Primer concrete contact: features and consumption per 1m2

A primer is a unique solution that is used to prepare a specific surface for finishing, such as painting. The use of such a building mixture allows you to level the surface, get rid of any defects on the wall and eliminate small cracks.

One of the most popular types of primer is concrete contact, the use of which greatly simplifies further finishing work.

Main characteristics and properties

Concrete contact is an acrylic-based building mixture that also includes cement, sand and special additives. This mixture is actively used to increase the adhesion of a surface that does not absorb moisture well, before plastering, laying tiles and other finishing work.

Among its main advantages are the following:

- high drying speed. Further finishing work can be started a few hours after applying the primer;

- moisture resistance. During the drying process, a special film is formed that does not allow water to pass through;

- durability. According to the manufacturer, the concrete contact primer has not lost its qualities for 80 years.

Thanks to its unsurpassed properties, concrete contact has been able to establish itself as a unique material that is durable, does not need a lot of time to dry and does not allow moisture to pass through. It is these properties that allow you not to worry about the quality of the repair done.

How to determine the consumption of concrete contact?

Consumption of concrete contact per 1m2 depends on many factors, among which the first place is occupied by the features of the treated surface

What matters is not the type of surface itself, but the porosity. It determines how much of the primer will be absorbed, which has a direct effect on its consumption per m2

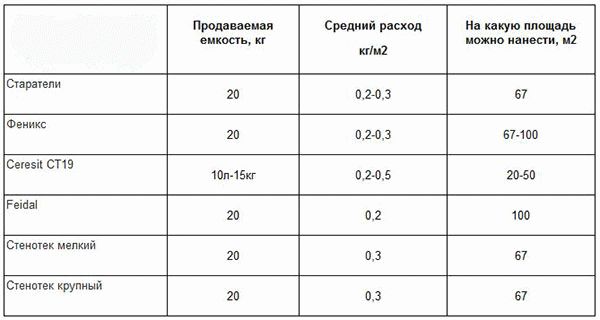

Primer consumption table concrete contact from different manufacturers

Primer consumption table concrete contact from different manufacturers

Depending on the porosity, the following types of surfaces are distinguished:

- Porous surfaces, which include brick or sand concrete. The primer is absorbed quite intensively, which leads to the consumption of concrete contact up to 0.5 kg per m2. If the porosity is too high, then you will first need to treat the surface with special solutions.

- Surfaces with medium porosity. These include concrete, concrete tiles. Consumption of concrete contact is about 0.3 kg per m2.

- Low-porous surfaces, for which the consumption of the primer is minimal - 0.1-0.2 kg per m2.

Is it possible to reduce the consumption of primer?

Most people wonder if it is possible to reduce the consumption of concrete contact primer. The answer is definitely no. First of all, this building mixture is notable for its affordable price, so there is no point in saving on it. In addition, this can lead to a decrease in the strength of the material, which over time will begin to crack or flake off.

It should be remembered that the quality of the primer and the work done on its application has a direct impact on future finishing work and the quality of the entire repair in general. If you reduce the amount of concrete contact primer per m2, the surface will lose its adhesion properties. In the future, this may cause the coating to separate from the base.

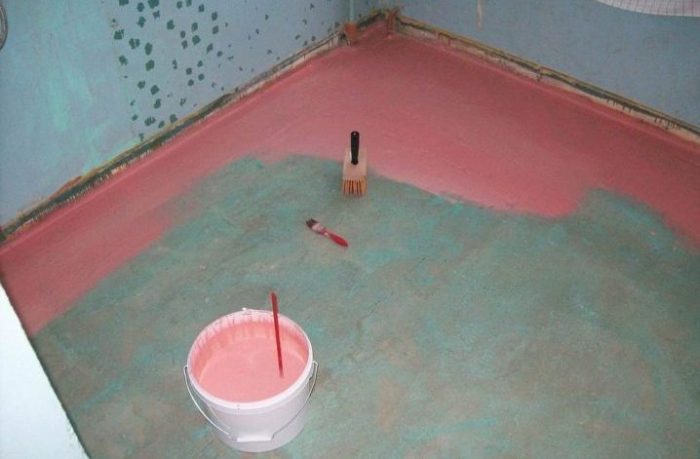

Reduced primer consumption may result in loss of surface adhesion.

Reduced primer consumption may result in loss of surface adhesion.

The primer plays an important role in the process of ensuring the waterproofing of the surface, which can be disturbed when the amount of mortar per m2 decreases.

Do not forget about an important feature of some finishing materials, which is that some coatings can dry out. The fact is that gypsum or Portland cement is present in their composition, and drying out becomes a natural reaction to a decrease in the amount of water.

Thus, the use of concrete contact is essential for the future of the entire renovation.

All the nuances of using this building mixture should be taken into account. The level of concrete contact consumption per m2 depends on the type of substrate and its porosity

It is not worth saving when using a primer, as this can negate all further finishing work.

It is interesting: DIY repair of a small kitchen in Khrushchev

Primer properties

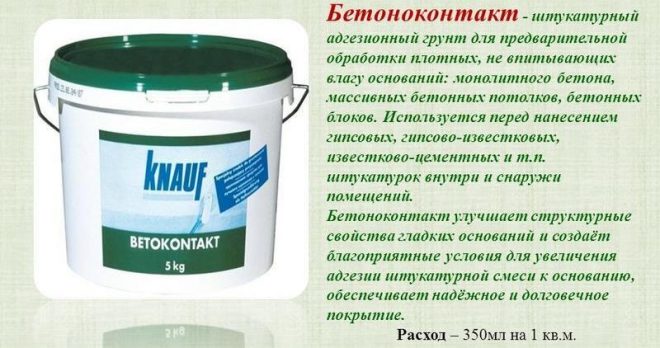

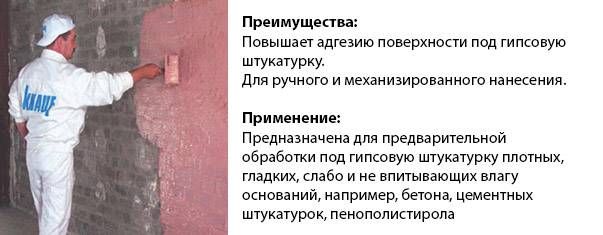

Knauf Betokontakt not only strengthens weak surfaces and increases the adhesion of smooth substrates before plastering. The ability of an acrylic mixture to clog pores and microcracks allows you to reduce the consumption of viscous (liquid) finishing materials and retain water in the leveling solutions, which is necessary for their normal setting. Thanks to this, the plaster does not exfoliate and does not crack from the rapid loss of moisture.

The performance characteristics of the Knauf mixture are also noteworthy. For example, fungicidal additives are already included in its formula, which means that additional antiseptic treatment is no longer required. Concrete contact itself does an excellent job of protecting walls from mold, reducing your repair costs. To this it is worth adding also the good vapor permeability of the created intermediate layer - it does not interfere with diffusion air exchange between the room and the street.

In some way, the disadvantage of the primer is the need to quickly start further work as soon as Betonokontakt Knauf is dry. It is impossible to postpone finishing, and even more so in parallel to carry out other activities in the room - a rough adhesive layer easily accumulates dust, deteriorating the properties of preparation.

Characteristics and consumption

Primer Betonokontakt from Knauf is produced with a mineral filler of two fractions, on which the scope of application of a particular composition depends:

- 0.6 mm - used before rough leveling;

- 0.3 mm - it is worth purchasing it to prepare plastered surfaces before puttingty.

The pink pigment introduced into the composition allows you to control the application and not miss a single area during processing.

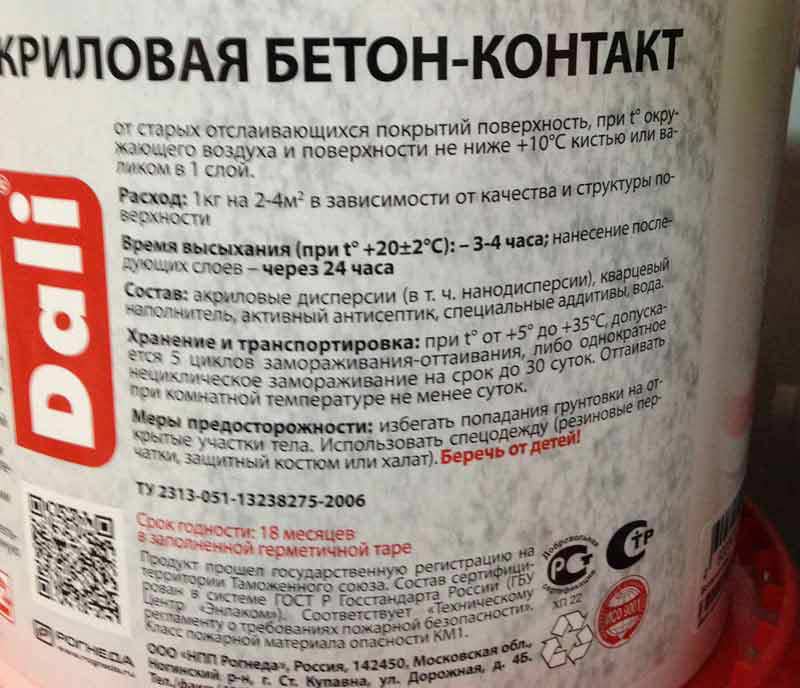

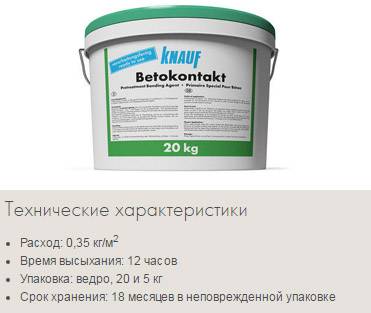

Knauf specifications:

- Acidity - neutral (pH 7.5-8.5).

- Drying time of the layer - from 3 hours depending on the humidity and temperature in the room.

- Service life - up to 80 years. Although the material is still too "young" to confirm or deny the manufacturer's claims.

- Wide temperature range of application - according to its characteristics, Betonokontakt can be called a primer for indoor and outdoor use. After drying, it retains its properties at -40 .. + 60 ° C, withstanding at least 5 freeze-thaw cycles.

- Possibility to apply in any convenient way (brush, brush, roller, mechanical spraying method).

- Absolute environmental friendliness - the use of an adhesive primer is allowed even in poorly ventilated rooms and does not require respiratory protection. There are simply no toxic solvents in its formula that can harm a person.

The consumption of the primer depends on the characteristics of the substrate: smoothness and porosity (absorbency). She will show the minimum result on tiles - 200 g / m2, on monolithic concrete of different densities, this figure will increase to 250-350 g / m2.

Knauf primer is already completely ready for application. However, before starting, it is recommended to stir it with a drill with a mixer nozzle at low speeds so that the fine-grained sand is evenly distributed throughout the volume. Work is carried out only after cleaning and dust removal of the base.In this case, the temperature of the wall to be treated must be within the range of +5 .. + 30 ° С.

Unlike many similar mixtures, here the manufacturer allows the primer to be diluted with water in order to reduce material consumption for 1 m2 and simplify painting the dispersion composition. However, for manual application, the amount of water should not exceed 50 ml / liter. Firstly, too liquid solution will not allow you to create a continuous "coat". Secondly, the sand will quickly settle at the bottom of the tank and will have to be constantly mixed.

For soft substrates, as well as for application by spraying, it is allowed to dilute the mixture with water in a ratio of 2: 1. Alternatively, experts recommend using a different technology. It allows you to reduce the consumption of Concrete Contact by 1 m2, but at the same time get a high-quality result. Processing is carried out in two layers:

Price

Recommendations for surgery

In order to do the job flawlessly on the first attempt, it is better to listen (owe?) To the advice that the masters share with the beginners.

Purchase and preparation of the composition

- Buying a quality product that has many positive reviews is the only way to protect yourself from all kinds of fakes. Checking the packaging (expiration date), quality certificate "without leaving the checkout" will give a chance to purchase a fresh and efficiently working product.

- If you are not sure what kind of primer is needed for a specific surface, then it is better to get all the information from sales consultants. They will post all the necessary information - about the manufacturer, about concrete contact: consumption, features of the types available for sale.

- After opening the package, the primer, similar in consistency to the paint, is also thoroughly mixed, for example, with a mixer-attachment. A high level of humidity (more than 75%) becomes an obstacle to the application of concrete contact. It will prevent the material from drying "properly".

The homogeneity of the mixture is the first sign of a quality product. Any lumps in a freshly opened container suggest otherwise.

Surfaces and work

Concrete contact does not like greasy stains on the paint, so problem areas are washed (wiped) with a sponge, then degreased. The use of a conventional primer will slightly reduce the consumption, since it will do its job - it will fill all the cracks in the base.

Large and small debris, dirt, irregularities or suspicious areas that threaten to crumble soon are obstacles that will have to get rid of. A prerequisite for work is a clean, but completely dry substrate.

Liquid-absorbing surfaces are sufficient reason to apply two layers of concrete contact. If the substrate has serious defects or unusual relief, then re-treatment of this problem surface is also required.

The tool is selected based on convenience, surface area. It can be a roller, brush, spray gun.

In the latter case, it is important that the size of the nozzle cannot impede the exit of the mixture components. Wide brushes are ideal

Rollers, on the contrary, increase the consumption, absorbing a large amount of the composition.

Mandatory drying of each layer, regardless of their quantity, is a rule that applies to almost all construction work. However, it is impossible to linger with fixing the finishing material on the last dried layer. Otherwise, enough dust will settle on it, and it will reduce the strength of the contact. Protection of the foundation from it is necessary. If 48 hours have passed after applying the concrete contact, then a new surface treatment will be required: this time with the usual deep penetration soil.

If not all of the concrete contact is used, then the package is stored at room temperature. Sending it for "wintering" on an open balcony is prohibited: as after freezing, the primer loses its unique properties. The shelf life of the material is from 6 to 12 months.

Properties and characteristics of concrete contact primer

Composition

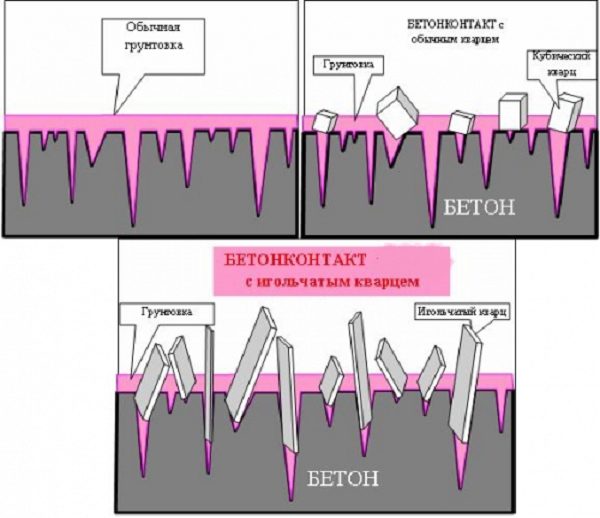

Betonokontakt is a styrene-acrylic dispersion consisting of water, processing aids, filler and pigment. The concrete contact primer becomes unique due to its special composition, in which fillers with a certain granulometry play the main role.

In cheaper domestic mixes, fillers are marble flour. And foreign manufacturers prefer to use quartz sand. However, in terms of technical characteristics, both the one and the other composition are practically indistinguishable in the quality of adhesion.

The adhesive primer is available in two versions:

- Concrete contact with 0.3 mm filler fraction;

- Soil with a fraction of 0.6 mm.

The large fraction assumes the use of primer for a rough finish, which is most often played by plaster. Fraction 0.3 mm is used for putty.

The composition may vary depending on the form of release:

- ready-made mass, packaged in buckets or barrels,

- dry - in the form of a powder mixture, which involves mixing with water.

Application

The concrete contact primer was specially created for the treatment of non-absorbent substrates, such as glass, some paintwork materials, tiles, etc. But this does not exclude its use for other purposes:

- preparation of the ceiling for painting;

- reduction of porosity and hardening of gypsum plasterboards for subsequent finishing;

- surface treatment before applying plaster and putty;

- treatment of floors before pouring self-leveling coatings or screeds, etc.

Adhesive concrete contact primer has some nuances of use. The primer can only be used at positive ambient temperatures from +5 to + 35 ° С.

Storage of open containers at negative temperatures is also unacceptable. However, this only applies to storage and use. The concrete contact primer, the characteristics of which are presented below, can be operated at temperatures from -40 to + 50 ° C.

Specifications

- The maximum size of the fraction is 0.3 mm, 0.6 mm;

- Complete drying - 3-6 hours;

- Frost resistance - at least 5 cycles;

- pH - 6.9-8.5;

- temperature for work - + 5- + 30 ° С;

- operating temperature - 40- + 60 ° С.

Consumption of concrete contact per 1 m2 ranges from 250 to 400 g, depending on the type of surface and granulometry.

Concrete contact is produced in accordance with GOST 28196-89, where it is ranked as water-dispersion compositions with acrylic copolymer.

Consumption of concrete contact: how much does it take for 1 m2?

For most people, the word "repair" is unlikely to cause at least some positive emotions. Usually this process is associated with huge expenses: effort, money and time.

One of those tasks that sometimes cause torment even for people with repair experience, albeit not professionals, is the need to increase the adhesion of certain materials. This is where the concrete contact primer will help.

What is concrete contact?

If you are not an experienced builder, you are probably hearing this word for the first time, so we should figure out what this substance is.

Concrete contact is a special type of primer that can turn absolutely any surface from perfectly smooth to as rough as necessary.

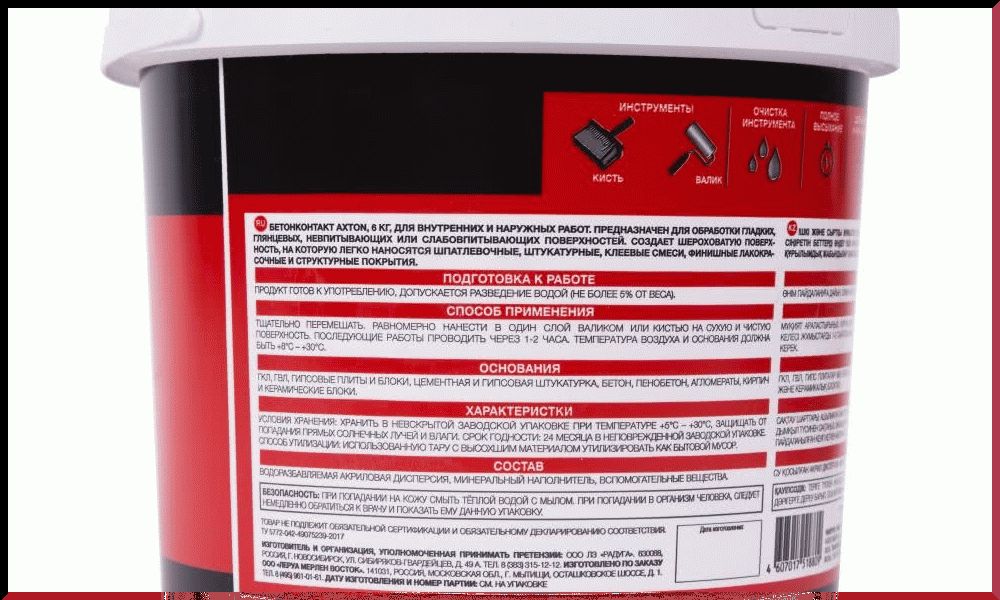

It consists of a very strong adhesive, as well as acrylic and quartz sand. Apply concrete contact for external and internal work. The main manufacturers of this material include Knauf, Prospectors, Master.

Advantages and disadvantages

This type of primer, like any material, has its pros and cons. Let's consider them in more detail.

- The main positive side of using this primer is that you don't have to remove old coatings from where you want to apply it before applying it.

- You can not use a reinforcing mesh during plastering work, and using a concrete contact on the plaster will increase its strength, since the solution penetrates into the plaster coating and holds it together.This means that after using the concrete contact you can, for example, drill or perform other similar work without fear of significant damage to the finish.

- When working with this substance, you may not use special protective equipment, because it is an environmentally friendly substance, which does not contain any solvents or other harmful substances that can harm your health.

- Walls treated with concrete contact will not stop "breathing", and mold and other types of fungi will never appear on them.

You may find it useful to know how to prime the walls under the wallpaper. Read this article.

- You cannot store this material in the cold because it will lose its properties.

- If applied incorrectly, it will not fulfill its basic properties.

Consumption rates

Despite the fact that the name of this material contains the word "concrete", concrete contact can be used on completely different surfaces.

Accordingly, the rate of its consumption will be completely different. It depends, first of all, on the porosity of the surface on which you apply it.

And although the simplest and most reliable way to determine the rate of consumption of concrete contact is simply to apply it to a part of the desired surface, an area of one square meter, let's still consider the approximate rate of consumption of this material.

- On surfaces with high porosity, such as concrete slabs, bricks or special porous stones, you should apply 0.5 kg per m2.

- For materials with medium density, such as concrete monolith or concrete tiles, you will need 0.3 kg per 1 m2.

- Low-porous surfaces (ceramics, tiles) will require at least 0.15 kg of concrete contact per 1 m2.

DIY primer application

First you need to clean the surface of debris and dirt, dust and everything else. Next, you need a roller or brush.

It is necessary to carefully place the concrete contact in the container and apply it with a roller in an even thin layer on the wall. Corners and hard-to-reach places are primed with a brush.

When performing work, you need to monitor the temperature in the room. It should not be lower than +5 ° C.

Now the main thing is done and you can rest a little. You must wait until the concrete contact is completely dry

Complete drying of the concrete contact usually occurs in 5-6 hours. After this time, you can proceed with further finishing.

It is impossible to delay with the continuation of finishing work, because after more than two days the surface will dry out and become dirty.

Now that you know about this wonderful type of primer, your renovation will be easy and enjoyable.

Video review of concrete contact primer.

DIY primer application

First you need to clean the surface of debris and dirt, dust and everything else. Next, you need a roller or brush.

It is necessary to carefully place the concrete contact in the container and apply it with a roller in an even thin layer on the wall. Corners and hard-to-reach places are primed with a brush.

When performing work, you need to monitor the temperature in the room. It should not be lower than +5 ° C.

Now the main thing is done and you can rest a little. You must wait until the concrete contact is completely dry

This is very important, because if it is even slightly damp, it will significantly reduce the quality of adhesion.

Complete drying of the concrete contact usually occurs in 5-6 hours. After this time, you can proceed to further finishing.

It is impossible to delay with the continuation of finishing work, because after more than two days the surface will dry out and become dirty.

Now that you know about this wonderful type of primer, your renovation will be easy and enjoyable.

Video review of concrete contact primer.

Case - how to make an accurate calculation of consumption

Take KNAUF Concrete Contact as an example. Consumption figures declared by the manufacturer: 0.35-0.4 kg / 1 m 2 Let's check them in practice. Professional builders recommend applying a test coat with measurements. To do this, take exactly 1 m 2 of the surface on which the primer will be applied. Ours is a cleaned wall with old plaster. You can draw a square with chalk. For convenience, we limit it with masking tape. Take a jar with a tool (for us it is a brush). We put it on the scales. We pour enough Concrete Contact into the jar so that the total weight is 1 kg - for ease of calculation.

We apply the primer, painting the entire square with high quality without gaps. We weigh again. On the scales 620 g.

Consequently, 380 g of soil was used for 1 m 2. That is, the real consumption for this wall is 0.38 kg / m 2, that is, it corresponds to the declared one. Multiplying the resulting figure by the area of the walls in the repaired room, you can find out exactly how much concrete contact is needed.

Maybe dilute a little with water?

Concrete contact produced on the basis acrylic additives, therefore to dilute it with water to save money is completely useless and even harmful. Water will make the solution non-uniform and it will lose its properties. The price of Concrete Contact should not suggest savings, because it holds building surfaces much stronger than conventional primers, even of deep penetration. Therefore, it should not be diluted with water.

Fictitious savings will result in real financial losses. Cracking of plaster, and peeling of layers and falling off of pieces of the wall will definitely not please you. Don't risk it!

And if you spread it thinner?

If you try to reduce the consumption of Concrete Contact by applying a thinner layer, then the subsequent adhesion of the coating to the working surface will also decrease. In addition, the waterproofing properties of the layer will also deteriorate.

If there are no “unpainted” spots left on the working surface at the visual level, priming can be considered complete.

Concrete contact dries at room temperature in 2-4 hours. Do not apply primer at zero or minus temperature, as well as letting him dry in the cold. But at the same time, the finished surface can withstand five freezing cycles down to -40 0 C.

2 Overview of manufacturers and recommendations for selection

There is a fairly wide range of concrete contact primers on the market from both domestic and foreign manufacturers. Let's figure out which primer is better to choose.

Among domestic concrete contacts, we note the following manufacturers:

- Plitonite.

- "Prospectors"

- Bolars

- "Foundation".

The most popular is the concrete contact Prospectors. The composition is sold in plastic buckets with a volume of 3, 5 and 20 kg. Material consumption is 0.2-0.3 kg / m2, drying time is 2-3 hours (in the temperature range 15-25 degrees). Concrete contact Prospectors has an affordable cost, so the price of a 20 kg bucket is 1,500 rubles, a 5 kg bucket - 420 rubles.

Basite T55

Concrete contact Osnovit T55 (20 kg) has also proven itself well. In addition to concrete surfaces, this primer can be applied to brick, plaster and tile walls. This composition contains 0.6 mm expanded clay fractions, which causes its increased consumption - 0.45-0.5 kg / m2. However, the coarser expanded clay aggregate provides increased surface adhesion, which makes Osnovit more effective than Prospectors. Also, the advantage of this composition is the drying time reduced to 1.5-2 hours.

If you need a primer with antifreeze modifiers, then it is best to choose Bolars concrete contact. The mixture is supplied in buckets with a volume of 2.5, 5 and 10 kg, the price of a 10 kg bucket is 600 rubles. Technical characteristics of the primer concrete contact "Bolars":

- frost resistance - 5 cycles;

- operating temperature range - from -40 to +60;

- drying time - 10 hours;

- consumption - 0.25-0.3 kg / m2.

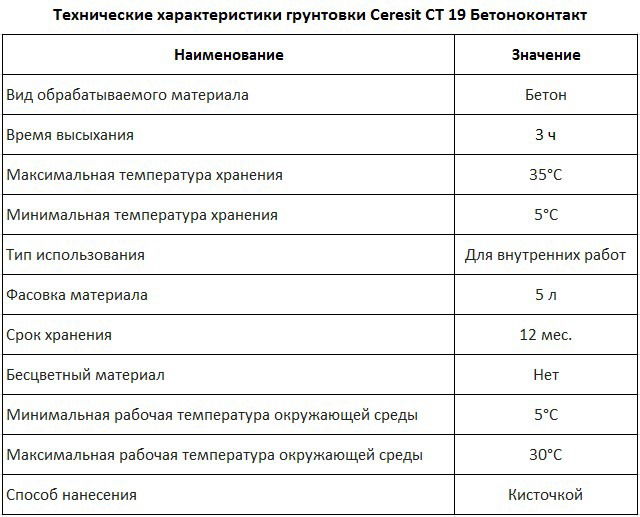

Ceresit CT19

Popular concrete contacts from foreign manufacturers are the compositions of the companies Glims, Ceresit, Feidal.In the case of an unlimited budget, it is worth using Ceresit CT19 - this is the highest quality mixture, the cost of which is 1200 rubles for a 15 kg bucket. Ceresit CT19 has a consumption of 0.5 kg / m3, this primer is used as an adhesive layer for the subsequent application of plasters, putty, adhesives and paints.

One of the most affordable imported concrete contacts is Glims (price 850 rubles for 15 kg). It is a reliable primer that provides adhesion of 0.7 MPa, its only drawback is the long drying time - 24 hours from the moment of application.

Feidal concrete contact

Concrete contact Feidal is a mixture of German production, a distinctive feature of which is the absence of solvents in the composition. This increases the drying time of the primer, however, its final strength becomes significantly higher. Material consumption is 0.3-0.35 kg / m2. Feidal is available in 4, 7, 14 and 20 kg buckets. The cost of a 20-kilogram bucket is 1,500 rubles.

Is it possible to save well?

No. This is the expert opinion of the manufacturers. They argue that a strong (sometimes even small) dilution of the composition will significantly reduce the adhesion properties of the concrete contact, which means that there is a possibility that it will not be able to stay on the surface. In addition, too liquid consistency will not ensure the quality of the coating: water will be absorbed or evaporated instantly, and this speed will prevent reliable adhesion.

A possible result of such actions is the formation of cracks. In this case, the whole process will have to be repeated, which means that material overruns are inevitable. Too watery mixture threatens with an invisible drawback, which will "backfire" in the future: the waterproofing characteristics of the base will be insufficient. The first potential consequence is the appearance of mold, but there may be others. Since the concrete contact does not differ in some unaffordable, astronomical price, due to the small benefit, it is simply unreasonable to meet with possible problems.

Advantages and disadvantages

The almost “magic” material has more of the first, but there are also some disadvantages.

First you need to list the merits. These include:

- Versatility. The mixture does not require tedious and thorough surface preparation prior to application. The only conditions are their smoothness, the inability to excessively absorb moisture.

- High strength. Any construction work is not afraid of the dried layer of concrete contact. Cracks in it will not appear even when drilling.

- The ability to make porous surfaces maximally protected from moisture. This applies to gypsum, wood, brick and foam, aerated concrete.

- Absolute insensitivity of the dried material to significant temperature changes. However, it can be applied if it is above + 5 ° outside.

- Environmental friendliness. There are no toxic substances in the adhesive composition that would make the primer unsuitable for interior work.

- High drying speed. A few hours after surface treatment, you can proceed to further finishing work.

- Durability of the layer. Manufacturers claim that the primer does not lose its qualities for 80 years.

- Complete absence of fear of ultraviolet radiation and fire safety.

- Water vapor permeability due to breathable polymers.

This list can include the unnecessary gauze bandage, which was previously used to fix "recalcitrant" plaster, and the ease of work for beginners: spreading pink "sour cream" on the surface (but not on the ceiling) is quite simple.

The disadvantages of concrete contact are still relative. It:

- fear of dust, it requires mandatory preliminary dedusting of surfaces;

- the need for constant stirring due to the fact that heavy ingredients "strive" to settle to the bottom.

As you can see, the advantages prevail over the disadvantages, which can not be considered as such at all.Many positive qualities make concrete contact a truly unique material that guarantees convenience, speed of work and reliability of finishing.

Recommendations

- When buying, always choose a product that specialists and ordinary buyers who have done repairs at home speak positively about. Cunning and cunning sellers can sell expired material or even a fake, you need to protect yourself from such a mistake.

- If you are not sure that this particular soil is suitable for the surface, use probes to check or check with the store's consultant for information. He will tell you which company is better to prefer, how to use it, for which surface it is suitable.

Before starting work, do not forget to get rid of the required space of excessive dust, large, small debris, and dirt. Use a vacuum cleaner for large debris (if it is the floor).

- Be sure to wait until everything is soaked and dry, and only then apply another layer or a fine finish in the form of tiles, for example.

- It is better to apply the finishing option immediately after the primer is dry. If this is neglected, then a sufficient amount of dust can accumulate, which subsequently will only lead to a decrease in strength. Therefore, cover the work area with protective material.

- Keep the rest of the primer in a positive temperature. If the concrete contact freezes, it will lose all its properties and its further use is useless.

- Try to purchase concrete contact from well-known and proven brands that do not seek to deceive, but value their reputation.

Dense, poorly absorbent substrates Drywall

Surface

Ceilings Walls

Specifications

Consumption 0.2-0.3 kg per 1 sq.... m Surface readiness for subsequent coating 2-3 hours (at temperatures from +15 to + 25 ° C) Mass fraction of latex by dry residue, not less than 60% Shelf life from the date of manufacture 12 months

Appointment

It is used for interior finishing work in all types of buildings and structures (A-B), including rooms where a wet disinfection mode is provided, except for surfaces that have direct contact with drinking water and food. It is intended for preliminary treatment of dense, poorly absorbing substrates (monolithic concrete, concrete blocks, concrete ceilings) before applying gypsum, gypsum-lime, plasters. As an adhesion primer before laying new ceramic tiles to the old one with using tile adhesive (tile adhesives "Prospectors"). As a primer before plastering old tiles with gypsum plaster. For pretreatment of gypsum board before facing with ceramic tiles.

Attention

The primer has a high viscosity, so it completely fills the pores of the base, almost without penetrating the very structure of the surface

Therefore, it is very important to thoroughly dust the surface before priming.

Safety precautions for use Surface preparation The substrate must be dry, solid, free of substances such as dust, dirt, organic contamination (formwork separating agents), loose elements.

The purpose of the primer is to prepare a surface for further finishing, such as painting. The primer allows you to level the surface, eliminate microcracks, and also improve the adhesion of the base to the decorative material.

Betonkontakt is no exception. This primer is suitable for concrete surfaces, but can also be used for brick or drywall. The use of concrete contact allows you to simplify the work with decorative finishing materials, reduce their consumption and increase the durability of the coating.

Consumption of Concrete Contact per 1 m2 depends on the characteristics of the surface on which the primer is used. At the same time, the main role is played not so much by its type (various grades of concrete, brick), but by its porosity.It is this factor that affects the rate of absorption of the primer, and, accordingly, its consumption.

Traditionally, the following surface options are distinguished

- No pores or low porosity. These include: ceramic tiles, painted walls, rubbed concrete. On such surfaces, the consumption of Concrete Contact per 1 m2 will be minimal: 0.15 - 0.25 kg. The primer is easy to apply in an even layer, and, as a rule, does not require additional leveling.

- Surfaces with medium porosity These are high-grade concrete, monolithic structures, self-leveling cement floors, facing bricks or concrete tiles. Here the consumption will be higher, and will amount to 0.2 - 0.35 kg per square meter.

- Porous surfaces. This type includes sand concrete, wall bricks and similar materials. Consumption of Concrete contact per 1 m2 is 0.3 - 0.5 kg, which is explained by the need to fill the pores. It should also be borne in mind that if the surface is highly porous, then it must be treated with special impregnations, otherwise the coating with a primer will not lead to the desired results. In addition, the absorption of the primer into the pores leads to unevenness of the layer, which requires regular trimming.

The best practical way to determine the consumption of a concrete contact is to test a surface area. To do this, you can stick masking tape on the wall, forming a square meter by meter. You will need a strictly defined amount of primer, approximately 0.5 - 1 kg (cooked). It is necessary to apply a primer until a smooth, uniform surface is obtained, without streaks and gaps.

When the square is finished, weigh the remainder of the primer and subtract it from the starting weight. The result is the consumption of Betonkontakt per 1 m2.

Is it possible to reduce material consumption?

In theory, yes, but you shouldn't. The cost of Concrete Contact is not so high to save a lot. But the lack of a primer can lead to a number of negative consequences: cracking of the decorative coating, delamination and deterioration of waterproofing properties.

Thus, the first priority is to ensure a high-quality application of the primer, not to save it.

.