Varieties of anchor bolts

The classification of anchor bolts offered by modern manufacturers is made according to many parameters. They all fall into two categories:

- with mechanical fixation;

- the use of chemical adhesive fillers;

- on the vibro-checker.

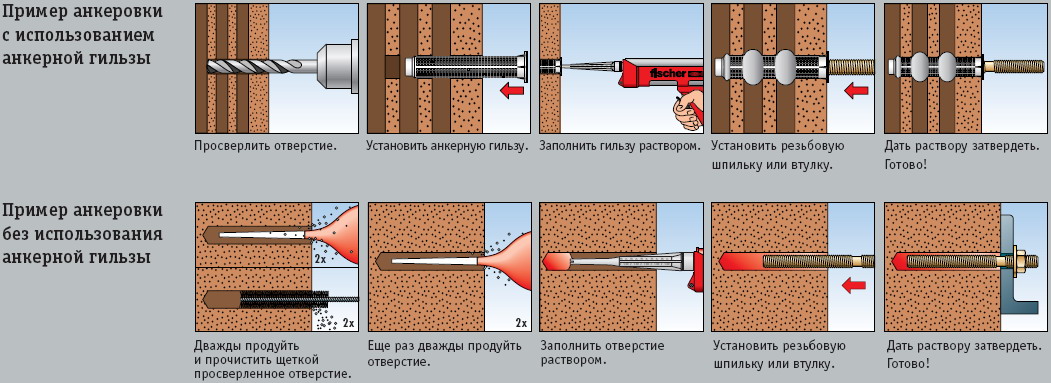

In the first case, the reliability of the fastening is ensured by creating conditions that significantly increase the friction force. In the second, fastening is added to the initial effect (mechanical fastening) through the use of reliable adhesive joints. In this case, the effect of adhesion is used - the ability of the adhesive to penetrate the pores of the material where the sleeve is placed. To implement the attachment, you need a tube of adhesive and a special gun. First, glue is squeezed into the hole. Then the anchor bolt is driven in. Such anchors are used to fasten structures in some brands of aerated concrete or in walls made of a material with a porous structure.

In more detail, the types of anchor bolts are classified according to the following parameters:

- purpose and field of application;

- form of design;

- geometric dimensions;

- type of attachment;

- head shape;

- bushing material.

More details on the purpose and scope of application are given below.

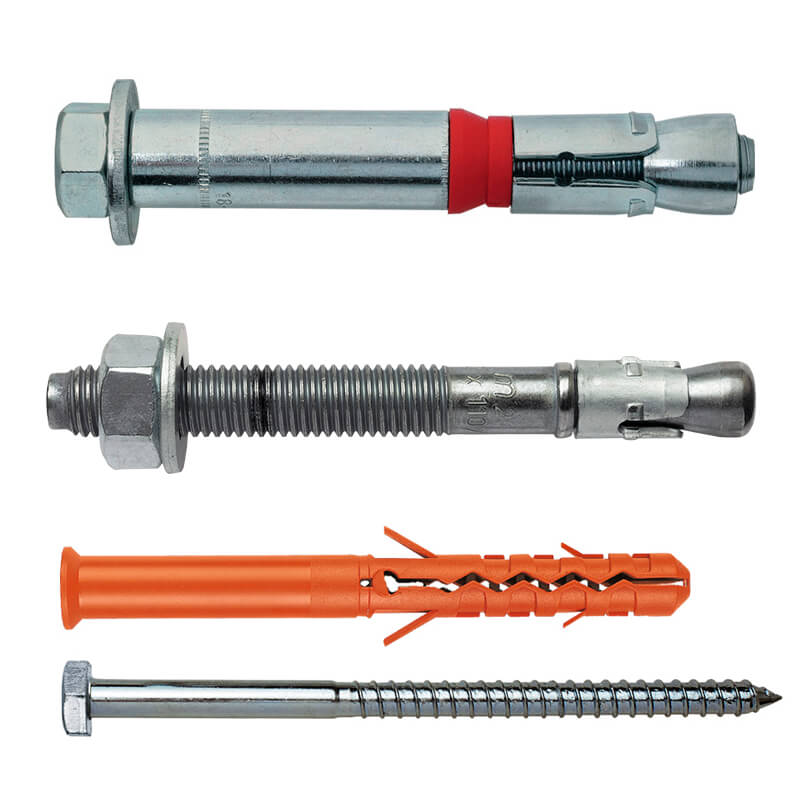

The following types of anchor bolts are distinguished by the form of design:

- hook-shaped design;

- with a ring fixed on the tip;

- with a fixed nut;

- stud anchor.

Mounted hooks used for subsequent installation hinged structures. Products are attached to the finished rings, which have a hinged system on ropes or cables. There are anchor bolts with a fixed nut. This allows you to set the screw-in depth of the anchor. The latter design is secured on both sides. They are tightened with a nut. Most often, such bolts are equipped with a tapered working part of the sleeve. The use of such a design allows you to choose the most optimal pressure on the walls of the hole, that is, the adhesion force of the anchor and the wall.

Anchor studs are classified into HAS and HST designs. They allow working in concrete that is prone to cracking. With their help, through fastening is carried out.

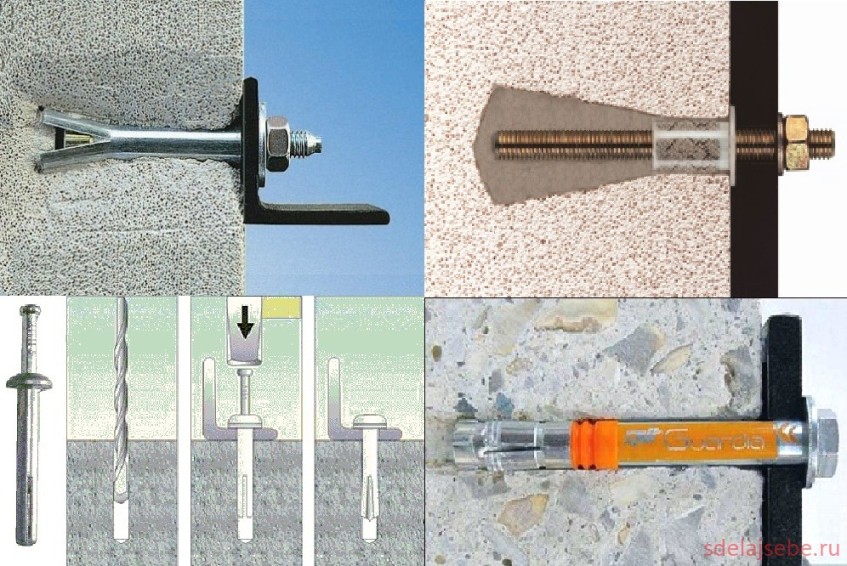

According to the type of fastening in the wall or ceiling, anchors are divided into two categories: expansion and wedge. The most widespread is the first type. In practice, one and two spacer structures are used. The product of the second type is equipped with two sleeves, which makes it possible to increase the resistance and improve the reliability of the fastening.

According to the shape, the heads of the anchor bolts are made under key or screwdriver... In the second case, the most common are the grooves for a Phillips screwdriver.

Depending on the type of fastening, they are subdivided:

- conventional anchor bolt;

- bolt with sleeve and nut;

- spacer-type collet bolt;

- driven anchor bolt.

All these designs work on the principle of expansion of the sleeve at the moment of tightening the bolt rod. The collet bolt has the most complex bushing design. There are four cuts on its surface. Therefore, at the moment of screwing in, its end takes the form of four petals, which makes it possible to increase the reliability of the installation. The drop-in anchor has a tapered sleeve with internal slots. As the anchor is driven into the hole, the sleeve contracts, the central notched parts expand.

Anchor bolts are made of steel or brass.In accordance with standards and building codes and regulations, steel is selected depending on the application and operating conditions of the fastener. In some cases, individual grades of carbon steel are used, for example, VSt3kp2; for low-temperature conditions, low-alloy steel of 09G2S-8 grade or their analogs is used.

Design

The word anchor means fasteners. Its purpose is to be anchored at the base of a structure. It looks a bit like a dowel. Therefore, some people confuse these products.

In fact, it is a complex product that can support significant weight. This fastener has a specific shape, due to which the reliability of installation will be ensured.

V while the dowel looks much simpler (one might say, almost primitive) and is suitable mainly for so-called porous materials. Accordingly, it is simply not capable of supporting significant weight. At the same time, without collapsing.

One of the elements of the drop-in anchor is a metal sleeve. And another one can be found directly on the spacer. Accordingly, the third part is a spacer.

To create them, experts use a very durable metal or carbon steel. In addition, the surfaces are subjected to additional processing. This procedure is necessary in order to protect the anchor from corrosion and also increase its service life.

They have a hole with an internal thread (its shape is tapered), as well as slots (mostly longitudinal), which have been specially processed. They are necessary so that on impact, the so-called. spacer shoulders.

Actually, they can withstand the entire load (this is their task).

The spacer can be driven into the housing with a standard hammer. And upon impact, the cone will expand in the narrow part of the hole.

Self-expanding ground anchors

These anchors are used to fasten guy wires using new technologies. The plates are designed to take tensile loads. They are immersed in the ground using a shock or vibration method.

These anchors are used to fasten guy wires using new technologies. The plates are designed to take tensile loads. They are immersed in the ground using a shock or vibration method.

Application:

- Permanent or temporary anchorage of functional power lines and telephone networks, which are fastened on match braces. Anchors are required for the installation of ski lifts and wind generators.

- Fixation of the unchanged, correct position of pipes and pipelines according to the projects. Caissons and reservoirs are also sometimes secured with these means.

- Dock bottoms, well bases are securely attached to the base. Self-expanding anchors fix and evenly set the foundations on which underground structures are being erected.

- They are actively used for the construction of underground devices, structures and communications. Foundation slabs and tongue-and-groove railings are reinforced, sometimes attached to the surface. Pits, retaining walls and trench elements are also developed according to a plan that provides for insurance of the reliability of fastenings with these anchors, sometimes they are the main method of fastening for a structure.

- Open and semi-closed methods of work are sometimes used to anchor the load-bearing walls of tunnels, where anchor data is also used.

- During the construction of foundation bridges, the formation of overpasses. Anchors are necessary when there is a need to strengthen existing structures.

- Some operations that are part of the functionality of road or landscape works require reliable fastening of elements.

- They are used in the construction and maintenance of hydraulic structures such as embankments, quay walls.

- Soil erosion can be prevented by using anchors, thanks to the strong, secure anchoring of geogrids and other systems that protect the soil from unintended movement.

Advantages:

- The ability to carry out work in an accelerated mode, ease of installation of anchors.

- The static test will be valid even if performed immediately after installation.

- There is no need to destroy the soil. Especially for the installation of pits for massive buildings, the earth does not dig, which increases the reliability of the structure and facilitates the work.

- High load-bearing capacity. It can be used for the construction of buildings of any weight and height.

- It is not necessary to deliver concrete blocks to the site and install them, since the anchors are held in the ground.

- During the installation process, it is possible, at no additional cost, to ensure the maximum accuracy of deepening the anchors into the ground, even in hard-to-reach places.

- In most conditions, installations are available for use.

- When the anchor is secured, brought into working position, it can immediately accept loads.

- The total cost of the installation is considered low as there is no need for drilling, supplying concrete blocks or grouting already fixed anchors.

Ground anchors have proven to be powerful and high-quality fasteners used for all types of buildings. To guarantee the reliability and durability of the building, before purchasing them, you need to make sure that the supplier has the required certificates, if necessary, the company designs and installs anchors.

The correct choice and installation of ground anchors will make the construction reliable and will last for many years.

Chemical anchor consumption. Their types. Read about it here.

And here is an article about the installation of anchor bolts.

What is Concrete Anchor Bolt

Many have heard that a special fastening element - an anchor bolt - is used to solve issues of fixing to the ceiling, internal and external surfaces of concrete walls. Not everyone knows what it is. Let's try to figure out what an anchor is. This is a metal fixture that allows you to securely fasten furniture, equipment and appliances on brick, stone, concrete and foam block surfaces, as well as on hollow panels and walls made of gas-filled blocks. The fastener is installed in a hole with a certain size.

An anchor is a fixation device capable of absorbing significant forces due to the following factors:

- frictional forces due to which the collet sleeve is held in the formed cavity;

- efforts of interaction of a special spacer mechanism with the inner surface of the channel;

- the adhesive characteristics of the adhesive ingredients inside the drilled hole.

Among the many varieties of fixing devices, wedge-type anchors, as well as expansion anchors for concrete, are in high demand. Their design features and technical parameters allow the fixing element to increase the diameter of the working surface when expanding inside the cavity. In this case, the magnitude of the friction force increases sharply. The anti-corrosion coating of the surface of such an element prevents the occurrence of corrosion and increases the service life.

Anchor bolt for concrete

Anchor bolt for concrete

Working principle and application

In the areas of fasteners with concrete, various stresses arise: torsion, fracture, displacement, shearing, contraction, separation.

The main basics of the functioning of concrete anchors:

- during the period of contact between the substance of the base and fasteners, F tr appears. - pressure is produced by pins, iron devices;

- sometimes, when anchored, the substance provides opposition to the reversal - due to the fastening union, the curved type of the base, the increase;

- the force in the mating area of the base and fastening is compensated for by the touching forces during monolithing or sticking - this is how the stowing smooth, adhesive staple works.

They are made of special steel in accordance with GOST, treated with a shell, anti-rust. The stick has D = 6-20 ml, L - up to 220 ml.

Each staple contains the following components:

- pin;

- a body with a shell of slicing in this body;

- cork with special grooves.

Foundation bolts play a major role in installation situations: tile structures, pillars, loggia ledges, staircase areas, facing and wall paths, technical equipment, communications, hoods, overhead lighting devices, etc.

With their help, various equipment and hanging furniture are fixed on the walls.

Application

Each type of developed anchors is used to solve specific problems. Therefore, before starting work, it is necessary to determine what a particular sample is used for. According to the approved standard, anchor bolts are used as follows:

- the mortgage is used at the stage of pouring concrete or the production of brickwork;

- spacer allows you to mount massive structures on a concrete or brick base;

- wedge are used in joints in which heavy loads are expected;

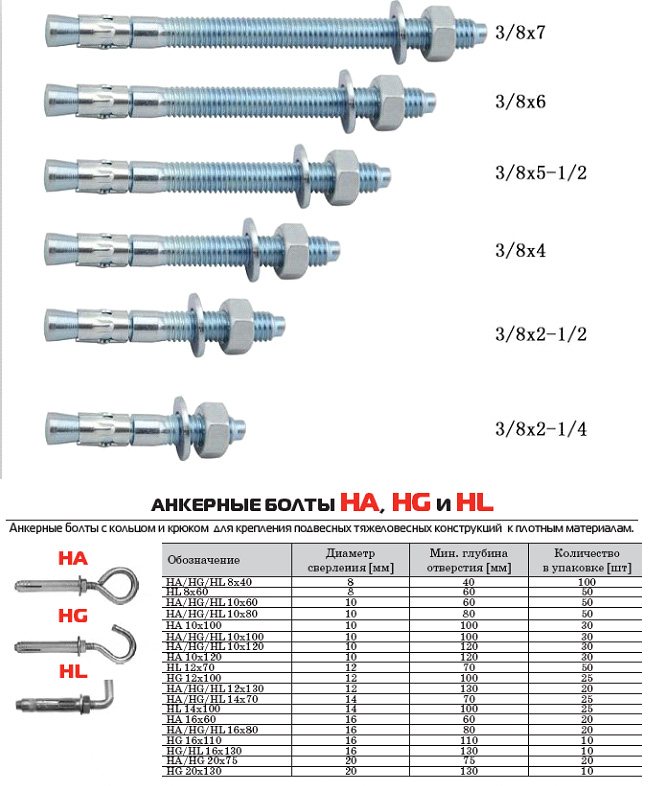

- bolts with a ring or hook are required for mounting suspension elements, fastening pivot joints, cables, chains or other tension structures;

- frame is used to install doorways, window frames;

- with the help of a facade anchor, various elements of the facades of buildings are fastened;

- the ceiling anchor allows you to reliably fix various elements of suspended structures to the ceiling (it must withstand the weight of any selected product);

- spring mounts are used to mount elements to thin-walled structures.

Before proceeding with the selection of the required anchorage, it is necessary to consult with professionals. This will help you avoid serious mistakes. The result of misapplication will be difficult to correct.

Anchor design, in contrast to other fasteners

A classic anchor is a combined metal structure consisting of a non-expansion (body or base) and an expansion (working) part. The base can be a bolt, screw, pin or nail, the spacer part can be in the form of a sleeve, cone, sleeve, etc. When using a fastener, the working part expands and, due to the friction and resistance of the material, holds the structure in the base material.

The main difference between the anchor and the dowel, which is similar in design and purpose, is the material of manufacture. The dowel consists of a soft part, usually plastic, in which a fastening element is fixed, for example, a self-tapping screw. The principle of fastening the dowel is based solely on the frictional force between the working surface of the fastener and the base.

Since the anchor is usually made of alloy steel or other metals (brass, aluminum), its fastening principle is based not only on friction between the main and working parts, but also on the resistance of the material. Anchors are capable of withstanding more severe dynamic loads than fasteners using a dowel.

How to remove an anchor bolt from a wall?

The easiest way is to try to loosen the anchor in a circular motion. If it is known that the hole made in the wall has a margin, then by pushing the tapered part deep inward, the bolt can be easily removed from the vertical surface. For those who are interested in how to pull out the anchor bolt, if the previous two methods did not work, we can recommend reaming the threaded connection of the nut with the stud, and then driving it deeper so that it stops expanding the clip. This will make it easy to pull the last one out of the wall, and then the bolt itself.

Basic structures of mechanical anchors

By their design, mechanical anchors are also divided into the following main types.

Bolt with nut

The simplest type of spacer fastener, which is a rod (bolt) with a tapered end, a sleeve with four notches and a nut. The nut acts as a retainer - with its help, the structure is fixed in a pre-drilled bore hole, the diameter of which is equal to the diameter of the sleeve.After driving the rod into the hole, the nut turns clockwise, thereby moving the rod outward. The tapered end of the stud expands the sleeve in the area of the cutouts, thereby securing the structure in the hole.

The simplest type of spacer fastener, which is a rod (bolt) with a tapered end, a sleeve with four notches and a nut. The nut acts as a retainer - with its help, the structure is fixed in a pre-drilled bore hole, the diameter of which is equal to the diameter of the sleeve.After driving the rod into the hole, the nut turns clockwise, thereby moving the rod outward. The tapered end of the stud expands the sleeve in the area of the cutouts, thereby securing the structure in the hole.

Anchor bolts are available in various sizes: the diameter of the rod is from 6 to 28 mm, the length is from 60 to 300 mm. Anchor bolts are used when working with dense materials (concrete, brick, stone).

Ring bolt

Ring bolt

Ceiling anchor, usually used for fixing lamps, chandeliers to the ceiling, cables, electric cables, suspended ceilings, etc. This type of fixture can be used on walls as an exception.

All the difference between such a fastener and an anchor bolt with a nut is that its outer end ends with an eyelet necessary for hanging the attachment or product. Fastening of such a design is carried out in a similar manner: the fixing nut, located immediately behind the end in the form of a ring, allows you to expand and fix the sleeve in the hole.

Hook bolt

Hook bolt

A bolt-type fastener with a hook head. It is used for fastening heavy structures to solid concrete, stone or brick foundations. The fastening principle is similar to other bolt-nut connections - after tightening the locking nut, the sleeve is deformed and fixed in the drilled hole.

Hex head bolt

An anchor of this type is analogous to a bolt with a nut, however, a standard bolt is used instead of a rod (stud) and nut. When tightening the bolt with a wrench, the tapered end deforms the sleeve, thereby filling the walls of the hole and securing the structure in it. It can also be produced in a version for screwdriver tightening.

An anchor of this type is analogous to a bolt with a nut, however, a standard bolt is used instead of a rod (stud) and nut. When tightening the bolt with a wrench, the tapered end deforms the sleeve, thereby filling the walls of the hole and securing the structure in it. It can also be produced in a version for screwdriver tightening.

Double-spacer

Double-expansion mechanical anchors are another expansion bolt with nut. The difference is that the design uses two sleeves (bushings, couplings) - a short and a long one. The short one goes inside the long one with its conical end. When screwing in the nut, the short sleeve expands with the tapered end of the rod and, in turn, expands the long sleeve. Double-expansion anchors can also have ring or hook ends. Anchors of this design are used to increase the reliability of the fastening.

Double-expansion mechanical anchors are another expansion bolt with nut. The difference is that the design uses two sleeves (bushings, couplings) - a short and a long one. The short one goes inside the long one with its conical end. When screwing in the nut, the short sleeve expands with the tapered end of the rod and, in turn, expands the long sleeve. Double-expansion anchors can also have ring or hook ends. Anchors of this design are used to increase the reliability of the fastening.

Nail

Nail type anchors are used when working with brick, concrete and stone foundations and intended for fastening lightweight structures. They are in the form of a hollow nail, inside which a riving element is placed. The anchor is driven into the hole by hand or using a power tool.

Nail type anchors are used when working with brick, concrete and stone foundations and intended for fastening lightweight structures. They are in the form of a hollow nail, inside which a riving element is placed. The anchor is driven into the hole by hand or using a power tool.

Installation of anchor bolts

The bolts are set clearly in size, before the foundation is poured with concrete. The problem here is that the reinforcing cage or formwork when pouring concrete can move and, accordingly, the installed anchors will also go away.

My way of exposing foundation bolts. Take a stepped foundation for example. In order to be able to securely fasten the anchor to the reinforcing cage, we fill in the lower part of the foundation. Two days later, when the concrete has risen and the reinforcing cage is fixed, you can start setting the bolts.

The first step is to complete the formwork setting. We fix it so that it stands "dead" does not move and does not fall apart when pouring concrete mixture.

After that, using a level, mark the elevation on the foundation minus 10 centimeters from its top according to the project. One person stands on the level, another holds the rail and the third with a marker marks the marks at the corners of the foundation on the reinforcing cage.

On the anchors, we also set aside minus 10 centimeters from the top of the design level of the foundation. Suppose the anchor protrudes from the foundation by 15 centimeters, then we set aside 25 centimeters from its top.When aligning the marks on the foundation and the anchor, we set them clearly according to the design heights.

Further, one cannot do without a surveyor with his precise instrument, which is called a total station. I have tried more than once to expose myself by pulling the lace along the axes, but did not fit into the dimensions.

There are several reasons for the wind, the lace has deviated, a tape measure with an error or a human factor is confused in the dimensions. In this case, the more accurate the better.

The surveyor, with an accuracy of a millimeter, takes out the axes to the foundations, to which we tie when installing anchor bolts.

Basically, the bolts are fastened by welding, but at the facility in Kstovo, the technical supervision took a pose if the project does not indicate that they need to be welded, then I forbid. He believed that this weakens the metal and it will not withstand the design load. We fastened them to a knitting wire, and as a result, all anchors were displaced during the pouring of concrete.

How is it fixed by welding? I forgot to say after exposing it is necessary to fix the reinforcement cage of the foundation by welding on stoppers. A stopper is a piece of reinforcement that is welded to the frame and rests against the formwork, in this way we do not let it move.

In addition, it is also necessary to weld on the reinforcement, for example an anchor with a diameter of 24 mm. stands strictly on the axis. We weld two reinforcement bars to the frame at a distance of 12mm. from the axis. As a result, the angle of their intersection is the place for the anchor bolt attachment. In the photo below, I showed what it was about.

Consequences of incorrect alignment of the anchor bolts.

If the foundation bolts are out of size, it will be visible after survey by a surveyor and dimensioning on the executive scheme. As a result, the company will have such consequences as cost overruns of money and time, calculated for the construction of the facility.

In Kstovo, when the technical supervision saw on the diagram that the anchors were not within the tolerances, it was forbidden to bend them by welding or expand the holes on the heels of the columns.

Kstovo

Incorrectly installed anchor bolts were cut off, chemical ones were installed strictly according to the bindings to the axes and the work continued.

What are high-strength bolts, how to prepare them before installation, what tool to tighten, read here.

Your thanks for my article is a click on any button below. Thanks!

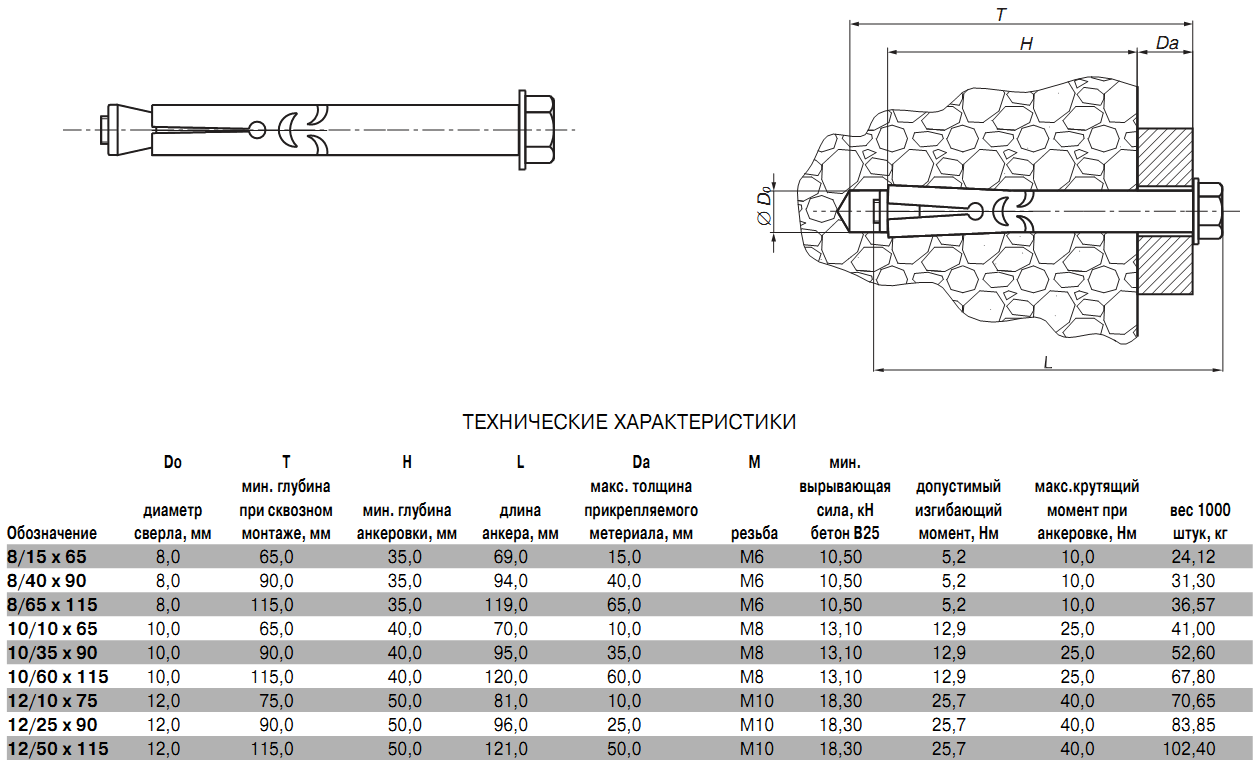

Anchor bolt markings

Since 2012, all anchor bolts are marked in accordance with the interstate standard. Its requirements apply to the territory of the countries that signed it. In this standard, the anchor bolt has the following designations:

- the first letter together with the number indicates the thread diameter, for example M8;

- the next number indicates the diameter of the drill, which must be used to prepare the hole, for example 10;

- the number after the slash means the thickness of the attached structure or product;

- the last digit after the "x" sign indicates the minimum permissible depth of the prepared hole in millimeters, for example 90.

Combining all the designations, the following abbreviation is obtained - M10 / 35x100. On construction drawings and plans, marking, in addition to digital designations, has special signs. They are placed in a circle and indicate the type of anchorage used.

For anchor products manufactured in other countries, their own markings are applied. For example, on the anchors of the German company Fisher, the marking is FBN 12/100. The first letters indicate the name of the product. Number 12 indicates the diameter of the anchor, taking into account the thread. The second digit defines the usable length. The number in the first square brackets is the usable length. The last two letters indicate that the anchor comes with a wide washer.

Therefore, for the correct choice of the type of anchor bolts, it is necessary to understand in detail the marking system and clarify the necessary characteristics.