How to paint?

Wood is an aesthetically pleasing material that is susceptible to various influences. It can be affected by moisture, temperature extremes in winter, UV rays and insect exposure. Block house elements made from natural raw materials are no exception. Impregnations and protective paints and varnishes will help to extend the service life of a wooden facade. The more expensive version of the block house is industrially processed in autoclaves. The elements of the coating are impregnated with compounds that protect the wood from fire, decay and the destructive action of other factors.

Those who bought raw parts should improve their properties on their own. This must be done before installation. It is advisable to process both the planks, and the crate, and the base. For this, impregnations and stains are suitable.

Impregnations do not change the appearance of the wood. All formulations can be divided into three groups:

- Water-soluble acrylics are used for untreated wood. They are good for interior decoration, as they do not have an unpleasant smell.

- Alkyd ones are made on the basis of white spirit and alkyd resins. They create a durable coating, but they have a serious drawback - a pungent odor. They are used only for facade work.

- Butter ones are made on the basis of natural oils, more often linseed. The coating is absorbed and dries for a long time, but it turns out to be resistant. But it is incompatible with some paints.

Stains change the shade of the wood towards darker tones. This does not form a smooth layer or film on the surface. There are also colorless, they perform only protective functions. Water-based formulations are available, as well as based on alcohol, solvents and wax.

The decorative coating can emphasize the natural structure of the tree or change it in accordance with the intention of the owners. In the first case, it is worth choosing a transparent varnish or azure. If the surface of the parts is not perfect, the paint will help to hide some imperfections.

For decorative finishing of a block house, you can use materials, taking into account their characteristics.

Varnishes create a transparent or translucent film on the surface.

Lapis lazuli have the protective properties of impregnations and at the same time create a thin waterproof layer on the surface. They are glossy and matte, transparent and tinted. Alkyd urethane glazes make wood more resistant to mechanical damage.

Paints - glossy, matte and semi-matt. For exterior finishes, it is better to choose oil rather than water-based.

Wax - traditional matte finish

It is important to remember that varnish or paint can no longer be applied over it.

Before painting the wall of a house sheathed with a block house, it is cleaned of dust or old coating. It is advisable to paint new parts before installation. Before applying the paint, the wood is treated with a primer. It will improve the adhesion of the enamel to the surface. To work on a large area, craftsmen are advised to use a roller, and paint over hard-to-reach areas with a brush.

Wall decoration options in a wooden house

There are many options for finishing a wooden house. It all depends on the operating conditions, finances, your desire and the style of the room.

Clean log house finished with paints and varnishes

If you strive for naturalness and environmental friendliness, you live in a region with a stably dry and stable climate, then a natural wood blockhouse is suitable for you.

In such a house you will always be haunted by the aroma of natural wood.

In such a house you will always be haunted by the aroma of natural wood.

This type of finish is increasingly gaining popularity among our stars. This primordially Russian style makes the room lively and the microclimate healthy.This type of finish attracts with its beauty, durability, environmental friendliness, uncomplicated design and simplicity. Such projects can be recreated with historical accuracy in the same way that houses were built many centuries ago.

Lining as a wall decoration with wood when it is impossible to polish the timber

Lining is a traditional material for home decoration. Its advantages are obvious - it is easy to install, looks quite aesthetically pleasing. The lamellas, with the help of special fasteners, are connected tightly.

Clapboard paneling creates a perfectly flat and beautiful surface

Clapboard paneling creates a perfectly flat and beautiful surface

Other advantages of this material include:

- quick installation;

- environmental friendliness;

- many shades of coverage;

- made from different types of wood.

Among the disadvantages are:

- high price;

- the need to erect a crate;

- the need for careful care.

Preparatory moments include not only the installation of the lathing, but also the processing and inspection of the lamellas themselves

It is important to pre-sand and dry them.

The final stage is varnishing the lining, sanding and another varnishing

The final stage is varnishing the lining, sanding and another varnishing

Block house - is a more modern type of lining. Usually, such blocks are made of high quality wood, which does not shrink, is not inferior in strength and strength, and in many respects even surpasses classical materials.

The block house allows you to preserve the unique microclimate of the room

The block house allows you to preserve the unique microclimate of the room

In addition, this finishing material does not lose its original quality due to the processing of wood. The texture of the material is no different from natural wood.

The main advantages of a block house:

- mechanical strength;

- environmental friendliness;

- aesthetic appearance;

- light weight;

- ease of assembly.

For interior decoration, lamellas with a thickness of no more than 25 mm are better suited. With an increase in thickness, difficulties may arise with high-quality fastening of the battens. In addition, this can lead to a decrease in the internal space of the room, which is highly undesirable. The disadvantages of the material include too low vapor permeability and increased flammability.

If you buy material in winter, then it is important to put it in a warm room to dry

Decorating a wooden house inside with plasterboard

Drywall is the ideal solution for when you need to hide or hide something. It can be some kind of communications, or defects in planning. Usually drywall is used when leveling walls. Most often, in a wooden house, drywall is used for finishing ceilings or erecting interior partitions. In addition, such coatings will become good solution for bathrooms rooms.

Drywall with a moisture-resistant coating can protect your bathtub walls from excess moisture

Drywall with a moisture-resistant coating can protect your bathtub walls from excess moisture

In addition, the drywall is fire-resistant. This is just the case when they can sheathe fireplaces or a stove, additionally protecting the wooden walls from overheating and fire.

For wooden houses, lathing from a bar is used as a basis for drywall

For wooden houses, lathing from a bar is used as a basis for drywall

Wall panels of different types

Wall panels for finishing a wooden house are quite a popular option. The choice of materials is quite large. The finish under natural veneer looks very interesting, as well as made of laminated MDF, which is not afraid of moisture and can repeat almost any texture.

MDF boards are able to imitate the patterns of not only wood, but also leather, bamboo, gypsum

MDF boards are able to imitate the patterns of not only wood, but also leather, bamboo, gypsum

Why wall panels are good:

- simple and easy installation;

- good heat and sound insulation;

- stylish appearance.

The panels are also convenient because you can choose them for any size. They are also attached to the lathing and have a tongue-and-groove fastening system. Externally, the seams are almost invisible. The coating looks like a single monolith.

Decoration with MDF plates can be selected for any interior

Decoration with MDF plates can be selected for any interior

Related article:

Installation of lathing

Collecting the puzzle inside the house begins with a frame made of beams. Both the ground for plaster and the blockhouse need preliminary installation in the form of a lathing, otherwise the final result, over time, may be distorted. Hardly anyone wants to live in the kingdom of crooked walls.

Detailed blockhouse installation diagram

Detailed blockhouse installation diagram

This manipulation during installation, often involves fastening to the base of beams with a diameter of 0.20 - 0.30 cm. One of the simplest ways of fixing is universal self-tapping screws, nails can also come in handy.

- Horizontally or vertically? In the horizontal position of the house block, the sheathing beams are attached vertically, and vice versa. If necessary, the board must be adjusted to the required thickness. If there is no skill in woodworking, you can put something under it (to increase). Meticulous preparation of the lathing will give you the opportunity to get a flawlessly even wall.

- The rescue level will control the surface drops by 5 plus.

- Between the boards there are special compounds to keep the vapor barrier warm.

Blockhouse assembly technology

Blockhouse assembly technology

Material selection

Decorative finishing should start with the selection of material. House block is divided into several types depending on the type of wood and material class.

Wood species

Block house lamellas can be made from several types of wood, differing from each other in texture, color, technical properties and cost.

The table shows the comparative hardness of some types of wood used for interior decoration.

For living quarters - living rooms and bedrooms, it is recommended to use coniferous wood. The subtle pine scent that will emanate from the walls and ceilings will have a calming effect on the nervous system of the inhabitants of the house.

In addition, the resin of coniferous trees has antiseptic properties, preventing the development of pathogenic bacteria in the room.

For cladding interiors with a high heating temperature (saunas, baths), it is recommended to use deciduous wood, since conifers tend to emit excess resin when heated.

For finishing the bath, the use of larch will be optimal.

You should also take into account such a factor as high humidity, therefore, wall decoration with a block house in such rooms involves the use of wood that is resistant to moisture.

However, an important criterion for choosing a wood species is personal preference. After all, the main purpose of finishing a wall with a block house is to create an interior pleasing to the eye, therefore, if you like the openwork texture of a Karelian birch or beech, buy just such a material.

Panel size

Use thin panels for interior decoration

When choosing panels, you should also pay attention to their size. Usually the width of the lamellas ranges from 80 to 230 mm, but there may be exceptions to these rules.

Wider panels are used for finishing the facades of buildings, as inside the house they will look too massive, creating an oppressive feeling and "eating up" the space.

As practice shows, for interior decoration it is better to take thin lamellas, 8 - 16 cm wide. The lamella thickness can be from 20 to 50 mm. The length of the slats of the block house can vary from 2 to 6 m, therefore, when choosing a material, this parameter should also be taken into account so that production waste remains as small as possible.

Material class

Top-class materials have a high price

In addition to the type of wood and size, the block house is also subdivided into classes depending on its quality.

It has enhanced decorative qualities, first of all, it is characterized by the almost complete absence of knots and other cosmetic defects. However, the cost of such a block of house is quite high.

The next class of material is "A" and "B".They have a greater number of knots, and some other defects are acceptable on their surface.

The cost of such material, respectively, is much lower than that of the extra-class, but if you are not too demanding on quality, then you should pay attention to this option of the economy class. Moreover, sealing small chips or dents is not a big deal.

Basement siding

Basement siding is used for finishing the building in the basement area. Such cladding is made in order to protect the lower section of the house from the aggressive effects of precipitation and constantly acting mechanical factors.

Siding plinth trim

To eliminate their harmful effect, cladding should be used, the thickness of which should be greater than 3 millimeters. To solve such problems, the installation of basement siding is used.

Basement siding

Individual elements of the building material have a relatively large thickness and are made of small dimensions in order to ensure the reliability of fastening and reduce the likelihood of spontaneous destruction of the structure due to its large weight, which does not correspond to the used method of fastening.

Fastening the basement siding

To give the house a presentable look, equipment is often used with its basement siding, which will not only provide reliable protection for the lower part of the building, but also perform an effective decorative role.

Basement siding also serves as a decorative role.

In accordance with the requirements of the owner of the building, you can pick up elements of basement siding that imitate various materials: wood, brick, stone. To ensure an affordable level of cost of building materials intended for the construction of a basement structure, manufacturers often combine it with raw materials available in the price category.

Basement siding imitating brick

In some cases, cement siding is used to clad the bottom of a building. It should be borne in mind that in order to perform the functions assigned to the structure, its height should not be lower than 15 centimeters from ground level.

Plinth finishing with cement siding

The advantages of basement siding lie in the possibility of its long-term use, the period of which practically corresponds to the operating time of a residential building, during which it is not necessary to carry out work to eliminate damage caused by mechanical force or natural adverse factors.

Rodents cannot appear in the house, the cladding of which is made in the style of basement siding, due to the reliable protection of all walls from the possible introduction of uninvited guests. The construction material does not crack and maintains a respectable appearance for a long period of time.

Basement siding has a long service life

When buying siding elements made from different materials, you should consider:

- the thickness of the structural element;

- the presence of defects on the surface;

- availability of certificates of conformity of products to the requirements of regulatory documents;

- manufacturer's warranty.

Basically, buyers prefer to equip their home with cladding made of natural materials, due to their environmental friendliness and hypoallergenicity.

Types of basement siding

When choosing elements of the future design, materials are popular, the appearance of which is imitated under natural wood or under stones. Wood siding is less popular in building cladding due to the high price and short-lived operation of the product.

Plinth siding under a tree

All types of siding are easy to clean when dirty. For convenience, a garden hose is used for such purposes, under the pressure of water from which any contamination can be easily removed with a sponge.

Siding needs regular washing and cleaning

Siding baths

Siding - decorative panels of a standard size: width - 22 cm, length - 125 cm. The material can be metal and vinyl, it has more than 10 colors.

To sheathe a timber bath with siding, you must first install a profile frame or a wooden crate on self-tapping screws. All installation work can be done independently. The surface of the walls is carefully treated with antiseptic compounds to prevent the formation of mold and harmful microorganisms.

The siding is installed in a horizontal position with an indent of 20 cm from the foundation of the building.

Bath siding has the following advantages:

- protection of the facade from atmospheric precipitation;

- resistance to temperature extremes and fading;

- inertness to deformation and mechanical damage;

- Fire safety;

- lack of toxic elements;

- good air permeability;

- low level of moisture absorption;

- availability of installation.

However, the material has some drawbacks:

- high cost of individual fixing elements of the structure;

- the appearance of deformations and backlash in case of violation of the installation technology;

- the need to create a flat surface for fixing the panels.

Self-finishing technology

Specialists are attracted to decorate the house, but to save money, you can do it yourself. When self-cladding a room with a block house, the following rules must be observed:

- Before starting installation work, wooden boards must be left indoors for several days. This is done to reduce the moisture content of the material.

- It is necessary to fasten the board along the guides.

- When fixing the panels, they should be installed so that the tongue is on top and the groove is on the bottom. This arrangement minimizes the ingress of dust or dirt into the grooves.

- When installing, a small gap must be left between the floor and the ceiling, which will serve as natural ventilation.

- The panels should also have a small gap between themselves. In the event of moisture ingress or temperature changes, this arrangement will prevent deformation of the material.

- Galvanized materials should be used as fasteners to avoid rust stains.

Block house preparation

Before the start block house assembly in any part of the house, it is necessary to wait some time for the new beams to go through the process of adaptation to the climatic conditions in which they will be located. The tree's susceptibility to natural decomposition makes it a good breeding ground for many insects and various forms of microflora. An important stage of preparation is the impregnation of wooden elements with antiseptic agents, which can significantly increase the resistance of wood to biological damage. Processing wood with a fire retardant increases the resistance of the material to fire and mold.

Assembling or installing the frame

The complete assembly of the frame can be divided into five steps. When installing, some of the listed steps can be skipped, in cases where there is no need for additional insulation of the room. Let's consider the installation steps:

- A vapor barrier material is attached horizontally to the wall. You can use nails to fix it, but it is more convenient to use a construction stapler.

- Sheathing bars are attached on top of the waterproofing. It is also recommended to place the first layer of lathing in a horizontal position.

- The heat-insulating material is mounted in the crate cells.

- After the insulation, the waterproofing layer is again installed.

- At the last stage, the second layer of the lathing is fixed, which is now in an upright position.

During installation, it is imperative to fix it at a level, since a block house will be installed on it.

Mounting

The panels are mounted horizontally from the bottom corner, along the pre-assembled crate. Clayers are used to fix the board; they are attached to the frame with self-tapping screws.The cladding panel is inserted into the legs of the fasteners, which is located with the groove down. The next board is placed with a groove on the spike of the bottom panel. This procedure is repeated until the entire wall is finished.

In case of rejection of the glue and using self-tapping screws as fasteners, installation begins with the preparation of seats for them. The step for fastening is approximately 40 cm, and the self-tapping screw is screwed into the spike with an inclination of 45 degrees. The fastening material is masked for aesthetics.

Finishing the corners is the most difficult. At this stage, when carrying out work, special elements are used for decoration of internal and external corners. However, they do not always allow you to completely hide all the cracks, therefore, a planed beam is used for camouflage, which is attached before the sheathing begins. This design allows you to fix the boards of the block house directly to the timber and gives the cladding an aesthetic look.

Decor methods

To give the block house surface improved properties and the required color shade, special impregnations are used that contain pigments and oils. Acrylic, alkyd, oil - such bases have painting materials. Glazing paints, absorbed into the wood, cover it with a uniform layer, do not create smudges. They enhance the natural beauty of the patterns. Painted timber stands out noticeably against the background of untreated boards.

In addition to glazing compounds, various impregnations, wood paints are used. They are made on a water basis. Organic and synthetic solvents are also used. Paints have their drawbacks that should be considered when using them inside the home. They hide the natural structure of wood and give off an unpleasant odor. For dyeing the timber are also used colored and colorless varnishes, stains with a rich range of shades.

What houses is a wooden block house suitable for?

The wooden block house can be used in all houses without exception. The cladding creates the effect of a hut or a tower; rural design motives are used. The style of decoration corresponds to centuries-old traditions.

There are no contraindications to the installation of the material, there are only usual technological requirements. If an external insulation is used, then, depending on its type, it may be necessary to create a ventilation gap (for vapor-permeable materials such as mineral wool) or its absence (for impermeable types such as foam, foam or EPS).

A wooden block house requires periodic maintenance - applying a varnish coat or painting. This need is due to the intrinsic qualities of the material and has nothing to do with the structures of the house. Periodic application of a layer of paint has a positive effect - the appearance of the house is renewed, the cladding is refreshed, it becomes brighter and newer.

Under the timber

The block house under the timber has a more austere and collected look. A canvas made of such a material looks like a wall made of high-quality planed timber, although structurally it can consist of any material you like.

The walls look smoother, the presence of planes makes the canvas neater. The style of the house and the style of the facade is more urban and tends to use architectural decorations

A log block house creates a more modern look to the house than when using log panels. The walls look smoother, the presence of planes makes the canvas neater. The style of the house and the style of the facade is more urban and tends to use architectural decorations.

Metal

A metal block house is a type of metal siding with a profile of panels for a bar or a log (for example, golden oak). The resemblance to traditional wood paneling is purely superficial. Material specifications and performance are typical for galvanized steel siding.

The metal block house has high strength and is resistant to external loads. At the same time, it is distinguished by low sound insulation, which is noticeable during the rain. The installation of the material is quite simple and does not require special preparation, the only condition is the creation of temperature gaps and loose attachment of the material to the support system, which makes it possible to move during expansion from heating.

A significant difference between the metal block house is the absence of the need to care for the canvas. The material is made in different modifications, has a wide choice of colors. The kit includes all the necessary components created for the decoration of corners, openings, abutments and other elements of the facade.

Vinyl

Vinyl block house, like metal, has only a decorative resemblance to a wooden prototype and has its own qualities and characteristics. The material is very elastic, which allows it to react painlessly to small mechanical loads. Absolutely not subject to corrosion, water, frost-resistant. At low temperatures it becomes more brittle, and can crack under mechanical stress.

During installation, one should be guided by the same rules as for metal siding - creating temperature gaps and loose fastening of parts to the subsystem. The peculiarity of the vinyl block house is the low weight of the panels, which makes it possible to use it on any house, without exception.

Design solutions

A thin and light block house is suitable for cladding both a city apartment and a country house. Moreover, the latter does not necessarily have to have a massive base; sheathing of a frame house is a fairly common practice in private housing construction. Moreover, there are many ideas for cladding.

It is not at all necessary to sheathe the entire room with a block house; it can be a certain zone. The material goes well with stone, brick, tiled surfaces.

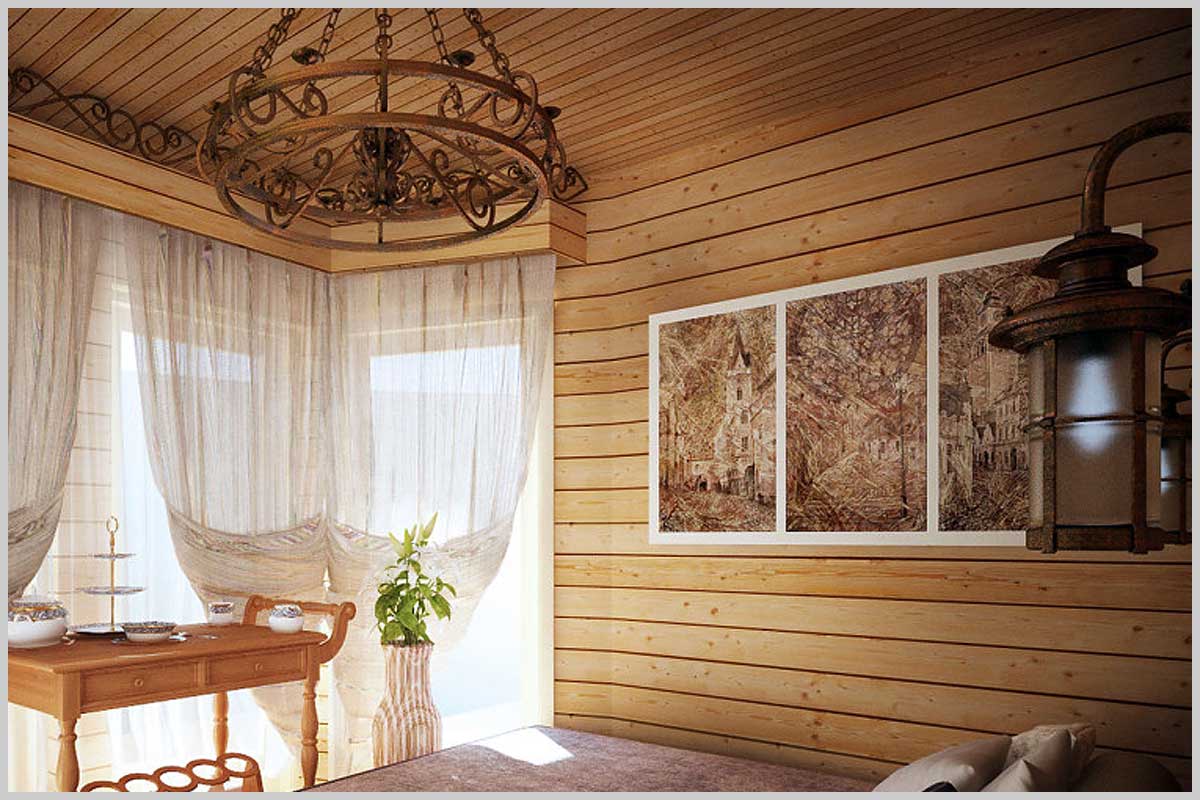

The block house can be combined with other wooden textures (board, clapboard), as well as delicate noble textiles. This warm natural material is harmoniously combined with wrought iron and glass elements.

A block house is the best option for recreating the atmosphere of a house in the Russian style - an expensive merchant's or more laconic, in some ways even ascetic peasant. Interior styles such as chalets, the atmosphere of a small hunting lodge are also impossible without the use of wood.

Due to the environmental friendliness of the material, it can be used not only in the living room and corridor, but also in bedrooms, dining rooms and even children's rooms.

The cladding of a block-house cabinet will add rigor, respectability to it, emphasize the status and good taste of its owner. It is better to choose a material of a darker shade, combining it with matching furniture, genuine leather, and original design elements.

For living rooms and bedrooms, it is better to choose lighter options, a combination of several different types of block house is possible

If panels for rounded logs are used, they will attract attention. In this case, furniture and accessories should have simple shapes, be rather restrained.

When finished with a block house, a bathroom can be turned into a luxurious boudoir. Usually a light-colored material is used here as well. As an option - bleached wood. For more aristocracy, you can add dark "logs". Choosing this type of cladding, you should carefully treat the wood with water-repellent compounds.

Block house installation recommendations

Before proceeding with the installation work, it is advisable to bring the material into the room where the ceiling sheathing is supposed to be. This will allow him to get used to new not only temperature, but also humidity conditions. To do this, the block house must be taken out of the packaging and laid out on the floor in order to avoid deformation.

After acclimatization, the panels are impregnated with an antiseptic designed to protect against excessive moisture, condensation under the ceiling and pests.

Modern protective compounds already come with a certain tint pigment that emphasizes the natural texture of the wood and colors it in the desired shade.

For example, antiseptics with a pine shade will color the products in a light yellowish tone that imitates the natural color of pine, and mahogany or wenge liquids will add a noble reddish or chocolate-black shade to the panels, respectively. The more layers of impregnation are applied, the richer the color will be.

Traditionally, finishing the ceiling with a block house begins with the construction of a lathing made of beams or ordinary metal profiles, attached to the surface with self-tapping screws perpendicular to the location of the block house.

It is from the lathing that the evenness of the resulting decorative panel depends. Therefore, if necessary, the ceilings must be leveled, or the lathing must be attached to fit the future plane. The resulting frame must also be treated with an antiseptic.

The fastening of the strips is carried out by means of locking elements cut into the side parts of the products. For additional good quality of fastening, fix the strips with clamps. The final stage is the decor of the joining seams with corners and the processing of the block house with varnish.

Choosing a block house as a finishing ceiling material, the owners receive not only a practical coating that has many advantages, but also an excellent design element that brings nobility and a unique smell of wood to the room.