Application of anchor plates for plastic windows

To keep the room warm, cozy and comfortable, you need to pay close attention to the windows. The comfort of staying in the room, the durability of the structure's service will depend on the quality and reliability of their installation.

The windows are installed for years, so you need to carefully consider all the nuances and make the installation correctly. There are many fastening materials, but anchor plates deserve special attention.

This material is ideal not only for metal-plastic windows, but also for wooden ones, as well as for various openings: brick, reinforced concrete, foam and aerated concrete.

This versatility makes anchor plates truly unique.

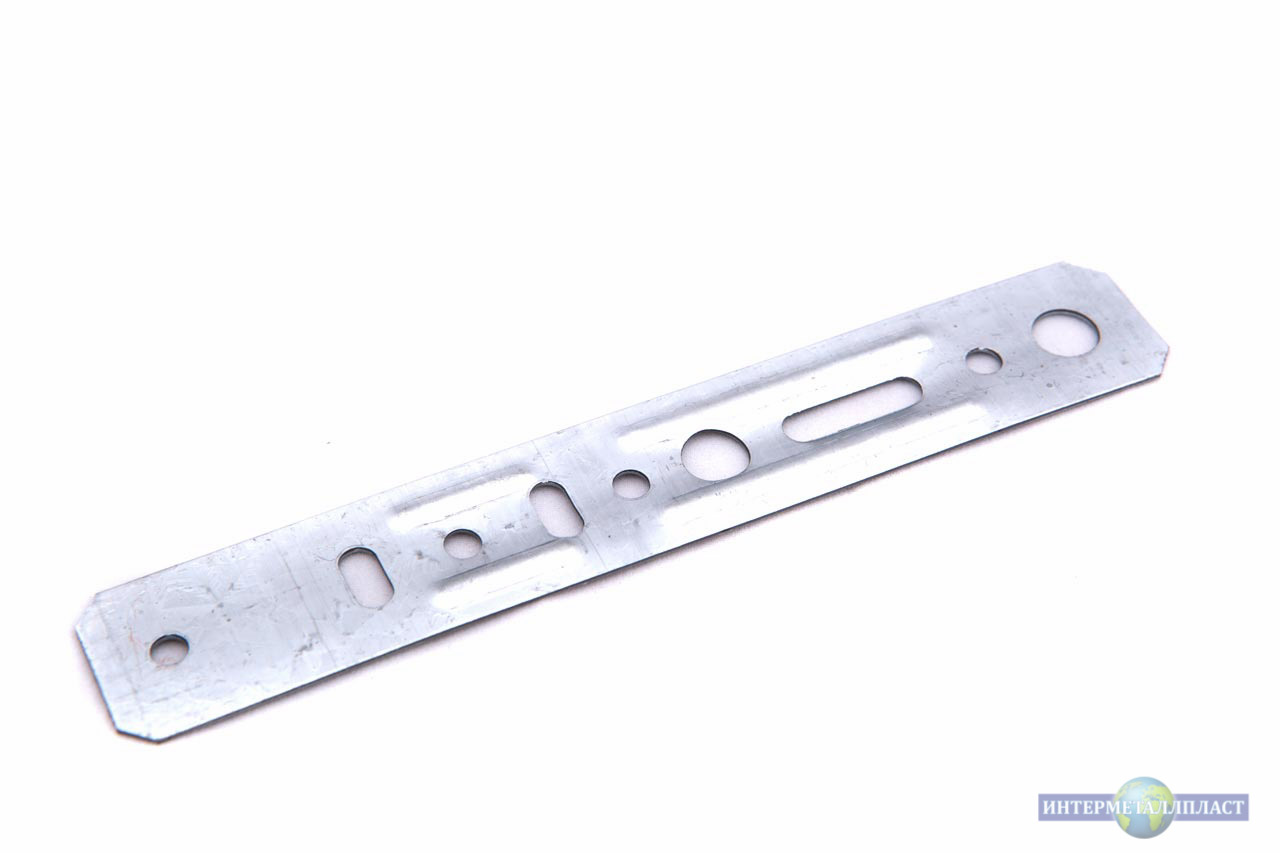

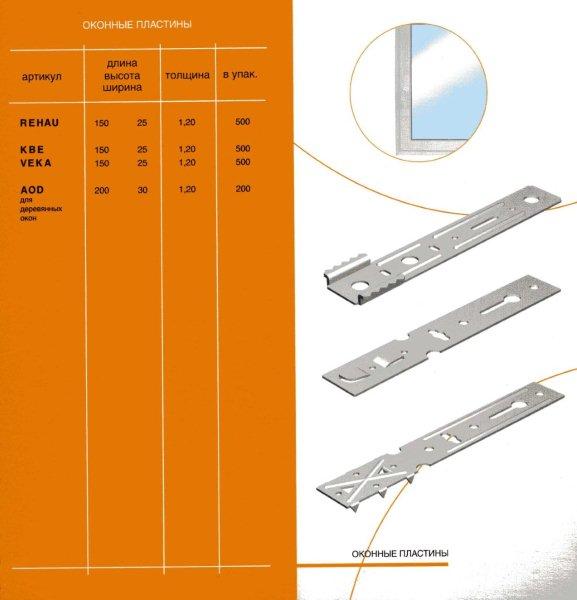

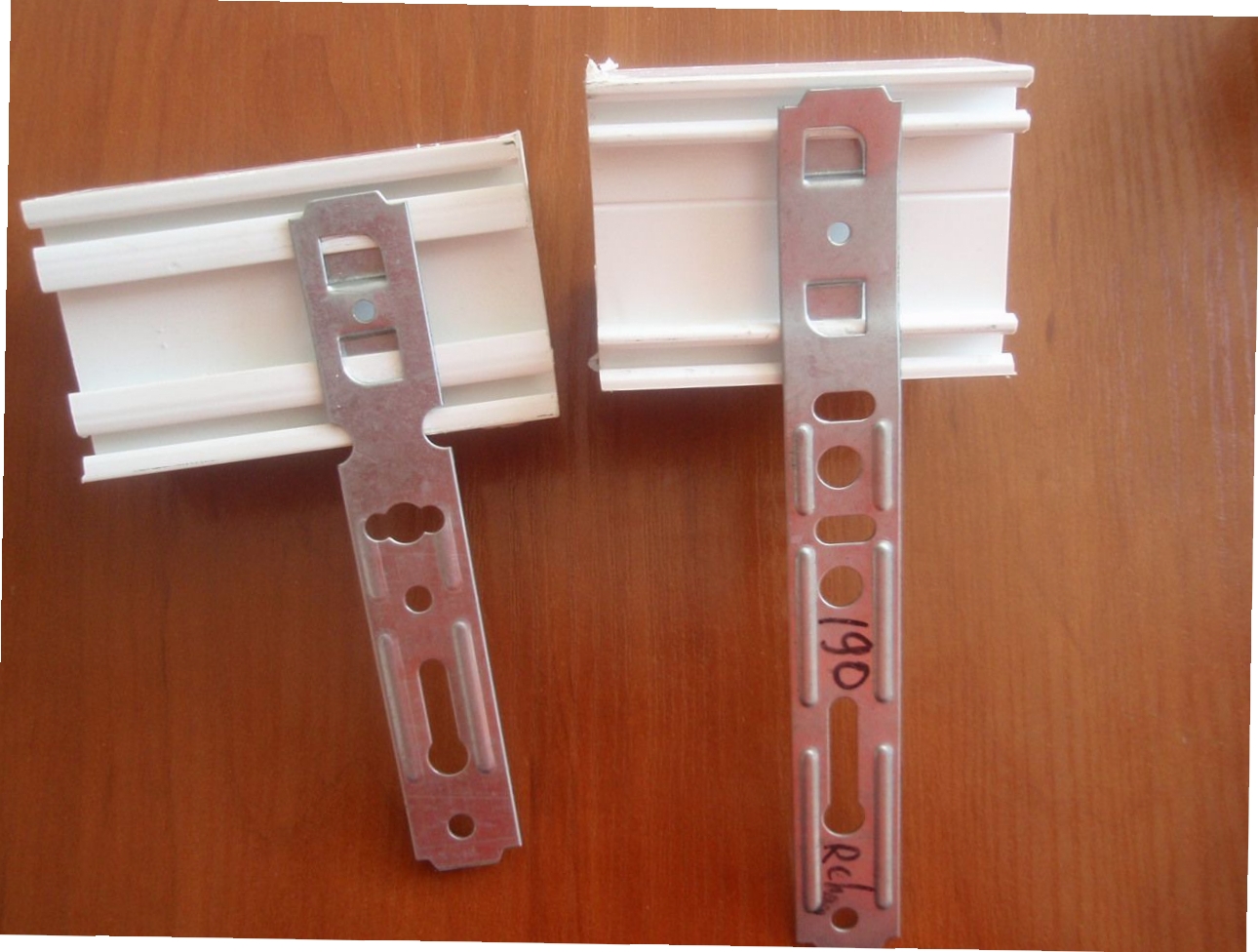

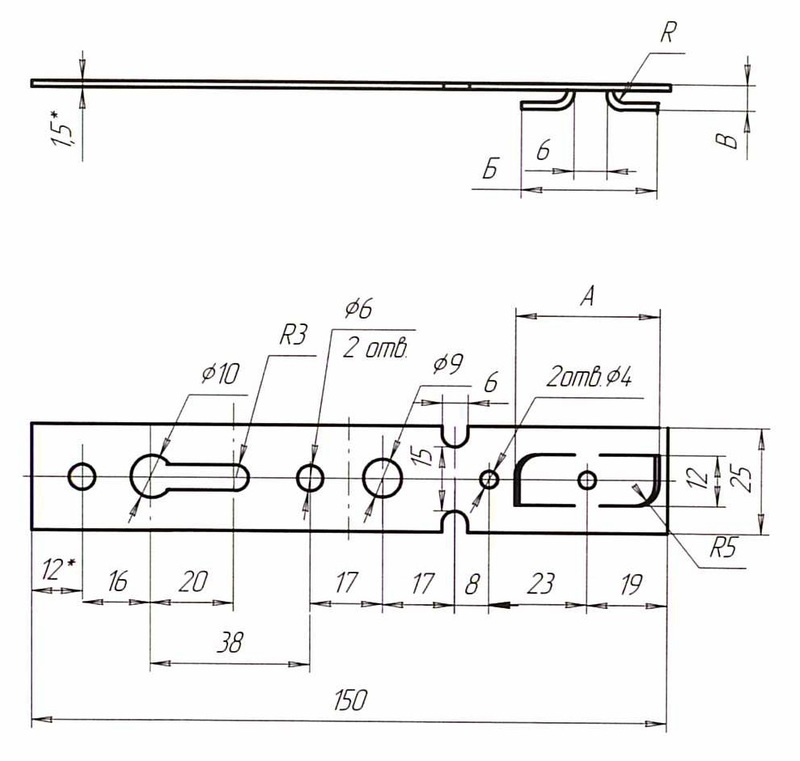

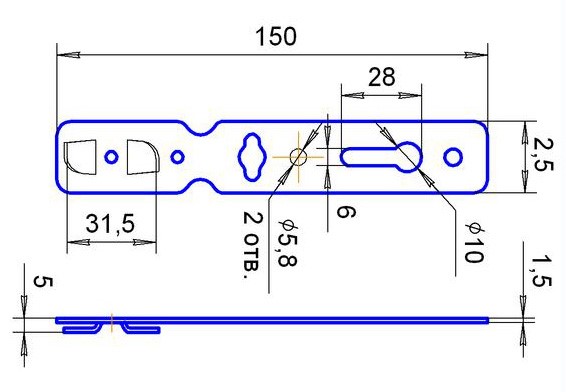

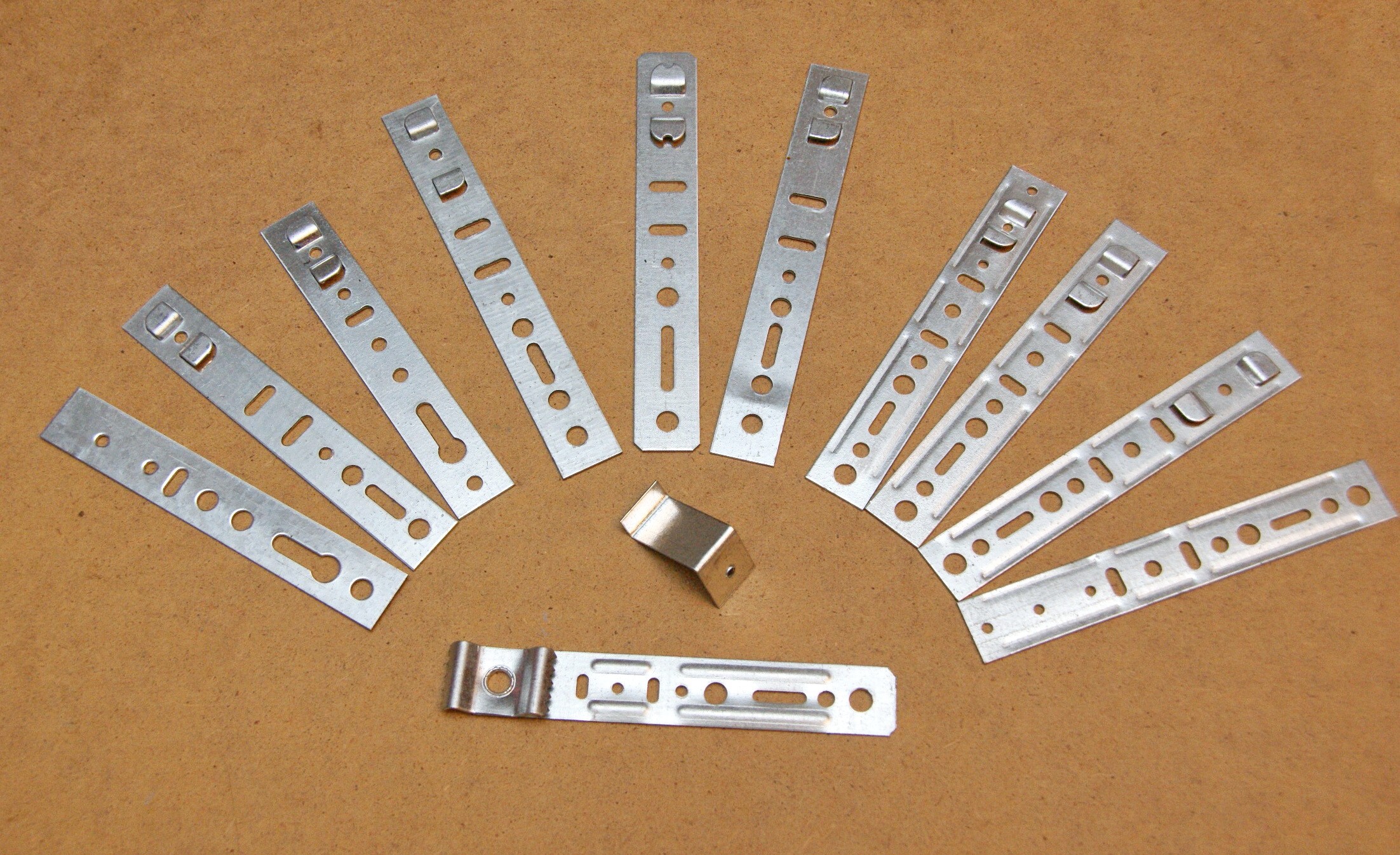

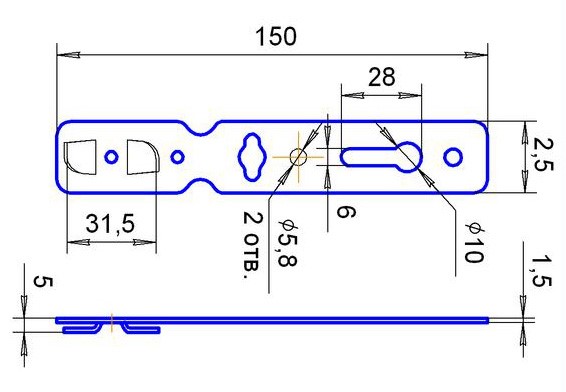

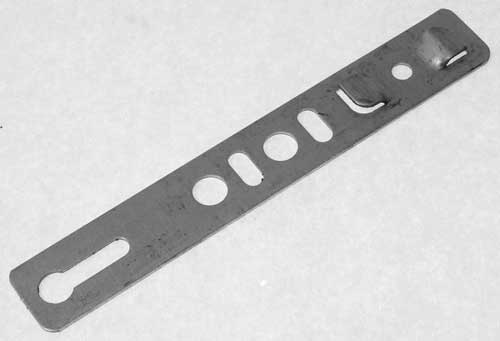

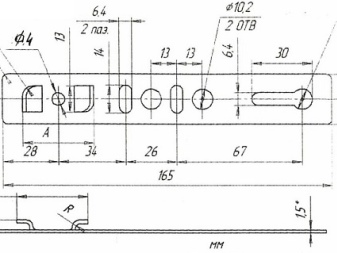

Outwardly, these are metal plates with round holes and notches. Products are made by cold stamping from galvanized sheet, the thickness of which ranges from one to two millimeters. They ensure the stability of the window structure.

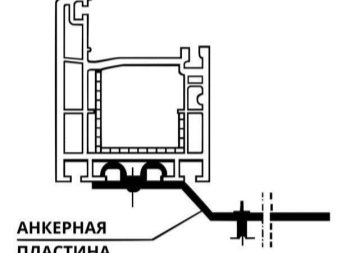

Rice. 2. Mounting anchor

Anchor plates are of two types:

- swivel;

- non-reversible.

The pivoting element is installed in case of complex installation, when it is difficult to fully secure the windows for some reason. Swivel crab allows installation at any angle.

Fixed plates are used in the classic installation of plastic or wooden window structures.

Basic installation principles

Now there are 2 ways of installing windows, which differ in the type of fastening unit and the method of fixing the frame to the window opening. This is an installation with and without unpacking. For self-installation of the window, it is wiser to choose the 2nd option, since it is simpler, does not require special skills, and the work does not take much time. In addition, it helps to avoid mistakes during installation and makes it easy to configure all the fittings.

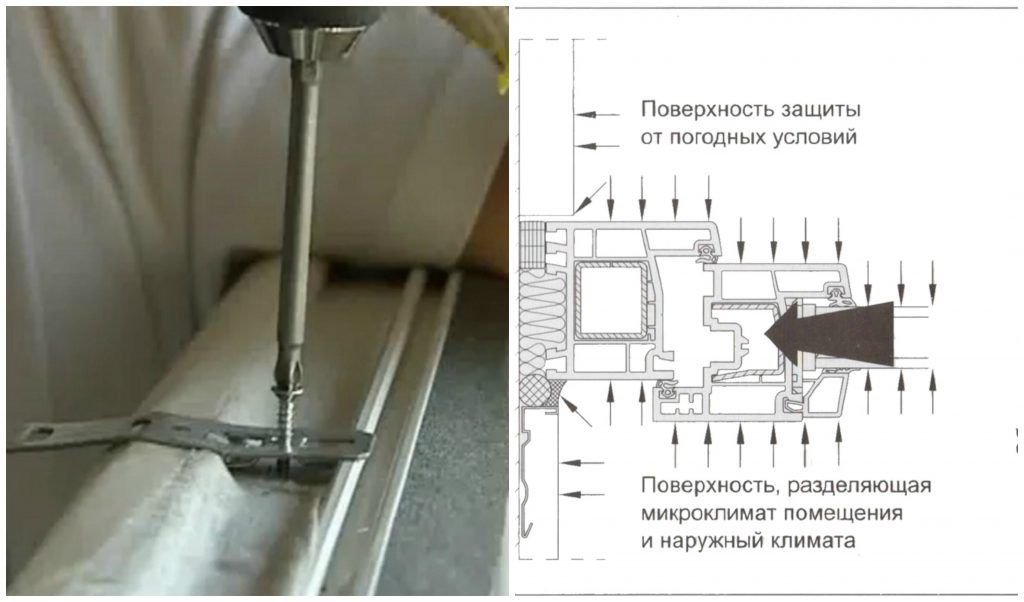

Installation without unpacking does not imply the removal of the glazing bead and the dismantling of the glass unit from the frame. The structure itself is attached to the anchor plates. The principle of forming such a fastener is shown in Fig. 1.

Before installing a new window, it is necessary to select the correct plates themselves. They are of 2 types: universal and designed for a specific model. That is, they take into account the requirements of a specific profile system. As a rule, such anchor plates are supplied with complex, non-standard structures.

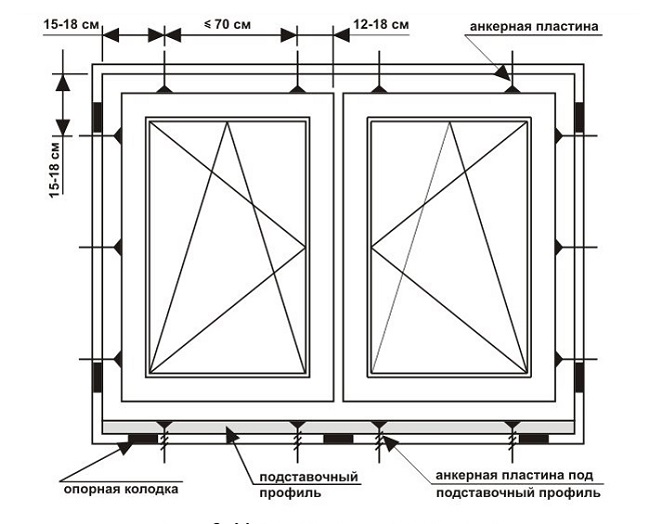

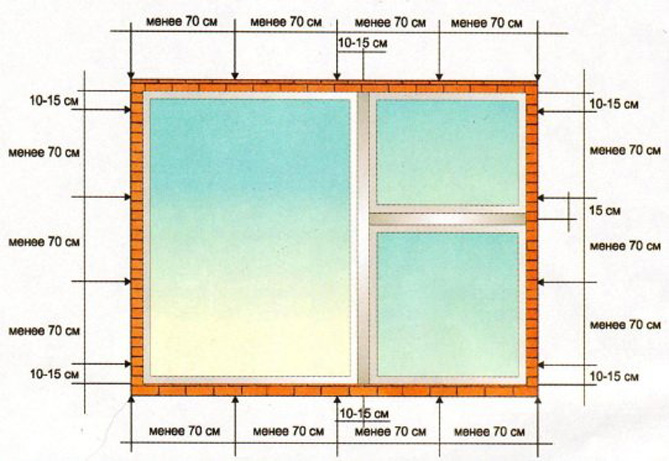

Figure 2. Layout of the anchor plates during installation.

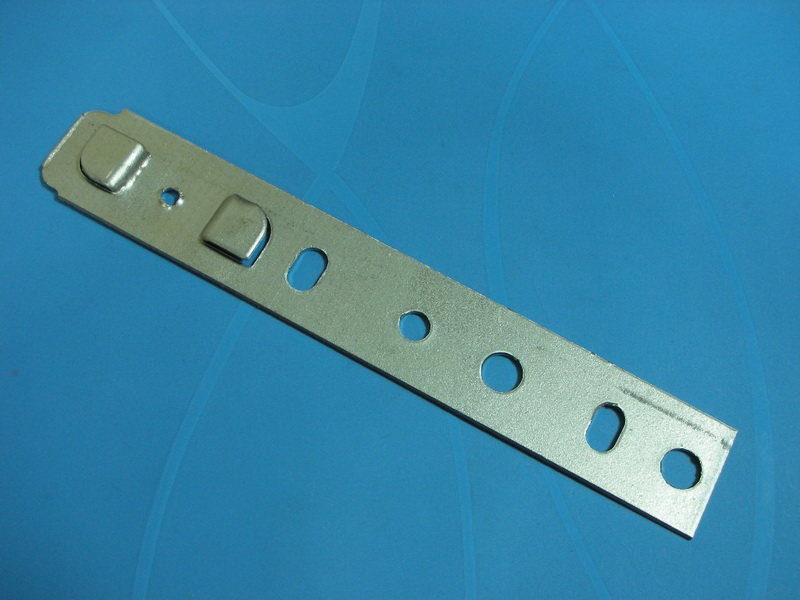

Specialized fasteners differ from universal fasteners in that they are equipped with ears. These elements are installed in the groove of the frame profile and fixed with self-tapping screws. Universal plates do not have special lugs. They are simply secured with bolts.

For the installation of window structures, experts recommend choosing bolts of type 4.5 * 25. Their body must necessarily be equipped with a drill for metal. Since the self-tapping screw is attached to a reinforced structure, another type of fastening may not stand up or will not fix the plate too securely.

Window installation rules

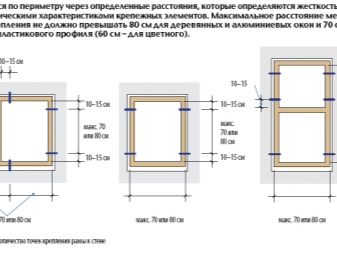

As a rule, it is recommended to install 5 anchor plates on a standard type window. Their location is shown in Fig. 2.

The central plate is fixed exactly in the middle of the frame, and the side plates are fixed approximately at a distance of 20-25 cm from the edge of the structure.

As mentioned above, the method of installing a plastic window without unpacking does not require removing the glazing bead and the glass unit itself. This becomes possible due to the fact that the frame is fixed by means of anchor plates to the outside of the window opening.Otherwise, you have to form through fasteners.

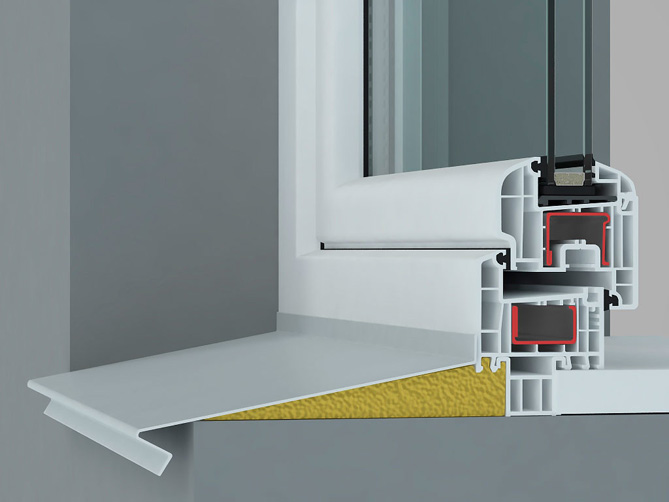

Figure 3. Diagram of the ebb installation.

But it must be remembered that large-sized structures (with an area of more than 4 m2) should not be installed using plates. After all, such a mount may not support the weight of the window. In this case, it is wiser to use anchor dowels. For plastic insulating glass units of small or medium size, plates will become the most rational way of fastening.

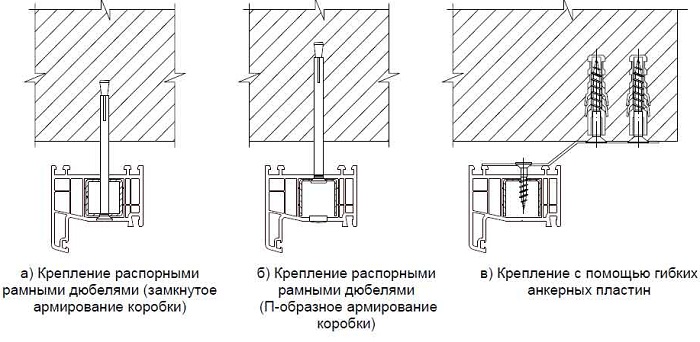

With the help of dowels, not only large windows are attached, but also doors. Professionals believe that this installation method is the most reliable. But it has a number of significant disadvantages:

- Installation with unpacking is difficult even for specialists. Often, with this method of installation, the glass unit breaks or cracks form on it.

- Installation on anchor bolts is almost impossible to do alone.

- Working with such fasteners requires experience and special skills.

- The work takes more effort and time.

If you prefer this installation option, then you need to purchase dowels 10 * 132 mm in size. In addition, a powerful hammer drill is required to install the anchors. Some modern stores selling construction and renovation equipment provide a rental service. Therefore, it is not necessary to buy an expensive device. But it is easier to install the window on the plates.

Features of fastening to anchor plates

This method of fastening the window system is as simple as possible and accessible to everyone.

Compared to the unpacking method, the method is considered absolutely safe for the window system, but the only drawback is that some elements of the fastening plate after installation will remain in sight. However, they can also be correctly disguised by hiding under the slopes during their final finishing.

It is easier and safer to insert a plastic window using plates than bolting

It is easier and safer to insert a plastic window using plates than bolting

There is one more recommendation from experts: if the window has an opening sash, which will be used very often, then the window may fail. This fixing is recommended for moderate opening or for blind windows.

The combined method of fastening is considered an alternative: the upper part of the structure is fastened to plates, and the lower one is fixed with anchor bolts.

Fastening according to GOST

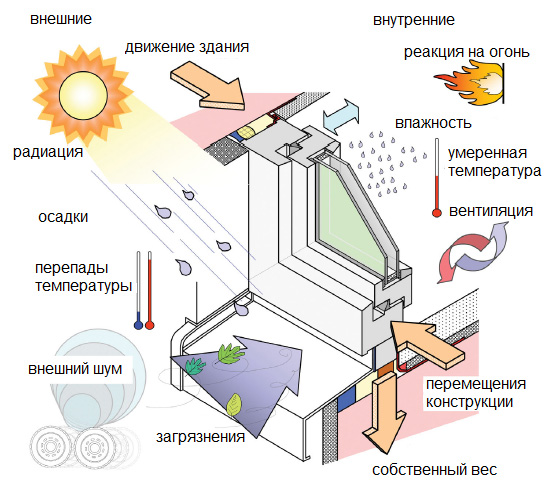

GOST also provides for clearly indicated distances at which fasteners and other structural elements should be located. All these parameters are designed, assumingthat depending on the conditions and temperature, the windows may deform slightly.

The minimum distances between fasteners must not exceed:

- for boxes of white PVC profiles: 700 mm;

- for boxes made of colored PVC profiles: 600 mm;

- distance from the inner corner of the window block: 150 - 250 mm;

- mullion connection to the fastening element: 120 - 180 mm

These dimensions can always be checked with a laser ruler.

Recommended minimum penetration (screw-in depth) and dowel fit

| The name of the wall material | Minimum depth, mm |

| Concrete | 40 |

| Solid brick | 40 |

| Slit brick | 60 |

| Porous natural stone blocks | 50 |

| Lightweight concrete | 60 |

Fastening to flexible anchor plates most effectively resists loads directed perpendicular to the plane of the window unit, such as wind loads, as well as operational loads arising from opening the sashes of a translucent structure.

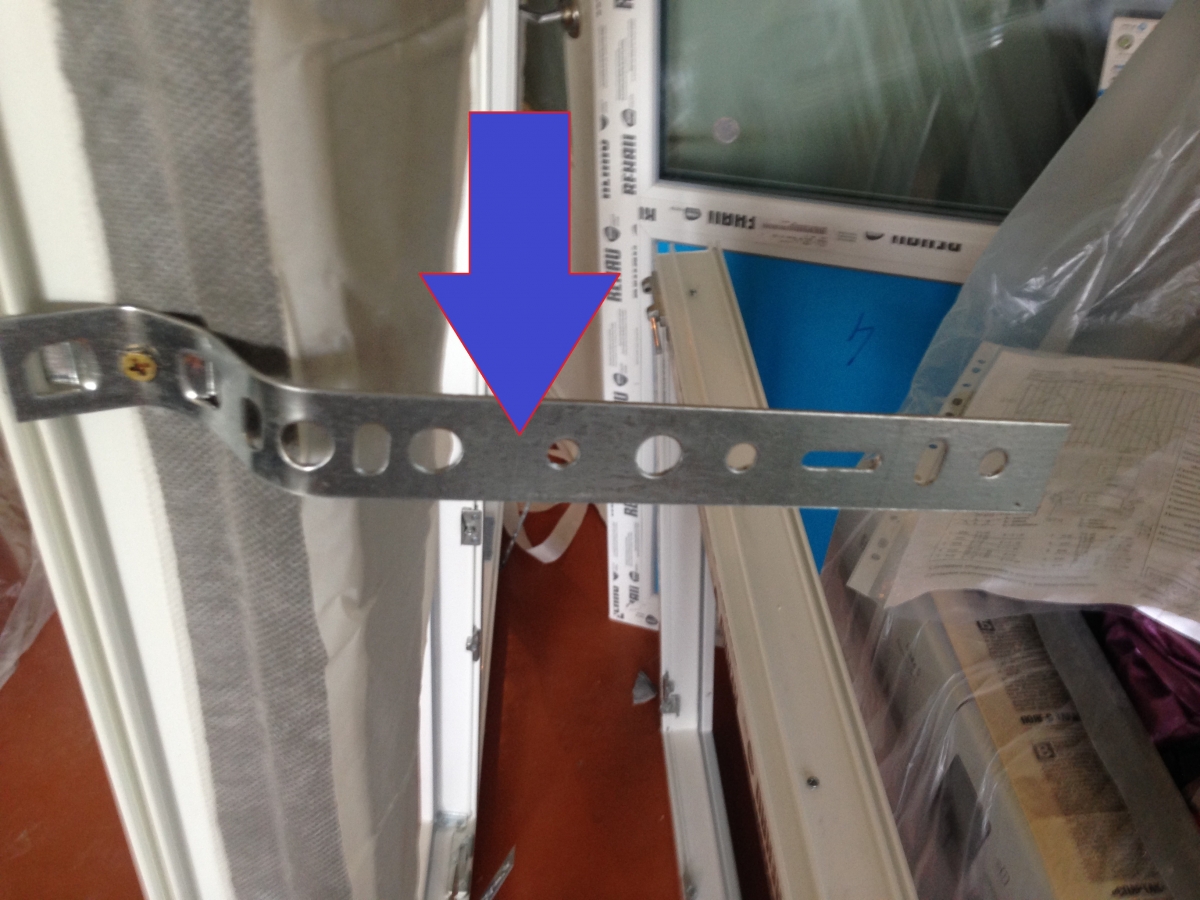

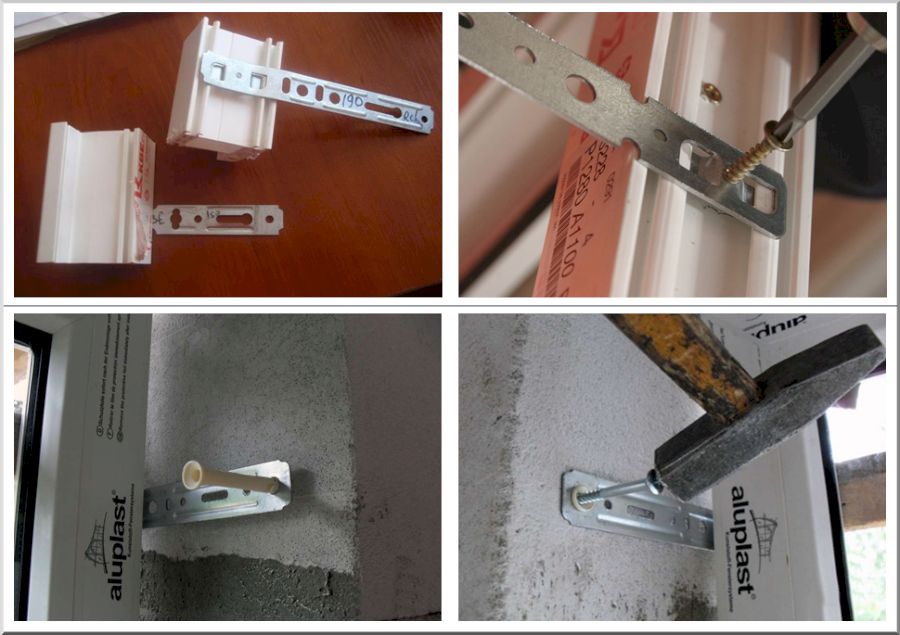

The bending angle of the plate is selected locally and depends on the size of the mounting gap. Plates are fixed to window blocks prior to their installation in openings using construction screws with a diameter of at least 5 mm and a length of at least 40 mm. Flexible anchor plates are fixed to the inner layer of a multi-layer wall with plastic dowels with locking screws (at least 2 attachment points per plate) with a diameter of at least 6 mm and a length of at least 50 mm.One of the conditions for the use of mounting plates is the further finishing of the slopes of the window opening by plastering or "dry" facing.

Please note that the anchor plate is attached to the wall, not to the plaster slope and must be under the sealing strips. which are used in installation !!!

The peculiarity of the anchor plates is that their use makes it impossible to install platbands covering the assembly seam without additional measures for deepening the plates into the slope and the subsequent sealing of the recesses with plaster mortar, putty.

It is better to fix plastic windows made of colored PVC only on anchor plates, because the coefficient of linear expansion of colored plastic is 1.5-2 times higher than that of white, and, accordingly, thermal deformations are greater.

Installation features

For a window block, fastening by means of plates is the safest, and metal parts can be hidden during the finishing process.

But before taking on an independent installation, you will need to study the rules for working with anchor plates.

The rigidity of fixation with any metal bar is slightly less than with anchors. If the window is blind, only the plates are sufficient. When installing a large product with heavy sashes, uniform load compensation is required, so you will not only need to insert the part into the groove and snap it into place, but also insure yourself with a self-tapping screw, which should go deep into the frame profile.

Fasteners on the sides are mounted at a distance of 25 cm from the corners, in the upper and lower parts, and at the top, the connection is placed strictly in the middle

It is important to maintain an interval of at least 50 cm and not more than 1 m between the plates.

Care must be taken to bend the parts correctly (only at an acute angle), which minimizes horizontal displacement and gives optimum joint rigidity.

In the opening, you first need to drill a hole for the anchor dowel, and then place it so that the wide neck presses the metal strip to the surface of the opening. To fix one piece, take 1 or 2 dowels 6–8 mm in size

Final fixation is carried out with a tapered locking screw.

Despite the fact that the connection is later masked by finishing the slope or plaster, it is advisable to make recesses up to 2 mm when preparing the points for fixation - this will ensure the position of the plates flush with the opening surface.

Consider the algorithm for installing a window system using the example of PVC products.

It is necessary to free the window frame from the packaging film, after which it is necessary to remove the sash from the hinges, install the additional and connecting profiles.

An accurate calculation is made at which points the fasteners will be mounted. The plates are inserted into the frame and placed in the opening. The location of the points is marked on the wall with chalk or pencil.

The frame should be pasted over from the inside and outside with mounting tape, vapor barrier and vapor-permeable, to ensure waterproofing.

The toothed elements of the plate ("paws") are inserted into the grooves on the profile at the required angle so that they fit snugly against the slope

Additionally, you can fix the part with a special self-tapping screw.

Observing the distance from the anchor to the edge of 20-25 cm, screw all the plates along the perimeter of the opening.

It is important that the correct fold of the fastener is present in two places of contact: to the opening and to the frame.

Each strip should be fixed with a self-tapping screw and screwed through a plastic nozzle into a reinforcing profile. The hole depth must be 10 mm more than the dowel length.

The frame is installed so that there are rigid seals under each section of the structure and in the corners

Thereafter, the structure is fixed vertically with mounting wedges.

Before finally rigidly fixing the parts, it is necessary to adjust the position of the block using a building level.

Final work - creation of an assembly seam, moistening it with water using a spray gun, thermal insulation with polyurethane foam. It is advisable not to allow its overabundance. For this, you can use a vapor barrier butyl tape, construction sealing mastic. At the end, the slopes are finished - with a plaster mixture, facing stone-polymer tiles, facade materials. If you choose between two methods of installing windows, in the absence of experience, professionals advise using plates.

When using anchor dowels, additional help is needed, the process itself will take a long time, and there is always a risk that the glass may be damaged. In addition, expensive equipment will be required - a high-power perforator and special dowels 10x132 mm. If a PVC window is fastened with bolts, then its depressurization is possible, in addition, with ignorance of the subtleties and improper installation, the geometry of the frame is violated, and it stretches over time.

In the next video, you will find the installation of PVC windows on anchor plates.

Installation of a window. Scheme of work

1. Preparing the window.

- the protective film of the window is removed from the outside of the product. Under the influence of sunlight and atmospheric precipitation, the protective film can be eaten into the profile. Therefore, the film must be removed from the outside at the very beginning of the installation work.

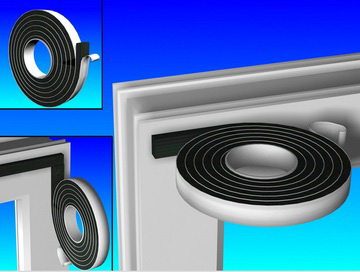

the frame is pasted over with an external vapor barrier - PSUL (along the outer surface of the frame). PSUL - a vapor-permeable tape will prevent the foam from escaping when processing the gaps, protecting not only the appearance of the structure, but also the foam from environmental influences - precipitation, ultraviolet radiation and wind, destroying the foam. The degree of compression of the tape should be at least 25% of it full expansion.

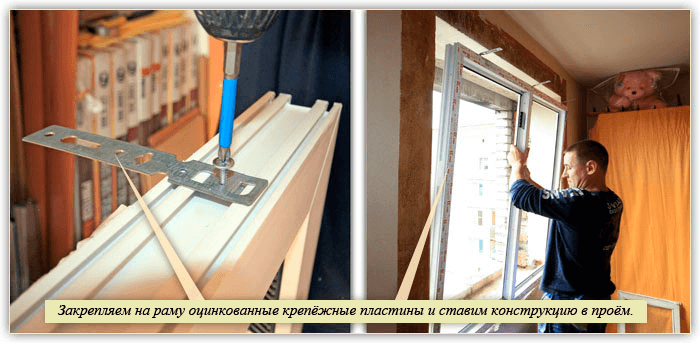

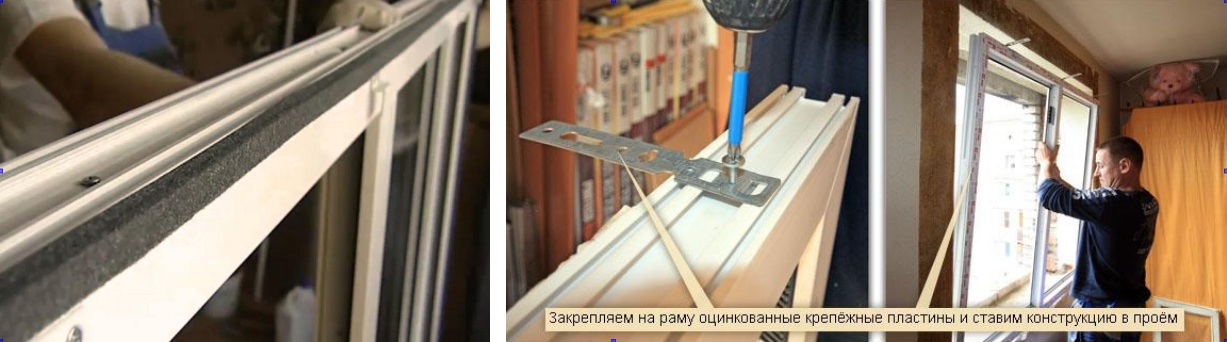

anchor plates are attached to the window block (window frame).

2. Installation of the window. (2photo alignment, window docking)

- the frame is installed in the opening (it is attached from 4 sides of the frame with a step of 70 cm, while the distance from the corner of the window frame to the first fastener should be no more than 15 cm);

leveled (using a level or a plumb line, the windows are set in compliance with the required mounting gaps within the permissible deviations - up to 1.5 mm per meter, but not more than 3 mm for the entire length of the product. should not exceed 8 mm.);

fixed and secured.

3. On the outer side of the window opening, a diffuse tape is attached under the ebb. Diffusion tape is a waterproof vapor-permeable tape made of synthetic non-woven membrane-type material. The tape has two adhesive strips on one side. One strip is intended for fastening the tape to the translucent structure, the other - for attaching the tape to the wall slope. The use of waterproofing tapes provides reliable protection of the construction foam from moisture from the street side and ensures moisture removal from the foam to the outside.

Diffusion tape is a waterproof vapor-permeable tape made of synthetic non-woven membrane-type material. The tape has two adhesive strips on one side. One strip is intended for fastening the tape to the translucent structure, the other - for attaching the tape to the wall slope. The use of waterproofing tapes provides reliable protection of the construction foam from moisture from the street side and ensures moisture removal from the foam to the outside.

4. Fittings are adjustable 5. The gaps are foamed. (3photos foaming gaps and foaming, view of a fixed window)

5. The gaps are foamed. (3photos foaming gaps and foaming, view of a fixed window)

Filling the mounting gap with mounting foam should be performed with a fully assembled and finally fixed window unit, while monitoring the completeness and degree of filling of the mounting gap (mounting foam is applied around the entire perimeter of the window frame, taking into account that this mounting material increases its volume up to 3 times) ...

6. Vapor barrier tapes are glued on.

Inside the room, the seam is treated with a special tape that has vapor barrier properties (made of aluminum foil). Width: the width of the mounting gap plus 30 mm or more.

7. The ebb is attached.

The ebb tide is designed to protect the lower part of the window opening and the assembly seam from rain, snow, ice.

When installing an ebb, one prerequisite must be observed: since there are special drainage holes on the outside of the window frame that cannot be blocked, it is necessary to make sure that the lower edge of the window frame is not deepened relative to the outer edge of the window opening. With this arrangement of the box, the ebb will firmly fit under the window from the outside. The ebb is installed under the window to avoid water seepage at the connecting seam of the ebb and the window frame.

At the end of the installation of windows, the protective film must be removed from the frames and sashes. Under the influence of sunlight and atmospheric precipitation, the protective film can be eaten into the profile.

The warranty for the assembly seam in accordance with GOST R 52749-2007 is at least 5 years. (guest photo)

Any deviations from the GOST requirements give serious savings, but lead to a loss of quality for the Customer.

The most common "economy" is the usual propene of the seam without steam and waterproofing of the seam. Such installation is 2 times cheaper!

Installation of plastic windows is a responsible process, on which how smooth their operation will be significantly depends. Of course, this operation must be performed by experienced professionals, only in this case it can be guaranteed that the windows will fully comply with all technical characteristics.

Assembly seam

An assembly joint is an element of a junction unit, which is a combination of various insulating materials used to fill the assembly gap and having specified characteristics.

The seam must meet the following requirements:

- Ensuring reliable fastening of the window unit in the wall;

- Providing the necessary temperature and humidity conditions at the point where the window frame is adjacent to the wall. In this case, the window block must be installed in such a way as to avoid freezing of the window slopes and the frame profile itself;

- Density and tightness;

- Low thermal conductivity and high durability;

- Susceptibility to temperature stretching-compression of the window block without loss of tightness.

GOST establishes the requirements that the three-layer construction of the assembly seam meets - it ensures the ideal preservation of the thermal insulation properties of the foam.

Assembly seam - 3 layers:

- Outside - waterproof, vapor-permeable;

- Central - heat-insulating;

- Internal - vapor barrier.

This design is designed to ensure the stability of the assembly seam not only against weathering, temperature and moisture, including from the inside, but also resistance to operational influences. In addition, it must be resistant to all kinds of deformations, both temperature and force.

The outer (outer) layer of the assembly seam protects it from moisture penetration, exposure to ultraviolet radiation, temperatures from -35 to + 70 ° C, partially prevents the penetration of cold air through the assembly seam, etc.

In addition, the outer layer of the assembly seam must have high vapor permeability (vapor permeability coefficient outer layer material - not less than 0.15 mg / (m * h * Pa) to remove condensate moisture from the installation seam to the street. To date, the most advanced technology is the device of the outer layer of the assembly seam using vapor-permeable self-expanding sealing tapes (PSUL). There is a fairly wide range of names for this type of material, but for sealing window assembly seams Not all are suitable. PSUL tapes intended for the installation of window blocks must withstand a water pressure in a compressed operating state of more than 300 Pa. PSUL must necessarily be resistant to ultraviolet light (the total dose of irradiation of the front surfaces during testing is not less than 5 GJ / m2).

The application of a plaster layer, putty or coloring compounds on PSUL is not allowed !!!

The central layer must provide the specified resistance to heat transfer of the assembly seam and the necessary noise insulation.

To create the middle layer, polyurethane foam or, more simply, polyurethane foam is used. (Polyurethane foam is a polyurethane foam sealant). The central layer should be made without voids, cracks, delamination and overflows. Sinks larger than 10 mm are not allowed. Water absorption of foam heaters of the central layer during full immersion in 24 hours should not exceed 3% by weight. The high heat and sound insulation characteristics of PU foam are retained only in a dry state. Moisturizing negates all of the above advantages. Therefore, keeping the insulation as dry as possible is the main task performed by the outer and inner layers of the assembly seam.

The inner layer must be airtight and provide reliable insulation of the materials of the central layer from the effects of water vapor from the side of the room.

Vapor barrier materials along the inner contour of the installation gap must be laid continuously, without gaps, breaks and non-glued areas. The vapor barrier materials of the inner layer of the assembly seam must have a vapor permeability coefficient of no more than 0.01 mg / (m * h * Pa). The vapor barrier sealing tape is made of aluminum foil coated on one side with a self-adhesive plastoelastic mass based on butyl rubber with a high tack degree. It is necessary to glue the tape tightly along its entire length. Any gap, swelling is a channel for moisture penetration. The width of the tape is determined by the formula: width of the mounting gap plus 30 mm or more.

Bolt Mounting Difficulties

A few more reasons why you should not mess with bolting when installing yourself, but you should prefer plates. In order to fix the anchor bolt, it will be necessary to drill a hole in the pvc window frame. As a result, depressurization of the insulating glass unit chamber is possible.

As a result of the fact that when drilling, a violation of the reinforcement of the system is possible, problems are observed in the future when the window system freezes. As a result, there is excessive moisture formation inside the room and the appearance of mold on the surface of the slopes.

When fixing the PVC window on the bolts, depressurization of the glass unit may occur

When fixing the PVC window on the bolts, depressurization of the glass unit may occur

With a lack of experience, without knowing the properties of the material from which the structure is made, it may turn out that it will stretch if improperly installed. It will be almost impossible to correct the geometry of the window frame.

There are still positive qualities of attaching plastic windows to anchor bolts:

- reliability of fastening the structure - in order to dismantle it, it will be necessary to perform the reverse order of work that was during installation;

- after fixing the window system, there is no need to carry out additional work, as is the case with fixing with polyurethane foam: time for solidification, leveling, cutting, finishing;

- the structure can be fully exploited immediately after it is installed;

- this method of connection is reliable and durable, and fastening materials in the form of bolts are common on the market and have an affordable price.

The process of attaching a window to plates

The first step is to fasten the anchor plates in increments of no more than 1 meter. In order for the frame to maintain a stable position, the fastening elements relative to the corners of the frame should be located at a distance of no more than 25 cm.

The distance from the plates to the corners must be at least 25 cm

The distance from the plates to the corners must be at least 25 cm

It is important to remember that the distance from the border of the window structure to the opening must be at least 2 cm.In the case when this condition is not met, it is necessary to make recesses in the surface of the opening to accommodate fasteners

For this, the plates are installed on the frame, then it is installed in the opening.

On the surface of the wall, using a pencil or crayon, mark the future location of the fasteners. Then the frame is removed and a recess is made in place of the marks with the help of a chisel, into which the plate must enter and tightly fix. This will allow you to subsequently effectively mask the plates when finishing the slopes.

At the next stage, a window structure is placed in the opening and its position is aligned with the help of wooden bars prepared in advance. Their thickness should not exceed 3 cm and they are installed only horizontally, while vertical alignment occurs, which is controlled using a level.

Vertical alignment is performed by level

Vertical alignment is performed by level

When the position of the frame is leveled, you can proceed to fixing the plates using dowels 6 * 40 with a concrete base or with self-tapping screws in other cases.

The gaps are closed with polyurethane foam.

The gaps are closed with polyurethane foam.

To avoid skewing the frame, the plates are fixed in order. First, the lower left corner is fixed, then the right one, monitoring with a level. The top plates are secured last. At the final stage, the joints are sealed with polyurethane foam.

How to mount on plates?

Anchor plates for PVC windows help to make the installation process quick and easy. One of the important advantages is that there is no need to pull the glass unit out of the frame. The profile system will not undergo drilling, which means that it will be possible to avoid problems that arise when drilling through the frame. Double-glazed windows will not depressurize, the structure will not lose rigidity, and will not begin to freeze. There is absolutely no risk of skewing the frame. However, it is also impossible to call the method perfect: one of the important drawbacks is its not attractive appearance, since part of the fastening after installation will be noticeable.

The second significant drawback is the increased load on the structure with frequent opening of the shutters. The window can quickly fail, which is why experts recommend fixing only deaf structures in this way.

How to fix plastic windows?

The choice of fasteners largely depends on the material from which the opening is made. What kind of fastening is most preferable for common types of buildings, we will consider further.

In a wooden or frame house

The best fasteners for plastic windows in wooden structures are anchor plates. The first and most important reason for this is the deformation processes that wood is subject to, depending on changes in ambient temperature and humidity. This is especially true for log cabins, even if the house was allowed to stand.

In the case of fixing the block with self-tapping screws through the frame, there is a high probability of vertical shrinkage of the opening, which will cause the squeezing out of the fasteners twisted into the lower and upper profiles. And it's good if these are opening sections, since the beginning of the extrusion will be visually noticeable. In blind blocks, the problem will be revealed only when the fasteners enter the glass unit.

Installation in frame structures should also be carried out on plates. In some cases, the sidewalls of the structure are fastened with self-tapping screws through the profile.

Video instruction:

Into concrete

High-quality concrete (lintels of window and door openings), drilling under the anchor with a ten-millimeter drill is not an easy task. For such situations, it is better to use plates, which can be fixed using self-tapping screws for a 6mm dowel.

Scheme of fastening window blocks to the wall

Scheme of fastening window blocks to the wall

In conventional panel high-rise buildings, concrete is more susceptible to drilling, and in most cases, fastening to an anchor does not cause any particular difficulties. As for the technical installation conditions mentioned above, there are a number of points that require special attention.

When glazing balconies or loggias, the structure must be placed almost flush with the outer part of the opening. Anchoring in such a situation is quite dangerous: the edge of the concrete floor or wall may be destroyed. Mounting on plates in such cases is the only correct option.

To the brick wall

Perhaps the easiest installation, but with some reservations. Unpleasant moments arise if the opening is partially destroyed or poor quality brick was used for masonry. In addition, in-situ drilling under the anchor can be complicated by the drill displacement when it enters the masonry joint. Therefore, it is necessary to clearly see the drilling site in order to make a hole in the middle of the brick.

The use of plates makes installation a little easier, since if the plate hits the seam, it can always be rotated slightly. The anchor plates, which snap into a quarter, simply slide to a comfortable position.

Most often, installers combine the type of fasteners: the sidewalls of blind sections can be safely fastened through the profile to self-tapping screws (a 6mm dowel and a press washer of a suitable length), sections with opening sashes - an anchor of 10 mm. Top / bottom - either plates, or no fasteners at all, only foam and spacers.

Combined fastening: top and bottom with plates, side self-tapping screws for concrete

Combined fastening: top and bottom with plates, side self-tapping screws for concrete

To aerated concrete

There are only two correct options for attaching to porous materials (foam concrete, aerated concrete and the like):

- Maximum length 10 mm anchor (202 mm). The fixation method is traditional - through the profile.

- It is more preferable to anchor with anchor plates. The plate is attached to the profile as usual: either it is screwed on with a screw, or snaps into the groove. The other side is fixed with an ordinary self-tapping screw, but through a special dowel for aerated concrete. For successful installation in this way, you will need a hex wrench or bit to screw the dowel into the seat.

In addition to these two methods, there is one more, but it is difficult to call it correct. Nevertheless, it is actively used by a certain category of installers. The fact is that foam concrete is a rather loose material, and self-tapping screws are twisted into it without drilling. It is tempting to fix the blocks with screws without any dowels. Disadvantage: you cannot re-tighten the self-tapping screw in the same place; poor quality of fastening under axial loads on the screw.

Video instruction:

To metal structures

Depending on the design of the opening, the window is fixed either on self-tapping screws for metal, or, which happens much less often, on anchor plates. The installation process depends on the thickness of the metal to which the block must be fixed. To a square pipe widespread on the construction market, the wall thickness of which is 2 mm, is attached with a press washer with a drill through a pre-drilled profile. If the metal is thicker and the self-tapping drill is not enough for successful drilling, a hole in the opening will have to be made before tightening the press washer.

Fasteners for PVC structures

Plastic structures are installed using anchors, self-tapping screws (in some cases with dowels) or anchor plates.

Anchors

This type of fastening is available in two versions: a classic anchor and an anchor for hollow materials.

- Classic anchor. Consists of outer galvanized sleeve, Phillips screw and sleeve. The principle of operation is as follows: initially the screw and part of the sleeve screwed onto it are inside the sleeve, which expands when the screw rotates in a certain direction, thus fixing the anchor in the seat. A regular anchor is excellent for fastening in dense materials (brick, concrete, cinder block).

- For hollow materials. In general, such an anchor is similar to the classic one - differences in the design of the sleeve and the sleeve, which now does not expand the sleeve, but deforms, pressing along the axis (deformation is possible due to special slots).Part of the anchor when screwed in significantly increases in diameter, which allows it to be fixed in a loose environment. In dense materials, such fasteners also hold perfectly.

The length of the dowels varies from 70 mm to 202 mm. The size suitable for installation is selected based on the thickness of the window profile (60 mm), the installation gap between the frame and the opening (standard 2 cm), and the material from which the opening is made. In brick or concrete, 5-6 cm is enough, therefore, in a normal situation, you will need a 152mm anchor.

For aerated concrete, use the maximum fastener length (202 mm).

Wood screws

There are two types of screws, like the anchors described above: ordinary ones - for wood and more special ones - for concrete.

- Self-tapping screws for wood. A quick and cheap way to fix the window block in the openings of wooden structures, and when using a dowel, the screw adheres perfectly to concrete, brick and similar materials. This fastening has another positive quality in comparison with anchors: ease of dismantling.

- Self-tapping screws for concrete (dowel). An alternative to anchors, which, unfortunately, is quite rare on the domestic market. This type of fastening is noticeably thicker in diameter than wood screws, which makes installation with it more reliable. The actual application is as follows: a hole of the corresponding diameter is drilled in the concrete base, after which you can screw the self-tapping screw without a dowel, directly into the concrete. There is one drawback: due to the heavy loads when screwing in, concrete screws often break.

Anchor plates

There are more varieties of anchor plates than screws and anchors combined. This is due to the fact that many PVC profile manufacturers produce plates specifically for their products, fortunately, they are universal and interchangeable.

The anchor plate is attached with one side to the outer part of the window frame, the other side is fixed in the opening with anchors or self-tapping screws. There are plates that are held on the frame by serrated protrusions or snap into a quarter of the profile. Some installers do not even fasten such plates.

The use of anchor plates is the simplest and most reliable fastening option. The only drawback is that after such an installation, you cannot do without finishing the slopes.

Rules for attaching a window to plates

Self-tapping screws should be used as a fixing element. No glue or foam will work. The use of an impact mechanism to create holes is only possible for concrete surfaces.

To avoid damage to the window frame with the drill, it must be of sufficient length. Additionally, you can protect the surface of the frame by installing a piece of pvc near the hole to be drilled.

Self-tapping screws are used as a fastening element

Self-tapping screws are used as a fastening element

When installing a window in a brick opening with vertical voids, holes for fasteners are formed in the interblock seams. To control the immersion of the self-tapping screw into the frame body, it is necessary to use a screwdriver with an appropriate function that limits the torque.