What is concrete contact for and is it possible to do without it

Among all the materials that are used to prepare surfaces for plastering or gluing tiles, concrete contact occupies a special place due to its versatility and unique adhesion - the ability to adhere to a wide variety of surfaces. With the help of this innovative primer, you can make such complex connections of completely different materials, such as wood-glass, metal-tile and many others.

Can concrete contact be applied to a damp surface?

When processing dense, non-absorbent substrates, it simply has no equal. Smooth concrete walls used to require a special fabric mesh bandage to hold the plaster in place. Now it is enough to process it with concrete contact, and the surface becomes uniformly rough, capable of firmly holding not only plaster and tile adhesive, but also any other finishing materials. Even environmentally friendly, creating a particularly comfortable microclimate in any room, but very capricious gypsum plaster, will be reliably fixed for many years.

What does concrete contact look like

What does concrete contact look like

Everything that is treated with concrete contact not only connects well, but also acquires special strength - the plaster fastened by it never cracks and does not crumble during the operation of the perforator. You can safely drill holes - they will be very neat, not a single extra piece will fall off.

Can concrete contact be applied to water-based paint?

In addition to strength, surfaces treated with concrete contact acquire high water resistance, due to which they can function in conditions of high humidity. Also, the water-resistant uniform primer reduces the consumption of finishing materials applied on top.

Basic composition of concrete contact:

- Acrylic dispersion, which is the basic component that organizes the adhesion of surfaces.

- Quartz sand, providing surface roughness (coarse-grained - for plaster or fine-grained - for putty).

- Cement.

- Compositions of chemical modifiers responsible for vapor permeability, hygroscopicity, resistance to mechanical and biological influences.

As you can see, concrete contact can be classified as environmentally friendly, harmless materials. The surfaces treated with it do not lose the ability to "breathe". Bactericidal components prevent the appearance of mold, fungi and insects. The indicator of the activity of hydrogen ions in solutions of concrete contacts corresponds to neutral acidity, which means that they do not pose a corrosive hazard to metals and do not react with lime-containing solutions. Sometimes coloring pigments are added to the composition of the components so that it is easy to determine where the application was and where it was not.

Wall application

Wall application

The properties of each concrete contact, as well as the conditions and shelf life, must be described in the accompanying documentation, in support of which a certificate of conformity to the quality established by the GOST standards is attached or presented upon request.

Can concrete contact be applied to gypsum plaster?

Attention! It is forbidden to use a concrete contact, which has expired, as well as one whose structure has become heterogeneous, lumpy. In practice, when determining which concrete contact is better to use, they rely on technical characteristics such as:

In practice, when determining which concrete contact is better to use, they rely on technical characteristics such as:

- fast drying time of the treated surface;

- degree of moisture resistance;

- the duration of the service life;

- cost rates.

Primer concrete contact: features and consumption per 1m2

A primer is a unique solution that is used to prepare a specific surface for finishing, such as painting. The use of such a building mixture allows you to level the surface, get rid of any defects on the wall and eliminate small cracks.

One of the most popular types of primer is concrete contact, the use of which greatly simplifies further finishing work.

Main characteristics and properties

Concrete contact is an acrylic-based building mixture that also includes cement, sand and special additives. This mixture is actively used to increase the adhesion of a surface that does not absorb moisture well, before plastering, laying tiles and other finishing work.

Among its main advantages are the following:

- high drying speed. Further finishing work can be started a few hours after applying the primer;

- moisture resistance. During the drying process, a special film is formed that does not allow water to pass through;

- durability. According to the manufacturer, the concrete contact primer has not lost its qualities for 80 years.

Thanks to its unsurpassed properties, concrete contact has been able to establish itself as a unique material that is durable, does not need a lot of time to dry and does not allow moisture to pass through. It is these properties that allow you not to worry about the quality of the repair done.

How to determine the consumption of concrete contact?

Consumption of concrete contact per 1m2 depends on many factors, among which the first place is occupied by the features of the treated surface

What matters is not the type of surface itself, but the porosity. It determines how much of the primer will be absorbed, which has a direct effect on its consumption per m2

Primer consumption table concrete contact from different manufacturers

Depending on the porosity, the following types of surfaces are distinguished:

- Porous surfaces, which include brick or sand concrete. The primer is absorbed quite intensively, which leads to the consumption of concrete contact up to 0.5 kg per m2. If the porosity is too high, then you will first need to treat the surface with special solutions.

- Surfaces with medium porosity. These include concrete, concrete tiles. Consumption of concrete contact is about 0.3 kg per m2.

- Low-porous surfaces, for which the consumption of the primer is minimal - 0.1-0.2 kg per m2.

Is it possible to reduce the consumption of primer?

Most people wonder if it is possible to reduce the consumption of concrete contact primer. The answer is definitely no. First of all, this building mixture is notable for its affordable price, so there is no point in saving on it. In addition, this can lead to a decrease in the strength of the material, which over time will begin to crack or flake off.

It should be remembered that the quality of the primer and the work done on its application has a direct impact on future finishing work and the quality of the entire repair in general. If you reduce the amount of concrete contact primer per m2, the surface will lose its adhesion properties. In the future, this may cause the coating to separate from the base.

Reduced primer consumption may result in loss of surface adhesion.

The primer plays an important role in the process of ensuring the waterproofing of the surface, which can be disturbed when the amount of mortar per m2 decreases.

Do not forget about an important feature of some finishing materials, which is that some coatings can dry out.The fact is that gypsum or Portland cement is present in their composition, and drying out becomes a natural reaction to a decrease in the amount of water.

Thus, the use of concrete contact is essential for the future of the entire renovation.

All the nuances of using this building mixture should be taken into account. The level of concrete contact consumption per m2 depends on the type of substrate and its porosity

It is not worth saving when using a primer, as this can negate all further finishing work.

It is interesting: DIY repair of a small kitchen in Khrushchev

How to work with concrete contact - recommendations for application

Ceresit CT 19 Primer Concrete Contact

Ceresit CT 19 Primer Concrete Contact

The manufacturer of the special primer guarantees the effectiveness of its application if certain conditions are met:

- while maintaining the room temperature in the range of 5–35 degrees Celsius;

- when performing work on impregnation of the base with a moisture content of no more than 60%.

There are certain limitations when using a primer. It is prohibited:

- use a primer mixture after thawing;

- cover the base with a negative temperature.

When performing work, there is no need to use personal protective equipment for the respiratory system and skin. After all, the soil does not have a negative effect on health, since it does not contain toxic ingredients.

To get started, do the following:

- Read the recommendations for use on the packaging.

- Open the container by carefully removing the sealed lid.

- Stir the mixture thoroughly until smooth.

When processing surfaces, adhere to the following requirements:

- apply the primer to the base in one step;

- stir the mixture regularly during application;

VGT Primer VD-AK-0301 Betonokontakt

VGT Primer VD-AK-0301 Betonokontakt

Application features

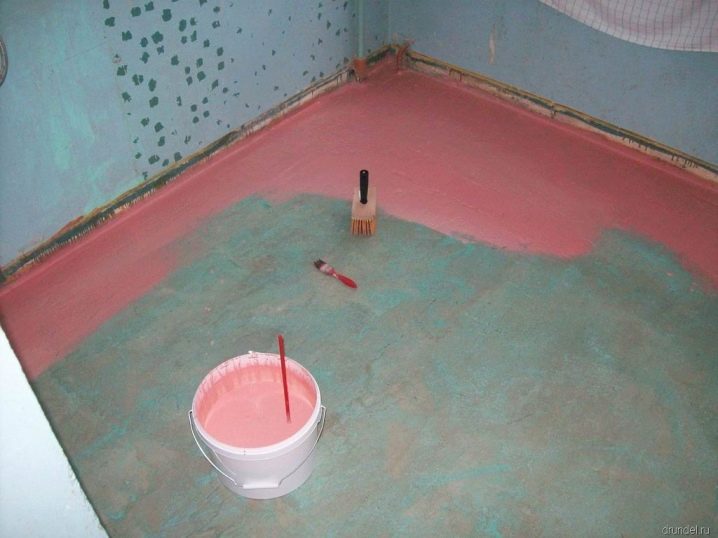

In the photo - applying a primer to drywall walls

One of the most popular today compounds intended for the impregnation of concrete surfaces is a deep penetration primer Betonokontakt. The main purpose of the composition is to improve the adhesion of concrete walls and finishing materials.

The primer is a mixture of acrylic, cement, sand and a number of additional components that provide the required degree of adhesion. Comparison with a sandwich will help to understand the meaning of using the composition. The sausage will not stick to a piece of bread, but everything will be different if the bread is spread with butter. In the case of walls, Betonokontakt acts as an oil.

The surface of the concrete walls is smooth even in those areas where reinforced concrete was cut with diamond wheels. Therefore, the layer of finishing materials on it does not adhere well and crumbles after a short time. In order to ensure the proper degree of adhesion, a microrelief must be created on the surface of the wall.

The application of a special primer forms a relief, which can subsequently be caught by plaster, tile adhesive, liquid wallpaper, etc.

Fine sand, which is known to have excellent abrasive characteristics, is responsible for creating the relief in the primer composition. As a result, after processing the walls with Concrete Contact, the surface feels like fine-grained sandpaper to the touch.

Primer Betonokontakt is produced in two versions:

- with a filler fraction of 0.3 mm (used to prepare the surface for subsequent puttying);

- with a filler fraction of 0.6 mm (used before plastering).

Composition and performance properties

In the photo - the traditional packaging of Concretecontact

The composition of the primer Betonokontakt consists exclusively of environmentally friendly and safe components, and therefore can be used for finishing any premises, regardless of their purpose.This finishing material has no pronounced odors, and, moreover, after drying, the finishing material does not form a vapor-proof film and the walls can "breathe".

Hydrophobicity is a property of primed concrete

Among the distinctive operational characteristics of Betonkotakt, the following qualities can be noted:

- small, in comparison with analogues, the time required for drying;

- hydrophobicity;

- vapor permeability;

- mold resistance;

- reducing the consumption of finishing materials;

- reliability;

- durability;

- affordable price.

On the market, Betonokontakt is represented by a wide range of products from domestic and foreign manufacturers. Despite the fact that there is a GOST for a primer Betonokontakt, the list of components may vary depending on the technology used by the manufacturer.

The composition of Concrete Contact from domestic manufacturers by and large repeats the recipe of a traditional water-dispersed acrylic primer. A characteristic difference is the content of granulometric fillers. Moreover, for coloring the treated surface, the composition may contain pigment additives.

Due to its low cost, marble flour is often used as a filler, which, however, has practically no effect on the quality of the finished finish. Some brands do not contain marble flour, but real quartz materials. However, the production cost of such primers is much higher, and therefore their price is high.

Application technology

In the photo - applying the primer with a brush

The instructions for applying the primer are not complicated.

Nevertheless, it is necessary to comply with all technological requirements, since the quality of the finished result depends on them.

At the initial stage, the surface to be treated is completely cleaned of dirt and dust.

It is especially important to remove all dust if diamond drilling of holes in concrete has been carried out previously. You should also clean up grease contamination, as they prevent the penetration of soil into the concrete surface.

If the soil is applied to old walls, it is imperative to turn off the power supply in the room.

Immediately before application, the solution must be thoroughly mixed in order to raise the sediment from the bottom of the container.

In addition, in the process of processing the walls with our own hands, we also do not stop mixing the solution so that it is homogeneous and does not precipitate.

We apply the solution to the wall with a velor roller or a brush with a brush in one or two layers.

Specifications

Primer "Betonokontakt" is presented in the form of an adhesive mixture with the addition of crushed quartz sand. The presence of these two basic components is responsible for the ability of the material to provide high adhesion between adjacent finishing layers. The composition has a pink tint, which allows you to control the uniformity of its application to the surface, and helps to immediately see unpainted areas.

The material is produced in two modifications - with a fraction of 0.3 and 0.6 mm. The first type is used for surface treatment before puttying, and the second - before plastering.

Soil acidity indicators correspond to pH 7.5-8.5, which indicates the neutrality of the solution. The mixture can be used both for external and internal work, retains operational properties in the range from -40 to +60 degrees and withstands up to 5 freeze-thaw cycles. In an unopened container, the mixture can be stored for up to 18 months.

The average consumption of "Betonokontakt" is 20 kg per 60 square meters and depends on the structure and type of base, ambient temperature and the required number of layers. For example, to process one square of tiles, 200 g of the mixture will be required, while for painting the same area of a concrete base, 350 grams will already be required.

The composition of "Betonokontakt" includes additives from fungicidal preparations, due to which the appearance of fungus or mold on the treated surfaces is completely excluded. Despite the excellent moisture resistance of the primer layer, the material has good ventilation and provides full air exchange in the room. The soil is produced in plastic containers with a capacity of 5, 20 and 22 kg.

The principle of applying concrete contact

Primer Bolars concretekontakt

Primer Bolars concretekontakt

In terms of quality characteristics, the primer does not always comply with GOST, and in general, it is not a product subject to mandatory certification. Many manufacturers are counting on this, making their products without proper control of production, technology and raw material base. To completely dispel all doubts about which concrete contact is better, watch the video in this article.

So, let's clarify again: concrete contact primer, consumption per 1m2 on average is 300gr / m2. Focusing on it, we are trying to adjust the specified standards to the actual thickness of the application.

How to do this, they will tell you general recommendations for all types of such compositions:

- Before concrete contact is applied, some surfaces are sometimes primed with a conventional compound to remove dust clumps and increase adhesion.

- A concrete contact is applied to a dry surface with ordinary painting tools: a roller or a brush. A brush with wider bristles is more productive.

- Make sure that the concrete contact layer is completely dry before continuing with finishing. Otherwise, the work will be ruined.

Particular attention should be paid to the manufacturer's instructions, which indicate not only the consumption of the primer per 1 m2, but also the subtleties of working with it. But not only this you need to know when preparing to work with such an adhesive material.

There are also a lot of certain subtleties:

- Some formulations are ready for use immediately after opening the can, others need to be diluted with water. It is helpful to have some information on the recommended surfaces to apply the primer to and which ones to avoid.

- It all depends on the chemical composition of the substance and affects its performance. If a mixture intended for interior work is applied when covering the facade of a building, then this can lead to sad consequences after the last layer of finishing material has been fixed. And then the concrete contact priming will have a colossal consumption.

- Some people use special technical means to apply such substances. The packaging will necessarily indicate if it is possible and acceptable in relation to a particular mixture.

- Drying times may not be as stated in a damp room. As soon as this has happened, it is necessary to immediately continue working so that dust and dirt does not accumulate on the treated surface, which will harm the adhesion properties.

- The best concrete contacts are acrylic. They do not interfere with the penetration of air and do not violate the microclimate of the room, no matter which side they are applied.

- In closed containers, concrete contacts can be safely stored for a year. One has only to comply with one condition: the ambient temperature should not fall below zero degrees. If the mixture freezes, it will lose all its properties, but it is resistant to mold, fungi and parasites.

- An open jar / bucket or diluted mixture cannot be stored for a long time. The solutions dry out quickly. Especially water-based ones.

Acrylic concrete primer "Luxorit"

Acrylic concrete primer "Luxorit"

Concrete contact is an inexpensive material. Therefore, when using it, you should not pursue a decrease in consumption, to the detriment of the quality of work. The lack of a concrete contact layer will bring more significant material losses than buying another package.

Types and characteristics

The main difference between the types of concrete contact is the size of the quartz sand particles, on which the choice of surface for processing with this mixture depends. In addition, there are primers that are intended for indoor use only, and a combination primer for external and internal use. The packaging of the primer always contains instructions describing the materials suitable for processing. It is worth trying to take into account the manufacturer's recommendations, this will reduce the consumption of the primer and get the desired result.

As part of a concrete contact, the following components are necessarily present:

- Cement or Portland cement;

- Quartz finely dispersed filler;

- Polymer, most often acrylic, component;

- Special technological additives.

The technical characteristics of the composition do not depend on the manufacturer, the type of mixture and are always the same:

- Environmental friendliness. The composition does not have an unpleasant odor and vapors harmful to health. To work with it, you do not need personal protective equipment for the hands and respiratory tract.

- Resistant to alkalis and aggressive media.

- Waterproofing properties.

- It is permeable to gases, which creates the correct air circulation in the room and prevents the formation of mold.

- Resistant to parasites, mold and mildew.

- Drying speed at room temperature and moderate humidity is only 2-3 hours.

- The service life declared by the manufacturers is 80 years. After this period of time, the concrete contact layer begins to collapse.

- The air temperature for work is 5-35 ° C, the recommended humidity is 60-80%.

To make the layer thickness and the uniformity of the coating easy to control, manufacturers add a white or pink dye to the mixture, which is clearly visible on the treated surface. Without dye, the concrete contact is a clear liquid.

The solution can be applied to any surface either manually or mechanically using a compressor or spray gun. There are options for using mechanical devices, this must be indicated in the instructions. In addition, specialized stores have a selection of mixtures in aerosol cans.

Any type of concrete contact must comply with GOST 28196: according to its characteristics, it belongs to water-dispersion compositions with an acrylic copolymer. If the GOST number indicated on the package is different, it is better to refuse such a purchase.

Mixture consumption per 1 m² depends not only on the size of the sand particles, but also on the porosity of the treated surface:

- for smooth and slightly porous surfaces such as painted walls, metal and glass substrates, ceramic tiles, the consumption of the mixture will be about 150 g / m².

- for a medium-porous surface made of concrete slabs or finishing bricks, the consumption will fluctuate within the range of 300-350 g / m².

- for a highly porous surface, such as concrete or building bricks, the consumption can be 500 g / m² or more; to reduce the consumption of concrete contact, the surface is covered with a deep penetration primer.

Primer Knauf Betokontakt

The building materials market is expanding, new products appear - successful and not so - there are real bestsellers. One of these useful developments was the Knauf Concrete Contact primer. The purpose of this composition is to separate layers of different properties, but at the same time ensure their strong adhesion to each other. Thanks to the new formula, the cladding can now be used on difficult substrates, saving time and effort in preparing them.

Primer Betonokontakt of the Knauf brand is an adhesion dispersed mixture on an acrylic basis. It is intended for application on low-absorbent high-density surfaces like concrete monolith, on which the adhesive or leveling mortar simply has nothing to cling to.The primer itself easily adheres to such a base, turning into a continuous dark pink film. And the adhesion with the subsequent layer is provided by fine-grained alkali-resistant sand in its composition, which gives the coating the required roughness.

In addition, Betonokontakt Knauf allows you to apply lime and gypsum plaster to cement, although earlier this was simply impossible due to chemical reactions that occur between two dissimilar materials. However, experts found many other types of work, where the new primer came in handy:

- Strengthening before plastering of low-density products (expanded polystyrene, gypsum plasterboards).

- Laying ceramic tiles directly on the old one without preliminary dismantling.

- Application on surfaces coated with oil or alkyd enamels for subsequent finishing.

- Reliable fastening of decorative stucco molding to any smooth surfaces after processing Knauf Betonokontakt.

- Preparation of metal structures, as well as concrete products with removed embedded elements for subsequent puttying.

- Strengthening dusty old concrete before finishing work.

Primer Betonokontakt, whose main task was only to ensure reliable adhesion of the plaster to smooth surfaces, turned out to be very functional. Thanks to her, many repair work has been simplified, especially related to the preparation of the bases and the dismantling of old resistant coatings. Where previously it was required to use several special compositions for various purposes or fiberglass mesh, now one almost universal Knauf primer is enough.

Primer properties

Knauf Betokontakt not only strengthens weak surfaces and increases the adhesion of smooth substrates before plastering. The ability of an acrylic mixture to clog pores and microcracks allows you to reduce the consumption of viscous (liquid) finishing materials and retain water in the leveling solutions, which is necessary for their normal setting. Thanks to this, the plaster does not exfoliate and does not crack from the rapid loss of moisture.

The performance characteristics of the Knauf mixture are also noteworthy. For example, fungicidal additives are already included in its formula, which means that additional antiseptic treatment is no longer required. Concrete contact itself does an excellent job of protecting walls from mold, reducing your repair costs. To this it is worth adding also the good vapor permeability of the created intermediate layer - it does not interfere with diffusion air exchange between the room and the street.

In some way, the disadvantage of the primer is the need to quickly start further work as soon as Betonokontakt Knauf is dry. It is impossible to postpone finishing, and even more so in parallel to carry out other activities in the room - a rough adhesive layer easily accumulates dust, deteriorating the properties of preparation.

Characteristics and consumption

Primer Betonokontakt from Knauf is produced with a mineral filler of two fractions, on which the scope of application of a particular composition depends:

- 0.6 mm - used before rough leveling,

- 0.3 mm - it is worth purchasing it to prepare plastered surfaces before puttingty.

What is concrete contact

When starting repair work, they acquire not only building materials. It is worth thinking about the rules for their use. Often, during self-repair, problems arise with the application of finishing coatings.

Plaster can peel off, tiles can peel off the wall, wallpaper peels off - this occurs due to the lack of the necessary adhesion of the finish and surface. That is why concrete contact is needed - to combine completely incompatible textures.

This can happen to anyone who has ignored the use of concrete contact.

This can happen to anyone who has ignored the use of concrete contact.

It is its use that allows you to achieve the necessary maximum adhesion for strong contact of the material with the base. This type of soil is represented by a mortar for surface treatment based on sand and cement. It contains polymer compounds that are resistant to alkali.

Where concrete contact is applied

The scope of application of concrete contact is quite extensive, although it has the same specifics. It all depends on the type of building material used.

Concrete samples with and without concrete contact after laboratory tests. The result is "on the face"

Concrete samples with and without concrete contact after laboratory tests. The result is "on the face"

The acrylic composition of such an adhesive mixture has a bonding element between the smooth side and the finishing materials. The solution seeps into concrete, brick, drywall, wood, metal, glass. Therefore, when concrete contact is applied, the surface becomes rough and reliably fixes paint, plaster, tiles, wallpaper.

Some manufacturers indicate directly with which material the primer can be applied. It does not contain harmful components, has no unpleasant odor, provides waterproofing, dries quickly, and has a long service life of up to 80 years.

Therefore, due to such properties, its use in construction and finishing works is possible:

- for processing the area where the laying of the facing tile is planned;

- to cover facades and structures before decorative installation;

- to minimize the number of pores in drywall sheets;

- for covering bases, both from the inside and from the outside of the premises;

- concrete walls, ceilings are processed before applying a layer of plaster, painting, for self-leveling floors.

A great variety of soil mixtures are presented on the modern market for construction products, and their price has a large run-up. And note that it is not always of high quality, a good primer will be in a high price category.

Treatment of walls with concrete contact, which are exposed to intense moisture

Treatment of walls with concrete contact, which are exposed to intense moisture

The concrete contact on sale can be found in buckets or barrels. It is used depending on the brand and the quality of the surface to be applied. If the treated area absorbs moisture well, then the consumption of the soil mixture is greater.

Preparing drywall for tiles

Surface priming

Do I need to prime the drywall before laying the tiles? Here, the opinions of professionals converge. The primer applied to the wall contributes to:

- decrease in moisture absorption

- strengthening fibers

- preventing the formation of pathogenic microflora on the wall from the gypsum board.

The cured plasterboard primer under the tiles creates a protective polymer layer that prevents the penetration of moisture that is in the tile adhesive.

What is the best primer for plasterboard tiles? It is recommended to treat the surface with an acrylic primer. It is non-toxic, dries quickly, spreads evenly over the plane and has high performance characteristics.

It is recommended to treat the surface with a primer as follows:

- The wall must be well cleaned of dust particles and debris. To do this, you will have to wipe the base with a damp sponge;

- When preparing drywall walls for tiles, the primer must be poured into a container, tray and, dipping a roller, begin to process the walls;

- Apply the primer evenly. To process hard-to-reach areas, you need to use a thin brush, and the solution is applied with a roller to the plane;

- As soon as the drywall primer under the tile hardens, a second coat is required.

Does drywall need to be primed before tiling? Of course, this stage in the preparation of walls for tiles is very important, the reliability of the finishing coating will depend on it.

After the preparatory measures, you can start filling.

Reinforcement of seams

It is necessary to reinforce the seam-butt-joint spaces in order to obtain the most durable and solid surface.It is the joint seams that are the most vulnerable places in the drywall structure, they can provoke the formation of cracks and cause the destruction of the facing layer, therefore, drywall must be reinforced in front of the tiles.

To prepare the wall for putty, the seams are filled with the appropriate compounds, which are selected according to their purpose:

- starting (leveling) composition is suitable for hiding various defects

- the finishing option of the putty is necessary to create a smooth base

- a special type of putty is used to seal the joints between the slabs

When choosing a filler for filling joints under a tile, pay attention to its composition. These can be gypsum, cement and polymers.

Gypsum-based plaster is not recommended for use in rooms with high humidity levels. Plasterboard putty under the tiles in the bathroom should be done with a mixture of either cement or polymer base. The last option is characterized by versatility of use, high cost and high working qualities.

It is necessary to reinforce the joints between the sheets using a special tape - serpyanka. Better to use synthetic tape (construction bandage). This technique will significantly reduce the likelihood of microcracking and strengthen the surface intended for laying tiles. Plasterboard putty under the tiles in the process of sealing the joints is applied first to the problem area, after which the tape is glued, and again everything is tightened with the mixture. It is imperative to reinforce the joints by gently pressing the tape into the solution.

Plasterboard putty

Having found out whether it is necessary to plaster drywall under the tiles, you can start processing the walls.

The first step is to plaster the corners using plastic protective corners. The working mixture is applied on both sides of the corner, and the corner is inserted, the layer thickness should not be more than 2 mm. When you press on the edge of the corner, you do not need to overdo it, the excess is removed with transverse movements of the spatula.

It is necessary to plaster the wall evenly, after the finishing layer has dried, sand it with sandpaper. Tiles are laid on the putty drywall by using crosses and a special adhesive.

Putty primer

How to primer drywall under the tiles has been described above. Acrylic primer is a good option.

It is recommended to apply a protective and strengthening compound 1-2 times, which will provide a reliable base for further finishing lining. Does drywall need to be processed before tiling? The answer is unequivocal - "Yes, if you do not want to redo the repair."