How to fix it?

In order to install anchor type fasteners, it does not matter, with a ring or a hook, you must do the following

- After carefully determining the location (since it will no longer be possible to dismantle the fasteners), use a hammer drill or an impact drill to drill a hole corresponding to the outer diameter of the spacer sleeve.

- Remove fragments of material and other slag from the hole, the best result can be obtained using a vacuum cleaner.

- Insert an anchor bolt into the hole, possibly using a hammer.

- When the spacer part of the anchor is completely hidden in the material, you can start tightening the spacer nut - you can use pliers for this. If the anchor has a special nut under the ring or hook, it is better to use a wrench and tighten it. The fact that the fastener is fully wedged can be judged by a sharp increase in the resistance of the screwed-in stud.

The following video talks about anchor bolts.

Materials (edit)

The material of the anchor can also be different:

steel;

It is clear that each material has its own advantages and disadvantages. Steel fasteners with high strength cannot be used in aggressive environments, including high humidity. Galvanizing significantly extends the service life of steel fasteners, but also increases its cost. Stainless steels of grades A1, A2 or A3, used for the manufacture of anchor bolts, do not corrode, have high strength, but are distinguished by high cost. Brass, despite not the best strength characteristics, can be used not only for fasteners in a humid environment, but also under water.

What are the sizes?

The dimensions of the anchor bolts are subject to standardization according to their production specifications. All anchor fastening hardware can be combined into size groups based on diameter, for example, an anchor for 8 has a sleeve diameter of 8 mm, and for 10, respectively, 10 mm. It is not difficult to determine the diameter of the anchor at 12.

The length can be from 18 to 100, 200 and more millimeters. The anchor with the formula 10x300 mm is a fastener with a sleeve diameter of 10 mm and a working surface length of 300 mm. The thread of the spacer pin is standardized with the sizes of ordinary bolts: M6, M8, M10, M12, M16, M20, etc. The sizes of a stud, like a simple bolt, can also be different: M8x100, M10x100, M16x200, etc.

Standard sizes of anchor bolts are illustrated in the table.

|

Diameter (mm) |

Length (mm) |

Thread |

|

6,5 |

18, 25, 36, 56, 75 |

M5 |

|

8 |

25, 40, 60, 80, 100, 120 |

M6 |

|

10 |

40, 50, 60, 80, 100, 120, 125, 130, 150, 300 |

М8 |

|

12 |

60, 75, 100, 130, 150, 180, 200 |

M10 |

|

16 |

65, 110, 150, 180, 220, 300, 360 |

M12 |

|

20 |

75, 105, 150, 200, 250, 300, 360 |

М16 |

|

24 |

300, 360 |

M20 |

When choosing anchors, you should correlate their length and diameter, since you will have to add the thickness of the attached material or object. The maximum material thickness that can be anchored is shown in the table. Increasing the thickness more than the recommended one can lead to the loss of fasteners or, more often, to the destruction of the enclosing material.

|

Standard size |

Maximum thickness of retained material (mm) |

|

6.5x18 |

3 |

|

6.5x25 |

5 |

|

6.5x40 |

8 |

|

6.5x56 |

28 |

|

6.5x75 |

47 |

|

8x25 |

3 |

|

8x40 |

12 |

|

8x60 |

32 |

|

8x80 |

50 |

|

8x100 |

70 |

|

8x120 |

90 |

|

10x40 |

5 |

|

10x50 |

12 |

|

10x60 |

15 |

|

10x80 |

40 |

|

10x100 |

60 |

|

10x120 |

70 |

|

10x125 |

80 |

|

10x130 |

90 |

|

10x150 |

110 |

|

10x200 |

130 |

|

12x60 |

15 |

|

12x75 |

25 |

|

12x100 |

50 |

|

12x130 |

80 |

|

12x150 |

100 |

|

12x180 |

130 |

|

12x200 |

150 |

|

16x65 |

20 |

|

16x110 |

65 |

|

16x150 |

100 |

|

16x180 |

135 |

|

16x220 |

175 |

|

16x300 |

240 |

|

16x360 |

300 |

|

20x75 |

25 |

|

20x105 |

55 |

|

20x150 |

100 |

|

20x200 |

150 |

|

20x250 |

200 |

|

20x300 |

250 |

|

20x360 |

300 |

|

24x300 |

220 |

|

24x360 |

280 |

The trading network may receive hardware with slightly different dimensional characteristics. It is very rare, but you can still find fasteners with non-standard dimensions: 6x25.6x30, 6x40, 6x60 mm. Even less common is anchoring with a small thread diameter: for example, M3. Such hardware has a very tough competition with plastic dowels and self-tapping screws, which are usually cheaper. More often, such small anchors have a very difficult folding spacer mechanism, respectively, their own special niche of application.

Views

The development of anchor fasteners has led to the emergence of several varieties of it. With a countersunk head for a Phillips screwdriver, they are usually used for mounting frame structures. With a nut at the end, it can be used for fastening objects and equipment with mounting holes.For heavy equipment, bolt head anchors are often used.

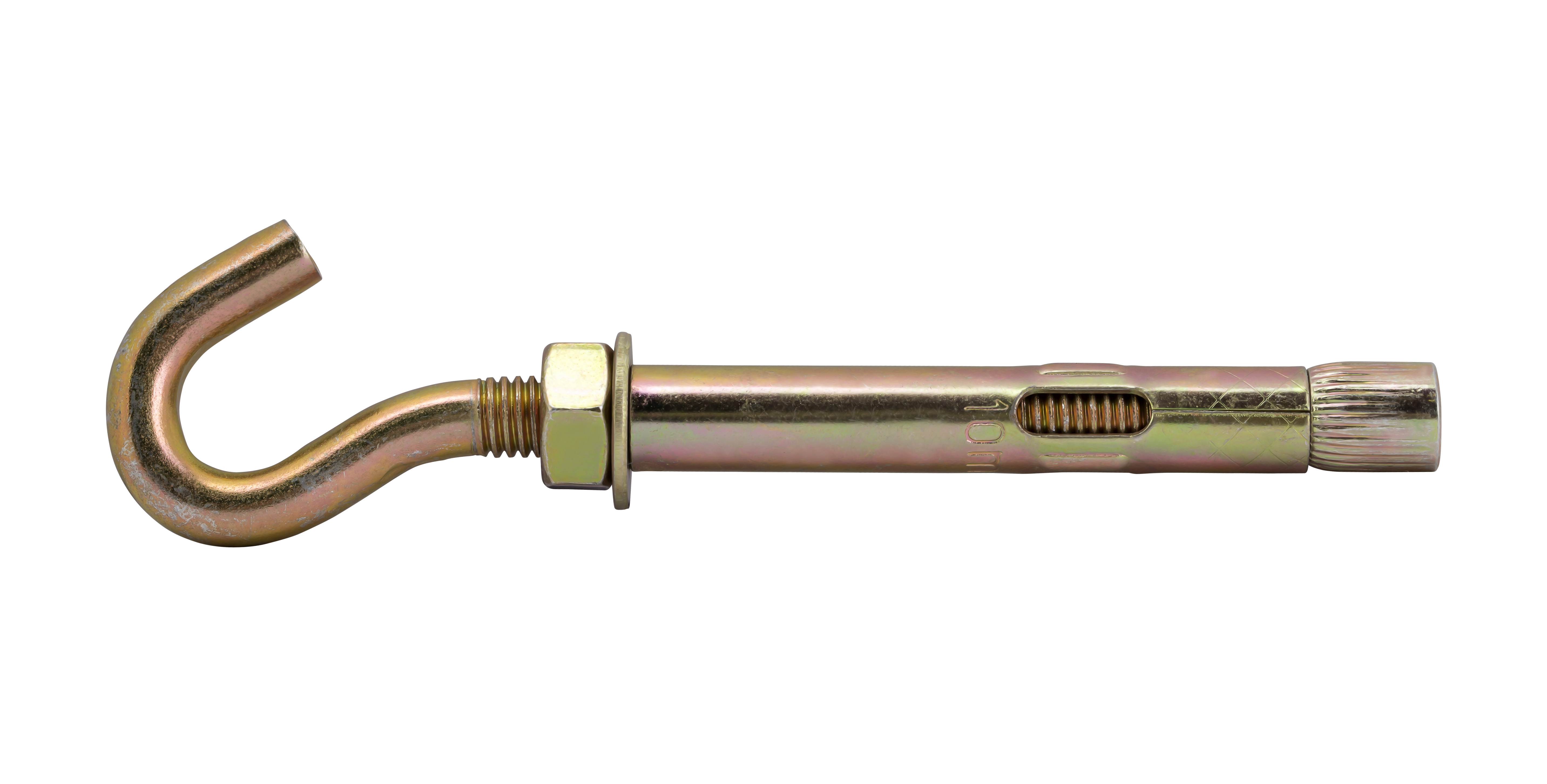

An anchor bolt with a ring can be either reinforced or bent. A slightly shorter ring forms a hook. Anchor hook is indispensable if you have to not only fix the object, but also mount and dismantle it. A kind of development of the hook was a simple bend at the end of the hairpin. Such an L-shaped anchor - a crutch - also has a wide range of applications. The working part is no less varied, the one that is fixed in the drilled hole.

The most common expansion anchor bolt has already been described above, there is no need to repeat it. The original solution - the duplication of spacer sleeves - led to the development of a special design of the anchor, called two-spacer and even three-spacer. These fasteners can be successfully fixed even in porous material.

For reliable fixation, the spacer part can have a folding spring mechanism, not just expanding the fasteners, but creating an emphasis on the inside of the coating, for example, a plywood or other partition, for which other fasteners of adequate reliability simply cannot be used due to the characteristics of the material.

Features and scope

Fasteners in wood structures have never been difficult. Even a simple nail is quite suitable for this, let alone a fastener that has a screw thread - screws or self-tapping screws do an excellent job with fasteners in wood. Can be fastened to wood and fasteners with hooks or rings. In this case, the reliability of the fastening will directly depend on the thickness and quality of the wooden structure in which the fastener is carried out.

The main elements of the anchor mechanism, which ripples the anchor fastener in the drilled hole, are a metal sleeve-sleeve with slots dividing it into two or more petals, and a cone nut, which, being screwed onto a rotating pin, opens the petals, which, in fact, holds the fasteners. This simple scheme is successfully used for concrete or solid bricks.

For hollow and hollow material, an anchor with two or more sleeves can be used, forming several anchorage zones, significantly increasing its reliability.

Why do you need such a clever fastener when there are cheaper screws and dowels? Yes, indeed, in some cases, fastening with a self-tapping screw and a plastic dowel is quite justified, especially if you have to use fasteners at many points, for example, when installing cladding or decorative materials. You can also resort to this method if increased requirements are not imposed on the fasteners: installation of shelves or wall cabinets, frames or paintings

But if you have to fasten rather heavy and bulky objects, it is still better to pay attention to the anchor bolts

Crutches or L-shaped anchors will be indispensable for hanging the boiler. An anchor with a hook at the end can be useful if you need to hang a heavy chandelier or punching bag. Fasteners with a ring are useful for securing cables, ropes or guy wires.