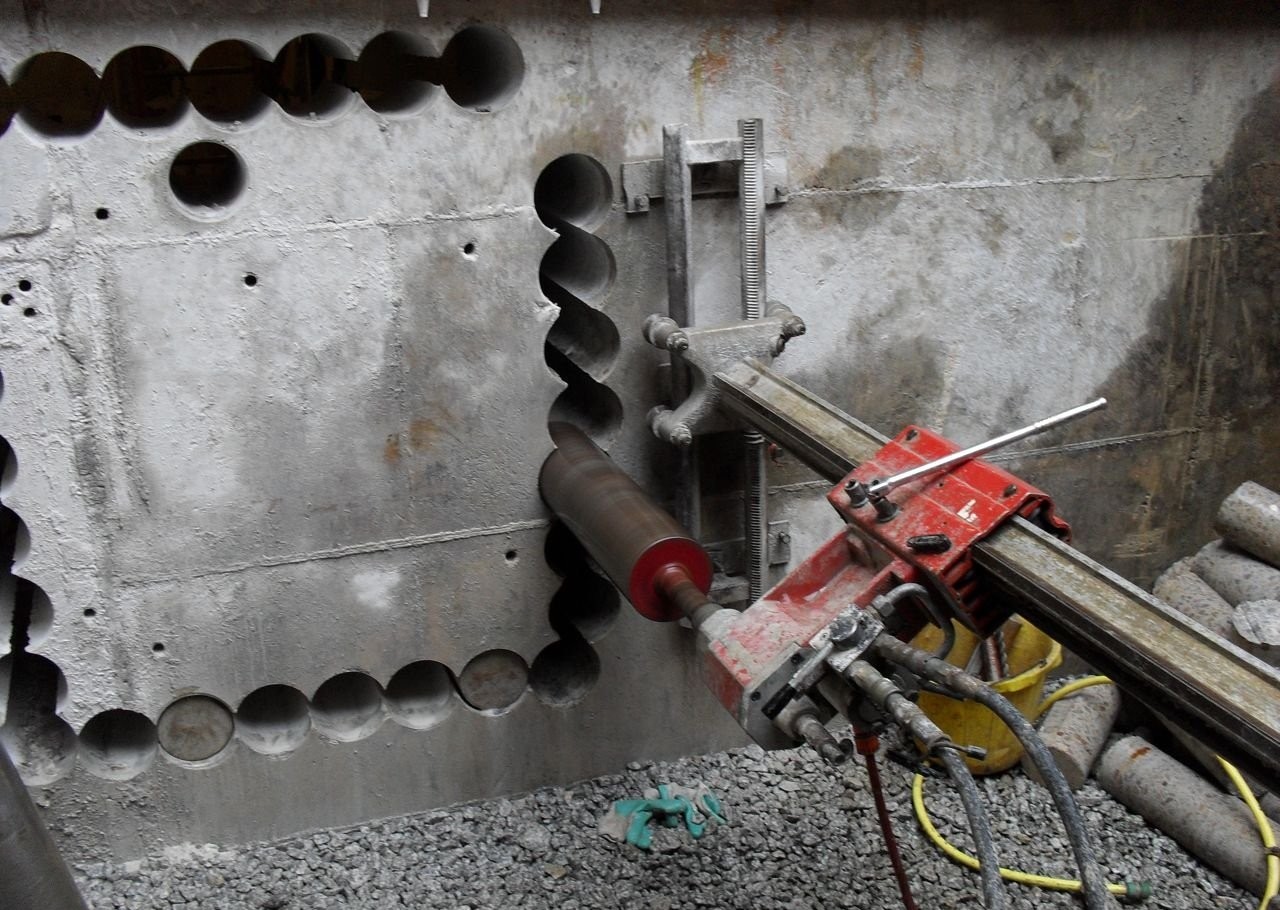

Diamond Rig

Drilling rigs for diamond drilling in concrete belong to the category of professional equipment. The tool has a different power, it is powered by electricity supplied from a household, industrial network (220 V and 380 V) or a generator.

The diamond drilling rig consists of a bed (straight or inclined, with the possibility of adjusting the drilling angle), a mounting platform, a motor and a bit for concrete. According to the degree of mobility, the equipment is subdivided into manual, mobile and stationary. The models differ from each other by the presence or absence of a mechanism for adjusting the angle of inclination of drilling.

The main types and characteristics of the drill

A drill is a cutting tool designed to make holes in various building materials. For drilling holes in concrete structures, a diamond drill for concrete is used, which is distinguished by its reliability. It is used as a tool for hand-held rock drills, the impact energy of which reaches up to 35 J.

- SDS Plus is the most widely used. The shank diameter is 10 mm, the mounting depth is 40 mm. You can buy it at any tool store.

- SDS MAX - provides the most durable and reliable attachment of the drill bit in the power tool. Able to withstand higher shock loads. Shank diameter - 18 mm.

Types of diamond drilling for concrete

There are two main types of drilling: dry diamond drilling without water and wet drilling

Dry diamond drilling is used in cases where the use of water for safety purposes is excluded, during finishing work, and also in the absence of a water source. It can be used for drilling in materials such as brick, aerated concrete and reinforced concrete. Cooling of the cutting edge surface is provided by air ventilation.

Diamond drilling is the most modern way of making holes in high strength materials.Our company uses all the latest techniques and equipment in this area. Diamond Hit technology is an advanced diamond drilling system, which is a dry drilling method using micropercussion equipment.

To obtain holes, it is used:

- Professional motor with micro impact function or special impact drill. Power of working tools is not less than 1000 W;

- HD diamond core bits;

- Vacuum cleaner for removing dust waste.

All equipment is very compact and allows you to drill holes, both from the holding rack, and manually. At the same time, the load on the floors is significantly less than in conventional wet drilling.

Domestic impact drills equipped with HD crowns allow holes up to 82 mm in diameter. With the help of micropercussion motors in the manual mode of drilling, holes up to 72 mm in diameter are obtained, and the use of a stand allows increasing the diameter at the outlet to 132 mm and the depth to 300 mm.

Wet diamond drilling is the main method for making holes in hard surfaces (wall, floor, partition, foundation). Its implementation requires constant access to water. In the process of work, water enters the surface to be treated, cools the tool and prevents it from overheating, and also removes dust from under the cutting tool. Due to the use of water, the noise level during drilling is reduced, the drilling speed is increased due to more efficient heat dissipation.

Carbide crown

Drilling concrete with a carbide bit is used when a large diameter hole is required, from 50 to 450 mm. It is manufactured in the form of a tubular product, which has a special shank for fixing in a hammer drill, a working cylinder and a special pilot drill that simplifies the use of the cutting tool.

Carbide crown

The carbide bit provides for the use of a hammer drill for hammer drilling. In general, the pros and cons of carbide bits are pretty much the same as perforating drills, but there are a few things to highlight.

| Dignity | disadvantages |

| Large diameter holes up to 450 mm | High level of wear on the cutting edge of the tool, which leads to the need for frequent replacement |

| Can be used both on rock drills and on special drilling rigs | Even higher levels of shock and noise during work |

| Compact equipment dimensions | Inability to make deep holes |

| Low efficiency when using low-power rock drills | |

| The formation of a large amount of dust and dirt during operation |

Despite the fact that carbide bits, the most famous of which are victorious ones, are still often used for domestic purposes, such a tool can hardly be called effective when performing large amounts of work. The high level of noise, which causes a lot of inconvenience to neighbors, as well as serious shock loads generated during operation, also causes great difficulties during the repair. This, with a high degree of probability, leads to the formation of cracks, plaster peeling and other unpleasant consequences.

Which drill to choose

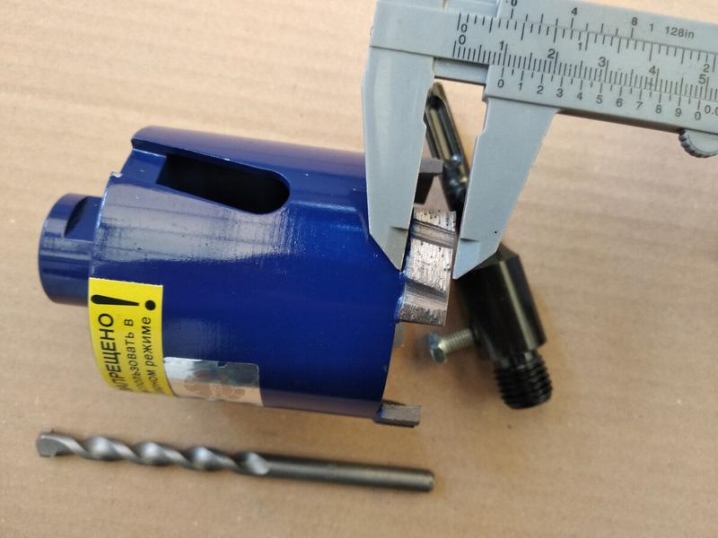

The material has a high level of strength; to work with it, you will need a special tool that can be used by a non-professional. Consider how to drill porcelain stoneware tiles at home.

Victory drill

The most economical option is a drill with a victorious tip. Its cutting part is made of a special hard alloy, which copes well with tiles, bricks and concrete. However, the product is still not intended for porcelain stoneware, so after drilling two or three holes it will have to be thrown away.

Pixabay

Pixabay

It should be borne in mind that the winner is afraid of overheating, besides, drills of small diameter (4-5 mm) can break during operation, so you need to buy them with a margin.

Diamond coated tools

Sometimes it is necessary to make a large number of indentations in the wall - not 2-3, but 5-10 or more. In this case, it is easier to purchase a gimbal with a sputtering applied by the sintering method. This technology is distinguished by the fact that diamond chips are attached to the base using hard solder, which consists of an alloy containing manganese or chromium. The hardened bond firmly holds the crystal fragments on the cutting element, thereby significantly increasing its resource. Such drill bits for porcelain stoneware can be used for both dry and wet drilling.

Instagram @svptool

Instagram @svptool

For holes with a large diameter (10-68 mm), you will have to stock up on a crown - a product made in the form of a hollow tube (cylinder). Its edges are also covered with sintered diamond chips.

The tool made in this way is highly reliable, but it is also not cheap.

Diamond core bits

If you do not need to drill a lot, it is advisable to use diamond core bits and drills with an electroplated coating. The essence of the method is that a layer of nickel compounds is deposited on the cutting edge as a result of an electrochemical process, into which diamond crystals are immersed.

Instagram @rzn_plitochnik

True, this layer does not have the necessary hardness, and the strength of its adhesion to the base also leaves much to be desired. As a result, the abrasive wears out quickly and after 5-6 holes the galvanized crown fails. But on the other hand, the price for it is an order of magnitude lower.

Steel feathers

Another budget tool for working with porcelain stoneware is feather (lance-shaped) borax for tiles. They are used if the diameter of the recess does not exceed 12 mm. The tool is equipped with a tip in the form of a cut feather (spear) sharpened at an acute angle on only one side. WITH you can use it prepare a place for the dowel, but this will take considerable effort: the drill moves very slowly, and with strong pressure it risks breaking. Nevertheless, it makes it possible to save on expensive professional equipment.

Ballerina

Often, in an already tiled wall, it is required to make several holes of different diameters. For example, for laying plumbing or ventilation pipes. In this situation, a special circular drill will come in handy, which builders call a "ballerina". The design of the device resembles a compass: a working part with a cutting edge is fixed on the axial element by means of a long lever. The lever allows you to set a certain radius. Sharpening can be made from pobedit or have diamond (corundum) spraying. However, despite this, the tip quickly deteriorates.

Instagram @plitochnik_vologda

Instagram @plitochnik_vologda

In order not to buy a new tool every time, it is better to immediately find a ballerina with a replaceable cutter. Changing the cutter is much cheaper than buying a new one.

We considered how to drill porcelain stoneware at home. Summarize. With a limited budget, it is better to use a lance-shaped gimbal or a drill (crown) with a working element from a victor. If you need to get the job done as quickly as possible, it is advisable to purchase several electroplated diamond tools. In order to drill a large number of indentations, you will have to spend money on a product with diamond grit, which was fixed by sintering - the most expensive option. Slots of different diameters can be made with a special device for circular drilling - a ballerina. It will be much cheaper than buying a separate diamond core bit for each size.

Range of crowns

Many manufacturers let in branded models.

The most popular of them are introduced by the table:

| Model manufacturer | Peculiarities |

|

|

Diamond core bits from Bosch are trusted by users. Crowns with a diameter of 68 mm are especially popular among consumers. They are used to drill holes with a hammer drill. |

|

|

Features of REMS tools:

|

|

|

A popular manufacturer is Enkor. His model 48280 is a diamond core bit for a hammer drill, drill. Peculiarities:

|

|

|

The American company DeWalt produces bits of any diameter for drilling shallow holes up to 80 mm in diameter. Lack of crowns - they can only be combined with diamond drills of the same company. |

|

|

Compared to victorious crowns, these are more durable and reliable products. The reinforcement tie, which strengthens the reinforced concrete structures, is easily removed. |

|

|

Tool head diameters up to 80 mm ensure high quality and precision. This is a versatile group of crowns. |

|

|

Diam Almaz, a domestic manufacturer and distributor of foreign companies, sells three types of concrete crowns:

|

Concrete, and even more so reinforced concrete, is a durable material that is very difficult to drill due to the presence of various fillers in its structure. Drilling tools have to deal with the most diverse materials, such as crushed stone and metal fittings.

This is the main obstacle to using a drill or drill that can overcome only one of these obstacles. Concrete drill bits can be a versatile tool for these jobs. Well, which of them to use, for a specific case - everyone decides for himself.

Purpose

Construction work involves the use of high-quality and highly efficient drilling elements. During the repair process, it may be necessary to drill through dense monolithic slabs, make recesses for switches and sockets.

In working with concrete walls, one of the most effective drilling elements are diamond core bits for reinforced concrete. Correct sizing and proper use of the device will ensure high productivity and tool life.

Tools with a cavity inside, used for drilling holes and drilling through concrete of any strength

Tools with a cavity inside, used for drilling holes and drilling through concrete of any strength

The use of diamond cylinders is relevant in the following situations:

- Work with a monolithic structure in order to further install fasteners for the staircase system.

- The versatility of the device for reinforced concrete and concrete allows the use of crowns in order to produce holes of various depths and diameters when performing facade work.

- Application for further installation of boxes for sockets, boxes and other hinged structures.

- Laying communications through reinforced concrete monoliths, namely work with plumbing, heating risers, electrical wiring, exhaust system and so on.

Attachment types

The lowest cost method is soldering. The cutting tooth or fragment is manually applied to a silver backing. Soldering gives a holding force of up to 12 Newtons during operation. At the slightest overheating, the silver layer melts and the fragment falls off. Supplied complete with water collector and manual water blower. So, for a crown of 12-32 mm per minute, up to 1 liter of water is required. Crowns up to a meter in diameter require up to 12 liters of water every minute. The relationship between water supply and bit size is non-linear.

Breaking strength - up to 40 N / m. As a driving force, there are special machines that cost a lot, which means that the crowns themselves are also not cheap.

Diamond deposition is the most common. It is obtained by both soldering and wedging during sintering. Such products penetrate tiles, tiles, porcelain stoneware and ceramics. Sold as a set - a specific working diameter range corresponds to a specific set.

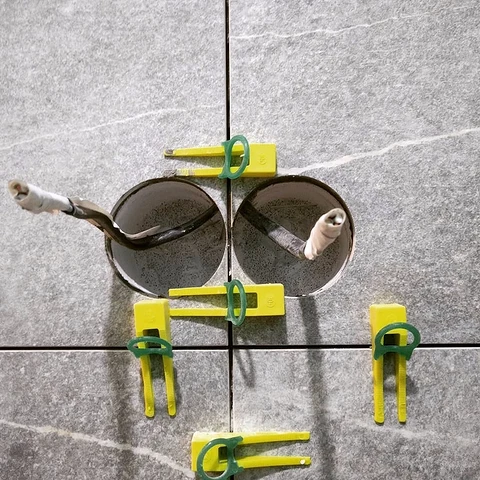

How to drill a hole in porcelain stoneware

It should be understood that porcelain stoneware tiles cannot be processed with a canopy. That is, a method in which a workpiece is fixed on a workbench in such a way that its processed part hangs above the floor is unacceptable. Otherwise, the material will split into pieces during the drilling process.

Instagram @grestool

Instagram @grestool

The hole should be positioned as far from the edge as possible. The recommended minimum distance from it is 1.5 cm. If drilling through is not required, it is advisable to make a mark on the drill in advance, to which it should reach during operation.

Using a puncher, you need to turn off the impact mode in a timely manner, otherwise the finish will be hopelessly damaged.

Drilling instructions win

When using drills with a victorious tip, it is necessary to set the rotational speed of the drill or screwdriver to 500 rpm. If we are talking about working with a diamond drill, then the optimal speed for it is 1500 rpm. In both cases, so that the tool does not slide on the surface of the tile, it is better to seal the treatment site with masking tape.

Before drilling on the wall, gently tap it: if the sound gives out the presence of voids, you will have to give up the work, since such a finish will not withstand the processing. It is undesirable to touch the seams - this is fraught with cracks. As a last resort, the hole must be made strictly in the middle of the joint.

As soon as the drill goes through the tile and reaches the concrete, change the drill to one that is designed for this particular material. If, of course, there is still a need to go deeper. The last two recommendations apply to tiles laid in as a topcoat on the floor.

When working on a workbench (or table), porcelain stoneware should be firmly fixed and ensure that there is a solid substrate (plywood or drywall) under its entire area.

The video shows the winning process.

Core Drilling Tips

Hole formation using diamond cylinders is not much different from similar operations with drills. And yet there are some peculiarities.

Instagram @grestool

Instagram @grestool

So, the recommended rotation speed of crowns depends on their diameter. If it is not more than 3 cm, the drill should be set at 800 rpm. A tool with a large diameter (from 6 cm) is best used at 400 rpm.

It is good if the model has a centering drill - it will help hold the drill in place. In its absence, it is better to make a special template: cut a hole of the required size in a plywood or drywall sheet.

Instagram @rzn_plitochnik

The finished stencil should be applied to the surface to be treated, fixed and drilled in it.After you manage to go deep into the material at least a millimeter, the plywood can be removed.

Watch the video on how to properly drill a tile with a crown.

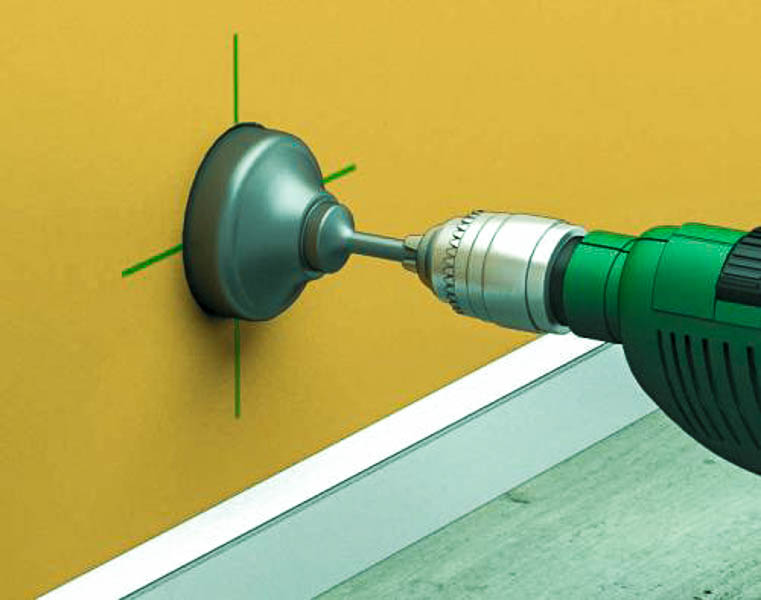

Working with a ballerina

The first step is to fix the cutter of the device at the distance from the axle post, which will correspond to the required radius of the hole. The distance can vary from 15 to 45 mm. It is recommended to make a small indentation in the center of the circle to be cut before starting drilling. It will help to correctly install the ballerina and avoid her displacement in the future.

In places where processing is expected, the surface of the material should be lubricated with machine oil (excluding the hole in the center).

Having fastened the device in the drill chuck, you can start drilling at low speeds

It is very important not to exert too much effort when doing this. Overloading the torch can damage the tile or break the tool.

In addition, you need to firmly hold the drill in your hands, avoiding distortions, otherwise the process will go unevenly: some part of the intended circle will be cut out, and some will not. To prevent the ballerina's working elements from overheating, drilling must be carried out with periodic stops.

Instagram @plitochnik_vologda

Instagram @plitochnik_vologda

Some experience is required to successfully operate the device. If you are using this device for the first time, it would be a good idea to practice a little on some unnecessary workpiece for a start.

Types of drill bits

Drill bits differ in the range of diameters. He also defines their specific purpose in each area of application.

14-28 mm - differ in a step of 2 mm. These are 14, 16, 18, 20, 22, 24, 26 and 28 mm. Rare exceptions include values such as 25 mm. Diamond bits with a small value - up to 28 mm - are used for drilling holes for chemical anchors. The latter are used for the construction of flyovers, bearing supports of large-sized machine tools and other heavy structures. Chemical anchors require a drill bit that is at least 4 mm larger than the stud itself. If this requirement is not met, the chemical anchor will not provide an adequate margin of safety.

In addition to diamond, carbide (whole) crowns are used. This allows you to transfer the rock drill to the rotary hammer mode, which makes it possible to break the concrete layer, under which lies its more durable layer with reinforcement. The nozzle of such a crown wears out quickly (prematurely) under increased loads.

For example, the working part has a serrated appearance, and the SDS shank fits most models of domestic and Japanese hammer drills used in everyday life. Such a solution is an option to quickly break through a concrete partition in an apartment under a small diameter, but these products do not differ in an increased service life. Due to the overstated impact force, the drilling quality suffers significantly.

How to drill a wall with a crown

We take a standard diameter of 70 mm, because we are going to drill holes for sockets. The tool should be checked again, there should be no traces of soldering or welding on the crown. If there are any, it will be simply impossible to work, since this is a factory defect. As a tool, we will use the most common rotary hammer with SDS plus shank.

It is advisable to use a hammer drill with a capacity of up to 800 watts inclusive, more powerful ones will exert very great pressure on the bit when drilling. And keeping the hammer drill evenly pressed against the wall is very difficult.

We will work exclusively in the drilling mode, not in the impact mode. This little nuance needs to be clarified, otherwise it can easily lead to breakage. The room in which the renovation work will be carried out will be very dusty, and for this you need to buy a spray gun to humidify the room itself, and not the crown. It is also worth considering the fact that when working with a powerful perforator, small fragments will fly in all directions, sometimes they are very sharp, here you need to buy personal eye protection, and take care of work clothes that will cover your arms and legs.Glasses will allow not only to protect your eyes from unwanted injuries and damage, but also to fully control the whole process, and not letting work go by itself.

Drilling concrete without impact

Diamond drilling of a porcelain stoneware or concrete wall is carried out without impact. For this, special installations or hand tools can be used. The second can provide only a small diameter, while the stationary equipment shows more outstanding results. With the help of crowns and drills, the surface can be processed without subjecting it to vibration. After all, the process will be quieter and more accurate. The walls of the tunnel look amazingly perfect. They seem to be polished. They do not require additional processing. This allows you to prepare channels for water supply and installation of exhaust systems, as well as sewer pipes and much more in a short time. There is no need to spend money on internal surface reinforcement.

Benefits of dry drilling

Walls can be drilled not only using wet, but also dry technology. Among the main advantages of the latter algorithm is the ability to work in clean rooms. If the process is carried out where there is no water source nearby, then this technology cannot be dispensed with either, this is its advantage. Air ventilation will be responsible for cooling the cutting edge.

Tool used for processing

When you have figured out the diameter and length of the drills, you can move on to studying the types of tools that are used when drilling. Among the most common options are stationary installations. On sale you can find drilling drills and machine tools. For small holes, you can use electric drills and hammer drills, which can be found today in almost any home craftsman. It will only be necessary to additionally purchase consumable accessories. Drills, however, are not as powerful as hammer drills, and not all devices have a vibration shock option. It makes the tool more expensive. If you do not plan to make holes in solid walls on an ongoing basis, then you should not overpay for the function either.

If you still have not chosen a tool, you should consider its types.

- Lightweight installations with a power of 1800 watts.

- More powerful models up to 2500 watts.

- The third group contains powerful units that operate at a maximum of 3300 watts. These devices are capable of making holes up to 350 mm and more. These machines can be used to manipulate the foundation, where holes are made for anchors. In this case, it is necessary to deepen up to 1.5 m. But 350 mm holes are made for the air ducts.

Lightweight installations are not capable of overpowering more than 130 mm. The main advantages of such machines are weight and affordable cost. The work algorithm does not require the use of a second handle. But this can shorten the life of the drill. Sometimes this work leads to the disruption of the segments.

The main stages of the technical process

The first step is the selection of a diamond unit and surface preparation. The place around the perimeter is freed from debris and unnecessary elements that could interfere with the work. It is necessary to plot the axes and determine the diameter. If the technology provides for the supply of water, it is supplied. Otherwise, you can use dry drilling technology.

It is important to take care of the power supply and air supply

Now comes the turn of the equipment, which is installed at the site of the future hole. Once all connections have been verified, the equipment is connected. It should not be located as tightly as possible to the surface, as this can disrupt the machine and damage the equipment. Which is not only destructive for the installation, but also dangerous for humans.

Frequent mistakes

First of all, the foreman (worker) observes safety precautions. He uses special clothing that does not pose a threat of tissue winding around the crown. A rough surface covered with a diamond layer is able to capture the material from which a protective suit is sewn. Requires protective gloves, a respirator and goggles that completely and tightly cover the upper part of the face.

The most common mistakes when working are as follows.

- The fracture or separation of the cutting tooth occurs mainly due to dry drilling or a stuck bit (jammed against a reinforcing bar).

- Abrasion of the nozzle in the area of the fragment adjoining - its sign is the changed color of the alloy. The reason is drilling without water, overheating of the bit, too fast rotation of the product at the point of work. For example, with frequent and long work on porcelain stoneware or steel, the crown becomes dull over time, both from exceeding the force and from overheating.

- A fragment that has tilted inward is formed when trying to bypass the standard hole diameter, abrupt start, lateral rubbing against the reinforcement.

- An element protruding outward indicates a too fast start, more than the required number of cutting fragments, exceeding the required drive power with worn fragments.

- Cracks and breaks on the product itself indicate an unacceptable load on the crown, including lateral impacts, horizontal beats (misalignment) of the entire product. The latter results in uneven wear of the crown, including wear of the nozzle walls.

- Dents on the crown indicate that the product was bent like an egg, it became oval. The reason is the sticking of the crown, strong blows to it.

Any other changes in the shape of the housing are due to excessive wear due to overloading.

See below for what diamond drilling in concrete looks like.

Bosch

Bosch REMS

REMS Anchor

Anchor DeWalt

DeWalt Arix

Arix SuperHARD

SuperHARD "Diam Diamond"

"Diam Diamond"