Areas of use

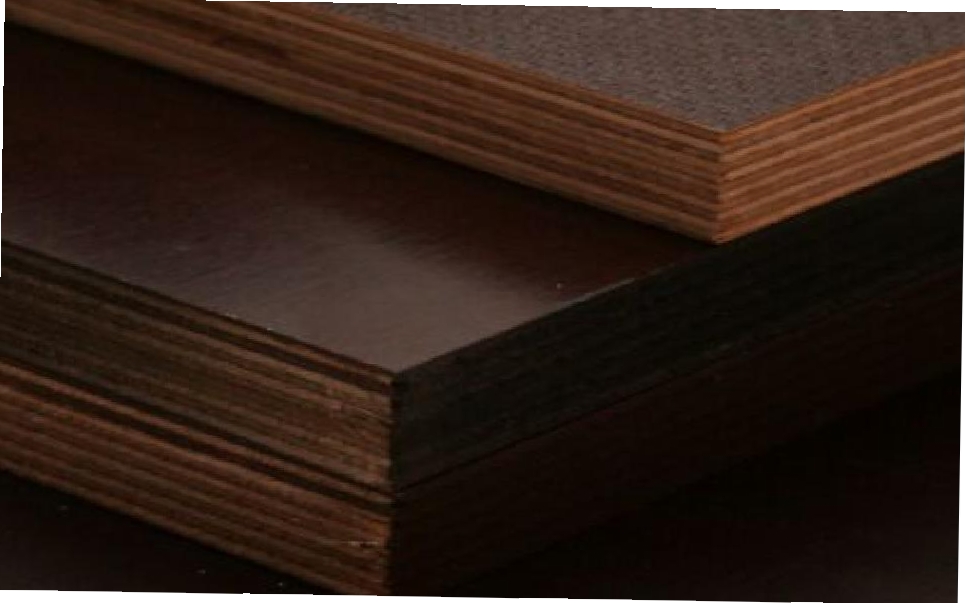

As mentioned above, modern bakelite plywood sheets are used in a wide variety of applications. That is why they are so popular and in demand. Let us consider in more detail in which areas you can not do without high-quality and wear-resistant bakelite plywood.

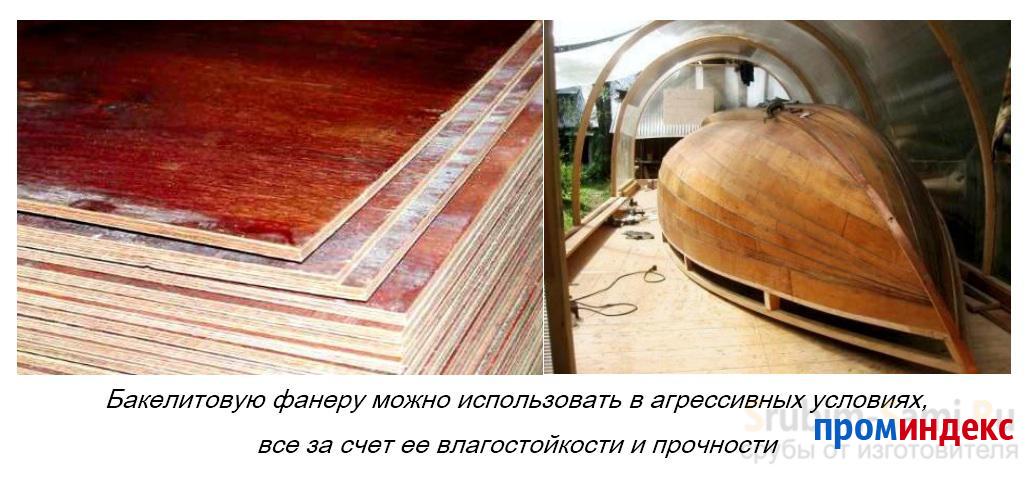

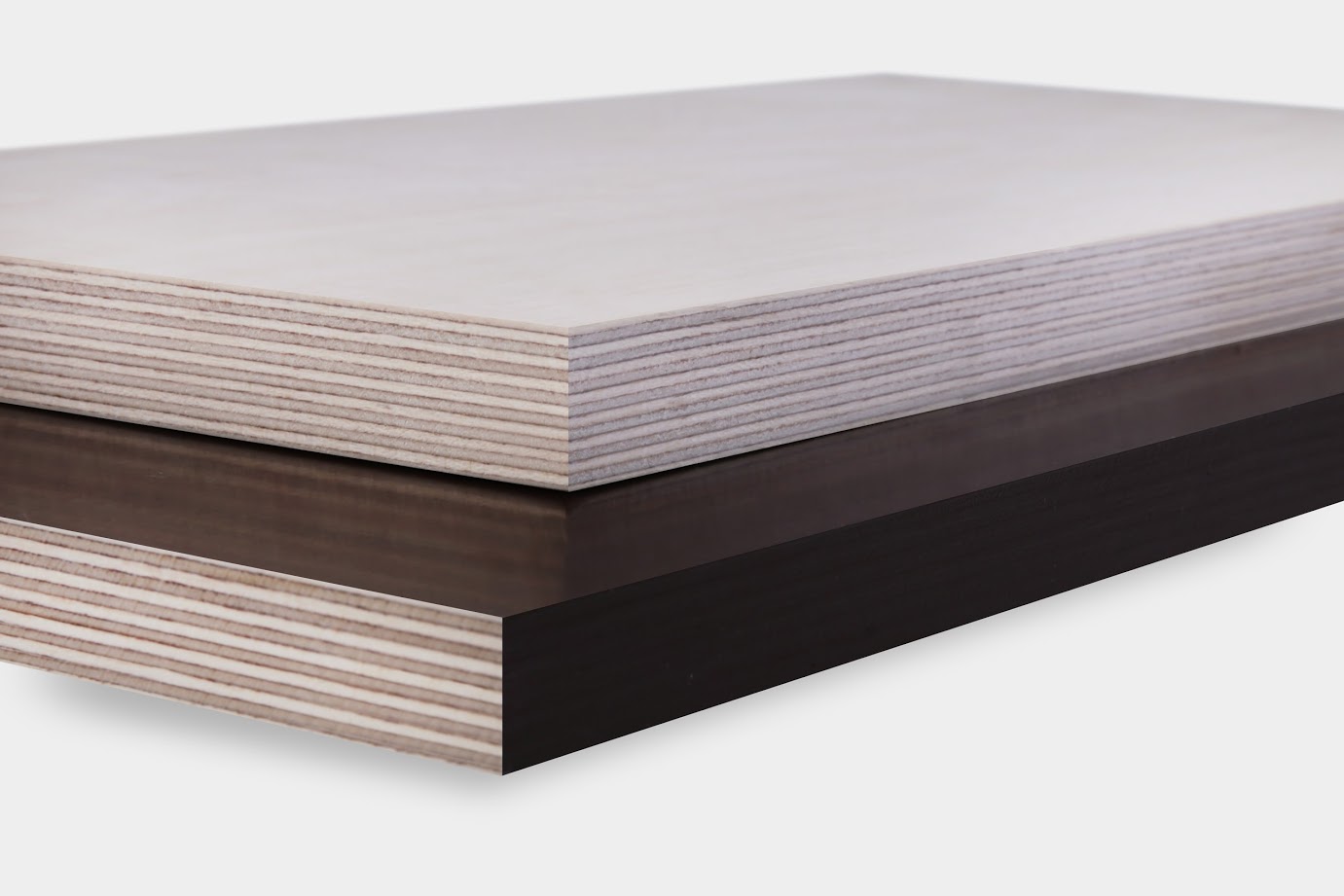

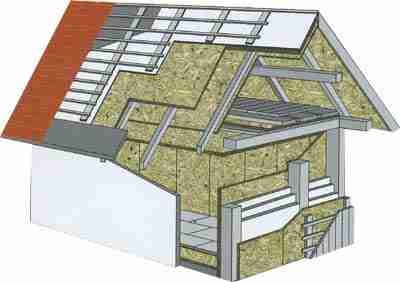

- In the construction industry. In most cases, the material in question is used in various kinds of construction processes. Often, it is from bakelite plywood that whole floating docks, locks and water locks are built. It is also possible to make a very strong formwork from the sheets, designed for repeated use. Bakelite plywood is used to make excellent supporting structures, awnings, partitions and other small or large architectural structures. Often marine plywood in construction work is combined with other types of this material.

- Automotive construction. Another area in which the material in question is used with enviable frequency. Very strong and durable floors are made of bakelite plywood in various vehicles (equipment can have different purposes). Few people know, but even vans for cars are made of such elements.

- Shipbuilding. Bakelite plywood has proven itself very well in shipbuilding. It is very often used for high-quality plating of decks, for different parts of boats. Reliable shipping containers are made of sheet material.

- Mechanical engineering. Bakelite plywood is widely used in modern mechanical engineering. Very strong and reliable components of various designs and mechanisms are obtained from it.

- Marine plywood is often used in the furniture industry. Very strong and durable structures that do not require special care are made from it.

The material considered is used not only for the manufacture of serious structures, such as boats, poles or supports, but also for the most ordinary interior and exterior facing of houses.

See below for an overview of laminated plywood.

Advantages and disadvantages

Bakelite composite has many advantages over other building and finishing materials, combining the properties of natural wood and high-strength plastic:

- versatility: due to its high strength, water resistance and fire resistance, it can be used in many industries;

- during operation, it is not damaged by harmful chemical compounds: alkalis, fuels and lubricants, kerosene, alcohol;

- environmental safety: does not emit toxic impurities into the air, can be used in the interior decoration of residential premises;

- aesthetics, plywood does not require additional finishing, except in special cases;

- much lighter than steel and other materials similar in strength and wear resistance.

There are few disadvantages to bakelite plywood, and they are all relative. These include:

- high specific gravity compared to other composites containing wood. Furniture and furnishings from it will put pressure on the supports - this must be taken into account when using;

- the high price is the main drawback. The cost of one thin sheet of grade FBS-1 is at least 2300 rubles, FBS - from 3500 rubles and more. Such types of work with its use, such as disposable formwork, become simply impractical.

Unique material: where to apply

Due to its technical features of production, bakelite moisture-resistant plywood is used in the manufacture of small boats, in the construction of aircraft and cars, for flooring. It is ideal for formwork fabrication.

Bakelite plywood Petrovich is suitable for manufacturing billboards, information stands. Sports equipment is also made from this durable material. Due to the unique combination of wood properties and increased strength, plywood can be used in interior decoration. "

Room decoration: how to apply the material

In construction, bakelite plywood is used for both internal and external work. A technological feature is the need to fix sheets to plastered surfaces, concrete structures using a special material such as definol mastic.

To increase the term of use, it can be impregnated with a special coating or impregnation. Film faced bakelite plywood is ideal for interior decoration. All joints and cracks on the walls must be pre-primed. The joints are closed with bars.

Moisture Resistant Bakelite Plywood

|

The Panera Agro company is a supplier of moisture-resistant bakelite plywood of Russian production. We work with both organizations and with individuals. Payment can be accepted through a bank, in cash, by credit card, WebMoney, Yandex.Money. Possible delivery by road. Waterproof bakelite plywood FBV, FBS, FBS-1 and FBS-1A GOST for shipbuilding, automotive, construction and operation in water and aggressive environments. |

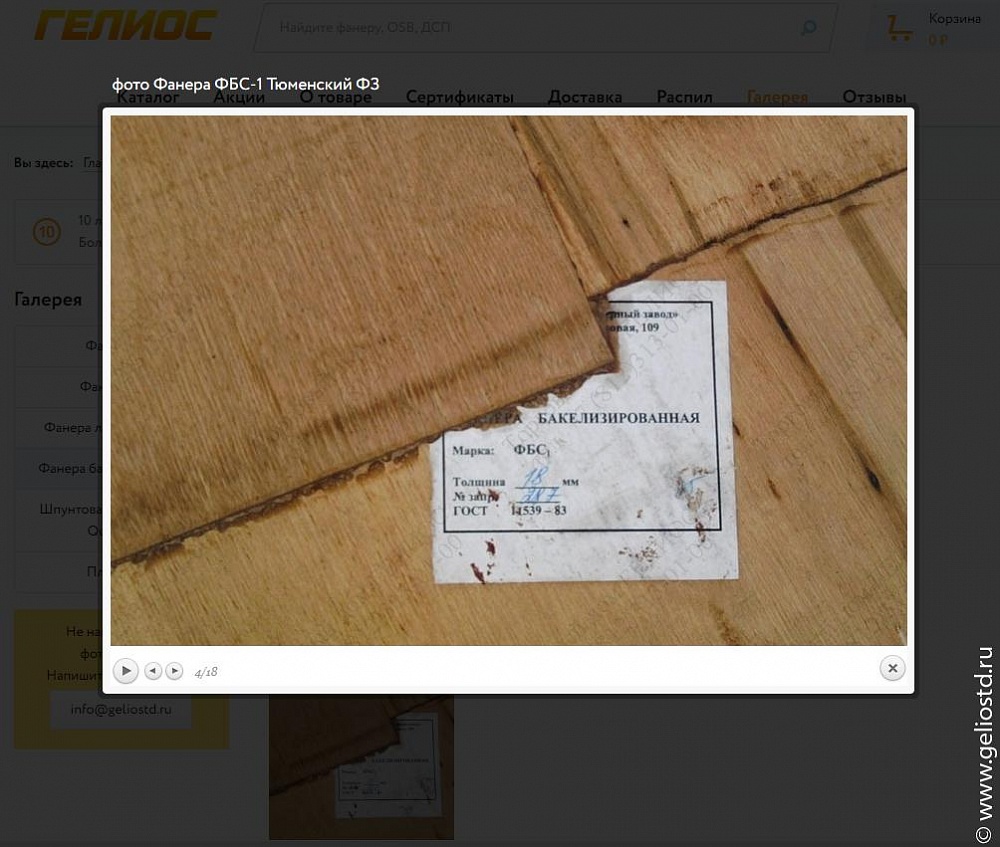

Bakelized plywood FBS 1 GOST 11539-83, size - 1525x1525 mm Buy

| Thickness | Thickness tolerance | Volume of 1 sheet | Number of sheets in 1 m3 | Number of sheets in 1 pack | Bakelite plywood price per sheet with VAT (rub.) |

| mm | mm | m 3 | PCS | PCS | 1 sheet |

| 6 | `+/-1,0 | 53,3 | 70 | 1 115 | |

| 7 | `+/-1,0 | 45,7 | 60 | 1 617 | |

| 10 | `+/-1,5 | 0,024 | 32 | 42 | 2 099 |

| 12 | `+/-1,5 | 0,028 | 36 | 36 | 2 481 |

| 15 | `+/-2,5 | 0,035 | 29 | 29 | 2 105 |

| 18 | `+/-3,0 | 0,042 | 24 | 24 | 3 091 |

| 20 | `+/-3,0 | 0,047 | 21 | 21 | 4 400 |

| 21 | `+/-3,0 | 0,049 | 20 | 20 | 4 720 |

| 25 | `+/-3,5 | 0,059 | 17 | 17 | 5 697 |

| 27 | `+/-3,5 | 0,063 | 16 | 16 | 6 130 |

| 30 | `+/-4,0 | 0,070 | 14 | 14 | 6 980 |

| Bakelite plywood dimensions: sheet thickness, mm | 10 | 12 | 15 | 18 | 20 | 21 | 25 | 27 | 30 |

| Bakelite plywood sheet weight, kg | 28 | 33 | 42 | 50 | 56 | 58 | 70 | 75 | 84 |

Bakelized plywood FBV GOST 11539-83, size - 2440x1220 mm. Buy

| Thickness | Thickness tolerance | Volume of 1 sheet | Number of sheets in 1 m3; | Number of sheets in 1 pack | Volume of 1 pack | Bakelite plywood price per sheet with VAT (rub.) |

| mm | mm | m 3 | PCS | PCS | m 3 | 1 sheet |

| 7 | +/-0,8 | 0,021 | 48 | 58 | 1,208 | 1 890 |

| 10 | +/-1,5 | 0,030 | 34 | 40 | 1,190 | 2 715 |

| 12 | +/-1,5 | 0,036 | 28 | 34 | 1,214 | 3 275 |

| 15 | +/-2,0 | 0,045 | 22 | 27 | 1,205 | 3 990 |

| 18 | +/-2,0 | 0,054 | 19 | 22 | 1,179 | 4 789 |

| 21 | +/-2,0 | 0,063 | 16 | 20 | 1,250 | 5 536 |

| Bakelite plywood dimensions: sheet thickness, mm | 7 | 10 | 12 | 15 | 18 | 21 |

| Bakelite plywood sheet weight, kg | 25 | 35,72 | 42,87 | 53,57 | 64,3 | 75 |

The difference between FBS bakelite plywood and FBV bakelite plywood can be found on the "DESCRIPTION" page

Promotions and special offers of factories

You can make shipment and delivery of Buckfaners directly from the factory. The machine can be assembled at the request of the customer, any

a set of produced thicknesses.

Specialist. price for bakelite plywood FBS-1. Size 2440x1220 mm Buy

| Thickness, mm | 6 | 7 | 10 | 12 | 15 | 18 | 21 | 24 | 27 | 30 |

| Price, rub | 1831 | 2120 | 3004 | 3587 | 4438 | 5291 | 6172 | 7173 | 8070 | 8966 |

Specialist. price for bakelite plywood FBS-1. Size 2500х1250 mm Buy

| Thickness, mm | 6 | 7 | 10 | 12 | 15 | 18 | 21 | 24 | 27 | 30 |

| Price, rub | 1889 | 2190 | 3099 | 3730 | 4637 | 5555 | 6475 | 7499 | 8460 | 9395 |

Specialist. price for bakelite plywood FBV. Size 2440x1220 mm Buy

| Thickness, mm | 6 | 7 | 10 | 12 | 15 | 18 | 21 | 24 | 27 | 30 |

| Price, rub | 1648 | 1907 | 2700 | 3222 | 3982 | 4744 | 5533 | 6443 | 7248 | 8054 |

Specialist. price for bakelite plywood FBV. Size 2500х1250 mm Buy

| Thickness, mm | 6 | 7 | 10 | 12 | 15 | 18 | 21 | 24 | 27 | 30 |

| Price, rub | 1730 | 2002 | 2834 | 3382 | 4180 | 4980 | 5809 | 6764 | 7609 | 8455 |

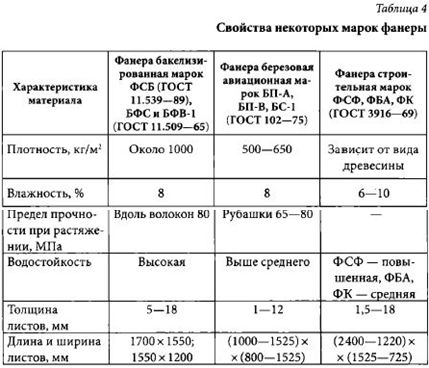

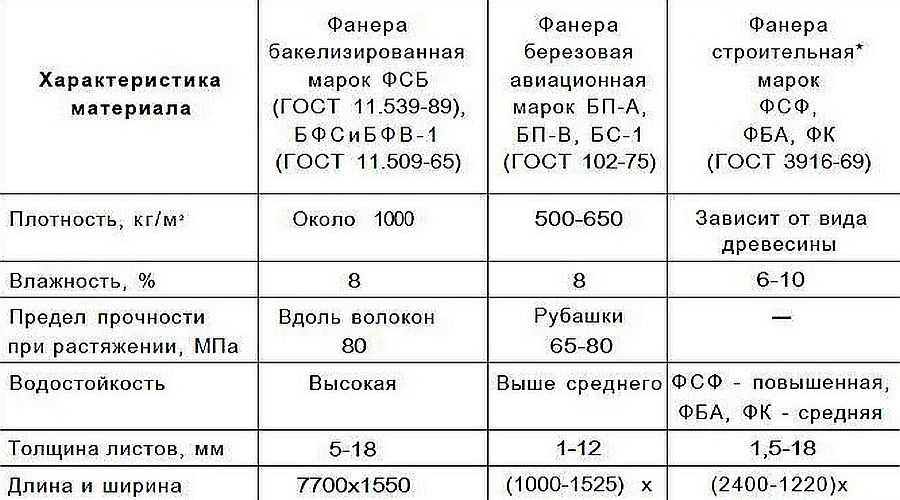

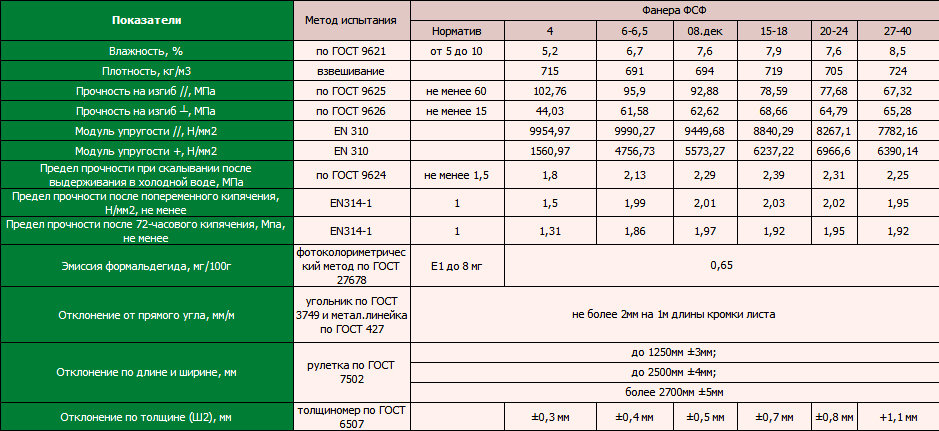

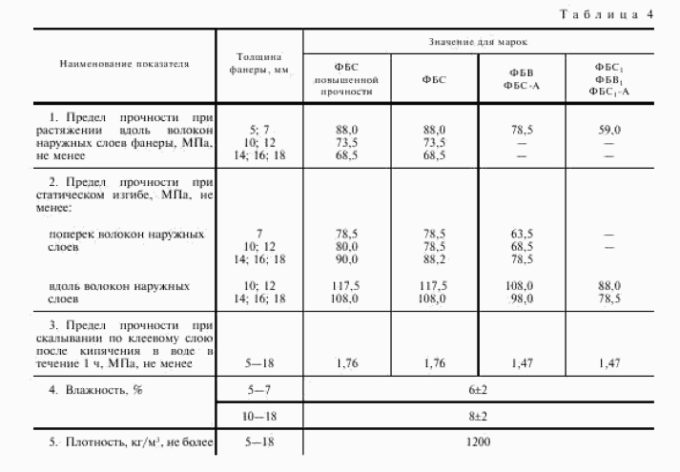

Technical characteristics of bakelized plywood FBS-1 and FBS-1A

- Plywood thickness

5mm, 7mm, 10mm, 12mm, 14mm, 16mm, 17mm, 18mm and further up to 40mm - Format: 1250x5700 mm; 1250x2850 mm, 1250x2500 mm

- Static bending strength, not less

across the fibers:

7, 10, 12 mm - 78.5 MPa

14.16 mm - 88.2 MPa

along the fibers:

10, 12 mm - 117.5 MPa

14.16 mm - 108.0 MPa - Tensile strength along the grain of the outer layers of plywood,

not less:

7mm -88.0 MPa

10,12,14,16 mm - 73.5 MPa - Chipping strength along the adhesive layer after boiling in water

within 1 hour (not less) - 1.76 MPa - Density: no more than 1200 kg / m3

- Formaldehyde emission class E1

|

Thickness |

5mm, 7mm, 10mm, 12mm |

14mm, 16mm, 18mm |

More than 20mm |

|

Limit deviations, mm |

+1,5-1,0 |

+2,0-1,5 |

+3,0-2,0 |

Technical characteristics of FBV bakelized plywood

- Thickness of bakelized plywood

7mm, 10mm, 12mm, 15mm, 18mm, 21mm - Format: 1220x2440 mm

- Static bending strength, not less

across the fibers:

10, 12 mm - 68.5 MPa

14.16 mm - 78.5 MPa - along the fibers:

10, 12 mm - 108.5 MPa

14.16 mm - 98.0 MPa - Tensile strength along the grain of the outer layers of bakelized plywood,

not less:

7mm -78.0 MPa - Chipping strength along the adhesive layer after boiling in water

within 1 hour (not less) - 1.47 MPa - Density: no more than 1200 kg / m3

- Formaldehyde emission class E1

|

Thickness |

7 mm |

10 mm |

12 mm |

15 mm |

18 mm |

21 mm |

|

Limit deviations, mm |

+0,8-0,8 |

+0,9-0,9 |

+1,0-0,9 |

+1,0-0,9 |

+2,0-0,9 |

+2,0-0,9 |

Certificates

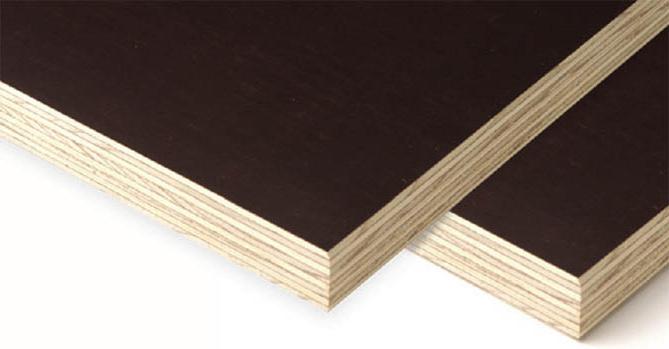

Buckfane or bakelized plywood, both FBS and FBV GOST 11539 83, are impregnated with bakelite varnish or laminated during production,

therefore they have the highest resistance to water. Such plywood can be used to sheathe piers that go into the water, and it will stand unchanged.

decades. Also, these types of plywood have a very strong structure, also due to the impregnation with Finnish Bakelite varnish. One of

applications are the cladding of street dance floors and verandas, which will also withstand constant high

mechanical stress, rain and snow, without changing the appearance.

Benefits of Bakelite Plywood

Bakelized plywood FBS and FBV has the following advantages over competitive materials of this type:

high strength.

wear resistance.

Plywood has a long service life, which is achieved due to the specific properties of the impregnation, which does not evaporate for an extremely long time.

heat resistance / fire resistance.

No wonder the tank. plywood is used even in tropical conditions and in high-temperature industries - this material perfectly withstands temperatures of +50 degrees Celsius, does not catch fire and does not smolder.

frost resistance.

As you know, any material cannot be used for a long time in conditions of increased cold, such as in Siberia or other frosty areas of the Earth. However, bakelite plywood is not afraid of temperatures as low as -50 degrees Celsius, while functioning perfectly.

moisture resistance.

Bakelized plywood 18 mm and no longer loses its strength, does not deteriorate under the influence of moisture. Add to this resistance to rot and insects / fungi and you have an ideal (though a lot worthwhile) option for roof and attic floors.

resistance to chemical. influences.

Tank. plywood is not afraid of aggressive environments - gasoline, kerosene, other fuels and lubricants, acids, alkalis, sea water do not harm the material, so it can be used in any production.

resistance to the influence of fauna (no bark beetles, mold and mice can damage the tank. plywood).

Of course, the plywood tank has its drawbacks as well. There are only a few of them:

severity.

Due to its impregnation, the specific gravity of the tank. plywood is slightly heavier than standard material, even if birch wood is used.

environmental insecurity.

Due to the fact that FBS plywood is abundantly processed with carcinogenic materials, it is not recommended to use it indoors. However, this does not apply to plywood FBV - an environmentally friendly material, which, however, has lower indicators in other parameters.

high cost.

Of course, thanks to such impressive parameters, the tank. plywood and stands accordingly. However, we can say with certainty that this material will work out every penny invested with its characteristics and features.

As you can see, bakelite plywood, the technical characteristics of which surpass other materials by an order of magnitude, is an excellent product with an extremely wide range of applications.

Foundation Block Technology

| The production of FBS (foundation blocks) is a very profitable investment, especially for those companies that have a concrete production or have their own vehicles. The technology lies in the fact that in 1 hour you can make 5 blocks, and in a day 40 blocks from 1 form. |

|

|

We offer you different types of forms - 3,4,5,6

Economic justification. The object of this feasibility study is a workshop for the production of foundation blocks (3,4,5) with a total capacity of 80 pieces per day.

Production infrastructure requirements

| Production area | 100-120 sq.m |

| The area of the adjoining open space | 200-500 sq.m |

| Temperature regime | standard, +1 - (+ 25) C |

| Lighting type | general, LED daytime running light |

| Electrical communications | ~ 220 V, ~ 380 V, 10 kW |

| Technical water supply | Not required |

| Exhaust ventilation | Not required |

| Sewer drain | Not required |

| Heating | Not required (for production area only) |

Basic equipment, fixtures and fittings

| No. | equipment identification | Qty | Total cost of equipment for the production of dry mixes, c.u. e. |

| 1 | Form 30 * 240 * 60 | 1 PC. | 4 500 |

| 2 | Form 40 * 240 * 60 | 1 PC. | 5 000 |

| Total: | 9 500 |

The term of production of forms is 45 days.

Shop personnel

| Profession | Quantity |

| Shaper | 2 persons |

| Total | 2 persons |

| Dependence of income on investment of financial resources in the production of polymer-cement artificial stone | |

| Sale of technology (set of documentation, training) | 500 USD |

| Total | $ 10,000 |

Disolver production time is 1 month. While you are preparing the production room for the installation of equipment for the production of blocks, we will manufacture all the equipment.

Production costs (fixed) per month

| No. | Cost item | Amount, cu |

| 1 | Industrial premises for rent | 400 |

| 2 | Depreciation of main equipment | 50 |

| 3 | Employee salary | 1000 |

| 4 | 400 | |

| 5 | Electricity | 200 |

| Total: | 2050 | |

| Production costs per day (22 business days) (Assuming an annual depreciation period.) | 93 |

Full production cost per day

The raw material cost of 1 block 30 * 240 * 60 is - 16 USD. The production capacity of the equipment is 80 blocks per shift. Thus, the raw material cost per day is 1280 USD. e. + Production costs 93 c.u. e. Total, total cost without taxes 1373 c.u.

Average market value of 1 block (30 * 240 * 60) - 35 USD those. 35 * 80 - 2800 USD

Economic efficiency

When you open the production of foundation blocks, your profit is: Full cost per month 1373 * 22 = 30,200 USD. The selling price of the product is 2800 * 22 = 61 600 USD.

Profit for the month 61600 - 30200 = 31400 USD (excluding taxes)

The economic justification of the opening of production on our own experience

Of course, in the first month, your volumes will not exceed 50%, analyzing from your own experience.

At the same time, the competition of materials significantly exceeded the consumption of imported materials in relation to our products, but time passed and our products have established themselves at low prices, since this is not our main business, due to discounts, the production time is 1-2 days, written guarantees. If you have a demand for it, then it is possible to produce 120 blocks per shift.

This business makes a lot of money, as the investment is minimal. Our company brought the technology from the West, and now there is no need for many forms (large investments), now you can do it quickly, efficiently and not expensively.

Thus, even with the sale of the FBS at the beginning, your profit will cover all your costs and you will receive a profit in the amount of 15,000-31,000 USD, and if you subtract taxes, the net profit will be approximately from 11,000 to 27,000 USD.

Burgundy

Burgundy, burgundy, burgundy Bite, bump, bump, bump. Saucer, saucer, saucer, saucer Flare, flare 270 ° C, flare, flare, flare 6 flare Burgundy burgundy burgundy Lol.РконÐμÑном иÑогÐμ ÑÐ'Ð ° ÐμÑÑÑ Ð¿Ð¾Ð »ÑÑиÑÑ ÑÑÑоиÑÐμл ÑнÑй мР° ÑÐμÑиР° Ð », коÑоÑÑй ÑпоÑоР± Ðμн пÑÐμвоÑÑоÐ'но пÑоÑивоÑÑоÑÑÑ Ð¿Ð¾Ð²ÑÑÐμнной Green light. Burgundy ± point, point, point, point, point. Burgundy, burgundy, birch Please.

Historical prologue

He is an airplane and not a train in Africa.

He is an airplane and not a train in Africa.

The invention itself belongs to the domestic chemist and inventor Yakov Davidovich Avrasin, who in the 40s of the 20th century, using formaldehyde resins, gave plywood the qualities that made it possible to build aircraft from this material. The need for the invention was caused by an acute shortage of light aircraft alloys.

The idea was picked up and implemented by Vladimir Petrovich Gorbunov, a well-known domestic aircraft manufacturer.

The process itself proceeded as follows:

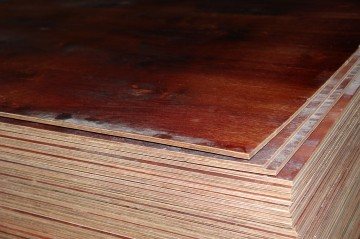

- After production, birch or pine veneer was impregnated with either cresol-formaldehyde or phenol-formaldehyde resins;

- After that, thermal pressing was carried out using high pressure (270 degrees Celsius, pressure of 6 atmospheres);

- Bottom line: at the exit we have a strong puff, comparable to steel in strength, somewhat heavier than wood, but also stronger than it.

From history to modern times

Cars with plywood bodies.

Cars with plywood bodies.

Currently, aviation has retained this material only in the so-called small aviation. The focus of the application has shifted from aircraft to shipbuilding. And although it is clear that no one will make the hulls of ocean liners from this material, baked plywood is quite suitable for boats, boats, yachts.

A few words about technology:

During numerous experiments, it was noticed that birch veneer is much superior to coniferous veneer in its ability to be impregnated with special impregnations (in this case, bakelite varnish);

With regard to properties

Plywood can be used in the construction of boats.

Plywood can be used in the construction of boats.

Like every material, plywood has its own standards, which determine the quality of products and the possibility of its use in modern industry. All features of bakelite puff can be found in GOST 11539 83 for bakelized plywood.

Let's talk about this in a little more detail:

- Water resistance. This property is achieved through all the same special impregnations or varnishes. The material is not afraid of either fresh or salt water;

- Fire resistance. Products made from such material do not burn. At a temperature of 350 degrees Celsius, plywood begins to char and does not support active combustion. The smoke that is released during this process does not have a pronounced suffocating effect;

- Not susceptible to decay or fungus. In principle, this says it all, plywood does not need additional protections and impregnations, there is no need for lamination;

- Heat resistance. The material feels great with sudden temperature changes in the range of 100 degrees Celsius. Products made from it can withstand a sharp temperature drop from -50 to +50 degrees Celsius;

- Strength. Due to the different arrangement of the veneer fibers, the material has good strength and is able to withstand significant loads in both the direct and lateral directions.

About application and brands

It is widely used in construction.

It is widely used in construction.

You already have an idea of what bakelized plywood is. It is necessary to walk through the area of application in order to completely dot the "and".

So, bakelled plywood is used in:

- Shipbuilding - hulling of small ships, including small sea yachts;

- Automotive - body floors, sideboards, containers, trailers;

- Construction work - erection of formwork for building up reinforced slabs, columns and other building structures directly on site. For the construction of awnings, partitions and other large and small architectural forms;

- Hydraulic engineering - manufacturing of hydraulic locking equipment - hydraulic locks, sluices and similar elements.

According to the types of impregnations, which largely determine the properties of plywood, the material is divided into grades.

Namely:

A boat made of plywood has surprised no one for a long time.

A boat made of plywood has surprised no one for a long time.

To facilitate the price component, some additional brands were thought out and introduced, the price of which is lower than that of those completely impregnated with phenol-formaldehyde varnishes. These are FBS-A, FBS1-A. In these cases, some layers are impregnated, for example, all but the two central ones.

As you can see there are only two brands FBS and FBV, which means bakelized plywood with alcohol-soluble varnish and the same, but with water-soluble varnish.

From brands to sizes

The form is a sheet, it determines a lot.

The form is a sheet, it determines a lot.

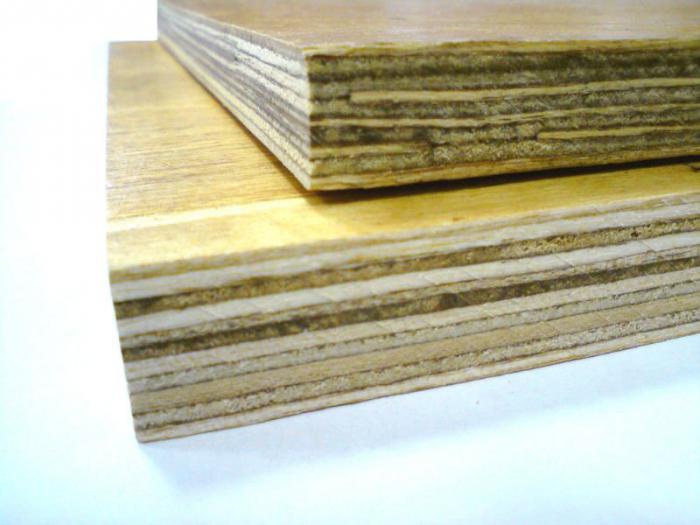

All plywood sheets are available in several sizes:

- By area 5700x1250, 2850x1250. Dimensions are in millimeters;

- In thickness from 5 to 40 mm, plywood from 5 to 18 mm is the most popular, especially when designing boats, boats, gliders with your own hands.

Some information about bakelite plywood

In the world, you cannot find a more unique and strong material with a wide spectrum of activity, like bakelized plywood. What it is? Bakelite plywood is a sheet of veneer that is treated with a special glue, thanks to which the material gets a lot of possibilities. It is worth noting that many people have not even heard of it, since it was previously used purely for industrial purposes. However, with the development of interior design and the desire of people to create the most comfortable dwelling, FB plywood gradually began to capture the construction market.

All the unique properties of bakelized plywood are attributed to its component - bakelite. This chemical was created by Leo Bakelando in 1909, who (un) modestly named the material after himself. In simple terms, Bakelite is an organic formaldehyde that has been crossed with phenol during reaction with an alkaline solvent. Due to the high presence of carcinogenic materials in the mixture, plywood treated with such an adhesive should not be used to treat the interior surfaces of a dwelling, but it just reveals itself remarkably well when used externally.

Specifically, bakelized plywood was invented in the 1940s by our compatriot Y.D. Avrasin, who in this way solved the emerging shortage of wood for the creation of aircraft. It was he who came up with the idea of processing plywood with Bakelite to obtain the so-called delta wood. With its help, the legendary I-22 fighter was created by the hands of V.P. Gorbunov, a Soviet designer. This plane gave rise to the parable of the plywood plane and tanks in the mouths of the people, which is not so far from the truth.

His experience was quickly adopted by other powers such as Japan. This country has always experienced an interruption in timber supply, so they used bakelite plywood to create an armada of fighters with kamikaze pilots at the wheel. Bakelite plywood is still used in aircraft construction, but recently, due to its characteristics, it is gradually moving to the construction market.

Bakelite plywood making method

Bakelite plywood FBS is created in the same way as standard plywood. First, the builders pick up a powerful tree with a mighty trunk, cut it down. After that, the trunk is sanded and spends some time in the open air, drying and releasing excess resin (if it is a coniferous tree). After that, the trunk is sent to the machine, where the veneer is removed from it - a thin rectangular sheet of wood with the same direction of fiber growth.Thus, the trunk is stripped of its woody shell until enough veneer has accumulated to create a single plywood sheet. Then comes the processing stage - each veneer sheet is covered with a water-soluble phenol-formaldehyde resin or bakelite varnish. These chemicals are both an adhesive and a protective layer for plywood. After finishing the processing, many veneer sheets are stacked on top of each other, forming a cake, after which they are sent under a hot press, where the finished plywood is created.