Concrete composition M300

The classic set of components for the production of heavy concrete of any brand includes the following materials:

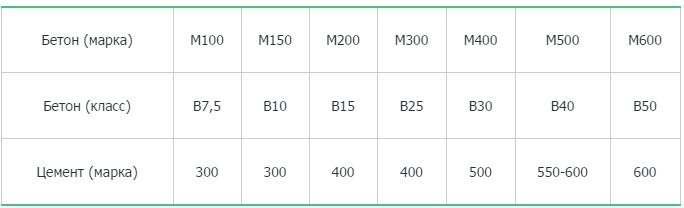

- Portland cement. At the same time, in accordance with the requirements of SNiP 5.01.23-83 for the preparation of building material, Portland cement of the CEM I 32.5N PC (M400) brand or the CEM I 42.5N PC (M500) brand can be used. Depending on the "percentage" of concrete tempering strength (natural strength, strength 70% or less, design strength 80 to 100%), this Normative Document identifies cement M400 or M500 as "recommended" or "acceptable".

- Crushed stone. It is allowed to use granite, limestone and gravel filler. Depending on the type of crushed stone, the concrete class is M300 B22.5 or B25.

- Sand. It is allowed to use a quarry, river or expanded clay product.

- Water. In accordance with the requirements of GOST 23732-2011, water for the production of concrete should not contain chemical impurities that can affect the setting of cement, the rate of hardening, strength, frost resistance and water resistance of the material. It is not allowed to use sewage, swamp and peat waters.

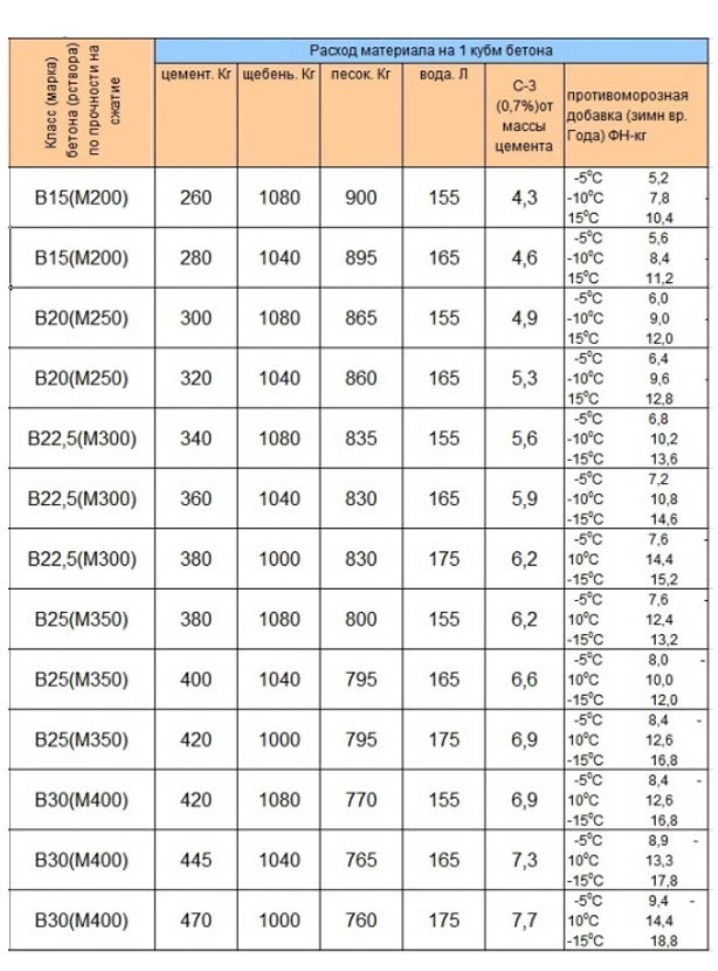

To increase frost resistance, workability, water resistance and frost resistance, as well as for the possibility of construction in conditions of negative ambient temperatures, special additives and a plasticizer are introduced into the concrete composition.

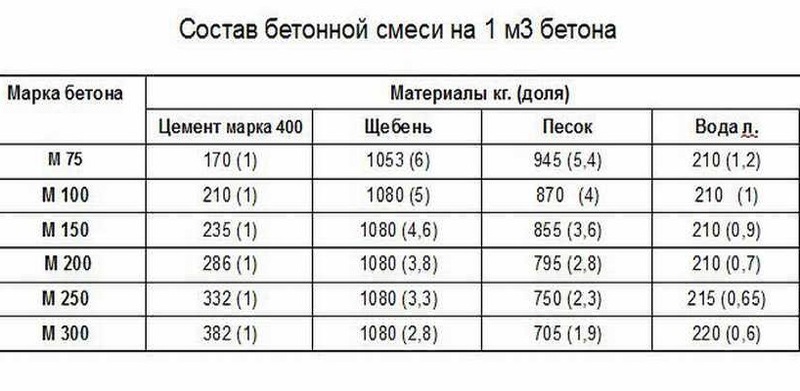

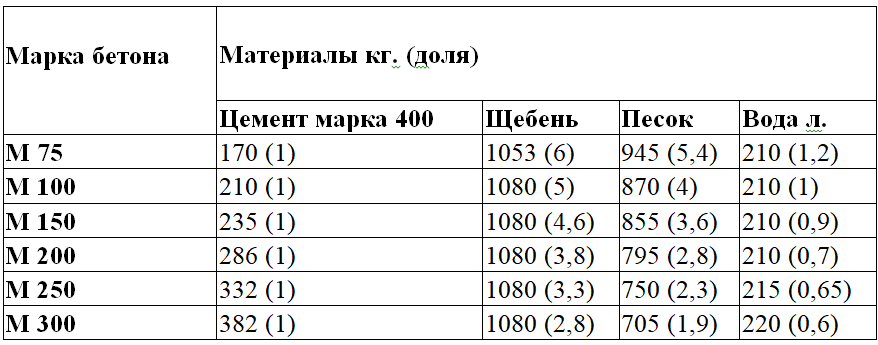

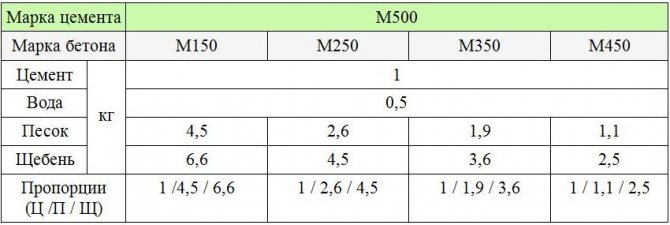

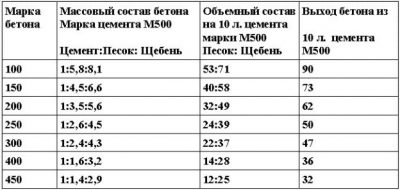

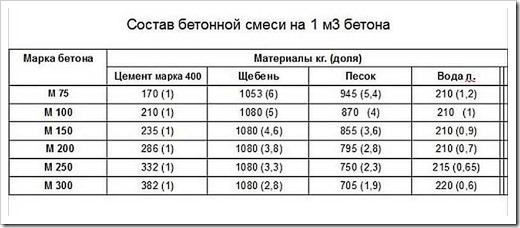

Proportions and composition of concrete m300 table for the preparation of 1 m3 of material

| Cement grade | Number of parts of cement / cement consumption in kg per 1 m3 of concrete | Number of crushed stone parts / crushed stone consumption in kg per 1 m3 of concrete | Number of parts of sand / consumption of sand in kg per 1 m3 of concrete | Number of water parts / water consumption in liters per 1 m3 of concrete |

| CEM I 32.5N PC (M400) | 1/335 | 3,3/1105 | 2/670 | 0,6/190 |

| CEM I 42.5N PC (M500) | 1/325 | 3,5/1105 | 1,8/580 | 0,7/230 |

The proportions of 1 cube of concrete M300 presented in the table may differ slightly up or down, depending on the accuracy of the calculations adopted in accordance with certain regulatory documents.

Concrete: characteristics, application

| Brand | Class | Strength, kgf / cm² | Application |

| M100 | B7.5 | 98 | Leveling floors, lightweight foundations |

| M200 | B15 | 196 | Blind areas, screeds, concrete paths |

| M300 | B22.5 | 294 | The most popular brand in individual construction: used for piles, beams, monolithic walls, slab and strip foundations, lightly loaded floors, stairs, screeds |

| M400 | B30 | 393 | Bridges, hydraulic structures, pool bowls |

| M500 | B40 | 524 | Dams, dams, underground storage facilities, runways |

The main characteristics of concrete are its frost resistance and water resistance.

M300, possessing these qualities, is also highly resistant to abrasion, and, unlike higher brands, does not set so quickly, which allows it to be transported over long distances (an important quality). All these properties of M300, together with an ideal price-performance ratio, have made this brand the most consumed concrete product on the market.

Diagram of concrete hardening processes.

In individual construction for the preparation of several cubes of M300 concrete, you can make an independent calculation of its components.

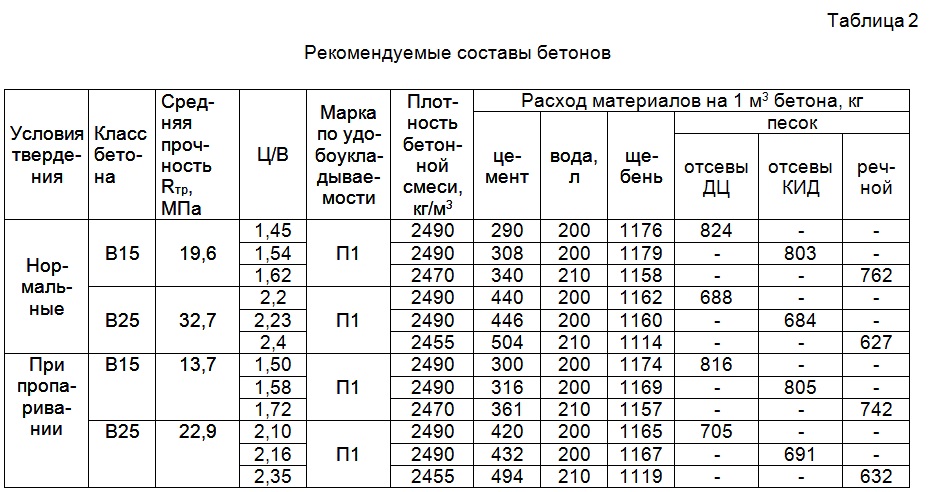

Let's start by choosing a brand of cement. To do this, we use the Bolomey-Skramtaev formula: Rb = A x Rts x (C / V - 0.5), where Rb is the strength of concrete; A - coefficient taking into account the quality of aggregates (0.4 - 0.6); Rts - cement grade; C / W - cement-water ratio.

We take the recommended C / V ratio from the table (for example, for concrete M300 and cement M400 we get: C / V = 1 / 0.5 = 2):

Table 1

| Cement, brand | Concrete, brand | |||

| 200 | 300 | 400 | ||

| 300 | 0.56 | 0.40 | – | |

| 400 | 0.64 | 0.50 | 0.41 | |

| 500 | 0.72 | 0.60 | 0.45 |

For cement M400 we get: 0.5 x 400 x (2 - 0.5) = 200 x 1.5 = 300 (close to the tabular value of 294).

For M500 we get: 0.5 x 500 x (1.67 - 0.5) = 250 x 1.17 = 292.5

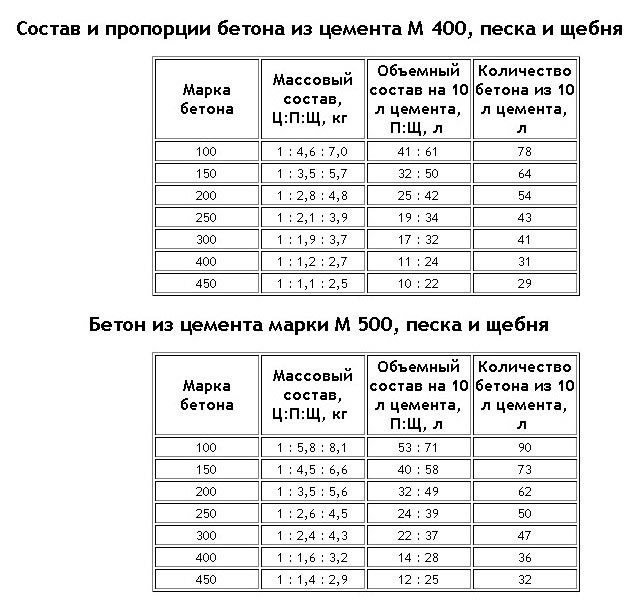

When choosing other brands, the C / W ratio significantly changes, which negatively affects the optimal concrete density, therefore, we will consider the proportions of sand and crushed stone for cement brands M400 and M500.

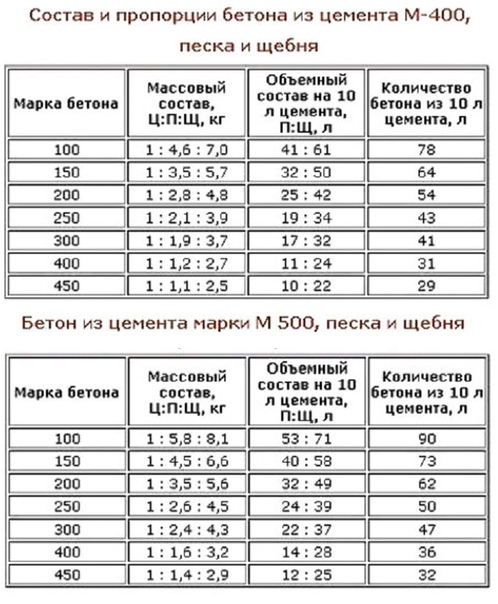

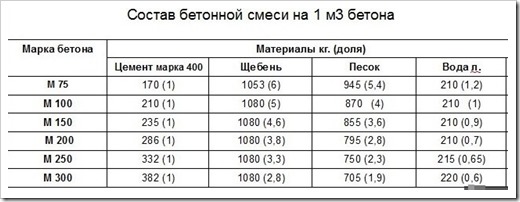

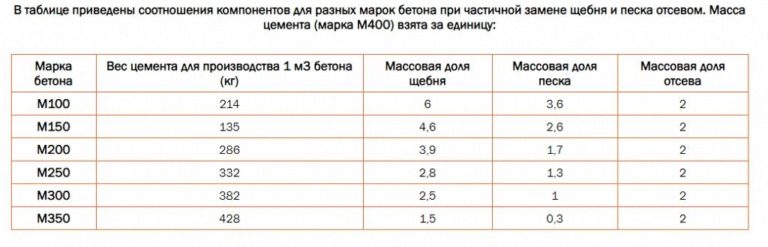

There are standard proportions of concrete M300 specified in the collection of documents "SNiP 82-02095". In particular, the following cement consumption rates are indicated:

table 2

| Cement | Consumption in kg / m³ for concrete M300 |

| M500 | 510 |

| M400 | 600 |

In the same document, we find the ratio of sand and crushed stone:

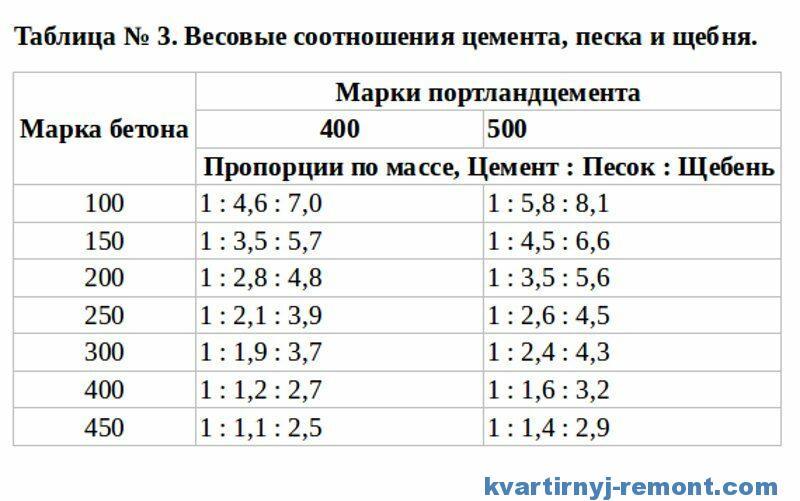

Table 3 (for concrete M300)

| Cement М400 | Cement М500 |

| Composition, C: P: U | Composition, C: P: U |

| 1 : 1,9 : 3,7 | 1 : 2,4 : 4,3 |

Now it is easy to calculate the number of components for the required volume of concrete solution.

Suppose that for the foundation for the garage in the country it is necessary to prepare 6.4 cubic meters of M300 concrete from M400 cement.

For one cube of solution, you need to take:

- cement (tab. 2) - 600 kg;

- sand (tab. 3) - 1.9 x 600 = 1140 kg;

- crushed stone (tab. 3) - 3.7 x 600 = 2220 kg;

- water (tab. 1) - 300 (15 buckets of 20 liters).

To get the total amount of material, multiply each result obtained by 6.4. The calculation is over. Regulations from the Internet and a calculator - these are all the tools for calculating the mixture.

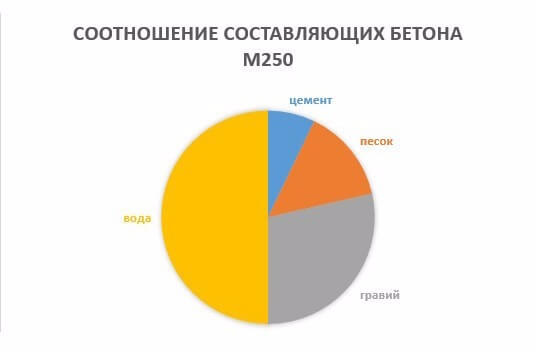

Composition and proportions of concrete М250

The main points on the proportions and parameters of this type of solution are contained in GOST R 7473. They must be strictly observed, otherwise the finished product will not have the required qualities, and will cope poorly with its tasks.

The composition of the brand is largely traditional for all types of solutions:

Cement - the most commonly used cement brands are M400 and M500. If you are going to make concrete yourself, be sure to check the expiration dates of the cement. If it is expired, it will make the solution of poor quality.

Aggregate - fine sand of 1 and 2 classes is used

It is very important to clean it during use. The sand should not contain any dirt, clay and other unnecessary impurities

Otherwise, the quality of the solution will deteriorate.

Coarse aggregate - used as granite / limestone crushed stone or gravel... The latter option is distinguished by good qualities and an acceptable price.

Water is used clean, without any additives or impurities.

Additives are used to improve the quality of the material. They can increase frost and moisture resistance, resistance to external influences, etc.

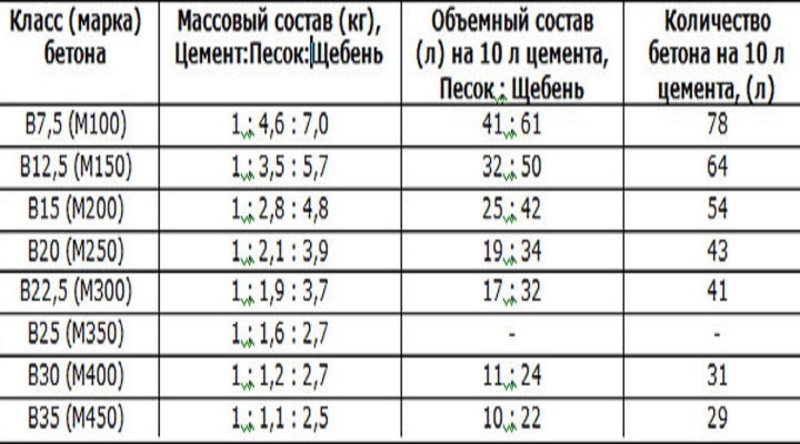

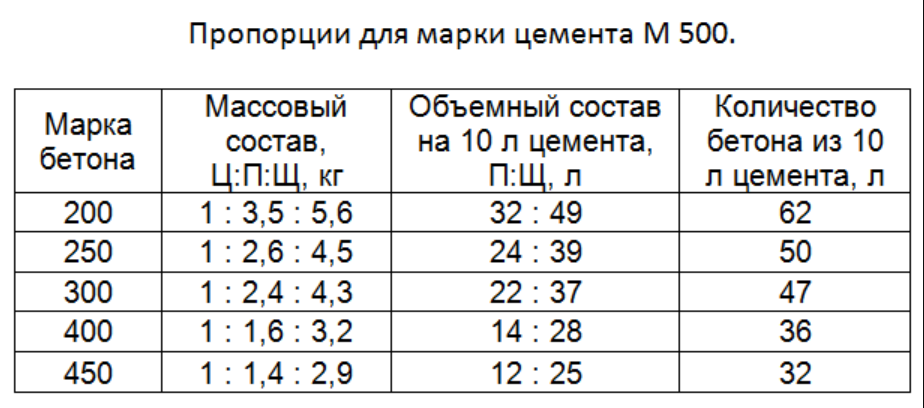

Proportions for concrete production:

- 1 tsp cement;

- 2.1 hours of sand;

- 3.9 hours of crushed stone.

For example, let's look at a recipe for a solution. Here's how many ingredients are required for one cubic meter of concrete:

- 330 kg of cement;

- 740 kg of sand;

- 140 liters of water;

- 1100 kg of crushed stone.

If you allow a deviation in these parameters, the class of concrete will deteriorate, it may lose some of its properties. This is another reason why the calculation cannot be based on the maximum performance of concrete. Even with a slight deviation in the proportions or mass of the components, its parameters decrease, which can negatively affect the entire structure.

General information

A characteristic feature of concrete is its composition, as well as proportions and preparation technology. It consists of cement, fine and coarse fillers, water and various additives. In addition, there are grades of concrete that do not include a large filler. There are different mixtures that are used for specific applications and also have different properties.

Designation and its decoding

The full strength of concrete structures takes place within 6 months, and in 30 days the concrete gains 70% strength. M300 is used in all structures on which a significant load is applied, therefore, one of the main indicators is its strength. The designation template MXXX does not indicate a specific brand, but is an indicator of the ultimate compression pressure.

The full strength of concrete structures takes place within 6 months, and in 30 days the concrete gains 70% strength. M300 is used in all structures on which a significant load is applied, therefore, one of the main indicators is its strength. The designation template MXXX does not indicate a specific brand, but is an indicator of the ultimate compression pressure.

In addition, there are other designation patterns, for example, FXXX and WXXX, indicating frost resistance and water resistance, respectively. The class of concretes M300 shows the totality of all grades, the ultimate strength of which is 300 kgf / sq. see Tensile strength is checked in laboratory conditions, when a force is applied to the parallel planes of a product cast from concrete in the form of a cube with a side of 150 mm. The strength of the concrete grade is related to its class. These indicators should be chosen for the construction and calculation of the finished structure at the maximum load that it can withstand.

M300 corresponds to class B22.5 with a coefficient of variability (CV), which is 13.5%.It shows the homogeneity of the mixture from which any grade of concrete is made. When this coefficient changes, the concrete grade will also change, that is, if its value is low, the grade increases and vice versa. If the concrete is M300, then with different values of the coefficient its class will change:

- At Kv = 5%, the class is equal to B25.

- With Kv = 13.5% - B22.5.

- At Kv = 18% - B15.

Main characteristics

Concrete is classified into grades, and this distribution is primarily related to the parameters of strength (B), density (D), water resistance (W), frost resistance (F) and mobility (P). One of the best options for most construction work is concrete M300, the characteristics of which are as follows:

- Strength: B22.5 with an indicator of 295 kg / sq. cm.

- Specific gravity of concrete M300: 1800-2500 kg / cu. m.

- Waterproof: W6-W8.

- Frost resistance: F200-F300.

- Mobility: P2-P4.

The strength index is the main characteristic and shows the maximum effect of forces in compression, at which the structure is destroyed. The specific gravity or density of M300 concrete depends on the type of coarse filler included in its composition. When using limestone, the D index is about 1800 kg / m3. m., and when using harder rocks (crushed granite, granodrite, and so on), it can reach a value of 2500 kg / cubic meter. m. Due to its high density, this type is classified as heavy. The density index depends on the presence of violations in the manufacturing technology and air cavities.

Water tightness (WXX) is a value indicating the pressure of water in MPa to pass through 0.15 m of concrete. For concrete grade M300, this indicator is equal to W5-W6, at a pressure of 0.5-0.6 MPa (approximately corresponding to 5-6 atmospheres), it does not allow water to pass at all. With the addition of hydrophobic cement, additives and thorough compaction of the mortar, an increase in the waterproof index is possible.

Frost resistance is indicated as an FXXX template and shows the number of defrost-freeze cycles without loss of strength. This characteristic can be increased in several ways:

- The use of additives that prevent the formation of air bubbles.

- Removing air from the concrete mix with vibrators, as well as with the help of various compactors.

- Decrease in the amount of water (impairs mobility).

- Use of solid aggregates instead of crushed limestone.

Application in construction

Since M300 has good indicators of strength, frost resistance, water resistance and mobility, it is widely used in construction. In addition, its main indicators can be adjusted by changing the components that make up the concrete mix. It is advisable to use it for the following works:

- Construction of sites, roads and curbs.

- Installation of walls and various supports.

- Construction of stairs, landings and foundation pouring in multi-storey buildings.

- Manufacturing of reinforced concrete products and fences.

- Production of sewer pipes that are constantly exposed to moisture.

- Construction of objects that are affected by constant temperature drops.

Concrete preparation

For large volumes of work, it is better to order concrete from the factory. Making a large amount of mortar by hand or even using concrete mixers is a difficult task, and laying in portions requires additional effort to ensure that the layers adhere well. However, you can also make concrete by hand. In this case, there are two sequences of actions:

- First, concrete and sand are mixed dry. It is mixed until the color is uniform. Then crushed stone is poured, everything is mixed again, and water is added last.

- First, water is poured, cement is poured into it. When everything is mixed, add sand and then coarse aggregate.

The order of adding components for concrete during mixing can be different

In the first option, there is a possibility that with manual mixing, an unmixed composition will remain at the bottom, near the walls of the container, which will lead to a decrease in the strength of the concrete.The way out is to mix everything well and thoroughly. But you cannot spend too much time on this: the solution will begin to set.

The second option has its disadvantages: it sometimes takes a lot of time to obtain a homogeneous cement milk (a mixture of water and cement). As a result, it is simply not enough for the formation of bonds with the backfill: the cement "seizes" and the strength of the concrete also decreases.

All this is not so critical when using concrete mixers, but also imperfect. There is another complication here. Concrete is usually delivered to the construction site in trolleys. The whole volume does not fit into one, and the remainder is left to spin in the concrete mixer. This is better than leaving it just standing, but if you stir it for too long, the mortar may begin to exfoliate, the result is that the strength of the concrete will be lower. Exit - two carts and two people who will take them. The filling method - the first or the second - choose yourself.

For small volumes, concrete can be mixed by hand

So after all, how to prepare concrete. The choice is yours. If the volumes are small, you can knead by hand. Just do it carefully. For pouring the foundation, it is better to order a mixer after all, but you can also handle it with a concrete mixer (or two, depending on the volume). And to solve problems with the heterogeneity of the mix (although it is better that it be good), process the concrete to be placed with a vibrator. Most of the problems will go away.

Next, we will talk about the requirements for concrete components, their sizes and qualities.