Facing material and material for backfilling holes

Each summer cottage has a cesspool to which the sewerage system of the house is connected. If the cottage is rarely used, then the walls of the pit can be overlaid with debris. This will allow the walls not to crumble, and the water to go into the ground.

In such conditions, the brick will last for many years, preserving the winter blanks of the owners.

If the old building materials are not useful in the house, then they can fill the holes on the country road. If it is broken, then it is poured into a pit and tamped. If it is whole, then it must be carefully laid out on problem areas. Old building material will not save the road and after a while will collapse under the wheels of cars, but for a while it will save motorists from puddles and bumps.

As you can see, the use of old bricks is quite wide. This material is not suitable for quality construction, but it can be used for other interesting purposes.

We continue to consider the important topic of maximum use of resources at the construction site. Brick fight is on the agenda.

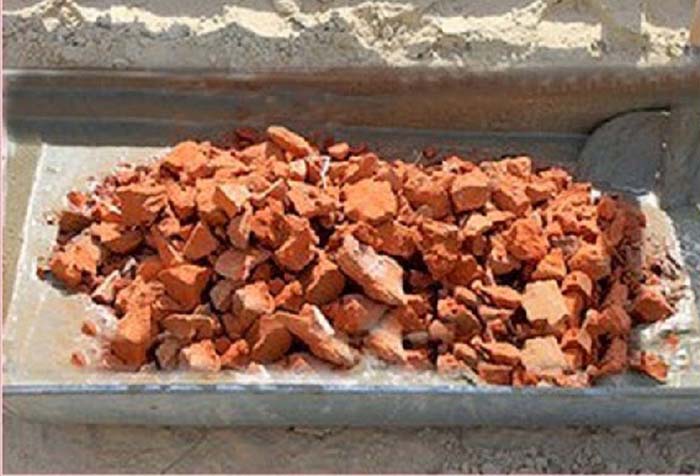

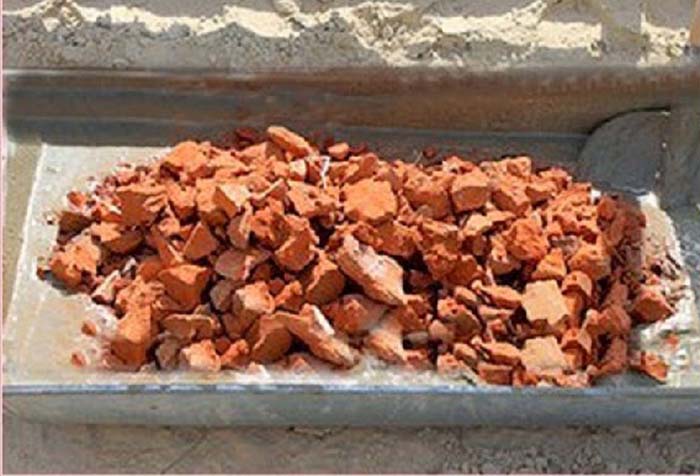

- a material consisting of stones and chips obtained by dismantling brick building structures or from waste from the production of building material (brick factory marriage), photo 1

.

Photo 1. Brick battle

Brick fight or brick chips - where used, dignity

At the industrial level, brick breakage is produced by using special crushing machines. Then the brick fight is sieved with division into fractions. Brick breakage can be purchased at crushing and screening plants or brick factories. Also, brick breakage remains on the construction site after masonry work during the erection of walls and partitions of buildings.

There are the following types of brick combat, depending on the size of the faction:

- screening - particle size 0 ... 10 mm;

- fine fraction - particle size 0 ... 20 mm;

- middle fraction - particle size 20 ... 40 mm;

- coarse fraction - particle size 40 ... 100 mm or 40 ... 70 mm;

- sometimes there are fractions of brick breakage with particles of 0 ... 100 mm and 0 ... 300 mm.

The relevance of the use of brick fighting is growing every year for several reasons:

- High cost of crushed stone and other aggregates.

- A large number of dismantled old brick buildings and structures.

- Purchased private plots often have brick buildings that need to be dismantled, and additional money must be spent for the removal of construction waste.

- When performing masonry work, there is always brick breakage and crushed stone.

Depending on the material from which the resulting brick battle, there are the following types of it:

- brick fight of red brick;

- brick fight from silicate bricks;

- brick fight from fireclay bricks.

The most common option is a red brick fight. Fight from silicate bricks has low frost resistance.

Where can brick fight be applied?

Variants of using a brick fight at a construction site:

- as a material for filling dirt roads, temporary access roads to a construction site;

- as a backfill for the foundation of garden paths;

- as a backfill for wells, pits, trenches, gaps between the foundation and the ground;

- as an additional or main aggregate for concrete (making a foundation for small buildings, concrete paths, a foundation for a fence, etc.);

- as a filler in three-layer walls (for example, when erecting well masonry walls) to increase the sound and heat insulation properties of the wall;

- as a soundproofing backfill for wooden interfloor floors;

- as a decorative material for decorating flower beds, alpine hills;

- for strengthening soils on slopes;

- as a drainage layer on swampy soils.

Photo 2. Scope of brick breakage and brick chips

Benefits of using brick fight

- low cost (significantly reduces the cost of concrete);

- sufficient strength characteristics;

- relatively high frost resistance of the material;

- sufficiently high sound and heat insulation properties of the material.

Alexander A. Konev

What can be made from recycled material

- Installation of heat and sound insulating backfill when arranging well masonry walls. Silicate chips are often used.

- When building local roads, as a base for the main surface, especially in swampy areas. On top of the scrap, granite crushed stone is poured, on which asphalt is laid. On such roads, it is permissible to add purified fractional crumbs when preparing an asphalt mixture. In winter and late autumn, temporary roads in rural areas can be constructed entirely of broken bricks.

- Backfilling of the road to suburban areas with ceramic battle, filling of holes and potholes during the repair of the constructed existing road.

- Strengthening the soil on steep slopes.

- Use as drainage layers in swampy soils, an underlying layer in trenches when laying utility lines.

- Used when filling the blind area around the perimeter of buildings.

- Temporary road from broken bricks to construction sites. Such an entrance will last for several years, and then it can be used as a base for laying a permanent coating.

- Large pieces of pottery are good for various landscaping. You can build an alpine slide using scrap as a fortified base, arrange garden beds, dry stream banks or garden paths. For filling the tracks, small fractions are used, and from medium and large you can lay out original patterns and compositions by ramming the crumbs into a compacted sand preparation or cement-sand mortar. In this case, you can use scrap only clinker, hyper-pressed or high-quality ceramic bricks, which guarantees the durability of the coating.

- A durable road to the site, in the absence of significant loads, capable of serving more than 10 years, can be obtained using fragments of clinker material.

- The chamotte material crushed into various fractions is used as a filler in refractory mortars.

- For the manufacture of gabions - rectangular boxes made of steel meshes filled with stone rubble and broken bricks.

- Replacement of a part of crushed stone with a brick break in the preparation of concrete mixtures. It will not be possible to obtain high-class concrete, but for non-critical structures such a mixture can be used if the following conditions are met:

- only ceramic scrap is suitable:

- be sure to break the pieces with a sledgehammer to medium chop;

- it is permissible to add no more than 1/3 of the volume of crushed stone;

- to concentrate such concrete in the middle of structures to reduce moisture absorption.

- It is unacceptable to arrange a foundation made of broken brick for residential buildings, but it can be used for various non-responsible outbuildings, fences, rest areas, gazebos, etc. Broken bricks are often used when installing fence posts. To do this, after installing the pillar, a brick break is poured into the pit with the installed pillar, compacted and poured with cement mortar. It is a simple, reliable, durable and cheap solution.

In conclusion: secondary brick raw materials, due to the cheapness of the material, are rational to use, but only when constructing structures without compulsory compliance with the requirements of GOST and building codes and regulations.

Is it possible to add a brick break to the foundation

Such material as brick has long been used not only for the construction of various buildings, but also as a foundation. This option is widely used in the construction of private houses with a height of no more than 3 floors.

In addition, when pouring a brick foundation, the following points should be considered:

- The soil should be solid, dry, not abyssal and not free-flowing.

- The groundwater level should be low.

But, even if the soil is a little mobile, then a brick foundation can be laid out, but you will first need to fill in a reinforced concrete base.

If the groundwater is high, then in this case additional special components are used that are added to the solution to prevent the destruction of the material from moisture.

Only by deciding to use a brick for the foundation, it should be borne in mind that its service life, compared to the concrete version, is much shorter.

In this case, the question may be of interest: "Is it possible to add broken brick to concrete?" This is what will be discussed in this material.

What is boot and how to use it

Booth, or, in other words, broken brick, appears as a result of the demolition of various brick structures, for example, houses, outbuildings and other objects. Also, secondary brick raw materials are obtained in the production of bricks directly in factories.

It is inevitable to get broken bricks in the process of laying out brickwork.

The use of recycled brick raw materials is very diverse.

It is used:

- For strengthening the soil on steep slopes.

- As a base for road surfaces during the construction of local roads, especially in marshy areas.

- Fireclay brick is used as a filler for mixing refractory mixtures and, possibly, other application.

Is it possible to add a brick to the foundation

The booth can also be used when pouring the foundation. But only when erecting small, one-story buildings. However, this option is not advisable if you plan to build a house.

Even deciding to replace part of the rubble with a brick fight, when making a concrete mixture, it should be understood that such a foundation will be less strong than that of solid brick or concrete. In addition, the service life of the brick breakage foundation will be significantly lower.

Also, there are several nuances when using buta in masonry:

- For the manufacture of concrete mix with the replacement of part of the rubble with rubble, only medium-sized ceramic breakage is suitable.

- From the total volume of crushed stone, brick breakage can be no more than 1/3 of the part.

- The concrete mix using rubble should be concentrated in the center of the foundation of the future building in order to reduce the level of moisture absorption.

Broken brick foundation, masonry options

To create a foundation from broken bricks, you can also use another masonry option:

- Having dug a trench under the foundation, first a sand embankment of 10 cm is made, which will serve as a pillow.

- Next, a 10-cm layer of concrete with reinforcement is poured. It is desirable that the reinforcement be completely covered with concrete.

- Next, a red, burnt brick rubbish is poured into an even layer. In this case, it is allowed to use both solid secondary brick material and fragments of medium or small size, up to crushed stone.

- Next, a new layer is poured with liquid concrete. The fact is that gaps are inevitable between the brick fragments. And the smaller they are, the stronger the foundation. Therefore, in this case, liquid concrete is used, which is able to fill these gaps to the maximum.

- After pouring liquid concrete, you should wait a little time so that the gaps are filled with the composition, and only after that you can compact the rubble concrete.

- Then re-reinforcement of the base is carried out using reinforcement rods. In this case, it is preferable to use a frame made of reinforcement for this layer.

- Next, the concrete is poured again and the rubble is backfilled.

The layers should be alternated until the basement formwork trench is completely filled.

Output

Asking the question of whether it is possible to add a brick to the foundation, then, in principle, this option is quite realistic to use. Only in this case it is necessary, without fail, to comply with certain conditions.

This applies to both the masonry technique and the pouring. In addition, the use of broken bricks is not recommended for the construction of residential buildings above one floor. Since the strength of such a foundation will be significantly lower than reinforced concrete.

Building materials are different

Brick occupies an important place among them. However, with all its many advantages, the material is easily damaged.

This means that you have to use broken brick mass.

What else can you use the remnants of bricks for?

From them you can make: thresholds for dressing rooms, supports for pillars (during the creation of fences, for example), as well as decorative bridges for the garden. They can be "thrown" over any body of water (pond, lake ...), if you have one, and through large flower beds. It will look very nice.

We continue to consider the important topic of maximum use of resources at the construction site. Brick fight is on the agenda.

Brick fight

- a material consisting of stones and chips obtained by dismantling brick building structures or from waste from the production of building material (brick factory marriage), photo 1

.

Brick fight or brick chips - where used, dignity

At the industrial level, brick breakage is produced by using special crushing machines. Then the brick fight is sieved with division into fractions. Brick breakage can be purchased at crushing and screening plants or brick factories. Also, brick breakage remains on the construction site after masonry work during the erection of walls and partitions of buildings.

There are the following types of brick combat, depending on the size of the faction:

- screening - particle size 0 ... 10 mm;

- fine fraction - particle size 0 ... 20 mm;

- middle fraction - particle size 20 ... 40 mm;

- coarse fraction - particle size 40 ... 100 mm or 40 ... 70 mm;

- sometimes there are fractions of brick breakage with particles of 0 ... 100 mm and 0 ... 300 mm.

The relevance of the use of brick fighting is growing every year for several reasons:

- High cost of crushed stone and other aggregates.

- A large number of dismantled old brick buildings and structures.

- Purchased private plots often have brick buildings that need to be dismantled, and additional money must be spent for the removal of construction waste.

- When performing masonry work, there is always brick breakage and crushed stone.

Depending on the material from which the resulting brick battle, there are the following types of it:

- brick fight of red brick;

- brick fight from silicate bricks;

- brick fight from fireclay bricks.

The most common option is a red brick fight. Fight from silicate bricks has low frost resistance.

Where can brick fight be applied?

Variants of using a brick fight at a construction site:

- as a material for filling dirt roads, temporary access roads to a construction site;

- as a backfill for the foundation of garden paths;

- as a backfill for wells, pits, trenches, gaps between the foundation and the ground;

- as an additional or main aggregate for concrete (making a foundation for small buildings, concrete paths, a foundation for a fence, etc.);

- as a filler in three-layer walls (for example, when erecting well masonry walls) to increase the sound and heat insulation properties of the wall;

- as a soundproofing backfill for wooden interfloor floors;

- as a decorative material for decorating flower beds, alpine hills;

- for strengthening soils on slopes;

- as a drainage layer on swampy soils.

Old boards on boxes

Not so long ago, we talked about boxes of the most diverse. It is very practical to use them in the country - to store tools, various things, vegetables and fruits in boxes. So it is for the production of such boxes that old boards are suitable. There is nothing wrong if they are chipped and with nails, the boards can always be processed with high quality.

A hot air gun will help to rip off excess paint from the surface, pliers will help to cope with nails, and new impregnations will provide protection for many years. Now that the boards are ready for the production of products, just knock them out of boxes and bunkers, and even racks for a summer cottage, shelves in cellars and basements.

Paths and roads

With the help of the battle, you can level the road near your house. To do this, broken white or red brick is poured into road bumps and rammed by hand ramming. Such "patches" will preserve the health of the car, and you will not have to remember "fools and roads", leaving the cottage.

By fighting, you can strengthen and decorate the paths on the territory of a country house. To do this, the track is first trimmed, 3-7 cm of battle is poured over the ground and tamped. If you have broken brick of two colors, then you can mix it and sprinkle the path with such a combined material - this is beautiful and practical, because walking in the autumn slush along a solid path without puddles is more pleasant than walking along a swampy path.

Broken brick perfectly permeates moisture, and after tamping it becomes an almost monolithic solid layer.

How to use broken brick

When planning how to use broken brick in the country, home craftsmen find interesting solutions, such as:

- paving beautiful garden sidewalks;

- creating borders;

- decoration of flower beds and high beds.

Also, when deciding how to use broken brick, it is recommended to use recycled material in the construction of gabions and the arrangement of foundations for alpine slides. Most gardeners are fond of decorating tall vegetable beds, the design of which provides for the formation of a powerful drainage layer, where different-sized fragments of the battle can also be effectively used. With the help of waste products, it is easy to build high-quality drainage when planting trees and shrubs.

As experienced tilers note, the use of unsightly material can give quite original results. For example, from a product that is not suitable for construction, you can arrange a path border by placing the specimens on the edge at an angle of 45 °. To get a unique masterpiece in the form of a garden path with an original masonry pattern, you can organize a composition of battle and a whole brick.

How do you get a broken brick?

Careful dismantling of brickwork helps to preserve the structure of the material that can be used for new buildings. Such a brick is more often used due to its low cost, constant availability and great opportunities for its implementation. Previously used brick can be safely used for backfilling paths or other purposes. In this case, it must be crushed with special mechanisms that transform brick fragments into small chips or into a mixture of different-sized pieces. The area of application of such raw materials is determined depending on the size of the fractions obtained.

For construction purposes, 2 main types are used:

Broken brick is used for filling pits and pits.

- Broken brick is formed during the dismantling of old buildings by breaking the walls of the building with a hydraulic hammer. In this case, large fractions are obtained, consisting of several bricks, fixed with hardened concrete mortar. Such building material is inexpensive, and if it is processed in crushers, it can be sold at a higher price.

- Brick breakage or scrap, which is obtained at the factory, is also often used for construction purposes. Due to the fact that it has not yet been used, it costs more than broken material.Some builders use such a marriage for laying utility rooms, but you need to first revise such a brick, choosing a more suitable one from the whole mass. It is advisable to purchase a chip without intermediaries from the manufacturer.

Often times, the line between combat and broken brick is blurred, and suppliers call both varieties the same. In this regard, before buying secondary building materials, it is necessary to clarify which type is offered for sale and what are the dimensions of chipped bricks. They can offer monolithic blocks consisting of several bricks, or small stones up to 2 cm in size.

The crushers can create pieces ranging in size from 1 to 70 mm. If you crush the walls with a hydraulic hammer, then you can get brick fractions from half to a whole piece (40-100 mm). You can also grind the battle at home using a sledgehammer and a hammer. The sizes of the fractions are selected taking into account the further use.

Brick bench and brick brazier

Paving a path with old brick is a good alternative to expensive paving stones.

Old brick can be used to build a bench. It can be installed on concrete or ground. A column of 5-6 bricks is laid out on a tamped or cemented place, fastening them with cement mortar. A 1.5 m bench requires a minimum of 3 posts. Metal corners are laid on top of the posts, which also sit on concrete. The columns must dry for at least 2 days. Next, polished boards are screwed to the corners, which are covered with varnish or paint.

Fighting bricks can be used to build such a useful device in the country as a brazier. Building material is an ideal material for a barbecue, because it heats up quickly and keeps the temperature for a long time. The construction of this structure begins with digging a hole along the previously measured perimeter. The hole is filled with broken building material or rubble, which are compacted. Next, the hole is filled with cement mortar and carefully leveled. The foundation should dry out for several days.

Brick bench.

Further along the perimeter, building material is laid out, fastened with cement mortar. We leave a small hole in one wall, which will be used for lining firewood or raking out the heat. Each brick must be set using a level to avoid skewing. Having laid out 5 rows, we install a metal lattice or steel rods, on top of which 2 more rows of bricks are laid out.

The width between the walls of the barbecue should be less than the length of the skewer. Further, a canopy is built over the barbecue to protect it from precipitation. For the construction of the walls of the barbecue, it is recommended to use only whole bricks and a minimum amount of mortar. Do not add a lot of cement between the broken building material, because it will crack under the influence of high temperature.

Metal in the country must not be thrown away!

Throwing out the rebar or mesh, you can be seen as a spender throughout the dacha cooperative, since everything related to metal, for many people, is immediately converted into dense bundles of cash. But it is so, because all the metal products that are in the country are very expensive, and sometimes it is much easier to use even old and rusty metal for some construction site or elsewhere than to buy a new one.

Let's look at a few examples in order to understand how much we need absolutely all summer cottage metal:

- The fittings and corners will be used to install new frames for climbing plants and hedges in the spring. From the same materials, you can make arches for grapes, a metal fence in a household yard, or just supports for plants;

- Metal beams and channels that remained after the construction or dismantling of a building will become an excellent basis for a summer shower in the spring, for a shed or during the construction of a cellar, because it is with the help of these materials that the ceiling and floors are built;

- Smaller metal elements in the country can always come in handy for pouring the foundation for landscape buildings, for bandaging it, instead of expensive fittings. Mesh, wire, pieces of a rod - everything will come in handy.

The base for the foundation and the path from the old brick

Breaking bricks is often used to level roads and fill holes.

Breaking bricks is used for construction work as a basis. Most often, broken building material is used in the construction of the foundation of the fence. Instead of rubble, bricks are poured or laid out in a dug trench under the foundation. Next, sand is poured and concrete is poured in a small layer. Next, crushed stone is poured and laid out reinforcement or metal rods. Experts advise using broken building materials only for the foundation for a fence or small outbuildings, such as a toilet, because when building a house, the walls and roof will press on the foundation. The building material will crumble, which can lead to cracks in the foundation.

At the dacha, old brick will come in handy when paving a path in the ancient Roman style. For these purposes, you can use both whole and broken building materials. It's best to use red because it looks spectacular. You will also need sand, fine gravel and construction tools. A start is made to mark the future track. Further along the length of the entire path, a layer of soil about 20 cm thick is removed. Crushed stone is poured onto the bottom, and sand is poured onto it, and everything is carefully compacted. Next, lay out the brick, alternating the broken one with the whole. Bricks must be tamped as much as possible. The cracks between them are filled with sand. So that the grass does not germinate between the building material, it is necessary to put a film on a layer of sand and carefully stretch it so that the water does not stagnate after the rain.

Brick foundation laying technology

Since the base can be built in the form of a solid tape or pillars, each of the options should be considered separately.

Tape

From bricks, you can build a strip-type base that can withstand the load up to a small wooden house.

The foundation is erected as follows:

- They make a marking of the trench, and then proceed to excavation.

- Lay a layer of sand cushion at least 15 cm. The material is leveled and compacted using special or self-made devices to obtain a dense and horizontal surface.

- Lay the waterproofing with an allowance on the wall. Roofing material can be used as the most affordable material.

- The formwork is mounted and a layer of concrete 10 cm thick is poured, which will increase the bearing capacity of the base.

- A few days later, they start laying, starting the procedure from the corners. The seams are performed internally or flush (if plastering is not expected).

- After the end of the laying, the foundation is left for a couple of weeks for the solution to completely solidify.

- The voids between the base and the ground are covered with sand, gravel or fine construction waste.

- A blind area is made on top of the trench, after which concrete is poured at an angle from the structure.

- The horizontal surface of the foundation is covered with a waterproofing layer.

If a strip foundation using bricks is being erected on unstable soils, it is necessary to take measures to strengthen it:

- the reinforcement is laid in 2 belts and 2 rows;

- for longitudinal reinforcement, fiberglass or twisted steel rods are used. The reinforcement is placed along the entire perimeter of the base, stepping back from the edge of 5 cm;

- transverse strengthening of the foundation is made of a reinforcing mesh with a wire of small diameter.

If the foundation is made of broken brick, then the procedure is carried out in the following sequence:

- A trench is made under the base and a layer of sand 10 cm thick is poured onto the bottom, which will serve as a pillow.

- A 10 cm layer of concrete is poured using reinforcement, while the concrete must completely cover the metal.

- Broken brick is covered with an even layer.It is considered permissible to use a battle of medium and small fractions, as well as solid bricks.

- Pour a new layer with liquid concrete. This is done in order to fill the gaps between the bricks and increase the strength of the foundation.

- Wait some time for the solution to fill the cracks, after which the concrete composition is compacted.

- Re-reinforce the concrete using reinforcement rods. For this layer, it is recommended to make a reinforced frame.

- A layer of concrete is poured again and the broken brick is backfilled. The procedure is repeated until the trench and plinth formwork are completely filled.

Columnar

A columnar foundation made of red brick is the simplest and most affordable option. To erect such a structure, you will need to prepare the following list:

- red solid brick of the M 150 or M 200 brand;

- sand;

- medium-sized crushed stone;

- cement M 400;

- bituminous mastic;

- reinforcing mesh;

- concrete mixer, shovel and trowels.

The construction process consists of the following stages:

- In accordance with the drawing, markings are made for the future installation sites of the support pillars.

- The centers of the supports are marked with a cord and stakes made of wood.

- The correctness of the marking is assessed by checking the diagonals, while the difference between the lengths of the diagonals should not exceed 20-30 mm.

- Pits are made along the marked centers of the supports. Their size should be such that it is possible to conveniently lay bricks.

- Using a level, the level of the bottom of the pits is leveled.

- A 10 cm layer of crushed stone is poured onto the bottom of the recesses, and a 50 mm cement screed is poured on top. The base for the support should be 50 mm wider than the brick pillar.

- A layer of roofing material is placed on the pillow.

- Re-evaluate the level of the pillow with a level.

- The laying is carried out, while every 2-3 rows a metal mesh is used as a reinforcing element. During laying, each row is checked with a level both horizontally and vertically. The masonry is done in such a way that it rises several rows above the ground.

- A week after the end of the masonry, the supports are covered with a layer of waterproofing using bitumen mastic, on top of which pieces of roofing material are glued.

- Fill up the voids around the brick pillars. To do this, use crushed stone, gravel or sand.

- Before laying the grillage, the horizontal surface of the pillars is covered with a layer of waterproofing.

Subsequently, for the construction of a structure, a wooden beam is laid on the posts as a grillage, concrete is poured, or metal elements in the form of a channel are used.

Which brick is better to use for the foundation

The base for the building can be erected not only from solid brickwork, but also using battle. When using this or that option, there are peculiarities that must be taken into account during construction.

Red brick

Due to the fact that high loads are placed on the foundation, the material used for its construction must be of high quality. Since we are talking about a brick, it must meet a number of requirements:

- strength indicator - not less than M 150;

- lack of voids;

- number of freeze-thaw cycles - at least 35;

- density - 1600 kg / m3;

- moisture absorption - 6-16%.

The listed characteristics are met by clinker and iron ore brick. However, the first option is expensive. Silicate brick is not suitable for the purposes under consideration: only ceramic corpulent is suitable. As for hollow ceramics, it is used for partitions, but its strength will not be enough for a supporting base.

When choosing and buying a brick, attention should be paid not only to its cost, but also to the condition of the material. It can be used, defective, have non-standard sizes, shapes and colors

If the material has a faded and uneven shade, then this indicates non-compliance with the technology of its manufacture. Brick with uneven sides and a loose structure is not suitable for building a foundation.

If you need to select ceramics for the underground part of the foundation, then a solid ordinary brick is used for these purposes. Its properties provide the necessary rigidity of the structure, due to which ground shifts in the off-season are excluded. The relatively low cost of the material, low weight and ease of installation allow almost everyone to make a brick foundation with their own hands.

When choosing a material, attention is also paid to the following factors:

- the correct block must have a weight of 3.5 kg;

- it is better to take material defects, while small depressions are allowed on the surface;

- the dimensions of a standard brick are 250 * 120 * 65 mm, but a thickened version can be used for the construction of the foundation - 138 * 288 * 65 mm.

From broken bricks

During construction, a lot of broken bricks are often left behind. Also, such waste can be purchased inexpensively and thereby save on construction sites. At first glance, this is rubbish, but if you figure it out, then a brick break can be used to erect a foundation, using it for backfilling, just like large stones, pieces of concrete, etc. However, it should be borne in mind that a foundation using a brick battle is suitable only for buildings on the 1st floor. It is not recommended to use broken brick for the base under a residential building due to its low strength. In addition, there are some nuances when using a brick battle in the masonry:

- to fill the foundation, only the average size of the ceramics is suitable for replacing part of the rubble;

- broken brick can be replaced no more than 1/3 of the total volume of crushed stone;

- to reduce the level of moisture absorption, the broken brick should be located in the center of the future foundation.

In order to unambiguously understand whether it is possible to use broken ceramics for the construction of a foundation in a particular case, you need to know the load that will be applied to the base, the number of storeys and material of the structure, as well as a number of other parameters. If the foundation is planned for the construction of a fence, then it is possible to butt it with a brick fight without fear, since the fence will not have such high loads as from a house or other structure.

What happens?

A batch of bricks just released from the factory can be different in purpose. After grinding, the secondary raw materials have all the key characteristics of the original product. Ceramic bricks absorb relatively little water. It tolerates frost well and has an excellent density. If initially the brick contained voids, the specific gravity of secondary raw materials reaches 1400 kg per 1 cubic meter. m, if it was solid - it increases to 2000 kg per 1 cubic meter. m.

Crushed silicate material does not survive the cold well, in addition, it easily absorbs water. The specific gravity of hollow silicate scrap is from 1100 to 1600 kg per 1 cubic meter. m. For a whole product, these indicators vary from 1800 to 1950 kg per 1 cubic meter. m. If originally the brick was chamotte, it remains refractory. At the same time, liquid water and water vapor hardly penetrate inside.

But the gradation is not only according to the origin of the brick scrap. There is also a division by size. If only particles no larger than 2 cm in diameter are present, the product is called fines. Anything more than 2 but less than 4 cm is already the middle fraction. The largest brick scrap has dimensions from 4 to 10 cm.

For ease of use, the fractions are separated and supplied to consumers separately. But you cannot immediately sort the recyclable materials by size. Before sifting through special sieves, you still need to free it from all unnecessary inclusions.

It is important to note that this is only a product that is processed industrially. Anyone who builds a house on their own can use even an uncleaned brick fight.

Advantages and disadvantages of using broken bricks

The key advantages of using waste construction resources are:

- ease of styling.For paving garden sidewalks and paths from brick fragments, only basic knowledge of working with the material and a simple set of tools are required;

- availability of products. The waste resource allows you to save a considerable amount on the preparation of materials;

- the possibility of recycling construction waste with significant benefits for the budget. That is, there is no need to take out the broken remains of products in order to clear the territory.

Among the disadvantages of using building material residues, the need for additional processing to extend the service life is noted. Moreover, this does not apply to clinker bricks, which are distinguished by high performance characteristics.

Brick fight is an excellent material for arranging garden paths

Brick fight is an excellent material for arranging garden paths